Introduction

Since the game started between BYD and CATL over the safety issue of ternary batteries, many domestic car companies have been trying to end the needle piercing and heat diffusion experiment within a certain range.

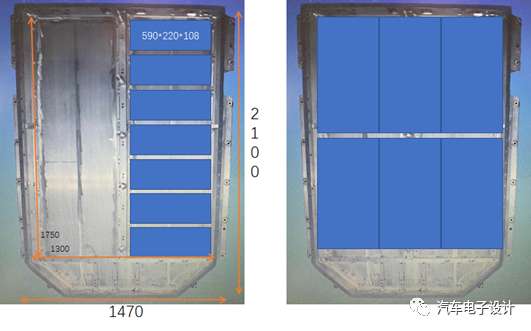

I have several questions about this experiment. The main one is related to the previous platform design of the Aion series, where the tray and module have undergone significant modifications. However, the simulation and analysis materials used in the presentation are based on the original 590 module. Is there any difference in the product selected for the experiment here?

Note: I am making some guesses based on the displayed materials, and the final interpretation still needs to be explained by GAC officials. With the mention of graphene and 1000 kilometers, GAC is not sparing any effort in promoting battery safety.

Differences in the Promotional Video

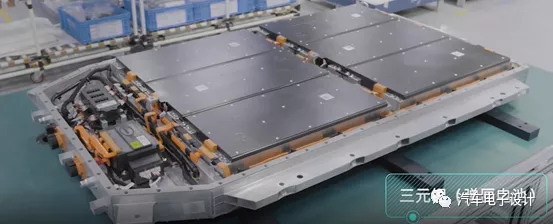

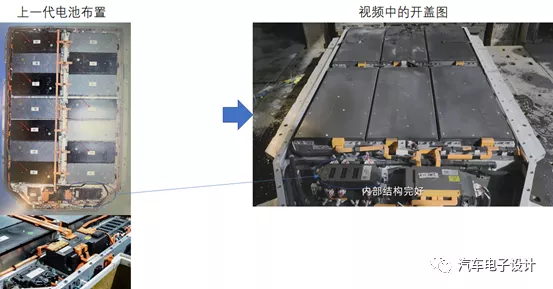

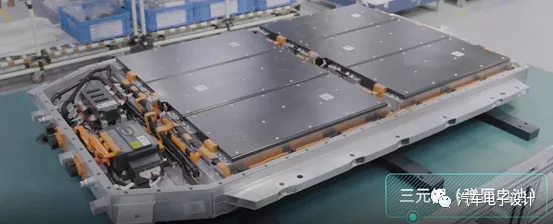

The biggest question I have is that the technical content mentioned before was based on the 590 module and related cells. However, in the video, six large modules were displayed after the experiment, which presents significant differences.

Based on the dimensions of the tray totaling 14702100 mm, the internal size is estimated to be around 1300-1750 mm. Therefore, all the figures mentioned in the presentation correspond to the left side and not the right side. The large module is estimated to be around 420800 mm (after changes in the tray’s beam design, the module’s width can be reduced to around 420 mm, and the spacing and edges between the modules are left with 10 mm).

Note: If a large module is made with 220 mm wide 590 cells, the module’s width will reach 450 mm, and the sum of three modules will be 1250 mm, which is too compact.

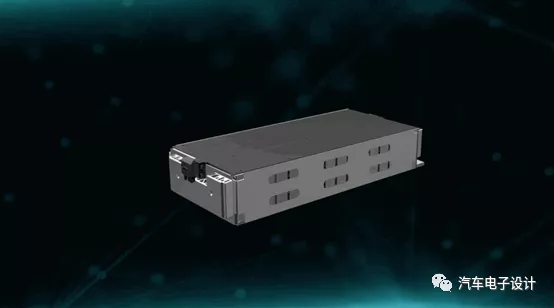

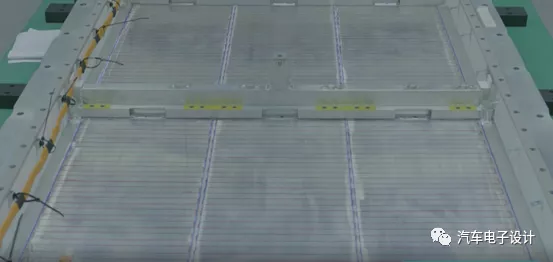

This is the module form promoted by Eon, which looks more like a 16-cell 590 module with the same specification as the 2P8S module of the previous Aion V series. In this module, the harmonica tube water-cooled plate is abandoned and integrated into the module.

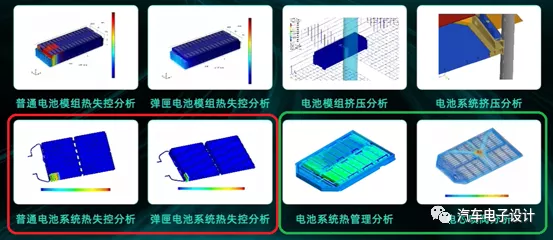

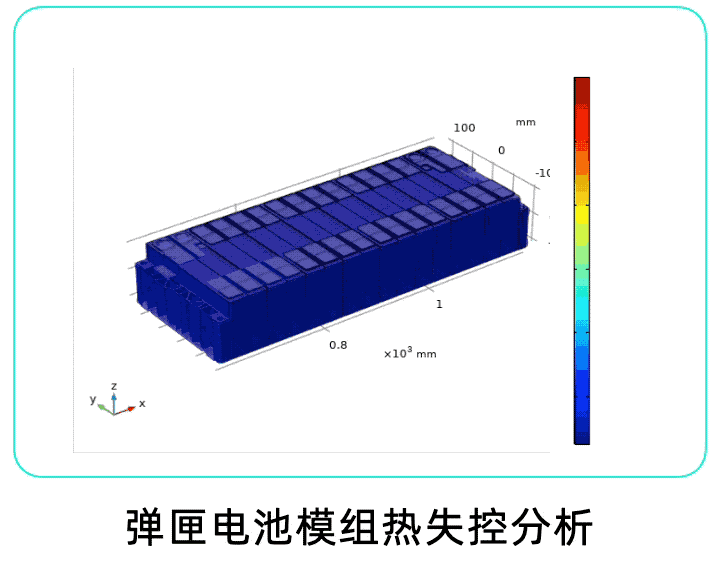

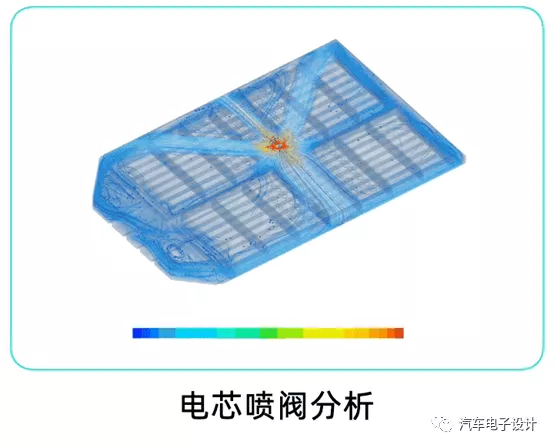

Especially for the simulation diagram of the thermal runaway propagation of the battery core and the diagram of the subsequent battery core spray valve, these are based on the 590 size battery. There are differences from the final diagram of the experimental results.

My biggest question is why the analysis of batteries and modules in the press conference is not consistent with the object of actual experiments.

Note: There is a high possibility that a special battery size was customized, or something different from the description in regards to the battery was used during this period of time.

Battery and System Measures

In addition to the story of graphene, EAon previously had three battery suppliers in mass production (Zhonghang’s 148 width single-layer thick battery and 220 width single-layer thick battery, Ningde’s 177 Ah and 234 Ah, and Funeng’s soft pack battery). The solution shown this time is based on the 590 single-layer thick battery.

Previously, when Funeng introduced themselves, they also claimed to be capable.“`

Looking at the experiment package, it seems to be using 148 battery cells. After displaying so much, there are still many questions remaining. The four measures discussed are:

1) Ultra-high heat-resistant and stable battery cells: This is more like a systematic switch from the 811 to the high-voltage 523 system. As for the application of nano-coating and doping technology of the positive electrode material, new types of electrolyte additives and high safety electrolytes, it seems to raise the heat control and heat-resistant points of the battery cells.

2) Ultra-strong thermal insulation for battery safety compartments: this mainly includes thermal insulation materials and high-temperature resistant shells (switch to steel cover with a temperature resistance of 1400°C?).

3) Rapid cooling system: achieved by a fully-integrated liquid cooling system (changed the cooling plate), high-speed heat dissipation channel, and high-precision heat conduction path design (meaning the side plate according to illustration). This involves the need for the entire vehicle to open the water pump for heat dissipation, mainly changing the design of the car.

4) Real-time control of the fifth-generation battery management system: using the latest generation of car-grade battery management system chips (is this an AFE that supports sampling and detection?), with 10 data collections per second and 24-hour all-weather patrol mode. Wake-up operation is performed by voltage and temperature detection inside the AFE.

Conclusion

Overall, the actions taken by Ayaan are quite confusing. According to the latest announcement data of the Aion Y, the energy density of this batch of AVIC batteries is around 160 Wh/kg. I wonder if they are already trying to control the results of the heat control experiment.

As installing insulation pads on all 16 battery cells of the 590 modules can cause expansion problems, switching to a large module design is safer. However, with such propaganda, the five-minute heat control warning has become a starting point, which still has a considerable impact on the application of high-nickel.

“`

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.