Author: Zhu Yulong

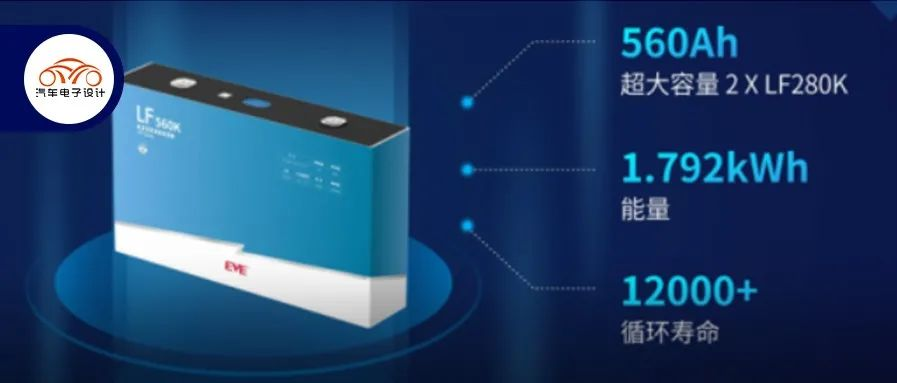

Last week, EVE Energy released the CTT technology and unveiled a huge LF560K battery with a capacity of 560Ah, twice that of LF280K, with a single cell energy of 1.792kWh. This sets a new standard for EVE Energy’s energy storage cells. In this article, we will explore the direction of stacked cells following this breakthrough.

EVE Energy’s Energy Storage Cells

In the past, the capacity of EVE Energy’s energy storage cells ranged from 32Ah to 304Ah. The sequence of energy storage cells is similar to the expansion branch of minibuses, and it can be divided into:

-

148mm series: 32Ah, 50Ah, with the thickness as the standard VDA thickness, and the height of 94mm and 130mm respectively.

-

200mm series: this is actually adjusted based on a width series from 200-209mm, with a height of 130-173mm, and thickness ranging from 36-72mm (1.5 times and 3 times thicker).

Of course, the main energy storage cells, LF280 (3000 cycles) and LF280K (long-life 6000 cycles), are more commonly used in large-scale energy storage.

These are some dimensions and cycle information I have collected. Note the difference in cycle life between 25°C and 45°C, and of course, I understand that all cycle life is based on temperature and rate.

The battery capacity of LF560K reaches as high as 560Ah, which is twice that of LF280K. The energy of a single battery is up to 1.792kWh, and the cycle life is more than 12,000 times (the exact definition of this 12,000 times is currently unknown). There are differences in testing methods and cell formulas from LF280, LF280N to LF280K.

CTT and Stack Technology

This time, the main thing is CTT (Cell To TWh). As I understand it, the goal is to achieve rapid scaling by reducing the full life-cycle cost of the energy storage system. Under the background of the TWh era, the urgent demand of the energy storage market for cost reduction is superimposed, and large cell technology integration and innovative products are launched.

Note: I won’t go into the details of CTT here, but it’s just a code name for cost reduction.

The CTT large cell technology can achieve extreme simplification of the system, the number of pack components is reduced by 47%, production efficiency is increased by 30%, container capacity is increased by 6.5%, and battery integration is greatly improved.

◎ The cost reduction brought by cell design is 5% (BOM materials).

◎ The cost reduction of cell production is 30% (referring to production line efficiency?).

◎ The cost reduction of battery system design is 20% (cells are larger and parallel connection is simpler).

◎ The cost reduction of battery system production is 30% (assembly production of the system).This resulted in an overall cost reduction of 10% through comprehensive consideration.

Technically, the shift here is mainly from winding to stacking technology.

The stacking technology doubles the total number of extremely ear-shaped cuts by full module cutting, solving the current collection problem of electronic conductivity, and achieving an 8% reduction in product DCIR. Stacking replaces winding, shortening the length of each pole piece by 100 times, leading to an overall yield improvement of 3% in battery production. I am currently not sure whether the pieces used here are intended to make a super-large pole piece shape or an internal parallel connection.

Eve Energy’s 3.0 stacking technology can achieve a stacking speed of 0.2 seconds per piece, and the capacity of a single stacking device is 1.3 GWh. This allows for a single-line capacity of 10 GWh and a total factory capacity of 40 GWh for subsequent energy storage battery super-factory construction. Scaling benefits and technological innovation help to reduce costs, with a 38% reduction in investment per GWh, a 20% reduction in energy consumption, and a 30% reduction in personnel input for the factory. The LF 560k super factory has already been constructed in Yunnan and Qinghai, and it is expected to start global delivery in Q2 of 2024, with a target of achieving a 100GWh energy storage battery production capacity in 2025.

In summary: In my understanding, the logic of such iterations has significant differences. Whether it is the shape of the battery or the competition between winding and stacking technologies, there will continue to be a lasting competitive relationship.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.