Author: Zhu Yulong

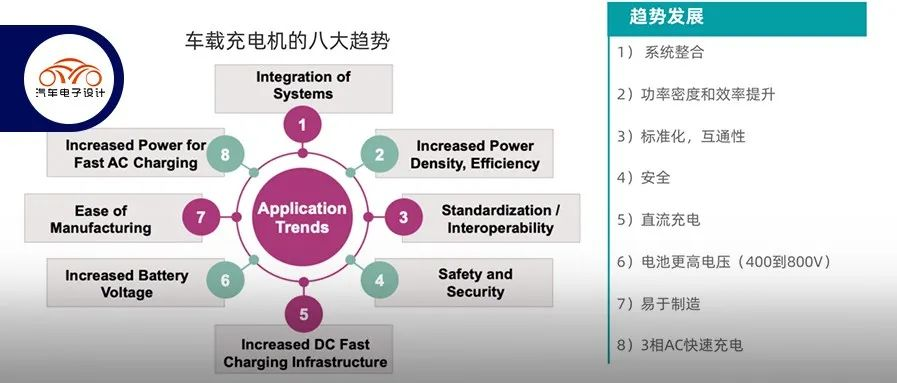

In early 2021, communicating with Master Liu Gang, one of the important reasons why he chooses to start a business in the energy storage field is that the trends of on-board chargers and DCDC are becoming simpler and simpler. In short, the trends are as follows:

◎ System integration

◎ Power density and efficiency improvement

◎ Standardization, interoperability

◎ Safety

◎ DC charging

◎ Battery higher voltage (400 to 800V)

◎ Easy to manufacture

◎ 3-phase AC fast charging

Meanwhile, the internal MOSFETs are moving towards modular packaging, and the whole small three-phase power electronic part becomes simpler.

I want to discuss this trend and also deeply analyze the materials introduced by Infineon about on-board chargers.

Main trends of on-board chargers

The main trends of OBC include:

Simplification of manufacturing

With the increase of electric vehicles, the current parts enterprises focus more on system cost, which is to reduce costs around innovation. Reducing BoM complexity and assembly work, paying more attention to reliability, and improving assembly costs. This is mainly due to the red ocean competition caused by quality and cost constraints of parts. To solve the problem in the manufacturing field is necessary.

Moving towards 800V

400V is still a key field, and many designs now consider compatibility choices. Upgrading from the main configuration of 400V to 800V is necessary.

When 400V increases in batch, it means that cost pressure has increased.After the battery is enlarged, three-phase design becomes more common at 400V (higher power level).

The concept of split battery can be used for 800V (2 x 400V). Some car manufacturers have made the battery similar to configurable by using relays.

Power Density

The smaller space of electrified powertrain makes it possible for small three-electronics to integrate higher power level concepts (OBC+DCDC) with weight optimization and cost modularization.

Power Level Improvement of Onboard Charger

This follows the car because the larger battery capacity has increased the demand for longer driving range. And car owners also hope to have shorter charging time at home, which is seen in higher adoption of pure electric vehicles worldwide.

In previous designs, the main power components mainly included PFC circuits.

We follow a trend in the selection of packaging for Infineon’s power devices, which is to solidify the designs into modules.

We follow a trend in the selection of packaging for Infineon’s power devices, which is to solidify the designs into modules.

Differences Brought by Power Modules

The adoption of module designs actually represents a standardization that requires a sufficient volume of demand concentration, resulting in many benefits after the packaging is determined.

◎High power density in small sizes

◎Reduced PCB and BoM complexity

◎Low stray inductance (modules and systems)

◎Reliable isolation (creepage)

◎Flexible assembly

◎Automotive quality (AQG 324) and reliability

◎Seamless traceability

◎Platforms for different topologies

This trend is very clear, as inverter technologies are already established and OBCs are more standardized than inverters, making this direction very certain.

Similar to the design of the inverter before, the PressFIT pressure contact pins are suitable for automated production lines, greatly improving installation efficiency and increasing reliability by hundreds of times compared to soldering. The module’s pressure contact pins achieve reliable connections with the PCB at low contact resistance, reducing production time, improving production efficiency, and lowering customer production costs.

In terms of the number of parts, there is no difference. It’s just that someone else has packaged it for you. Once the huge amount is made, the advantages of single-tube design are gone.

In terms of volume, the use of GaN devices is currently insufficient as the module is imported.

Feeling the difference in volume changes, I feel that the miniaturization of the entire OBC has been accelerated by the introduction of modules.

If overall heat dissipation and a series of assembly operations are taken into consideration, this production-oriented design can minimize production costs.

The comparison of manufacturing process is particularly notable, with many unnecessary steps eliminated, just like the story in Inverter. If this trend continues, the automakers may not need to rely on third-party electric module suppliers anymore.

The comparison of manufacturing process is particularly notable, with many unnecessary steps eliminated, just like the story in Inverter. If this trend continues, the automakers may not need to rely on third-party electric module suppliers anymore.

Summary: This is the power of standardization. With increasing demand and technological advances, chip manufacturers and end customers now dominate the entire process, leaving little room for the intermediate links.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.