Tesla CTO Straubel gave a keynote speech on “Tesla Will Refactor the Electricity Grid of This Century” at the SDF 2015 conference in Korea. He used the high emissions of carbon dioxide as a starting point and introduced the development of battery technology as preparation to explain to us the super factory that Tesla is building — a power plant that can provide cheap and sufficient clean energy for the world.

In the following text, Xiao Dian will replay Straubel’s speech in full.

How Tesla was born

In today’s society, the vast majority of energy that drives everything comes from fossil fuels, and the transportation industry is the most concentrated sector that uses fossil fuels. Fossil fuels drive 95% of all people and goods on this planet.

A few months ago, something quite interesting happened, but it was largely overlooked.

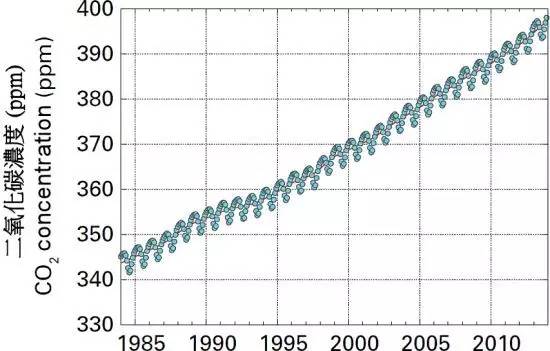

In early (2015), the concentration of carbon dioxide in the atmosphere of the earth, where we all live, exceeded 400 parts per million for the first time. This is a very significant milestone event, especially when you look back at everything that has happened in the past few hundred years, because it is not only the first time in this era, but also the first time in the past few hundred years.

The concentration of carbon dioxide approaching such a high level was already a million years ago. The change is accelerating and astonishing.

To a large extent, this is the result of the widespread use of chemical fuels as energy in modern society. So, for me, how to deal with this problem is a very attractive subject.

Take a look at this picture, I think it is one of the biggest challenges that the whole society will face for the remaining time of this century.

In fact, the challenge is how to make the whole society run normally without using fossil fuels. This is an interesting challenge. In the eyes of engineers and entrepreneurs, there are opportunities and challenges.

This is an opportunity to reshape car technology and power grid supply technology. It is with this in mind that we see a huge opportunity to reshape the world’s production and energy usage. So, 12 years ago, in 2003, we created Tesla Motors.

Tesla creates electric cars around a battery pack

You know, it was a crazy idea at that time. Nowadays, Tesla is endowed with various titles, so it’s easy for people to forget its situation at the beginning.

Initially, we were a very small and unknown company, with a group of Silicon Valley engineers attempting to create a brand-new car. It seemed like a ridiculous idea. No one gave us money, and our financing was very difficult for quite some time. But when we finally made it through that period, we were able to produce the first product that could be pushed to the market.

It was a very inspiring innovative adventure, especially when we saw customers participate with us and take risks together. Of course, its establishment was not just a simple vision. We needed some opportunities and time to create a product that could stand out in fierce competition.

At the beginning of the 21st century, a significant transformation was completed in the field of battery technology, and it was then that we created Tesla. We seized this once-in-a-lifetime opportunity and tried to do something unprecedented.

Batteries have been around for a long time. It is a technology device with a history of more than 100 years. Lead-acid batteries were once considered energy-saving batteries by most people, and they were used to start gasoline cars. In fact, they were also used in early battery-driven cars. They were very bulky and had a small capacity. If you use them, you cannot create an electric car with enough competitiveness in terms of range.

This situation changed only after the invention of lithium-ion batteries. Through this, we could finally imagine an electric car that was more efficient than a gasoline car.

Lithium-ion batteries were not invented for cars. They were originally invented to manufacture electronic consumer products such as laptops and smartphones. It all started in Japan and South Korea in Asia. They are the birthplace of commercialization and industrialization of lithium-ion batteries. Tesla used lithium-ion batteries very early on. We were the first company to try to adjust laptop and mobile phone batteries and put them into cars.

This was an extraordinary idea. At that time, a group of people were lining up to tell us what a terrible idea it was.

In fact, the real challenge was how to ensure the safety of these batteries, how to ensure their efficiency, how to control this new type of chemical, and how to apply the powerful performance they could provide to an unprecedented product.

Take a look at what these batteries look like. This is one of the sections in the battery pack that we tried and eventually equipped in the Roadster at an early stage.

We installed about 7,000 of these batteries in the car. Assembling them safely, which involves cooling and connecting, presented a huge challenge. We also wanted to redefine what an electric car is and the meaning it has for consumers.

We installed about 7,000 of these batteries in the car. Assembling them safely, which involves cooling and connecting, presented a huge challenge. We also wanted to redefine what an electric car is and the meaning it has for consumers.

Most people think an electric car is like a golf cart: slow, short-range, ugly and not fun to drive. But take a look at the Roadster, our first-generation product.

We said we didn’t want to make a slow car. We wanted to make a car that can go fast, look cool and be sexy, like the best sports cars in the world. The success on the Roadster proved that we could create a brand that people care about.

We kept that trend going. With better technology, we could lower the price and increase the size of the market.

The Roadster had a relatively small market, while the Model S and Model X had a market that was 20 times bigger and a purchase price that was half of the Roadster. A big part of this was due to improvements in battery technology, which increased the performance of the Model S.

We really started with just a battery pack and built a car around it, like a blank sheet of paper. We didn’t try and shoehorn battery into an existing gasoline car. We said we wanted to make a car with four wheels and electric powertrain, and that sounded like a battery pack fitting underneath it.

As you can see, the flat plate at the bottom of the chassis is the battery pack.

It is a very large, flat battery pack. It’s a different shape, but it gives the car great handling characteristics. And it armors the electric car, meaning it makes the car perform better in many ways than a gasoline car.

What’s even more exciting is that fundamental technology, materials science and research are all continuing to improve, which will allow for dramatically improved battery performance.When we started creating the Roadster, our technology had already doubled the performance of the two series of electric cars that the General Motors Company had attempted in the late 1990s. Specifically, we made the Roadster’s first 200-kilometer range possible.

At that time, this was very magical and was the result of many years of scientific, inventing, and engineering accumulations. People often ask when the next breakthrough or major event in the battery field will occur. But that’s not how things happen.

At that time, the manufacture of high-capacity batteries was due to the accumulation of hundreds of small inventions. When we started selling the Model S, it was still being continuously improved, with performance increased by 40%. As we look forward to the next generation of products, our third-generation product, we hope that battery performance will continue to increase by 40%. These improvements may not seem significant, but they are the foundation for making these electric cars better. Because they relate to how we control costs effectively and how many people are willing to buy our electric cars.

How the Tesla Super Factory Was Born

As the production scale of electric vehicles expands, the number of batteries we need also increases. It is very exciting that there is such a large electric car market in the world with so many electric cars.

Now, approximately 100 million new cars are sold worldwide every year, and we produce only about 50-60 thousand, occupying a very small part of all the world’s vehicles. We deploy and use approximately 4 billion kWh (1 kWh= 10,000 degrees) of electricity on every lithium-ion battery. Anywhere in the world, this is the largest battery pack running on the road. Unique!

As we look ahead to 2020, the end of this era, we believe that there will be nearly one million electric cars on the road altogether at that time. Their total driving requires approximately 70 billion kWh of electricity. Remember, there will be approximately two billion cars on the world’s roads at that time. So, 1 million is only a small part of the 2 billion, but 70 billion kWh is a huge number for the current battery industry.

Therefore, every time we see any changes or developments in batteries and battery materials, we are very excited.

In fact, South Korea is the world’s largest lithium-ion battery production country, and LG, Canon, Samsung, SBI and other battery manufacturers are all in South Korea, which is very exciting. Secondly, Japan and China follow. However, the growth of lithium-ion batteries is currently mainly driven by various forms of consumer electronics such as notebooks, mobile phones, and tablets.In the next five to ten years, we will see a great transformation in which new technologies and applications will greatly promote the development of lithium-ion batteries, a level of progress that consumer electronics will never achieve.

Buying a Model S is equivalent to buying 7000 rechargeable batteries, while buying a laptop is only equivalent to buying 3-4 batteries. Therefore, compared to consumer electronics, the demand for electricity by electric car consumers has increased significantly. And this is just the surface demand of Tesla, not to mention the global consumption.

In 2014, Tesla’s demand for lithium-ion batteries accounted for only 10% of the world’s total demand. But in 2020, this proportion will exceed 100%. However, it is obviously impossible to exceed 100% of total demand because we still need to produce laptops, mobile phones and other electronic products. Such a huge energy storage demand is both a huge challenge and a huge opportunity.

To seize this opportunity, we need to reflect on how these batteries are produced. Since their invention, they have been produced in a way suitable for electronic products. But we believe that batteries are already very suitable for vehicles or power grids. So what we are doing is basically rethinking or imagining a very large factory. In this factory, we are vertically integrating from start to finish to produce batteries at lower costs and then use them to expand production scale. Therefore, we can reduce car prices at an unprecedented speed.

We call it the Gigafactory. It is called “Giga” because it is a storage unit of one billion watt-hours (or one million kilowatt-hours). Such a factory plans to produce 35 billion watt-hours (or 35 million kilowatt-hours) of batteries per year, which is equivalent to the global battery production in 2013. It is a very large factory.

This is part of what the building looks like.

It is located in Nevada, USA, and is gradually taking shape. We expect that the first battery will be produced here by 2016 (it is reported that this Gigafactory will be completed in the second half of this year, so we’ll see). This is just one of many factories in the future. Tesla will not monopolize the entire lithium-ion battery market.

On the contrary, I believe that if almost all automakers in the world plan to produce more electric vehicles, they will all need similar factories. Therefore, we expect the growth of battery technology, which will be very exciting and amazing.These factories are also focused on the overall production process. Nowadays, many battery manufacturers only focus on a part of the production process. Then they own multiple factories around the world to produce different parts. But this is not really the best practice because it greatly increases the cost and complexity of the entire supply chain. So what we do is to put everything under one roof.

We are trying to complete the entire production process from raw materials to battery packs in one factory. This is the most efficient cost control method we can imagine. If you put all of these together, you can see all the professional technology, experience and knowledge we have in the battery field.

Tesla has driven over a billion miles, which is quite surprising. And during those billion miles, no one was injured due to battery problems. Those billion miles used over 5 billion kWh of batteries, which are the lowest cost batteries in the world today.

Then, if you put all these together, we see a huge opportunity to apply expertise and engineering technology to the supply chain in factories and then put the batteries from the supply chain into the production of electric vehicles. This is really an exciting and promising future.

The challenge is how to combine intermittent renewable energy sources such as solar and wind power with electric vehicles or other modes of transportation. There is no direct way to do this yet.

As I mentioned at the beginning, part of Tesla’s mission or goal is to achieve transportation without fossil fuels. To achieve this goal, you must find a way to combine the two. Electric vehicles indirectly end the use of fossil fuels, but this is not what we really want to do. We have started deploying a new type of product and launched a brand-new business unit weeks ago. We call it Tesla Energy, which uses all of our battery expertise and architecture and has produced several products for the grid.

So we have two special types of products. One is for household use and the other is for commercial or public utility buildings. Some details are the capacity of the household battery packs is about 10 kWh, and the commercial battery packs used by hotels, restaurants, and other businesses are around 100 kWh.

These products we plan to complete extend consumer interest from the purchase of electric vehicles to the purchase of household battery systems, and even to the purchase of solar or other clean energy from public facilities for household use.We see that most of our customers are interested in this and they voluntarily adhere to the principles of upstream companies in the energy chain, seeking a way to achieve carbon neutrality in energy use. Products designed specifically for special markets will be sold directly to the public sector to help them solve scale problems. These batteries are aggregated into many different models and production lines. Our chief engineer is very proud to be able to create such products.

However, our concept is to integrate them together to achieve scalability, just like combining single solar panels into a whole. This way, we can better utilize the batteries.

We have applied this method to practical use through the automation of electronic devices and computers. Therefore, they do not need to rely on a large string of battery packs to work, and they can all run independently. If you need to, you can replace or remove one of them at any time.

Overall, there is a larger market beyond the existing electricity grid market.

There are over a billion people in the world who still cannot use electricity, so there is still a lot of room for the development of the electricity grid. In addition, more people use very poor power grids, such as extremely incompatible power grids. Now, it has become very cheap to deploy a microgrid or a solar panel in a few households or in a small community. Just pull the wires and establish a central generator, and the new grid can cover the entire area. This is a fundamental change, and our technology makes it possible.

This will be the first time ever that we cross the old method and establish a grid.

The old method has been around for over 100 years, it was jointly invented by Edison and Tesla, and it has been and still is the way the grid is built. In the coming years, as battery prices and solar prices fall, we will usher in a huge transformation. So this is something I am very excited about.

The best analogy is the role that batteries play in today’s world of smartphones. The use of landline phones is no longer important anywhere, and the world no longer needs them. Mobile phones provide better and more convenient service for everyone. So I think the same thing is happening in the energy sector. You will go beyond existing infrastructure and come to a new world.

Overall, what we need is to no longer use fossil fuels, not to save energy, after all, it is not difficult for us to drive micro-cars or turn off the thermostat. We want to use this curiosity, creativity, intelligent engineering, and invention to help us find a sustainable technology, ultimately to achieve the goal of making the world a better place, at least better than the world we build today with fossil fuels.

I think this will be the beginning of an energy revolution that will change everything. In the future, people will have cars they love more, and can use new clean energy at home, which will not produce pollution and will be cheaper.This is all the content of my speech today, thank you very much.

▼

More Information

J.B.Straubel once said in public that he loves batteries more than cars. If Musk sincerely loves the earth, then Straubel is the one who loves batteries wholeheartedly.

He loved hands-on work since he was a child and was one of the first people to study the application of lithium batteries in cars. He once spent $1,600 to buy a used Porsche and converted it into an electric car, and then realized the bottleneck of batteries. He worked with Stanford’s solar car team to explore the application of 18650 lithium-ion batteries in vehicles and sought financing from Musk. With Musk’s support, he began to study battery packs and was later invited by Musk to join Tesla, becoming a founding member of the Tesla team and has been with the company ever since.

In an interview with the New York Times, he shared some of his hobbies. Speaking of books, he loves to read biographies of scientists and engineers, such as Walter Isaacson’s “Steve Jobs”, and his favorite book is “Wizard: The Life and Times of Nikola Tesla” written by Marc Seifer.

He said that many people in this world will tell you that something is impossible to achieve or too risky. But you must be the one who disregards these words. You can say it is brave, or you can say it is unreasonable. The fact is, it can often lead to either trouble or truly innovative breakthroughs.

Surprisingly, he watches the same movie every year called “October Sky”. Based on Homer Hickam’s true inspirational story, the movie tells the story of a boy born in a mining area who is obsessed with making rockets. The protagonist of the story eventually became a scientist at NASA.

Straubel said that watching it once a year makes him want to work harder.

There’s a line in the movie that says, “Thank you for believing in us before we believe in ourselves.” This is for all of you. Why are Internet giants investing in the automotive industry?

Why are Internet giants investing in the automotive industry?

The Queen of the Internet tells you what future cars will look like in 23 slides

Five key issues affecting Tesla

What is Apple researching on electric vehicle charging?

Exciting electric vehicle news

Looking for electric vehicle enthusiasts

Contact Daiji at WeChat ID: iidaji.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.