Author: Zhu Yulong

Recently, in the search for information about solid-state batteries, the team leader of Mercedes-Benz’s solid-state research group, Hansen Chang, mainly introduced Mercedes-Benz’s views on solid-state batteries in terms of research. This can be compared with BMW, another German luxury car company, to analyze together. The common feature of the two luxury car companies is that they are both laying out research for the next generation (RD In-house):

- Mercedes-Benz

Exploring the construction of a super battery factory in Europe with Stellantis, and subsequently investing in ACC under Stellantis. The goal is to promote the research and reserve of the next generation of batteries. The main investment in solid-state batteries is in QuantumScape and Factorial Energy. Currently, through partnerships with these two companies, they are jointly developing the next generation of solid-state batteries. They are also heavily investing in battery anode materials to achieve high energy density and improve fast charging speed.

- BMW

The strategy is clear, turning to cylindrical attempts, and is the only European car company that has not built a battery factory (but has built a large-scale battery trial production line); solid-state batteries are invested in SolidPower. Currently, they are deepening their cooperation with SolidPower and plan to test the car in 2022 and launch the prototype of solid-state batteries before 2025, which will be used for mass production vehicles before 2030.

Mercedes-Benz’s Judgment on Advanced Batteries

Judging from the evolution of the power battery route used by electric vehicles, the current level in 2022 is about 500-700Wh/L, and the energy density of advanced high-energy density batteries is 700Wh/L. From the traditional standardized (Lib standard) power battery, it will gradually switch to advanced batteries (Post LiB) and can impact 1,000Wh/L by 2030, achieving higher energy density batteries.

This data is the volume energy density Vol Energy Density obtained under conditions of 25 degrees and 1/3C testing.

Mercedes-Benz of the future will develop solid electrolyte materials with higher safety and energy density than traditional lithium battery technology. As a replacement for highly flammable organic electrolytes, the use of solid electrolytes will improve safety and stability, making it possible to use high energy density materials.

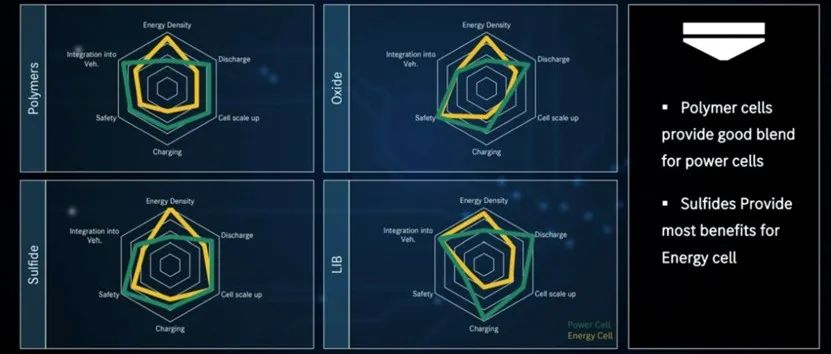

Compared to the lithium battery technology currently used, solid-state batteries using sulfide electrolytes are more advantageous in terms of safety, and polymer batteries are suitable for power type batteries (suitable for high rates). The advantages of oxide electrolyte batteries are high safety and high energy density at high temperatures. Solid-state sulfide electrolyte batteries are expected to be used in the automotive field, but some issues still need to be addressed.

At present, Mercedes-Benz is mainly still in the research stage, and solid-state battery technology is being developed in the research reserve field.

In Mercedes-Benz’s view, solid-state batteries have the following strategic values:

- Improve energy density and safety

- Realize differentiation of different vehicles (high-end models)

- Conduct in-house ASSB R&D, develop materials and battery prototypes

Looking at the development of solid-state batteries, despite many companies announcing investment in it for many years, it is still in the early stages. As European and American solid-state battery start-ups go public, they have not yet reached a stage where they can take on heavy responsibilities in the past year. Therefore, these start-ups and automotive companies plan to commercialize batteries by 2025 (preliminary on-board).

Looking at the collaborator car companies, even if the commercial preparation of solid-state batteries begins in 2025 (at which time car companies may be prepared to pay a relatively high price for batteries), I think the focus will still be on the progress of some luxury car companies between 2025 and 2030. They need to make the battery energy density and volume more efficient, which is advantageous for them to reduce the weight and improve the handling of the entire vehicle.

Until now, when we look at domestic solid-state battery companies, because the scale of traditional batteries is already very large, they need to quickly increase their production capacity, from small-batch production testing and iteration to quickly improve it. This group of semi-solid companies has started planning production capacity from 2GWh to 5GWh.Summary: As battery cost becomes a hot topic, people are more inclined to expect the low-cost performance of sodium batteries, and the concept of solid-state batteries has made people start to doubt. Focusing on semi-solid-state batteries (condensed phase) may be more appropriate.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.