The content of this article is sourced from 42how and has been translated by ChatGPT

Wherever there are people, there is a community. This week, the open war of words between two Chinese power battery giants, BYD and CATL, became the biggest hot topic that the public has been feasting on.

It is worth noting that both companies are industry leaders, and it is not common for them to publicly confront each other. The safety issues of power batteries caused by a single “needle” have brought BYD and CATL for the first time to compete with each other in public.

Many people may not be very clear about the incident, so let’s review the incident from the perspective of chronological order.

Cause of the incident

In fact, it all started with the launch of the BYD Blade Battery.

On March 29th, BYD released an official statement claiming that their new Blade Battery is capable of changing the industry. The battery uses a new manufacturing process based on lithium iron phosphate cells, and its main advantage is that it has improved energy density and is also safer for users.

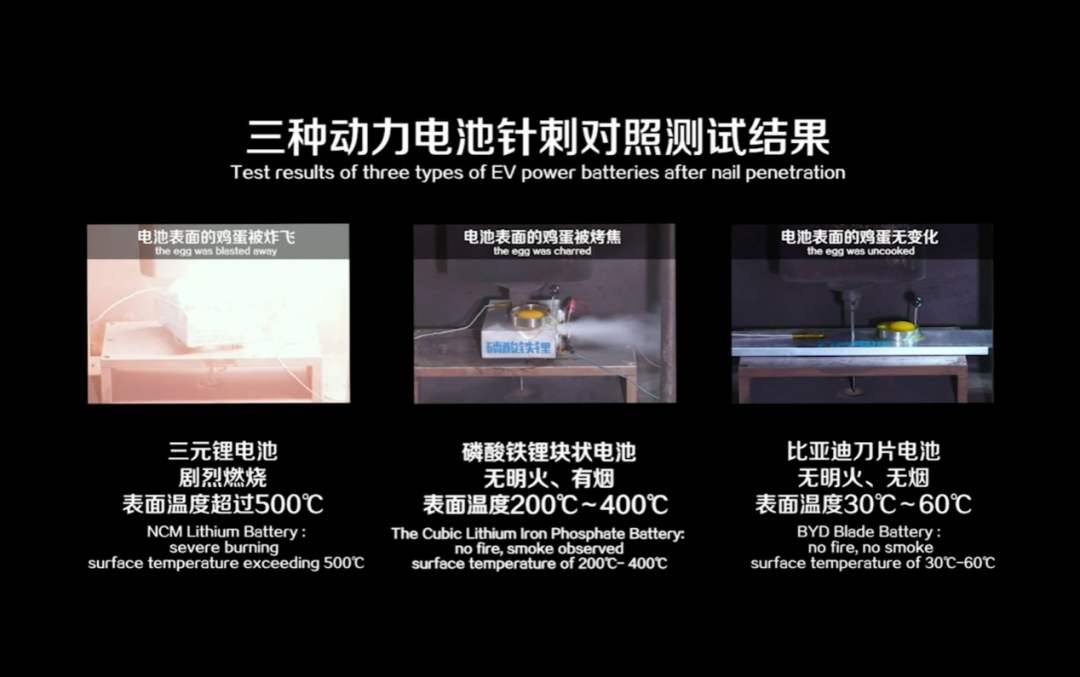

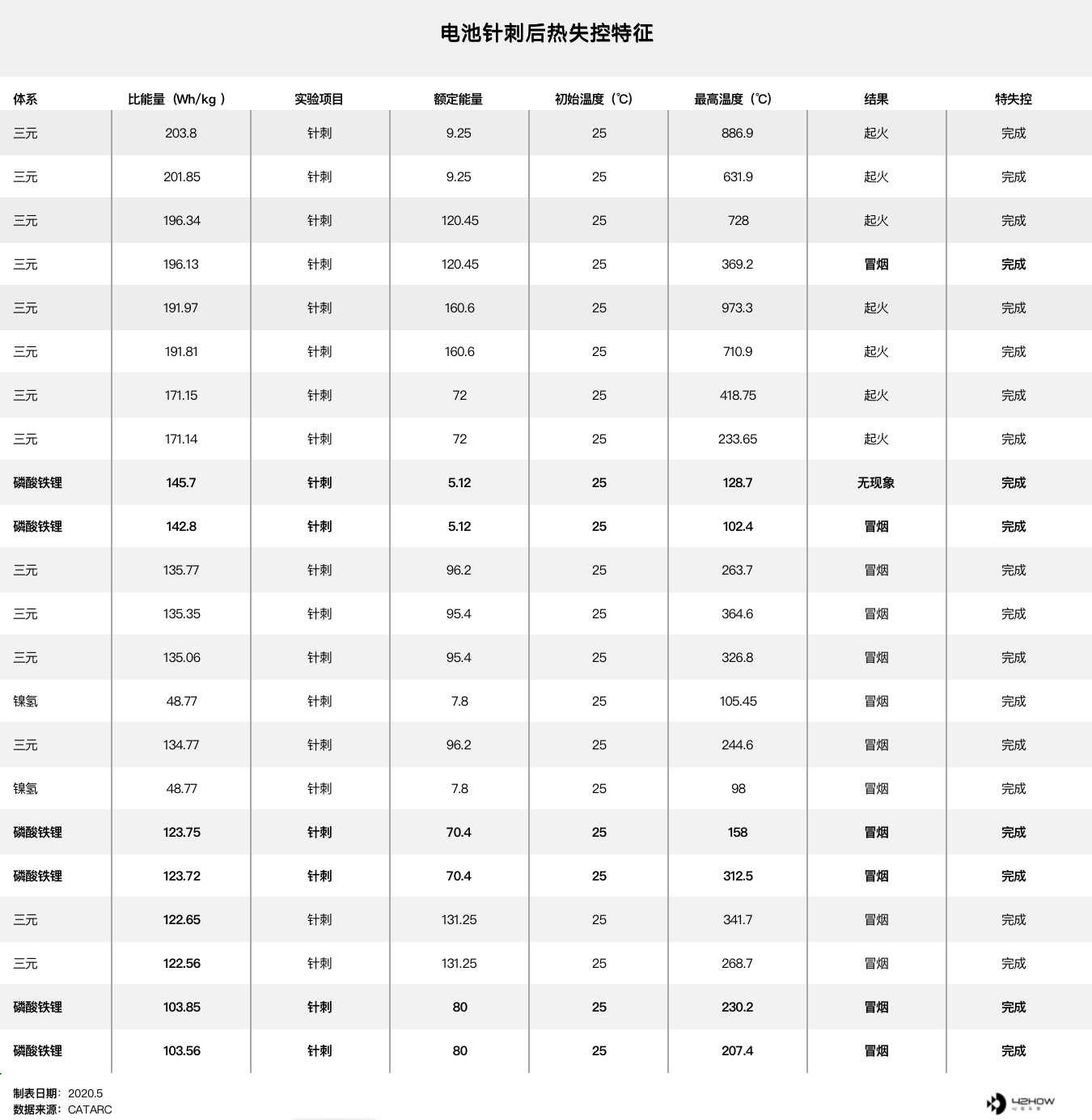

And that’s not all, in order to verify the safety of the Blade Battery, BYD demonstrated a needle puncture test on ternary lithium batteries, lithium iron phosphate and blade batteries at the launch conference.

As a result of the experiment, the ternary lithium battery violently burned, the surface temperature exceeded 500 ℃, and the egg on the battery surface was almost cooked; the blade battery of BYD had no open flame or smoke, and the surface temperature remained between 30-60 ℃ and the egg showed no obvious changes.

Based on the experiment results provided by BYD, the majority of people in the industry considered that BYD intentionally targeted CATL’s ternary lithium battery products with their experiment results, planting the seed of the conflict between the two sides.

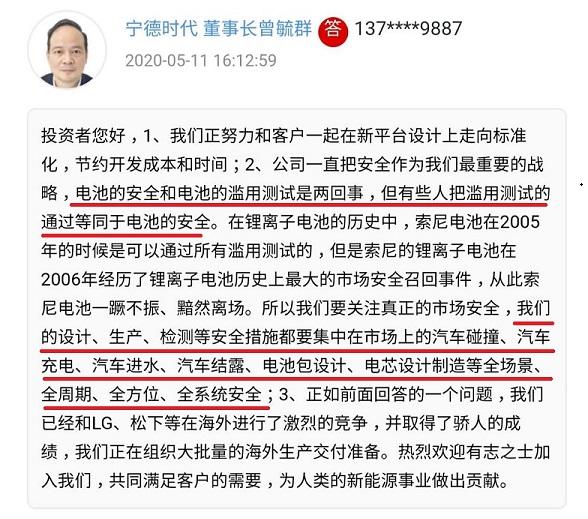

On May 11th, at the online annual performance briefing for the year 2019, the Chairman of CATL said in response to investors’ questions, “Battery safety and battery abuse testing are two different things, but some people equate the pass-through of abuse testing with battery safety.”

CATL’s Vice Chairman, Pan Jian, also said that CATL’s ternary battery and lithium iron phosphate battery have products that can pass the needle puncture test, and the “Blade Battery” structure is a kind of CTP innovative concept that CATL has already mass produced. CATL has already mass-produced several of the best CTP structures, CTP-0, CTP-1, CTP-2.

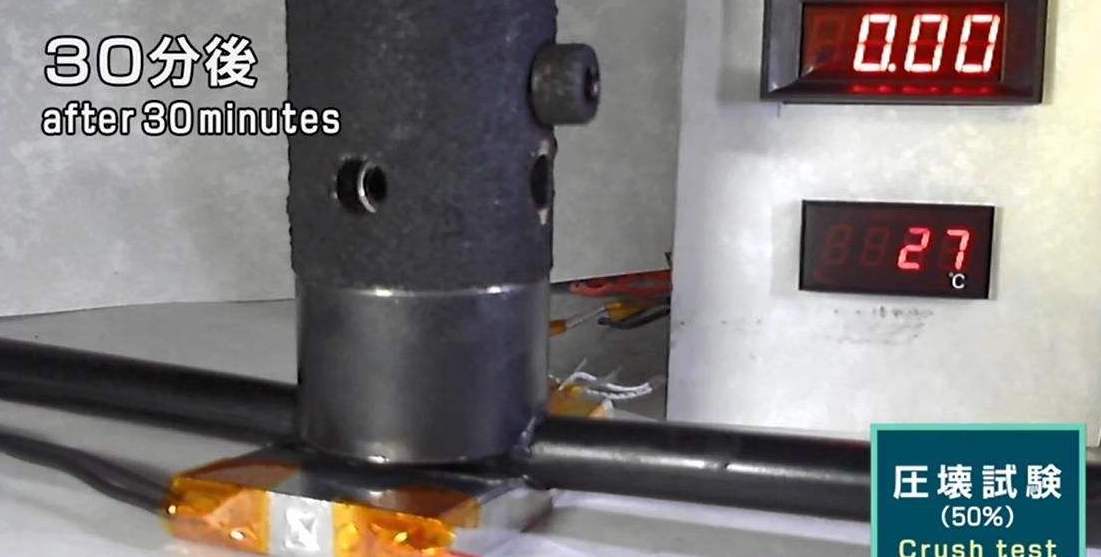

Although CATL did not point out who the “some people” were, it was still believed by many netizens that they were responding to the experimental results provided by BYD earlier.Ningde Times implied that “the product, which had already undergone the needle piercing test, had already entered mass production, and even the blade process had been mastered.” On the late night of May 11th, Li Yunfei, the Deputy General Manager of BYD Auto Sales Company, posted a Weibo challenging Ningde Times, “If you dare, come and try it on our product.” However, Ningde Times did not respond to the challenge. In fact, the incident could have ended peacefully as it is normal for competitors to compete with each other. However, just as the event reached a stalemate, netizens ignited a new round of debate. On May 21st, Weibo user “Little Lithium” posted a needle piercing test video of Ningde Times’ 811 ternary lithium battery monomer. From the video, it can be seen that the needle penetrated the battery and immediately caused a fire and explosion. Upon seeing this video, Ningde Times could no longer remain silent. They posted a two-part anti-attack video on their official Weibo on May 22nd. In the video, it shows that when the tester used a steel needle with a diameter of 5mm, a cone angle of 45°, and a speed of 25mm/s to pierce the ternary battery, the steel needle broke upon contact with the battery pack. After watching the video, netizens were furious, commenting that “is Ningde Times trying to show off their low IQ?” and questioning why Ningde Times tested the battery pack instead of the battery core. However, this was just a part of Ningde Times’ strategy. On May 23rd, Ningde Times posted another video on their official Weibo showing that they had already mastered the technology of ternary batteries passing the needle piercing test as early as 2017.The voltage of a certain 5-series ternary cell before puncture is 4.213V and the temperature is 23.9℃. After puncture without smoke or fire, an hour later, the voltage drops to 3.724V and the temperature rises to 93.7℃ according to national standards. The voltage of a certain 8-series ternary cell before puncture is 4.15V and the temperature is 24℃. After puncture for an hour, the voltage drops to 4.075V and the temperature rises to 37.7℃. Moreover, CATL also disclosed a document certifying passing the safety test of Germany Rhine lithium battery in 2017.

The conditions for the puncture test at that time were that the battery was fully charged, the steel needle had a diameter of 3 mm, and the insertion speed was 80 mm/s. During the entire process, there was no mass loss, no electrolyte leakage, the safety valve did not open, and the battery did not catch fire.

From the two videos, it can be seen that CATL wants to express that battery safety is not equal to passing the nail penetration test. Battery safety involves many scenarios, and the nail penetration test is not a common scenario. CATL has also mastered the technology of nail penetration. Therefore, the routine of CATL’s public relations is still deep. Smoke bombs and bombs are thrown one by one, one bigger than the other. If you don’t watch it continuously, you won’t be able to keep up.

Therefore, the “palace fighting drama” between the two giants has settled, but the safety debate around power batteries has just begun.

Power Battery Safety and “Needle”

Understanding the beginning and end of the incident, we can see clearly that the conflict between BYD and CATL is whether the nail penetration test represents the safety of the battery.

Then we need to know what the nail penetration test is.

First, we need to understand a concept:

The nail penetration test simulates the scene of a metal object piercing the battery. Generally, the battery shorts after being punctured by a needle.

The core purpose of the nail penetration test is not to necessarily cause an internal short circuit in the battery, but to simulate the probability of thermal runaway occurring under the scene of a metal object piercing the battery.

Therefore, it is not important to pierce through the battery, but to manage the thermal runaway after the short circuit caused by piercing.

The lithium battery nail penetration test in China started from QC/T743. This standard was published by the National Development and Reform Commission in 2006, with a report number of QC/T 743-2006, and became effective on August 1, 2006. This standard is a new industry standard for the automotive industry, which specifies the requirements, test methods, inspection rules, marks, packaging, transportation and storage of lithium-ion batteries for electric vehicles.

The formulation of the standard in China at that time was actually very strict. The heat released instantly during the nail penetration test process mainly comes from the internal short circuit of the battery. Moreover, the short circuit is continuous during this process until the entire internal energy of the battery is completely released.In the past, the needle puncture experiment did help improve battery safety performance. However, at the same time, the Chinese battery industry was relatively fixed on lithium iron phosphate products.

But it is worth noting that there is a time difference here. This standard was issued in 2006, when not even smartphones were popular, there were only a small number of commercial new energy vehicles, and the lithium battery industry in China did not have the prosperity and rich experience it has today.

Therefore, when formulating safety standards for power batteries, more reference was made to the battery testing standards for consumer electronic products, but there are essential differences in meeting automotive regulations and consumer levels.

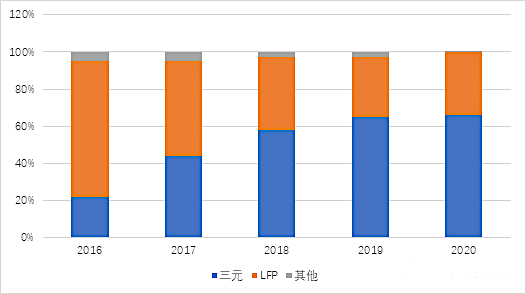

As new energy vehicles have become a national strategic industry, top-level strategies are changing. To promote electric vehicles, product competitiveness needs to be enhanced, and energy density is the key. It is an industry consensus that ternary lithium batteries have higher energy density than lithium iron phosphate batteries under unit volume.

Therefore, since the subsidy for power batteries was introduced in 2017, the product route of batteries has been transformed, and safety standards have also been improved.

As the new energy vehicle industry deepens and accumulates rich experience, battery manufacturers, host factories, and management agencies at the national level have found that the needle puncture experiment is an equivalent verification under single condition and cannot completely reproduce the differences in internal short circuits of batteries.

Therefore, in the “Management Regulations of Production Enterprises and Products Access to New Energy Vehicles” released in January 2017, the “battery monomer” needle puncture was listed as a temporarily unimplemented item in GB/T 31485-2015.

At that time, international standards such as IEC 62660-2 and IEC 62660-3 did not adopt the needle puncture test as a battery safety standard. This was also the first step for power batteries to interface with international standards, and therefore, NCA cells used by Tesla have achieved long-term high growth.

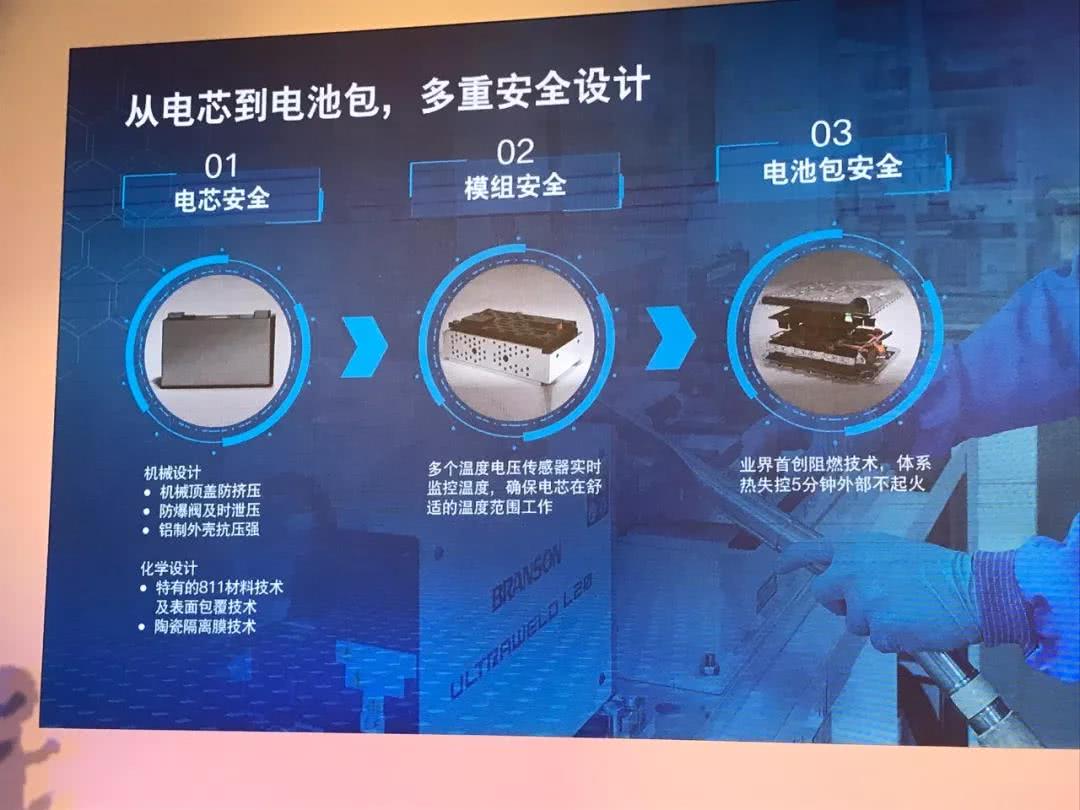

Therefore, the judgment of battery safety has undergone fundamental changes in direction, from single-cell batteries to attention to the thermal runaway propagation characteristics of battery systems.

So, does this mean the needle puncture test is meaningless?Obviously, UN GTR 20 (Global Technical Regulation for Electric Vehicle Safety) does not include penetration test of individual battery cells. Instead, it considers penetration test as a trigger condition for the thermal runaway of individual battery cells, and requires the battery system to not catch fire or explode within 5 minutes after thermal runaway, so as to leave sufficient time for passengers to escape.

Passing the penetration test can simply indicate that it is difficult for individual battery cells to trigger thermal runaway. Optimizing individual cells can subsequently determine whether the battery system can control the spread of thermal runaway.

This is actually easy to understand. Battery safety runs through the entire use process of the battery, including the design of the cell unit, system design, pack protection, and vehicle-level optimization, to ensure the safety of power batteries in every stage of their life cycle, and to truly improve the safety performance of batteries.

This point is more comprehensive than BYD’s experimental performance. Firstly, in terms of material, ternary is indeed less stable than lithium iron phosphate, but its energy density is better than that of lithium iron phosphate. From the video response of CATL, it can also make the ternary battery cells not ignite or explode after being penetrated at the cell level.

For example, in the era of traditional cars, gasoline is the main source of energy, but gasoline itself has the characteristics of low ignition point and easy volatilization, and it is common knowledge that it will catch fire when it encounters fire. However, it can achieve global transportation through special storage methods. Therefore, gasoline can be ignited, but continuous power supply can be provided through vehicle optimization and fuel tank protection.

This also explains why CATL released the first video, which indicates that CATL has made substantial progress in optimizing at the pack level. The second video is clearly stating that as early as 2017, CATL had already mastered the products that can pass the penetration test. It is obvious that this combination was specifically designed for BYD.

Overall, penetration testing is currently just a means of triggering thermal runaway by causing local short circuits, and evaluating the overall safety of battery packs through it is somewhat one-sided. Using penetration testing can only indicate that it is not easy for individual battery cells to trigger thermal runaway, but the impact of the battery cell unit and other components on the pack is also significant. The reason why UN GTR 20 does not include penetration testing is to guide OEMs to pay attention to system control.

Automakers and Suppliers Choose the Best Solution

Behind the penetration test is the competition for battery safety, but the deeper level is the route competition. You should know that the two giant companies focus on different directions: BYD mainly uses lithium iron phosphate, while CATL mainly uses ternary lithium batteries.

Due to the market’s demand for endurance, ternary batteries with higher energy density have become mainstream.As vehicle manufacturers, host companies must ensure their products meet the highest safety standards. Therefore, they must exercise even greater caution in selecting their suppliers. If they aim to achieve a greater market share, their products must be competitive. For electric vehicles, battery life is a core metric, making ternary lithium batteries an essential aspect of current technological systems.

Ningde Times Group Chairman Zeng Yuqun stated that, in essence, their focus remains on putting safety first with regards to battery safety. They have committed to system-level safety in all scenarios, in a comprehensive and full-cycle effort. This approach is in line with the needs of most vehicle manufacturers, and is one of the reasons why Ningde Times Group has been able to quickly secure the European and domestic markets.

According to data from the China Automotive Power Battery Industry Innovation Alliance, in 2019, the installed capacity of power batteries for EVs in China reached 62.2 GWh. Ningde Times Group accounted for 31.46 GWh, with ternary batteries accounting for over 80\% of the total. Ningde Times Group has a market share of over 50\%. Prior to collaborating with Tesla, Ningde Times Group had already partnered with many Chinese carmakers, including SAIC, Dongfeng, Changan, BAIC, GAC, and international brands such as BMW, Daimler, Hyundai, Jaguar Land Rover, PSA Peugeot Citroen, Volkswagen, and Volvo.

To clarify, with regards to the Ningde Times Group video, there have been accusations that the battery used in the experiment was not of a production grade. However, we reached out to a representative from Ningde Times Group and received verification that the individual battery cells used for testing are indeed mass-produced and used in commercial vehicles. Due to confidentiality agreements with automakers, they cannot release the names of the companies. In other words, Ningde Times Group has mastered the technology of pinhole safety tests and is now mass-producing and commercializing them.

In conclusion, it is evident that both giants place great emphasis on the safety of the batteries. This demonstrates that the market is prioritizing and improving safety practices. We agree with the three points highlighted by Ningde Times Group:1. Both ternary and lithium iron phosphate (LiFePO4) have their own characteristics to meet different market demands;

-

International recognition is shifting from monomer safety to system safety;

-

Chinese standards and international regulations are fully converged, and the focus is on system safety.

Battery safety cannot be judged merely by nail penetration tests. Currently, it is impossible to solve the internal short circuit issue from the material end, similar to the difficulty in addressing low-temperature performance with LiFePO4. For ternary cells, optimizing from a systems level is more in line with practical demands.

LiFePO4 and ternary lithium batteries meet different market demands and are not necessarily in conflict with each other. However, overly emphasizing one specific test can lead to biased conclusions.