Introduction

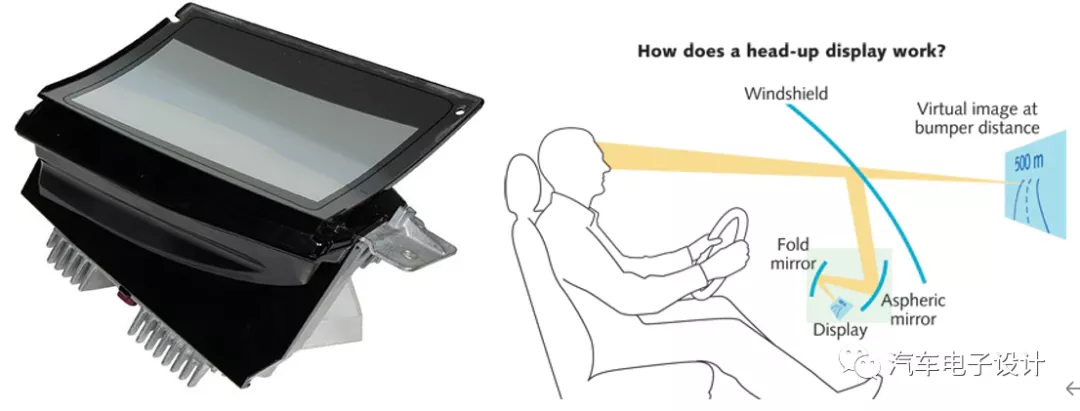

In the past few years, I have two friends who started their own businesses in the field of HUD, which is a trendy direction in the automotive parts industry. HUD (head-up display) is a solution that enables drivers to view important information on the windshield without looking down at the instrument panel. With the development of the MEB architecture, this technology may be extended to more electric vehicles in the future. The following is a teardown of the projection HUD system for old BMW TFT, for reference only.

Teardown of Windshield HUD

The working principle of the windshield HUD is to project driving-related information onto a transparent medium in front of the driver.

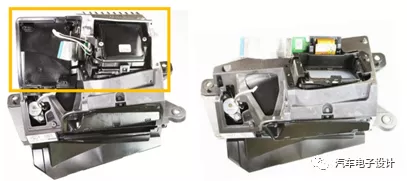

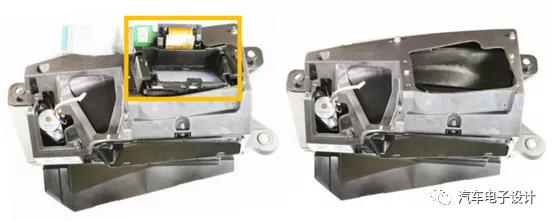

From the overall interface, we can refer to the HUD made by Japan Seiki for BMW to decompose it. From the overall structure, it mainly consists of a main control PCB board, an LED light source unit, a display part, and a mirror part. A total of three PCB boards are used here: the main control PCB board, the light source PCB board, and the display adapter board.

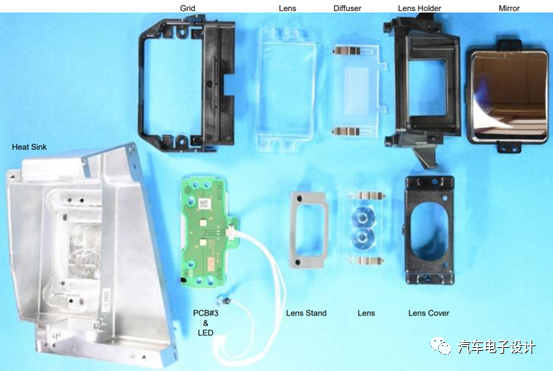

1) LED light source part: The LED needs to provide enough bright light to allow the driver to see the projected images and information clearly. Here, an independent LED array board is designed. Since the projection effect is determined by the brightness of the projection light and ambient light, the LED here needs to be bright enough. As shown below, the LED board is directly under the heat dissipation shell.

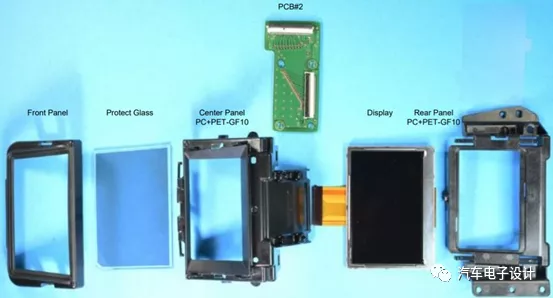

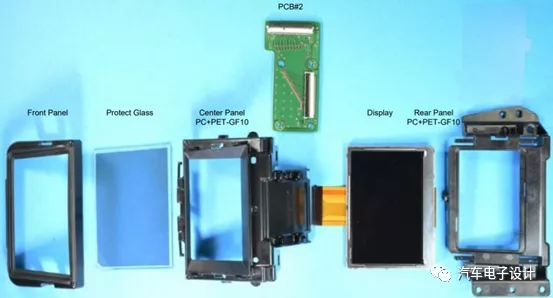

2) The content displayed on the LCD screen is an important component of the entire projection. These contents are reflected to change the angle of the light source and eventually imaged on the windshield. The structure is shown below.

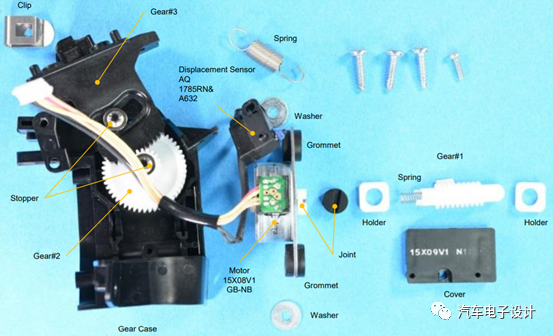

3) The last part is the control of the reflective structure, mainly controlled by a DC motor to control the position, and the structure is relatively simple.

3) The last part is the control of the reflective structure, mainly controlled by a DC motor to control the position, and the structure is relatively simple.

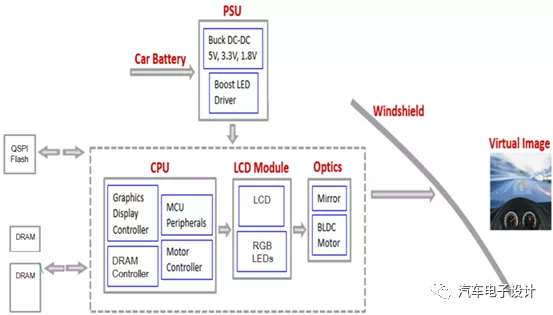

From an overall perspective, the HUD is a purely optical device, and the automotive electronics part is a light source, screen and image display. Below, another HUD motherboard from Continental in mainland China is used as a reference. After integrating the motherboard, the main cost is still glass and so on.

The irregular curved surface of the windshield glass will cause distorted images by direct projection. In the design, a non-spherical mirror needs to be added to correct the image. This is completely an optical know-how.

HUD with integrated mainboard and LED board

Continental also supplies HUD to BMW. In a teardown in 2015, the overall assembly consists of the following components, mainly including:

LCD display unit (1.8 inches, 480 x 240 pixels), 40.8 mm x 20.4 mm visible area, 85 um x 85 um pixel size, produced by a Japanese display company (ACX416AKN-E)

HUD housing, made of aluminum alloy; there are also projection window frame housing, concave mirror housing, and flat mirror housing

Concave mirror, injection-molded polycarbonate, silver coating

Main control board controller: Using 83.3 MHz CPU, 136 KB SRAM / 160 KB NOR flash; with I2C and 6 stepper motor controllers

DC motor, DC brushless motor with integrated gearbox

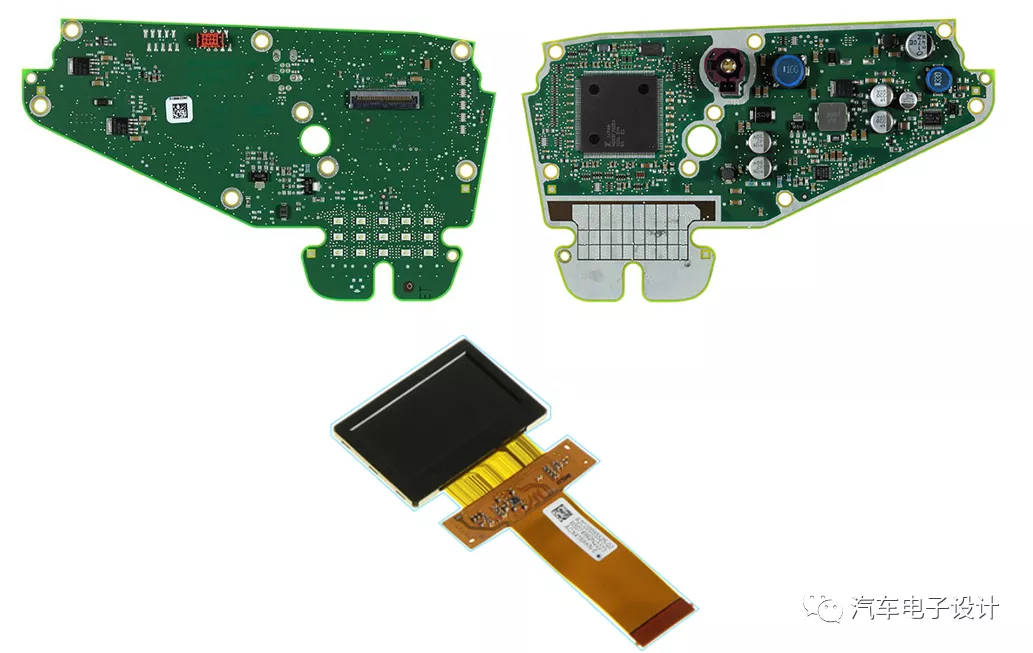

As shown above, the main control board mainly includes graphic control, main control communication, and motor control.

As shown in the mainboard below, the difference from Japan Precision Machinery is that the mainboard and LED board are integrated, and there is no special design content from the perspective of automotive electronics.

Summary

From the trend of new cars in recent years, the popularity rate of HUD is still growing rapidly. The cost reduction of this thing is partly due to the optical aspect, and partly due to the reduction of the electronic BOM. From a future perspective, it is reasonable for a main control unit to directly transmit the content to be displayed onto this display screen. Many automotive electronic components seem to be related to electronics, but the proportion of electronic parts inside is very low, mainly mechanical and material issues.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.