Weekly Index

Weekly News

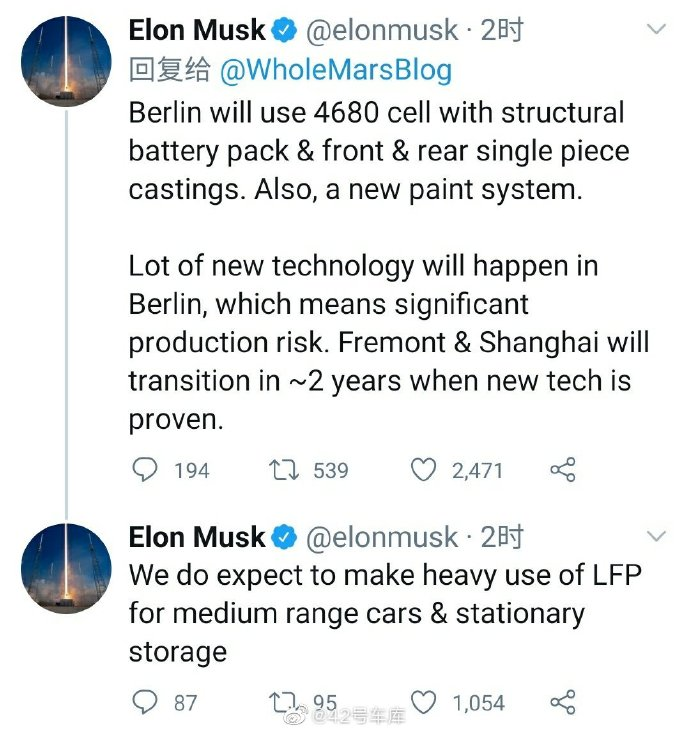

Elon Musk: Berlin Factory to Use New Technologies Unveiled on Battery Day

Elon Musk tweeted that new battery technologies unveiled on Battery Day, including the 4680 cell, battery pack integration, a new structural battery pack, and a new paint system, will be used on the Tesla Berlin factory.

Elon also mentioned that the introduction of new technologies carries a significant risk, but if the production runs smoothly at the Berlin factory, the Fremont factory in the United States and the Shanghai factory in China will also undergo corresponding upgrades and renovations within two years.

Commentary:

Elon Musk has emphasized the significant challenges involved in the mass production of new technologies several times before and after Battery Day. Considering the production hell that Model 3 went through earlier, Elon’s understanding of this issue should be profound and cautious.The landing of new technology always brings a series of challenges, but Tesla has been challenging industrial limits since mass production, breaking the conventional cognition of the automotive industry. The series of technologies released on Battery Day are no exception. We believe that when Tesla’s new technology is officially implemented, the new energy automobile industry will usher in a new pattern.

LG Chem announces the research direction of the next stage of power batteries

This year’s Global New Energy Conference, LG Chem announced three key R&D directions in power batteries.

-

High energy density: In terms of electrochemical materials, LG is actively developing advanced positive electrode materials to obtain better energy density and safer availability. LG has developed long cells for MEB and BEV 3 and can develop large-size integrated modules with integrated cooling (using effective cooling devices to maintain the best use environment for the battery), which can maximize the available space of soft pack cells.

-

Fast charging: To achieve the goal of charging in less than 15 minutes, the development of silicon-based positive electrode materials will be crucial, including the use of high-performance conductors (the application of carbon nanotubes).

-

Low-cost design: This is similar to CTP. LG has also invented a term called MPI (module-pack integration), which seems to be similar to the domestically called matrix design. Two modules are spliced together, and an opening plate is used instead of a U-shaped bracket (previously used to completely wrap the module structure).

Quick Review:

At present, the cost, replenishment speed and safety of power batteries are still important factors hindering market development. From the self-ignition accidents of electric vehicles before, it is not difficult to see that the approach of blindly pursuing energy density is not desirable.

From Tesla’s Battery Day and LG’s strategies, it can also be seen that the technological advancement in materials has approached the limit, but there is still a lot of exploration space in the process of battery cell-Pack.

Therefore, optimizing the electrochemical properties of the battery and the manufacturing of battery packs will be two parallel development paths for a long time in the future.

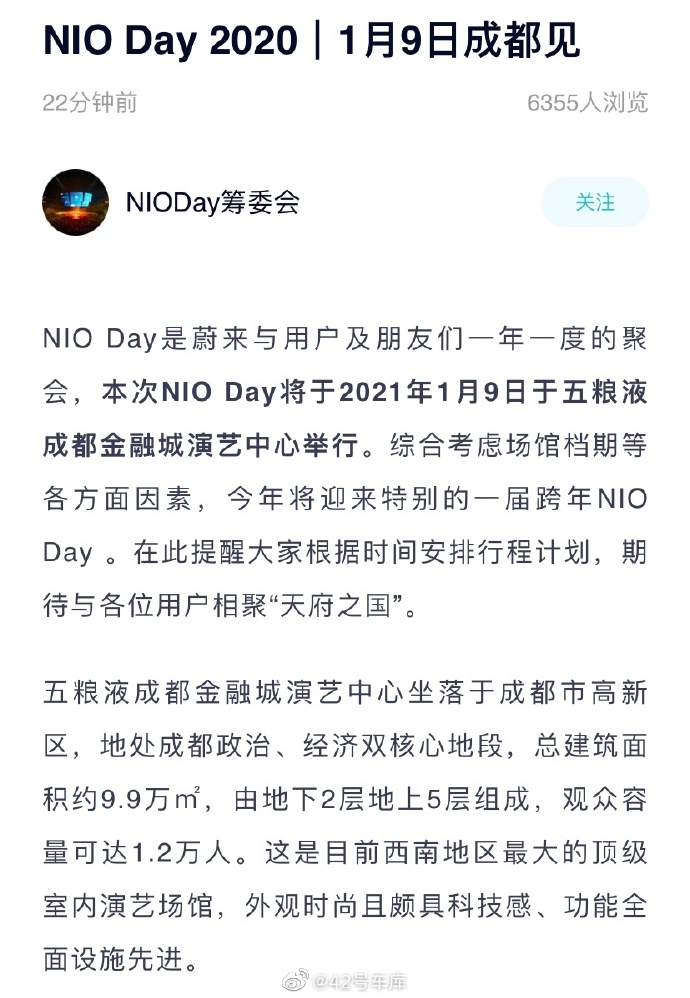

2020 NIO Day will be held in Chengdu on January 9, 2021

On October 6th, NIO officially announced on the NIO APP that the 2020 NIO Day will be held in Chengdu on January 9, 2021.

Quick Review:Recently, NIO has been coming up with one explosive event after another. First, the delivery data in September reached a new high, and then the NIO Pilot (NOP) function was officially rolled out to users. However, what is even more exciting is the NIO Day in 2020. Previously, Li Bin promised that NIO will launch a new car every year. Currently, the mid-term redesigned ES8 has been completed, and the EC6 is about to be delivered. Therefore, the most likely production version will be the previously rumored ET7 sedan. If everything goes smoothly, the production version of ET7 will fill the gap in the sedan field for NIO, and consumers will have more choices.

Mercedes-Benz to Launch Four Pure Electric Car Models in 2021

Mercedes-Benz announced their plan for the future at the online investor and analyst conference on October 7th.

-

Starting in 2021, Mercedes-Benz will launch four new pure electric car models one after another, all of them based on the Mercedes-Benz EVA large pure electric car platform. EQS is the first model, planned to be launched in 2021, with an official WLTP range of over 700 km. The other three models are EQE, EQS SUV, and EQE SUV.

-

In addition to the large pure electric car platform, Mercedes-Benz has also developed an MMA platform for compact and medium-sized cars, which will be launched in 2025.

-

Starting in 2021, both AMG and Maybach will start to launch electrified products. The most famous G series will also offer an electric model.

-

In terms of power batteries, Mercedes-Benz mainly cooperates with companies such as CATL, Farasis, and the California-based battery material company, Sila Nano. Mercedes-Benz will develop the electric motor in-house.

-

Mercedes-Benz has announced the “EQXX Vision” technology project, which mainly clarifies their future plan for electrified products. At present, Mercedes-Benz has deployed an automotive engineering team in Stuttgart, mainly to explore breakthroughs in battery life and energy efficiency.

-

In terms of software, Mercedes-Benz announced that they will launch the MB.OS operating system, which is developed in-house by Mercedes-Benz and is expected to be released in 2024.

Quick Comment:

Mercedes-Benz’s strategy announcement is very grand, covering both luxury benchmarking and mass-market products. This is admirable in terms of the traditional automaker’s ability to plan strategies.

However, in terms of timing, Mercedes-Benz is a bit later than some other major automakers, and the road ahead may be more difficult. As for whether Mercedes-Benz can maintain its current market position after a full transition to electrification, it depends on the product strength of Mercedes-Benz’s new products next year.

Foreign Media Tests Volkswagen ID.3 High Speed RangeBattery Life recently conducted a highway endurance test on the new Volkswagen ID.3 Pro S, with an average speed of 119 km/h, the actual endurance of ID.3 Pro S was around 350-360 km.

There are three endurance versions of ID.3:

- The entry-level model is equipped with a 48 kWh battery pack, with a WLTP endurance of 330 km;

- The mid-range model is equipped with a 58 kWh battery pack, with a WLTP endurance of 420 km;

- The top-level model will be equipped with a 77 kWh battery pack, with a WLTP endurance of 550 km.

Battery Life fully charged this top-level ID.3 Pro S at a service area and drove at a constant speed of 130 km/h on the highway. They drove a total of 351 km, with 9 km of remaining endurance, and an average speed of 119 km the whole journey.

Fast Comments:

Although 20 kWh/100 km is a very high energy consumption value for ID.3, it should be clarified that for electric vehicles, the faster the speed, the higher the energy consumption. Moreover, as the speed increases, the energy consumption will increase exponentially. Reaching an average speed of 119 km/h is already quite high for an ID.3; thus, energy consumption on Chinese highways remains unknown.

I wonder if Germans are still satisfied with the endurance of the ID.3?

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.