Introduction

What I find interesting about BYD is that they have developed a blade PHEV module based on the design of blade batteries. The module consists of multiple batteries connected in series, forming a long strip module of 25.6 V & 1.22 kWh (1P8S), as shown in the figure below.

Q4 2020 data

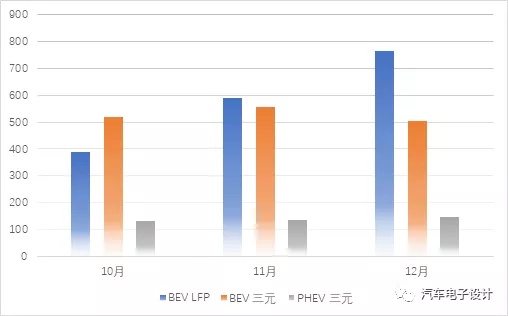

BYD is currently transitioning from ternary batteries to LFP batteries, as shown in the graph below. With the rise of Han EV every month, the proportion of LFP batteries has exceeded that of ternary batteries.

Looking at the MWh of batteries installed in December, the number of LFP BEV battery cells has reached 764.5 MWh, exceeding the 503 MWh of ternary BEV and the 146MWh of ternary PHEV. It can be said that when BYD announced their intention to participate in a needle-prick experiment at a conference, it actually represented BYD’s continued transformation, not only expanding the use of LFP blade batteries, but also introducing them into PHEVs.

So what does this thicker battery cell mean? In fact, this information was released earlier, indicating that a capacity of 8.3 kWh to 21.5 kWh can be achieved using soft pack battery cells with a 1P or multiple P design.

Blade module

Similar to the LFP battery cells used in BEVs, this technique is similar to the method described in a previous patent, and is somewhat similar to the nickel-hydrogen batteries developed by Toyota. Different numbers of small-capacity battery cells are packaged in a long module, forming a U-shaped connection with a single end connection, as shown in the figure below.

The photo of the released PPT below actually has a very similar structure to the previous patent. Two battery cells are combined to form different structures using single-capacity cells for 1P and 2P. After the single blade module is made into 8S, in order to achieve an 8 kWh battery pack, only 7 modules need to be used, and the overall structure is not complicated.

The photo of the released PPT below actually has a very similar structure to the previous patent. Two battery cells are combined to form different structures using single-capacity cells for 1P and 2P. After the single blade module is made into 8S, in order to achieve an 8 kWh battery pack, only 7 modules need to be used, and the overall structure is not complicated.

From the structure inside the module, the tray is very streamlined, and the cold plate uses a cold refrigerant direct cooling mode, which can achieve high integration efficiency and low height for the entire package. Therefore, based on this series of batteries, it can be relatively easy to switch among cars such as Tang DM and Song DM. Due to the power characteristics of LFP, a pulse self-heating mode is introduced through an external inverter to improve it, and internal heat dissipation may be more effective for heating. The thermal management structure of the package has not been designed for heating. Note: In my understanding, complete switching can be performed later.

In terms of publicity, the LFP module used in this PHEV has not yet been widely discussed. The innovation of this structure actually changes the existing soft pack module line. In fact, the update and iteration of equipment in recent years is really fast.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.