By Liu Hong

Introduction

Due to the participation of Chinese companies, the world’s leading laser radar manufacturer has retreated from the Chinese market, mainly because its products have lost price competitiveness in China. Currently, Chinese laser radar manufacturers are no longer inferior in technology to foreign ones. Among the top 20 companies, including Hesai Technology, RoboSense, LeiShen Intelligence, Beike Tianhui, Huawei, Beixing Photonics, JiaGuang Technology, FSLaser, Voyah Technology, and FSLaser, 7 companies use MEMS (Micro-Electro-Mechanical System) mirror technology, and 4 companies use ToF (Time of Flight) technology (one of which has two technologies).

MEMS Mirrors Have Become the Mainstream of Laser Radar

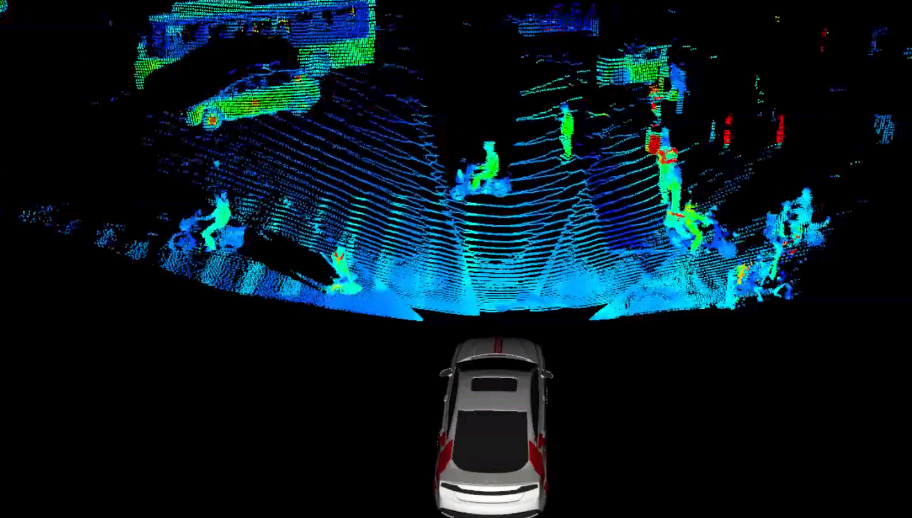

Laser radar is one of the many sensors used in autonomous driving. A few companies, such as Tesla, only use cameras. Some scenes (such as pure white or pure color) may be difficult to recognize, while laser radar can quickly calculate various information such as distance and speed to achieve high-resolution environmental recognition. The optical and electrical systems of the previous mechanical laser radar were very complicated, and only technology companies such as Google and Baidu are still using it, and it cannot be mass-produced. The latest technology is to use MEMS scanning mirrors for laser radar. Some domestic Tier 1 companies have already begun to use domestically produced MEMS mirror chips for targeted project production.

Dr. Shen Wenjiang from the Nanotechnology and Nano-Biomimetics Research Institute of the Chinese Academy of Sciences said that currently, in the field of MEMS scanning mirrors, domestic and foreign companies have reached the same technological level, but domestic chip foundries still face difficulties, which has aggravated the shortage of chips in the automotive industry and needs to be solved urgently.

What Are the Forms of Laser Radar?

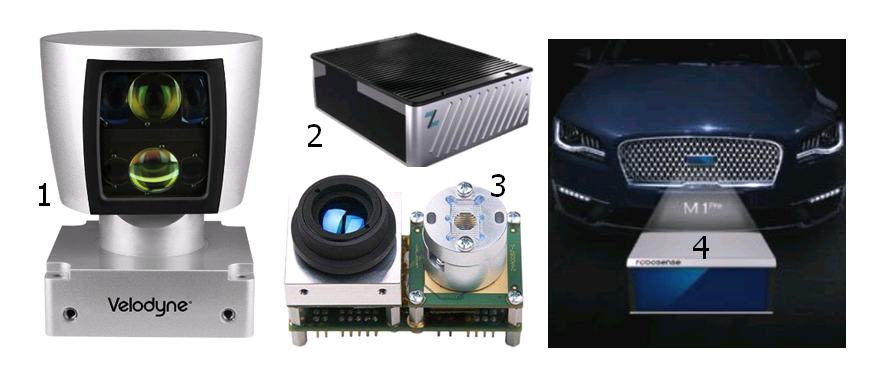

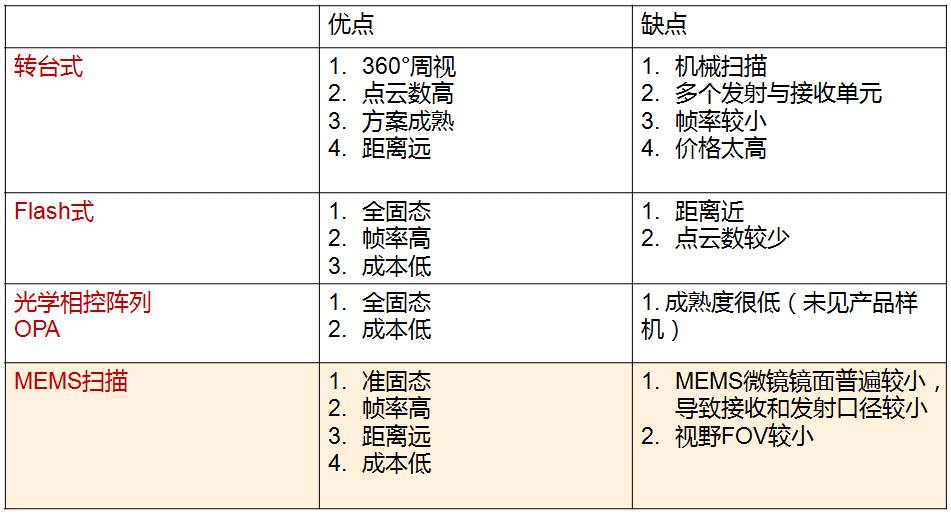

What paths have laser radar development gone through so far? What are the advantages of MEMS laser radar compared to other types? Dr. Shen Wenjiang said that the earliest laser radar was mechanical, and even now, mechanical is still a major player, because those who use laser radar are no longer traditional car companies, but startups that develop autonomous driving solutions. Previously, a 64-line radar was sold for approximately $70,000. Due to the participation of Chinese companies (such as Hesai), it is now cheaper, and similar products in China have high quality and better overall quality. Many North American companies are buying them.

After mechanical radar, solid-state radar comes as the next generation radar. There are several types, and one of them is called Flash. It emits laser using bursts of light and detects signals with a detector. Due to its solid-state structure, its size is much smaller, but the problem is that it overexposes at close range and cannot measure distance far enough (its capability is not enough). Therefore, the current flash radar measurement range is generally limited to within 50 meters. Another pure solid-state radar is OPA (Optical Phased Array), which is similar to the millimeter-wave radar that uses radio frequency signals and scans via phased array focusing. It is implemented on an optical wavelength scale, so it is more challenging than the millimeter-wave technology. Some companies are developing plans based on this technology.

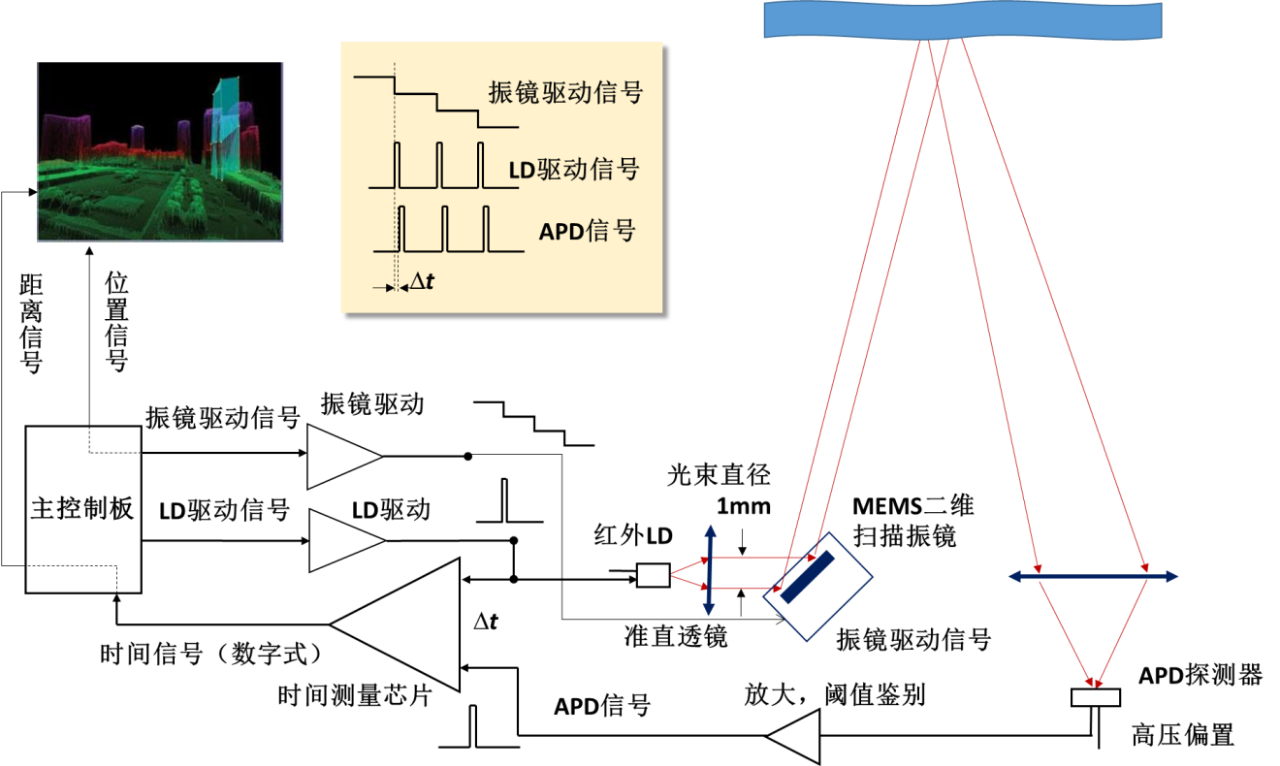

MEMS mirror or scanning mirror, is a tiny mechanical device that can scan at very high frequencies along the x and y directions. MEMS chip is currently used for laser scanning projection, and it can scan at a frequency of 40kHz, which is equivalent to 40,000 scans per second. The MEMS mirror is a silicon structure micro mechanical device. Some MEMS mirrors are driven by electrostatic force, while others use electromagnetic force, such as the ones that the Suzhou Nano Institute produces. These chips have a coil on them, and in the magnetic field, a current generates an Ampere force, which drives the MEMS mirror to scan.

Since automotive radar differs from consumer products and needs to comply with various automotive regulations, developing automotive lidars requires a lot of work.

The angle resolution of lidar has reached 0.2 degrees. For example, a car 100 meters away can scan many points and calculate and display the car’s contour. Compared with other sensors, the current MEMS lidar’s point cloud data rate is around one million per second, much smaller than that of images. Therefore, it does not require as much computational power from the processor.

Shen Wenjiang believes that MEMS solutions are more reliable and have a higher chance of being commercialized. Compared with mechanical solutions, MEMS has many advantages, such as easy installation, smaller size, and lower price, which make it more likely to be popularized in passenger cars. Mechanical radar consists of a laser detector placed on a platform, and 64 lines require 64 sets of lasers and detectors that correspond to each other. Power and signals need to pass through the turntable and connect to the circuit below, so it is a very complex optical and electrical system and is not conducive to mass production.

# MEMS LIDAR and Its Application in Autonomous Driving

# MEMS LIDAR and Its Application in Autonomous Driving

MEMS LIDAR can achieve laser pulse scanning with only one laser and MEMS mirror combination, making it easy to assemble. In terms of cost, since it uses semiconductor technology, the cost will be very cheap if produced in large quantities. In addition, in terms of resolution, for example, if a MEMS LIDAR achieves 64 lines, only a dot matrix generated by scanning the pulse emitted by a single laser with a MEMS mirror can form 64 lines. Therefore, it is very easy to achieve high resolution, and it is also very small in size. In the future, the cost of MEMS LIDAR is expected to be controlled within 1,000 yuan.

From the situation of the five LIDAR listed companies worldwide, we can also see the technological trends. Among them, four companies are from the United States, and one is from Israel. Two of the five listed companies use MEMS solutions. Therefore, MEMS solutions are still highly regarded by the industry and investment community.

MEMS Mirror and Autonomous Driving

The Suzhou Institute of Nano-Tech and Nano-Bionics, part of the Chinese Academy of Sciences, was jointly established by three parties in Jiangsu Province in 2006. Its focus is on semiconductor optoelectronic devices, lasers and detectors in various bands, as well as biomedical imaging, stem cells, carbon materials and lightweight materials.

The institute has been encouraging the commercialization of scientific and technological achievements. Shen Wenjiang said that his team at the institute has done a good job in the niche field of MEMS mirrors and has cooperated with many domestic companies that produce LIDAR. The institute was one of the earliest to develop MEMS mirrors with large mirror plates that are electromagnetically driven. Traditional MEMS mirrors used in optical communication during the MEMS boom around the 2000s were mainly electrostatically driven, with a mirror size generally around 1mm. Currently, international corporations including ST, Bosch, Infineon, Hamamatsu and Intel are all developing MEMS scanning mirrors, with the technology advancing rapidly and market competition becoming more intense. He believes that the institute’s technology is at the leading edge internationally and outperforms foreign products in certain technical indicators. The chips produced by the institute for LIDAR have been adopted by Tier 1 companies for the mass production of LIDAR.

Nowadays, new car builders like Huawei and Tesla are promoting autonomous driving. Unlike traditional car companies, they use the latest technology to showcase futuristic and advanced features in their vehicles. However, he thinks that full automatic driving may still have to wait a few more years to be fully developed, and that it needs to gradually transition from intelligent assisted driving to higher levels of automatic driving. Nevertheless, for new car builders, autonomous driving is definitely a selling point.## Opportunities and challenges coexist

Suzhou Nano focuses on chip design and sample development, while mass production depends on MEMS foundries. In fact, the process of MEMS devices is not highly complex, only micro-level. Overall, domestic MEMS foundries are still in the initial stage, with more mature products such as microphones and pressure sensors. MEMS foundries feature “one device, one process,” so MEMS mirrors are relatively new products for foundries, and both the process introduction and mass production require solving many new problems. Cooperation with MEMS foundries requires growing together with them.

MEMS mirrors are already very small. Where will they go in the future?

Shen Wenjiang believes that the development direction is mainly to develop specific MEMS mirrors for specific market applications. For example, MEMS mirrors used in lidar require large mirror surfaces. The larger the mirror, the more focused the pulse of light emitted by the optics, enabling it to travel further and receive stronger pulse signals. In addition, in laser scanning projection applications, a higher scanning frequency is required to achieve higher projection resolution. Another significant application of MEMS mirrors is in optical communication, including optical switches and optical routers. Currently, most of these chips are imported from the United States and Canada, but this should be an important area for domestic substitution in the field of optical communication.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.