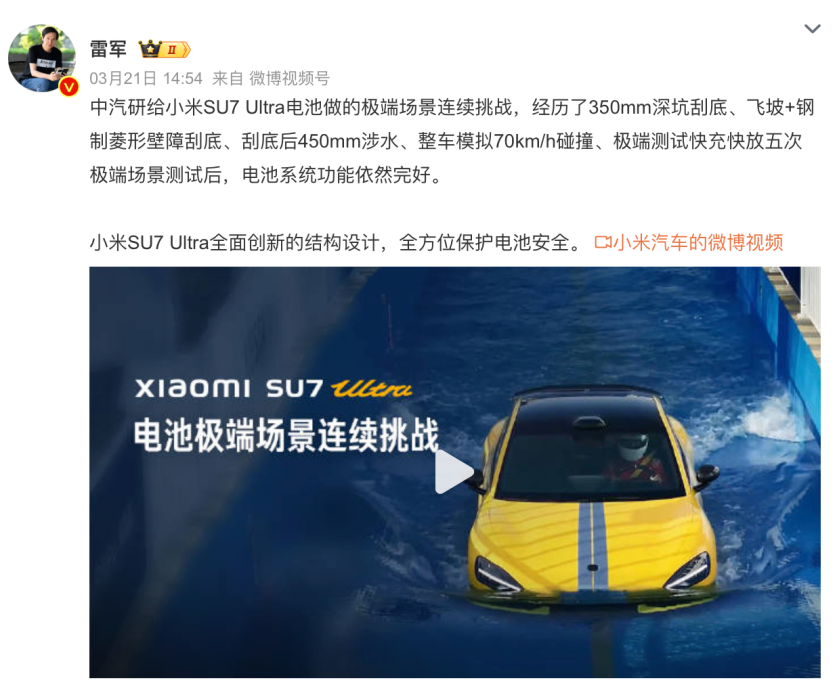

Recently, the XiaoMi SU7 Ultra underwent a series of rigorous tests at CATARC, including:

- 350 mm pit bottom scraping;

- Ramp jump + steel diamond wall obstacle scraping;

- 450 mm water wading post-bottom scrape;

- 70 km/h vehicle collision simulation;

- Five cycles of extreme rapid charging and discharging.

After enduring various extreme tests, the battery system of the XiaoMi SU7 Ultra continued to function normally, a testament to the safety of the CATL Kirin Battery.

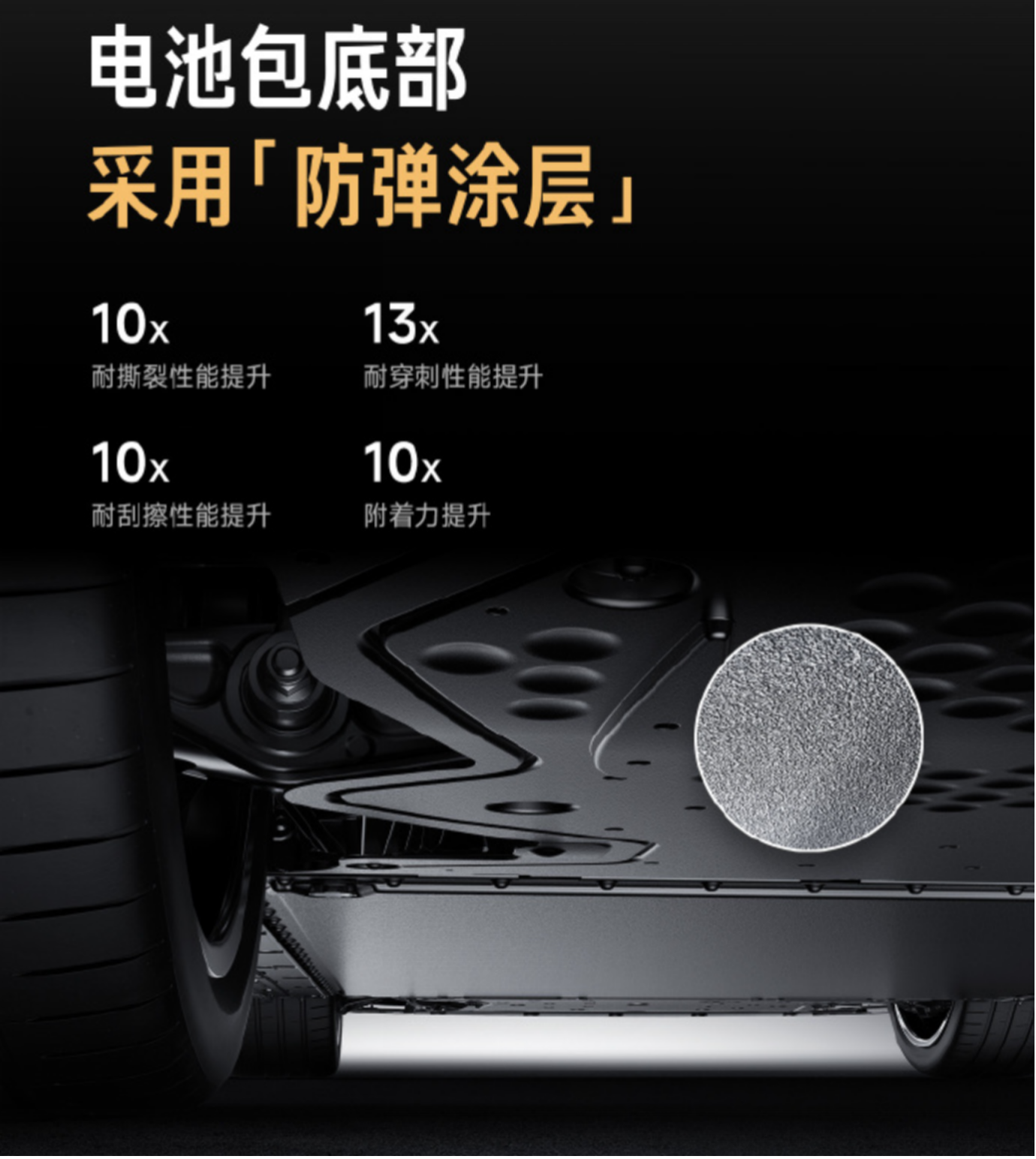

The CATL Kirin Battery integrated into the XiaoMi SU7 Ultra features a tank armor-grade protective coating, which enhances its tear resistance by 10 times, puncture resistance by 13 times, and scratch resistance by 10 times, along with a 10-fold increase in adhesion compared to traditional PVC coatings.

Structurally, the Kirin Battery’s pack design includes ample impact deformation space at the bottom to maintain structural integrity even under significant impact.

Furthermore, the static waterproof rating of the Kirin Battery is IPX8, and the dynamic waterproof rating reaches IPX9K, the highest standards for electrical equipment waterproofing.

The Kirin Battery also incorporates CATL’s proprietary NP2.0 technology. In the event that a cell overheats due to a fault, NP2.0 uses a thermal-electric separation design to physically isolate the cell’s relief vent (smoke exhaust direction) from high-voltage circuits. The cell bottom has an independent relief channel and mica shield, ensuring high-temperature fumes are expelled through a dedicated bottom channel to prevent secondary damage.

Additionally, the manufacturing process of the Kirin Battery is highly advanced, utilizing PPB-level craftsmanship that controls cell defect rates to one part per billion.

In summary, the XiaoMi SU7 Ultra’s impressive performance in CATARC tests is significantly supported by the critical role of the CATL Kirin Battery.

This article is a translation by AI of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.