Wearing yellow safety vests and taking to the streets to demand the resignation of the president is not something I have ever witnessed. However, for the people of France, it appears to be a commonplace scene. The “Yellow Vest” movement has entered its fourth week, which is accompanied by vandalism, arson, attacks on police, and damage to historic monuments. The civilized Europeans can no longer tolerate rudeness, and the catalyst for this riot was something that costs only a few cents.

Starting from January 1st, 2019, the French government announced that it would levy a fuel tax of 6.5 euro cents per liter on diesel and 2.9 euro cents per liter on gasoline. The purpose is to fulfill the Paris Agreement, and invest the increased revenue into the development of renewable energy and other energy transition plans. The price of fuel in France has risen by about 20% since 2018. Faced with another price hike, people could not bear it anymore, and then the large-scale uncivilized behavior in civilized countries broke out.

French President Macron is a young leader with green dreams, but his dreams were overshadowed by the “Yellow Vest.” On December 4th, French Prime Minister Philippe announced that the fuel tax increase would be suspended, and then canceled the decision to increase the fuel tax.

Just as France was in chaos, the Belgian people also put on yellow reflective vests. It seems that wearing this eye-catching clothing can make their determination to protest against rising oil prices more firm. According to the latest news from Yiwu, “Yellow Vest” movement will continue and may spread to other European countries because the merchants in Yiwu have received a large number of orders for yellow vests…

The protests in Europe may continue, and politicians may compromise, but the future of traditional energy is self-evident. For politicians, balancing people’s demand for traditional energy and the promotion of new energy is particularly important. For automakers, how to turn around and embrace new energy is a huge challenge.

The Solidified Volkswagen Group Must Break Through to Enter the New Era

Before writing this passage, I suddenly remembered talking with a leader of a state-owned enterprise last year. He generously shared with me various ideas on enterprise transformation and innovative development, and I was inspired. But when I asked about the implementation, he seemed a little disappointed. “Stabilizing the stock and avoiding the increment” is the sentence that I remembered most clearly.

In 2017, the Volkswagen Group had 630,000 full-time employees and over 100 production bases in 27 countries, covering products from motorcycles to heavy trucks. Its total output for 2017 was 10.7 million vehicles and profits exceeded 10 billion euros. If you don’t have a concept of 630,000 employees, the total population of Wolfsburg, the city where the Volkswagen headquarters is located, is only over 120,000.

For Germany, the importance of Volkswagen is self-evident. However, the huge size and importance to the country are not good for transformation, after all, “a small boat is easy to turn around.”In addition, one factor that adds to the challenge of transforming Volkswagen comes from labor unions. Unlike the ones just organizing events and celebrations, labor unions in Europe and America may interfere in any matters concerning workers’ conditions and benefits, and could even organize strikes and protests. Elon Musk has tried his best to avoid the United Auto Workers interfering Tesla, as he doesn’t want to be restricted by them. Unfortunately for Volkswagen, more than half of its supervisory board seats are controlled by labor unions.

This year, traditional auto manufacturers have all sensed the coming of the automotive revolution. For Volkswagen, a traditional automotive giant, this is a terrifying signal. Without transitioning or a successful transformation, the giant could face subversion. So waiting for death is not a good solution. Volkswagen needs someone who dares to rebuild everything, and this person is Herbert Diess.

Diess is not a Volkswagen veteran in the traditional sense. His former employer was BMW in Munich. After joining Volkswagen, he didn’t fit in as a newcomer, but remained maverick. He didn’t ride on private cars or private planes. Instead, he drove an up! happily, making him the same as ordinary Volkswagen employees.

Diess’s focus was to trim the workforce first. After a tug of war with labor unions, he finally achieved his goal of worldwide layoffs by 30,000 people. Trimming the workforce was only the first step. Diess then made a speech at a high-level meeting, claiming that only one third of the high-level executives could meet his expectations, while one third were superfluous and the remaining ones should consider whether to fully engage or withdraw. With the new boss on board, Diess’s words must have offended some people, but he didn’t care at all.

In addition to reducing the workforce and “threatening” high-level executives, Diess also focused on cost-cutting, demanding that each sub-brand should save 10 billion euros per year, and factories and offices should improve efficiency by 30%.

Moreover, Diess wanted to raise people’s awareness of the crisis. At last month’s Volkswagen supervisory board meeting, Diess said that considering current circumstances, there would be a 50% chance that German cars would still be globally leading in 10 years. At this supervisory board meeting, Diess once again succeeded when his 2018-2023 mid-term development plan was passed, and the supervisory board agreed to invest 44 billion euros in the field of electrification, autonomous driving, mobility services, and digitalization.

Then, more than just having a sense of crisis, early this month Volkswagen Group’s product strategy manager Michael Jost announced that 2026 would be the year when the Volkswagen Group launches its last generation of combustion engines. This message was later confirmed by a Volkswagen spokesperson.Volkswagen has finalized its schedule which is terrible news for the development team of fuel cars. However, Volkswagen still did it and reached an agreement with the union mentioned before to provide additional job protection for workers who may lose their jobs due to the transformation. Even if this decision makes some people feel sad, Diess still hopes to awaken more people and make Volkswagen’s transformation a firm step forward.

Volkswagen with electrification is still the “People’s Car”

With a calm heart, Diess who received the money is about to embark on a great journey of change, and the electric car is the top priority.

Volkswagen will transform three original German factories into electric car factories and will build another electric car factory in Europe around 2022. In China, six factories under Volkswagen Group will produce electric car models before 2021. In the next two years, 30 new energy car models under the Volkswagen brand will be launched in China. In 2020, Volkswagen Group plans to deliver approximately 400,000 new energy vehicles in the Chinese market. By 2025, Volkswagen will put 50 new car models on the market and sell 2.5 million electric cars.

At present, the cost of electric cars is significantly higher than that of fuel cars. Tesla Model 3 is considered to be an electric car developed for “ordinary people”, but currently, its price still cannot reach the “ordinary” level. Although Elon said that in about five or six months, the starting price of Model 3 could be lowered to $35,000, Mr. Ma Yilong is notoriously unpredictable. For Tesla, Model S and Model X have established a high-end image, and have been labeled with various labels such as technology, advanced and intelligent. Even if the price of Model 3 is not that low, some people will still rush to buy it. However, for Volkswagen, all of this is difficult to establish.

For Volkswagen Group, perhaps Audi’s brand premium capacity is far inferior to Tesla, so if Volkswagen wants its electric car products to remain “Volkswagen”, the Volkswagen Group must find a way to reduce costs and then reduce prices. For us, the giants of the automotive industry like Volkswagen join the game of electric vehicles, which further illustrates the arrival of the era of electrification.

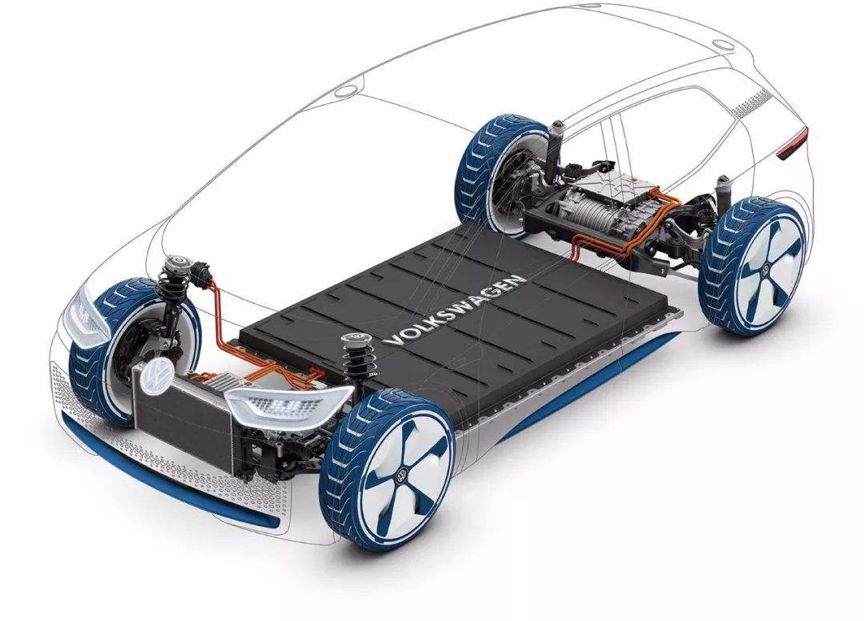

The way that Volkswagen Group reduces costs is platformization, which is not only for electric cars but also for fuel cars. Volkswagen’s electric car platform MEB has a high degree of compatibility and flexibility, it can be loaded with round, soft package, or square battery cells, and can also be applied to various body shapes such as cars, MPVs, SUVs, etc. The size adjustment range is also significantly stronger than the fuel car platform. MEB will be shared among Porsche, Volkswagen, and Audi brands in the future, and may even be shared with electric car models under Ford, and the most important purpose of all of these measures is to reduce costs.“`

At the same time, Volkswagen Group is considering building its own battery factory in Europe with SK, because the current leading power battery companies, LG, Samsung and Ningde, are all in Asia. Volkswagen is very worried that these Asian companies will not be able to supply batteries in time and affect its production progress. In fact, this has already happened. Holding the battery, which accounts for more than 40% of the total vehicle cost, in its own hands is also an important plan for Volkswagen’s electrification route.

Thomas Sedran, Chief Strategy Officer of Volkswagen Group, said that according to predictions, the manufacturing cost of electric vehicles will be lower than that of comparable fuel vehicles for the first time in 2023. That day will be the future eagerly awaited by Diess and the Volkswagen Group.

Automatic Driving Makes Volkswagen Hesitate?

Compared with the firm belief in electrification, Volkswagen Group is clearly struggling to decide how to bet on automatic driving. At the beginning of this year, Volkswagen announced a cooperation with Aurora, a Silicon Valley autonomous driving company. The company was jointly founded by former autonomous driving directors of Google, Tesla and UBER, as well as former software engineering directors of Space X.

However, just last month, when Aurora was authorized as the first company in Pennsylvania to conduct unmanned driving experiments on public roads, Diess wanted to spend $13.7 billion to acquire only 10% of Waymo’s shares. Although this plan was stifled by the supervisory board, it can still be seen that Volkswagen does not intend to bet on one company. In addition to Aurora and Waymo, it is rumored that Volkswagen Group is also negotiating with Apple’s unmanned driving project “Project Titan”, and it is still unknown what kind of spark will happen next.

Volkswagen’s hesitation is actually not difficult to understand. Volkswagen still has some experience and resources available in the field of electric vehicles, but it is still in the initial stage of automatic driving. It is crucial for the Volkswagen group to find a reliable and powerful partner while the Audi autonomous driving team is working hard. It is difficult for the huge Volkswagen to gamble on a “startup company”.

To Be the Boss of Electric Cars, What is Volkswagen’s Virtue and Ability?

As a habitual leader, Volkswagen Group still wants to take the lead in the field of electric vehicles. However, facing strong opponents like Tesla, what confidence does Volkswagen have?

“`The Volkswagen “people” has supported this grand dream to some extent. Diess, who studied mechanical engineering and manufacturing science, worked for Bosch, a global automotive parts giant, for more than 10 years, and gained an understanding of automotive production and manufacturing from the perspective of suppliers. During his 20+ years of work at BMW, he has managed factories, procurement, and the company’s global motorcycle business and retail network, and later was also responsible for the R&D business. Diess’s rich resume makes him one of the few people who can combine extensive experience in production, manufacturing, sales, R&D, and parts supply.

Meanwhile, Thomas Ulbrich, the CEO of Volkswagen Group’s E-Mobility department, which was established in February this year, previously served as the board member for production and logistics at Volkswagen and has rich experience in production and logistics. Compared with Elon, who had never worked in the automotive industry before, leaders of Volkswagen Group’s electric vehicle business clearly have more experience.

In addition, the large number of factories and huge supplier network make Volkswagen have stronger production capacity. Despite Tesla’s strong technical capabilities, Elon is still busy with the production process, which is extremely painful for both Tesla and himself when it comes to increasing production capacity. For Volkswagen, this process will at least not be so difficult. After transformation and training in more than 100 factories and with more than 600,000 employees worldwide, Volkswagen Group can start producing electric vehicles with full dedication, which is much faster than starting from scratch like other new automobile makers.

Moreover, Volkswagen Group’s economic strength cannot be underestimated, and this will also be one of the key factors supporting Volkswagen’s transformation and becoming a leader in electric vehicles.

In 2017, Volkswagen Group ranked third in global corporate R&D spending at 102.2 billion, after Samsung and Google, and is the automobile industry’s top-ranked company. The research and development of electric vehicles is also a burning issue, and the existing huge business of fuel-powered cars provides solid financial support for Volkswagen Group.

Charging stations that must be built after being fined may become a powerful guarantee for Volkswagen’s advancement in electrification. Due to the emissions cheating scandal, Volkswagen was fined $2 billion in the United States for building charging stations. Volkswagen’s subsidiary, Electrify America, will deploy 484 DC fast-charging stations in 17 cities and highways by mid-2019, followed by three more cycles of construction.Although Volkswagen was fined for building charging piles, every cloud has a silver lining. Despite the fact that the charging piles are not as exclusive as those of Tesla, the construction of a large number of fast charging piles has enabled Volkswagen to keep up in the field of charging and provide infrastructure guarantee for the large-scale sales of its electric vehicles.

In 2018, we finally saw that traditional auto giants were no longer mocking Tesla, no longer developing stocks stubbornly and fearing change, no longer afraid to try and instead embarked on a new direction with great strides.

Although Volkswagen, Mercedes-Benz, BMW and other traditional auto giants seem to have not yet come up with amazing products, at least we can expect that future intelligent electric vehicles will not be monopolized by Tesla, and we will have a wider range of excellent intelligent electric vehicles to choose from, just like today’s gasoline vehicles.

Only in this way can things become interesting.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.