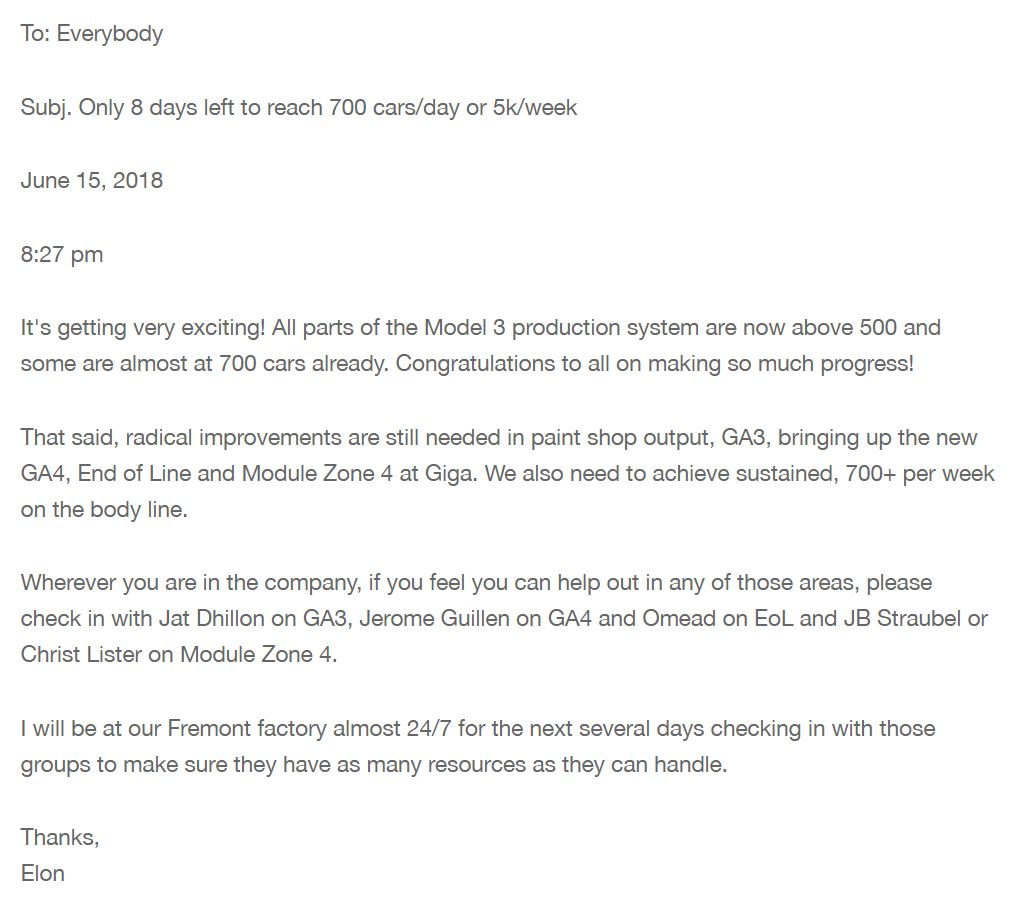

Q2 is about to end, and as we count down, the one year anniversary of the Model 3 production capacity issue ruling automobile media headlines is also approaching. At such an important moment, Tesla CEO Elon Musk’s company-wide email has arrived.

Here are the key points of Elon’s email:

-

The production capacity of all aspects of the Model 3 production system is over 500 vehicles/day, with some achieving 700 vehicles/day (i.e. 5,000/week).

-

Bottlenecks to capacity improvement are: painting process, assembly line 3, newly established assembly line 4, end of the line, welding process, and Unit 4 of the battery pack module production line. Of these, the painting process requires “thorough improvement and upgrading.”

-

Jat Dhillon will monitor assembly line 3, Jerome Guillen will monitor assembly line 4, Omead Afshar will monitor the end of the line, and JB Straubel or Christ Lister will monitor Unit 4 of the battery pack module production line.

-

Elon Musk will spend the next few days at the Tesla factory in Fremont, California, 24 hours a day, 7 days a week, to ensure that the aforementioned production teams have sufficient resources to support their capacity improvement efforts.

How should we interpret this email?

First of all, with regards to the first point, it’s worth noting that Model 3 production capacity went from the entire factory working tirelessly at the end of Q1 to barely reaching 2,000 vehicles/week, whereas now it has steadily improved to 500 vehicles/day, which is still quite an achievement. However, there are less than 15 days left until the end of Q2, and we need to leave a week to validate the sustainability of producing over 700 vehicles per day. That’s why Elon said at the beginning that “Tesla only has 8 days left to make a lot of cars.” When combined with the second point, we can see that there are still many challenges remaining.

Secondly, the situation is not optimistic. We can see that of the four major processes for automobile production at the Tesla factory in Fremont, only the stamping process is problem-free, while the remaining three processes all have problems, especially the painting process, which had never had a problem before and now requires “thorough improvement and upgrading.”At Gigafactory 1 in Nevada, the battery pack automation line for Model 3 also encountered problems. Tesla split the battery pack module production line for Model 3 into four stages, and the battery pack supply had been the biggest bottleneck hindering the production capacity growth of Model 3 since last August until the end of the year. The reason was that Tesla outsourced the first two stages (Zone 1-2) of the four stages to suppliers, and the supplier’s solution simply did not work. Tesla’s German automation team (Tesla Grohmann) took over and developed a new production line on their own, which solved the problem.

However, the email above shows that this time the problem occurred in the fourth stage (Zone 4), which has been fully self-developed by Tesla from the beginning, and the current person in charge is Tesla’s CTO JB Straubel, who is second only to Elon.

How to explain the new problems that have emerged one after another?

The first reason is the challenge of dramatically increasing production capacity. In fact, it’s as Jie Wang, the Chairman of WM Motor, said, producing 100,000 vehicles per year is a threshold, producing 500,000 vehicles per year is another threshold, and producing 1 million vehicles per year is yet another one.

Many production lines/technologies ran well on models such as the Model S/X, which produced 100,000 vehicles annually, but when applied to the Model 3, which has an annual production capacity of 200,000-300,000 vehicles, serious problems arise.

The more critical problem is that the management team, led by Elon, is too obsessed with process innovation in the manufacturing stage. This means that, while overcoming various problems encountered in the process of increasing production capacity, the Model 3 production line also needs to verify the feasibility of new processes.

In mid-April, Elon admitted in an interview with CBS that Tesla’s excessive automation was a mistake, and some processes are better suited for human operation. Tesla even dismantled the super complex conveyor belt network in the welding process. He has mentioned similar statements many times.

However, at the recent shareholder meeting, he mentioned that the new third production line had a significant efficiency improvement compared to the first and second lines. This indicates that even if Tesla suffered a great loss for being too innovative, could not achieve the Q1 production target at one point, Tesla still insists on rejecting the conventional practice of copying production lines to increase production capacity, and adding new process innovations to every newly established production line.

Frankly speaking, it is difficult to evaluate whether this approach is right or wrong, especially when Model 3 orders have been backlogged for two years, and order cancellations have exceeded 10%.The third and fourth points, take a look at these people, other than the chief designer Franz von Holzhausen, who has no idea about manufacturing, and the engineering vice president Doug Field who is on vacation, the other three are all on the front lines of production. In addition, the guy in charge of overseeing the production line named Omead Afshar is actually a project manager for the Tesla CEO Office. With such a boss, who would have thought that the CEO Office position would also require sleeping in the factory?

Finally, although Tesla did not achieve its target of 2,500 vehicles per week in Q1, the achieved 2,000 vehicles per week was already very aggressive. Tesla’s statement is that if this growth rate can be sustained, the production capacity growth rate of the Model 3 will exceed the growth record set by the first mass-produced car model, the Ford Model T, in modern automotive industry history.

Subsequently, Tesla provided guidance for 5,000 vehicles per week for Q2. It is still a very challenging task to increase from 500 vehicles per day to 700+ vehicles per day in just 8 days. Can this speed be maintained? We will see in the Q2 delivery announcement in 20 days.

- Tesla’s earnings conference call was interrupted when CEO Elon Musk left…* Why can’t Tesla Model 3 production capacity rise?

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.