Unconsciously, it’s time for my ID to have its second regular maintenance. My little blue has been accompanying me here and there, eating the least but working the most. Today, we went to the 4S store to give it a thorough physical examination. Can’t mistreat our hero at home.

The examination went smoothly, and the result is that it’s very healthy! Today, I would like to talk about the chassis workmanship of my ID.

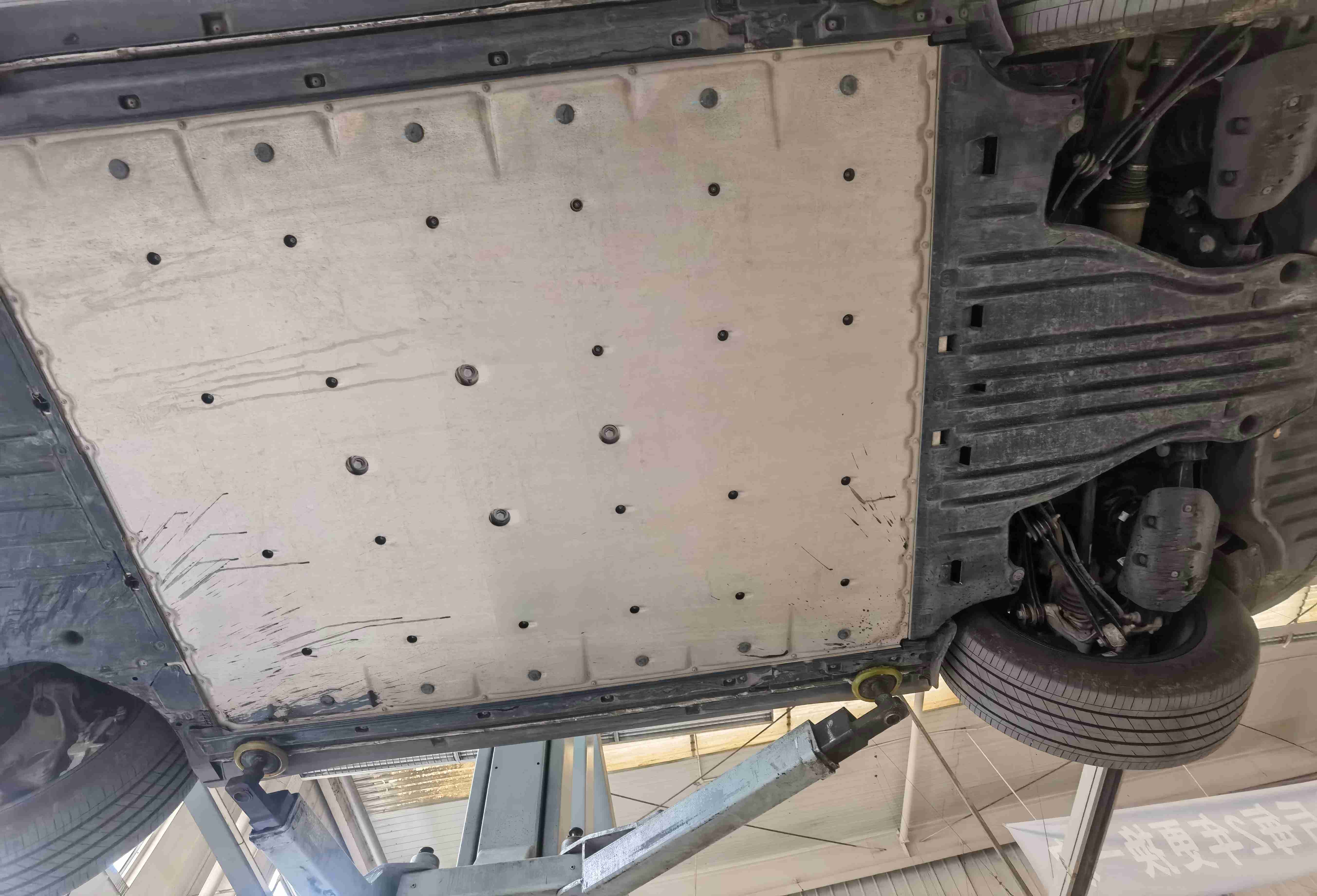

When the vehicle lifting machine raised it up and I saw its chassis, I couldn’t help but admire Volkswagen’s workmanship, it’s undoubtedly excellent!

First of all, the sealing work is done well. The front and rear guard plates protect as much as possible to prevent the chassis from being damaged by flying stones on the road. The most important thing is that the battery is also enclosed in special thick aluminum alloy to improve its mechanical strength. This ensures that the battery is not affected by any strong impact from any direction or long time driving on bad roads. It not only guarantees the safety of the battery pack but also minimizes the weight.

The suspension of the ID also contributes to its good control. In addition to the nearly 50:50 axle load distribution and the low center of gravity design of the MEB platform, the five-link rear suspension of the ID plays an important role. The optimized structure of the strong and thin plates + forged aluminum materials of the ID provides drivers and passengers with a high level of comfort when driving on bumpy roads.

Of course, precise calibration is also Volkswagen’s traditional skill, which is impressive. As a German car fan, handling is everything!

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.