In the consumer end, everyone just realized that the automotive industry has entered the era of intelligence.

However, in the product development and manufacturing end of the automotive industry, the word “intelligence” appeared even earlier. The digitization and intelligence of production tools often come earlier than products themselves.

Data and intelligence are the productivity of the next era, and digitization technology is the best production tool. With the combination of the two, production efficiency will be greatly improved.

Digitization technology is a brand new production tool

Many manufacturers talk about future development from the perspective of smart industry manufacturing, while others discuss the potential of vehicle data from the perspective of service operation mode. However, it is the first time that we start to talk about the development strategy of digitization from the perspective of product research and development.

At the media open day event held by FAW in December this year, FAW comprehensively demonstrated its four capabilities for the first time, including electrification, intelligence, networking and digitization. The difference between FAW’s four transformations and the automotive industry’s four transformations we usually talk about is that “sharing” has become “digitization”.

This slight difference actually changes the entire strategic framework. “Electrification”, “intelligence”, and “networking” are the development directions of the entire industry, while “digitization” is an important foundation for the entire development process.

How to understand digitization technology?

FAW’s Executive Vice President Liu Qiming said that embracing the digital era means embracing digitization technology.

Digitization technology includes four aspects: data collection, classification, modeling and calculation, and transmission. In the product research and development process, data collection technology, classification technology and modeling calculation technology have reached a constantly improving level. On this basis, FAW connects its two parks, three centers and four test bases into a data network, using 4G/5G technology for data transmission.

In other words, first, we must digitize the interface of each stage and each node as much as possible, and then save and apply the data.

What are the benefits of doing so?

Let’s take a simple example.

We have mentioned in a previous article that in addition to the chassis and power system, the white body is also a major challenge in the domestic vehicle research and development, and wiring layout is one of the difficulties in the white body development process.In the era of smart car promotion, Tesla has attracted a lot of consumers’ attention to the length of the vehicle harness. The Model S has a whole vehicle harness length of 3 kilometers, while the Model 3 has a whole vehicle harness length of 1.5 kilometers, and the whole vehicle harness length of the Model Y will be reduced to 100 meters.

The reduction in harnesses first means a change in the data transmission scenario for vehicles, and secondly, it represents a simplification of the original complex process.

At Pan Asia, this has already become the reality brought by digital development. Liu Qiming introduced that the application of digital technology can now achieve automatic harness design, which was unimaginable in the past.

They can set how the sheet metal parts should connect the harness, how the plastic parts should connect the harness, and what kind of connector is the best design between two harnesses. By accumulating these data, they can automatically find the routing, thickness, and fixed point of the harness, and even the size of the hole that the sheet metal parts should punch, and how much space the plastic parts should leave.

The data here comes from Pan Asia’s results of digital development, that is, the use of KEB (Knowledge Based Engineer). KEB can successfully integrate knowledge, regulations, standards, and norms into a set of applicable tools.

Just take another example.

Every time a photo of a collision accident appears, there will be netizens discussing whether the design and quality of this car are problematic. Such problems should be mastered by relevant engineering personnel and integrated into KEB during the design and development stage. For example, after designing a front bumper, whether to modify the styling design can be checked with KEB to see if it meets the collision regulations.

From these two examples, it can be seen that digital technology not only improves the efficiency of engineering research and development, but also benefits consumers.

Digital simulation tools can optimize the process of automobile testing and validation, improve the quality of research and development, and make product quality more secure. In addition, user usage and feedback data can also be presented to R&D personnel in real-time, allowing R&D personnel to accurately grasp user needs.

Digitalization is a brand new productivity

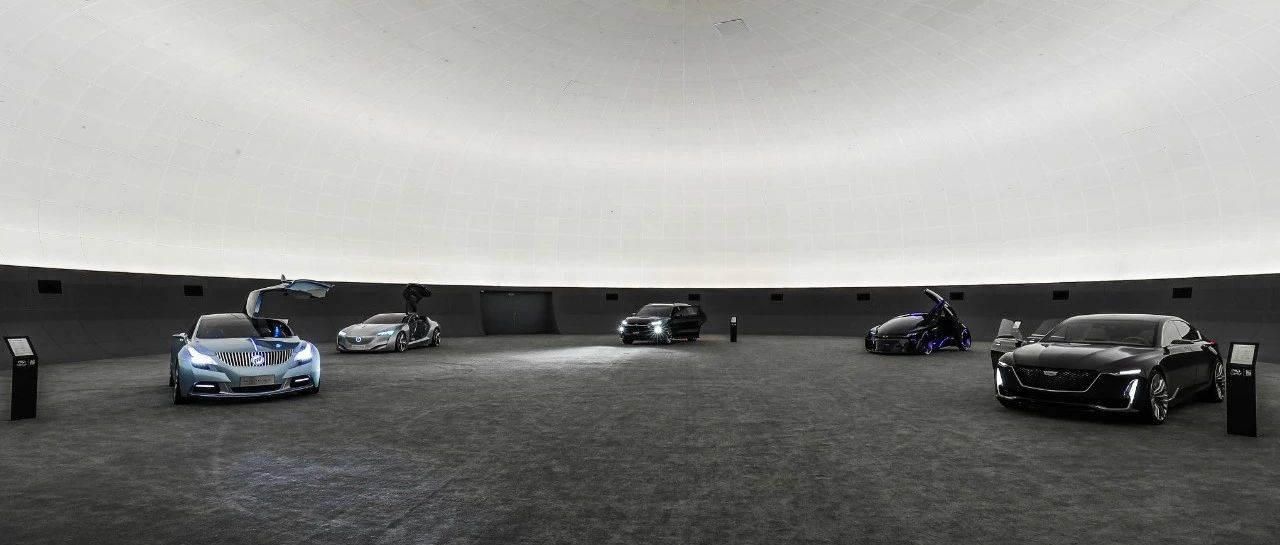

Pan Asia’s full name is SAIC-GM Pan Asia Technical Automotive Center. It is the first Sino-foreign joint venture automotive design and development center in China. It was established at the same time as SAIC-GM on June 12, 1997, and has complete design, vehicle, and drivetrain development capabilities.

The origin of Faran’s entire digital transformation strategy dates back to 2012, in order to better transition from the Industrial 3.0 era to the Industrial 4.0 era.

The complete definition of Faran’s digital strategy includes transforming information about automobile products and the R&D process into data that can be interpreted and processed by computers, using digital models or artificial intelligence to obtain optimized technical solutions. Additionally, it includes interconnectivity through automated systems to achieve agile development processes and accurate information collaboration.

Data alone is useless. How to regard the role of data in the company’s productivity, and how to drive the flow and application of data in the entire company through what kind of organizational structure, is a more complex issue.

Faran explains that they ensure the same source and full sharing of data in the entire company. In the years of digital management practices, work has been reduced from being calculated by “monthly” or “weekly” to being calculated by “hourly”, and the R&D cycle has been shortened. This is particularly critical under new automotive trends.

The digital application of KEB for wiring harness, mentioned earlier, is a digital application in the R&D process. In addition to this, digital technology also includes product digitalization and business digitalization. It is easy to understand the digitalization of products, that is, describing engineering plans such as design parameters and performance indicators digitally.

Some people may say that home design software can be used to design decorations on the computer, such as pipelines, hidden pipes, and soft decorations. But automobiles are too complex, with many subsystems, and even digital R&D tools like KEB reach over 200. Achieving complete digital interaction requires a phased approach. Therefore, product digitalization is still an important topic.

Regarding business digitalization, it represents digitalization in management.

For example, knowledge is structured management to form a KBOM (Knowledge business one map) business knowledge integration model. For example, using TiMS test business comprehensive management system to monitor test situations in various parks and locations. For example, using TDS engineering vehicle operation remote monitoring platform to view the test vehicle situation in various experimental bases across the country.The digitalization process is actually an endless iteration. As Liu Qiming put it, digitalization has no end.

More importantly, this process will result in better products being polished.

-

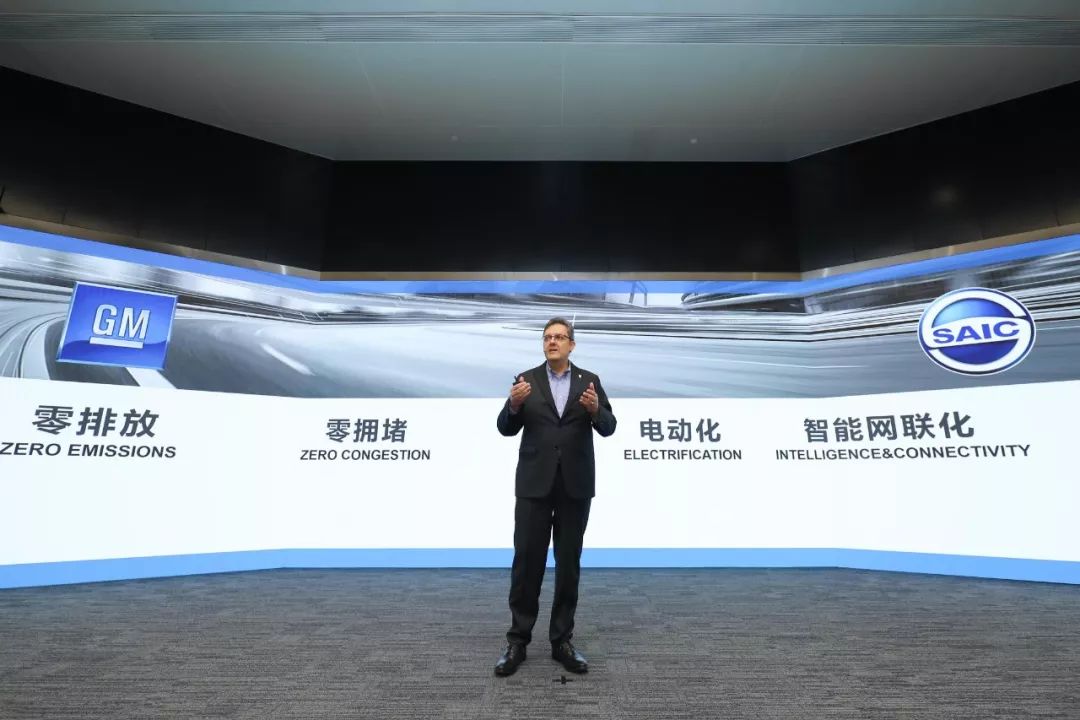

How Is GM Layout Electric In The Field of Autonomous Driving?

-

From Model S to Model 3, Evolution of Tesla Electronics and Electrical Architecture

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.