Author: Qiukaijun

In 2020, a newly established power battery company suddenly entered the installed capacity ranking and ranked 8th. Its main product is lithium iron phosphate battery.

This company is Rui Pnergy. Rui Pnergy was established in 2017 and is an enterprise of Qingshan Industry Investment, the world’s largest stainless steel producer. Qingshan Industry saw the huge opportunities in the new energy vehicle industry and initiated a power battery company that synergizes with its own rich mineral resources.

In just three years, Rui Pnergy has attracted the attention of the industry and has a larger scale for expansion. On April 20th, the media day of the 2021 Shanghai Auto Show, Rui Pnergy demonstrated its new lithium iron phosphate power battery and directly promoted it to the electric vehicle company.

Rui Pnergy quickly entered the power battery industry and gained a foothold, and its growth rate is impressive. But in the eyes of the company, Rui Pnergy’s initial performance was only a “small outbreak” after more than 20 years of battery research. They have a larger goal: to make high-quality and cost-effective power batteries.

Achievements with Wuling

The hottest electric vehicle company in 2020 is undoubtedly SAIC-GM-Wuling. In 2020, SAIC-GM-Wuling sold 174,000 electric vehicles, becoming the champion of pure electric sales that year.

The success of SAIC-GM-Wuling is due to the suppliers, and they have also given back to the suppliers.

Rui Pnergy is one of them.

Rui Pnergy’s current main customer is SAIC-GM-Wuling. In 2020, Rui Pnergy supplied E100 and E200 to Wuling. Among them, E100 had the most shipments, up to 8,000 sets per month.

In 2020, Rui Pnergy’s installed capacity was 0.99 GWh, of which SAIC-GM-Wuling accounted for 73%.

In 2021, Rui Pnergy started to supply SAIC-GM-Wuling’s popular car Hong Guang MINI EV (internal code name E50) due to production capacity constraints, with a monthly shipment volume of nearly 10,000 sets.

Rui Pnergy’s current products include lithium iron phosphate and ternary batteries, but lithium iron phosphate is the main product. In 2020, 78% of Rui Pnergy’s installed capacity was lithium iron phosphate, and customers included SAIC-GM-Wuling, Dongfeng, Golden Dragon, Yutong, Foton, Shenlong, and other companies. Ternary batteries are fewer, with customers being Yundu Auto and WM Motor.

“Although others may call Ripower an up-and-comer, we have just managed to outperform the market.” To outperform the market, one client in particular was a major help – SAIC-GM-Wuling.

SAIC-GM-Wuling was already well-known for its large purchasing scale during the era of traditional fossil fuel vehicles. For many new players in the power battery industry, this large and powerful client was a dream to work with. How could Ripower win such great clients?

“We had already gained recognition from Wuling very early on, but we managed to enter the project relatively late.” said Zhang Xiaocong, the marketing director of Ripower. The Ripower team had already had project cooperation with the leaders and technical personnel of Wuling for quite some time since the 2017 Shanghai Auto Show. There have been many exchanges to strengthen the relationship between the two companies.

At that time, Ripower invested RMB 1.73 billion to build its Wenzhou factory with high automation and modernization. Prior trust and Ripower’s performance back then impressed Wuling. By the end of 2019, Ripower’s batteries were already announced to be used in Wuling vehicles.

“Very early last year, we managed to seize an opportunity for a national subsidy adjustment and capitalized on it.” said Zhang Xiaocong.

Catching the Wave of Lithium Iron Phosphate

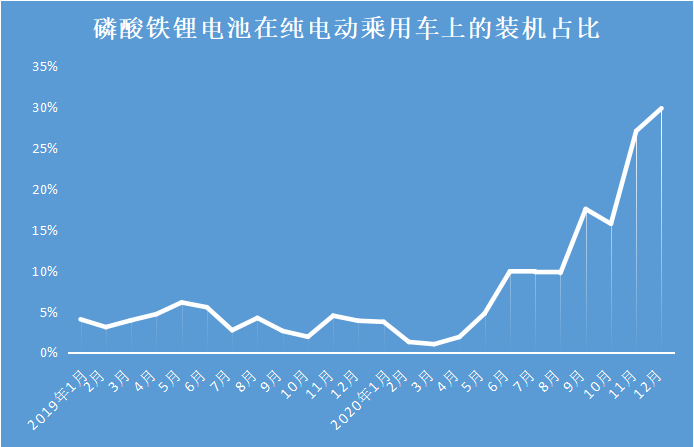

Ripower’s rise in 2020 conveniently coincided with the resurgence of lithium iron phosphate batteries.

Prior to mid-2019, subsidies for new energy vehicles (NEVs) were relatively generous. But after the big subsidy reduction in July of that year, subsidies were reduced by nearly 75%.

In this policy background, the previously more advantageous ternary batteries’s limitations on cost became more evident. This gave lithium iron phosphate batteries a chance to return to the spotlight. Especially with the leadership of products such as Tesla’s China-made Model 3 and BYD’s Han EV, lithium iron phosphate batteries made a strong comeback.

For Ripower, the resurgence of lithium iron phosphate was a great opportunity.

“The direction we had set out initially was to simultaneously advance power and energy storage, take off with both wings, and enjoy harmonious development. As for energy storage, we would definitely go for lithium iron phosphate.” said Zhang Xiaocong.

At the end of 2018, Ripower’s first mass-produced lithium iron phosphate product was 50AH which has become very popular. Many competitors are currently studying and referring to our product.

Currently, the development trend of lithium iron phosphate batteries is more favorable for the direction of RuiPuo’s technology. From the first three batches of automobile announcements in 2021, the proportion of electric passenger cars using lithium iron phosphate batteries has reached 42.75%.

Zhang Xiaocong cited a survey, stating that including energy storage, the battery shipment volume of lithium iron phosphate batteries in 2021 is expected to approach a market share of over 40%.

“Demand for lithium iron phosphate batteries is increasing significantly. Currently, in addition to high-end long-endurance passenger cars, except for ternary batteries, whether it is ordinary passenger cars, buses, construction machinery, light trucks, logistics, microvans, ships, forklifts and so on, including energy storage, basically over 90% are lithium iron phosphate batteries.” Zhang Xiaocong said, “Moreover, these markets are currently booming.”

Old Team, New Opportunities

Although lithium iron phosphate batteries have presented new opportunities, there are many Chinese battery companies that manufacture them, so why has RuiPuo risen to the top?

RuiPuo Energy was established in 2017, but they are not new to the electric vehicle battery game.

In the “former RuiPuo Energy” era, the core team of RuiPuo Energy had already jointly researched batteries for over 20 years.

The square aluminum shell lithium ion batteries that are widely used today were developed by the RuiPuo team from 2008, and their goal has always been for use in cars. “Starting in 2008, we cooperated with SAIC Motor to develop a square aluminum shell power battery. Up to now, we have been developing lithium iron phosphate aluminum shell power batteries for more than ten years, and we have a deep foundation.”

In addition, the RuiPuo team has also collaborated with Dongfeng and supplied pure electric buses in bulk in 2014, which have been operating in cities for promotion and application. They have also manufactured electric mining carts, port electric material handling vehicles, and more.

“RuiPuo Energy was only established in 2017, but it was just an outburst of previous efforts,” Zhang Xiaocong explained.

Technological level should be reflected in product competitiveness. Zhang Xiaocong introduced, in terms of energy density, RuiPuo’s products have reached 180 Wh/kg. “Last year, our high specific capacity lithium iron phosphate batteries were second only to CATL in terms of shipments.”

In terms of cycle life, the production volume of energy storage products has reached 6,000 cycles, and the standard cycle life for vehicle products is 4,000.In terms of safety, the characteristics of lithium iron phosphate materials are relatively prominent. “Iron lithium batteries can pass the needle puncture test with a 100% success rate,” said Zhang Xiaocong. RuiPuo’s product safety is better than the industry standard. He introduced that RuiPuo lithium iron phosphate products have obtained JET certification from the Ministry of Economy, Trade and Industry of Japan. “As far as I know, Ningde Times and BYD have been certified before, and we are the third.”

In terms of low-temperature performance, RuiPuo’s products have achieved charging at minus 10 degrees Celsius last year.

RuiPuo will not stop there. According to RuiPuo’s publicly available product roadmap, they plan to achieve an energy density of 200 watt-hours/kilogram, a cycle life of 8000 times, and fast charging performance of 4C around 2025. The advantages of product performance still need to be maintained through technological research and development.

“Last year, RuiPuo Energy soared, and many friends said that RuiPuo is a dark horse. Actually, to tell the truth, it is still our technological accumulation and advancement that determine this,” said Zhang Xiaocong.

Making High-Performance and Cost-effective Batteries

RuiPuo Energy ranked eighth in the industry and fourth in lithium iron phosphate in 2020. What about this year?

“This year we should be able to rank third. Our lithium iron phosphate shipments are expected to reach 3.5 GWh this year. Last year was 0.8 GWh, and this year it should be about four times higher,” said Zhang Xiaocong.

Due to its outstanding performance in 2020, RuiPuo Energy has good customer development prospects.

Cao Hui, chairman and general manager of RuiPuo Energy, stated that most of the mainstream domestic auto companies have contact with RuiPuo, either already in the supply chain or in negotiations. “We have also established contacts with some international car manufacturers, and some are in deeper communication.”

The strong growth prospects are due to their judgment of the market situation and product strategy.

Zhang Xiaocong believes that in the early stages of the development of new energy vehicles, China lacks high-quality power batteries, but in recent years, high-quality power batteries have emerged.

“What is missing is a high-quality product with a reasonable cost-effectiveness ratio,” said Zhang Xiaocong. RuiPuo Energy’s positioning is to “make the most cost-effective product in the industry with quality in the top-middle level and an absolutely fair price.”

“By making high-performance and cost-effective batteries, everyone can afford to use them and buy electric vehicles with peace of mind,” said Zhang Xiaocong. In the future, electric vehicles with a range of below 500 kilometers will become the mainstream. Lithium iron phosphate batteries can also meet the demand. As long as the cost-effectiveness problem is solved, electric vehicles will be more competitive than traditional fuel vehicles and can enter thousands of households as soon as possible.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.