*Author: Da Yan

As a global auto parts giant, ZF launched its latest in-vehicle supercomputer “ProAI” at the Shanghai Auto Show and demonstrated its latest achievements in the field of high-voltage electric drive systems and autonomous driving. Unlike other capital newcomers to the automotive industry, ZF has not launched a high-profile public relations campaign. Instead, it has products that have already landed in the market, or will soon be landing, demonstrating the steady pace of development of a global auto parts giant.

“ProAI” provides unlimited possibilities

The new generation of “ProAI” is designed by ZF for the “software-defined car” and the new electronic and electrical architecture requirements, and is currently the world’s most powerful in-vehicle supercomputer. This supercomputer, which will be mass-produced in 2024, can provide technical support for autonomous driving at all levels from L2 to L5 for both passenger and commercial vehicles, and provide the most solid foundation for new business models based on massive data to be created by upcoming automakers.

Scalability is the biggest highlight of “ProAI”. This mainly refers to its ability to flexibly provide computing power ranging from 20 to 1000 TOPS according to the actual usage scenario. Compared with the previous generation of products, ProAI’s computing power has increased by 66%. And 1000 TOPS is also the highest computing power that can be achieved in mass-produced products on the market. However, higher computing power does not bring higher energy consumption. The latest generation of ProAI has an energy consumption as low as 3 TOPS per watt, which is also a 70% improvement compared with the previous generation.

Flexibility is also a major highlight of “ProAI”. At the beginning of development, ZF cooperated with several chip manufacturers including Nvidia and Xilinx. The modular setting strategy also means that “ProAI” can be equipped with different System-on-Chip (SoC) variants from different manufacturers to facilitate customers to build their own system solutions.

In addition, “ProAI” can also run ZF’s own software, software systems provided by other developers or third-party suppliers. Standardized connectors or options for connecting more ZF “ProAI” units also make “ProAI” flexible to install and use in any car model.

In terms of artificial intelligence, “ProAI” also leaves plenty of room for imagination for automakers.First, it can integrate environment measurement data, including data from radar, lidar, cameras, and audio mode recognizers, through a 360° graphic processor fusion to provide massive data sources for artificial intelligence. Secondly, the ProAI also has a measurement data interface (MDI) that can forward sensor data collected intact to the central storage system to achieve the purpose of continuously training the autonomous driving system controller.

Changing the rules of the game with 800 V electric drive

In the field of electric drive, ZF has developed an 800 V component electric drive system. The system uses power electronic semiconductors with silicon carbide as the material, which can not only significantly improve the overall electrical efficiency of the electric drive system and increase the range, but also greatly improve the vehicle’s power performance, especially its start-up acceleration performance, and allow the entire vehicle system to obtain higher charging power.

In the just-concluded Rome Station of the Formula E championship, ZF’s 800 V electric drive product achieved excellent results with a second-place finish, showcasing the product’s strength. Moreover, the reliability of the ZF 800 V component electric drive system has been proven through testing in the extreme and harsh environment of the Formula E, which is enough to meet people’s daily automotive needs.

Automated valet parking drives ZF’s overall autonomous driving forward

In the field of autonomous driving, ZF demonstrated its strong capabilities in automated valet parking technology.

In terms of technical route, this system is based on visual simultaneous localization and mapping technology (vSLAM) to achieve centimeter-level precise positioning and real-time map generation, which is different from the technical routes of other OEMs or component companies’ products. It includes a front camera, a front radar, four surrounding cameras, and twelve ultrasound sensors, forming a 360-degree surrounding view to eventually avoid pedestrians and obstacles in parking garages.

The biggest highlight of the entire system is that ZF cooperated with visual and mapping partners to combine real-time mapping with positioning functions, allowing the vehicle to have learning capabilities.

In fact, people’s parking destinations are relatively limited, mostly confined to their own garages and company garages. ZF’s strategy is to allow the controller of its automated parking system to locate and map on its own, and through continuous repetition and learning, it can be more responsive to different situations and avoid potential accidents caused by various unexpected situations to the greatest extent possible, and ultimately handle various unexpected situations encountered in garages with ease.

When it comes to autonomous driving beyond parking, for ZF, it is fully capable of supporting Level 4 and Level 5 autonomous driving in terms of hardware, and what is now limiting its commercialization is the more complex traffic conditions on city roads.

For example, there might be bicycles on one side and electric cars on the other, and something might fall off a large truck driving nearby. To deal with such extremely complex scenarios, the current system cannot achieve 100% recognition and timely response in terms of software, and the only way to approach Level 4 or even Level 5 autonomous driving infinitely in the future is constant learning on the existing autonomous driving platform. ZF has already laid a solid foundation for this.

Sticking to the advantage supplier position in the commercial vehicle field

Compared with passenger cars, the benefits of deploying new energy and high-level autonomous driving technology on commercial vehicles are more obvious.

On the one hand, commercial vehicles are used much more often than passenger cars, and energy-saving and emission reduction effects of using purely electric or fuel cell technologies are more significant. On the other hand, the cost of commercial vehicle drivers is not low, and using a high-level autonomous driving system can not only directly reduce the configuration of two drivers per vehicle, but also enable the remaining driver to become a safety supervisor, greatly reducing costs and also significantly reducing the driver’s workload.

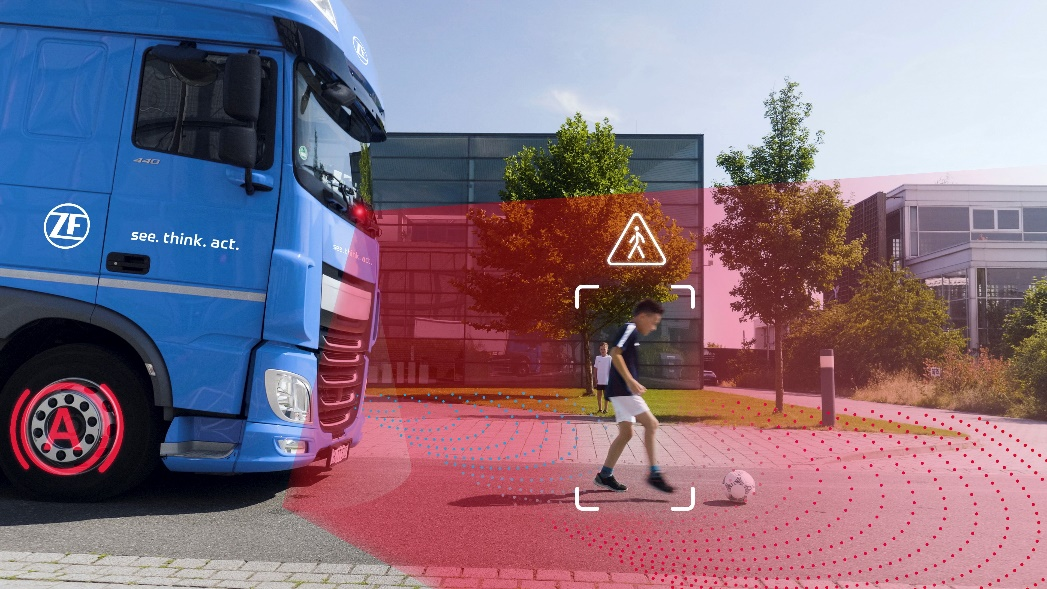

As a global leader in commercial vehicle technology, ZF demonstrated its latest solutions in the field of autonomous driving for commercial vehicles at the auto show. The most noteworthy of these is the OnGuardMAX (AEBS) system, which achieved global mass production in April and will debut on domestic roads in China.

AEBS can effectively identify various moving, stationary, and stopped objects in front of the vehicle, and apply brakes to bring the vehicle to a complete stop in emergency situations based on pre-set programs. With the relevant laws and regulations already in place in China requiring the installation of similar systems, the market prospects for ZF’s OnGuardMAX are promising.

In addition, ZF has also launched multiple leading systems, including OptiPace™, providing Chinese commercial vehicle customers with higher safety, lower emissions, and electric and automated technology solutions for large vehicle transmission systems and autonomous driving operations.The Predictive Cruise Control (PECC) is able to adjust the vehicle to the most economical operating speed based on cruise and map information, while reducing driver workload and minimizing braking wear and emissions. The Autonomous Driving Open Platform Technology (ADOPT) provides an efficient and flexible standard interface for the development of commercial vehicle autonomous driving applications. By effectively controlling the relevant driving system of the vehicle, it transforms the instructions of autonomous driving artificial intelligence into the vehicle’s real dynamics.

As for the central electric drive system Cetrax CP, it is developed by ZF specifically for the Chinese market and is the second electric drive product designed for commercial vehicles, including electric motors, inverters and controllers, and will soon be mass-produced in China.

With major OEMs strengthening their own software engineering and artificial intelligence capabilities, and various Internet giants entering the smart connected vehicle market, it is inevitable for traditional automotive component companies like ZF to transform towards electrification and intelligence. At the Shanghai Auto Show, we saw the upcoming products from ZF.

At the ZF press conference and subsequent media visits, we heard the most about ZF’s hope to continue to deepen the Chinese market while allowing the Chinese market to take on more global responsibilities, including research and development. Currently, ZF not only imports more leading products into the Chinese market but also develops more technically advanced products in China and exports them to the global market in a reverse manner.

With the increasingly fierce competition in the domestic automotive market, especially in the era of software-defined cars, OEMs have higher requirements for component companies. There are more and more short-cycle development projects of about six months, which requires ZF to further strengthen its local research and development capabilities. Only by doing so can it better meet the product delivery needs of domestic customers and compete for market share in the domestic automotive market. For ZF, localization is the shortcut to solving all problems. Only by taking the path of localization well can ZF’s future road become wider and wider.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.