Author: Mr.Yu & Michelin

If Steve Jobs interpreted to the global tech community that jeans would become the highest-level fashion, then Huang Renxun and Elon Musk, with their different faces in the East and the West, repeatedly remind the world that black leather jackets are the icon of the new era.

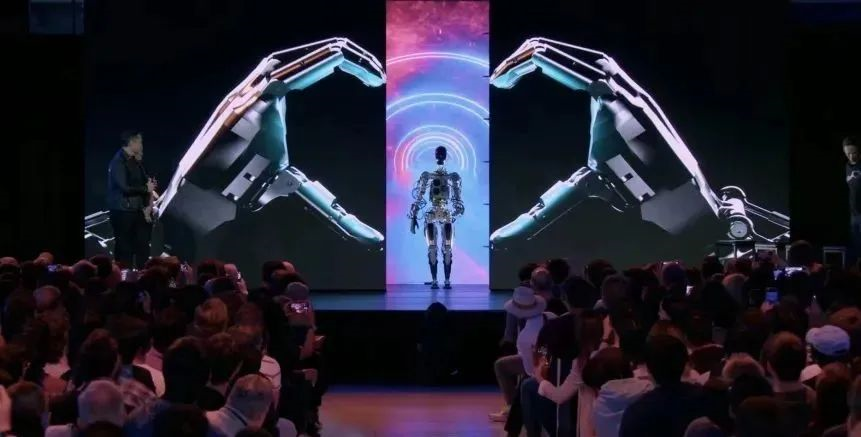

At this year’s Tesla AI Day, Musk did not spend too much time warming up. The stage screen divided left and right, and the humanoid robot Optimus strode onto the stage with its unrecognizable gait.

If you are Optimus Prime, then the Matrix of Leadership must be on your chest, the treasure of the planet Cybertron?

Finally, the robot makes an appearance, and the mass production unit price may be half of the Model 3

As a loyal fan of Transformers introduced in China in the 1980s, the charismatic pillar brother is of great special significance to me. Therefore, I will continue to call this prototype Tesla Bot by Optimus’s English original name in the following text.

Optimus, with various circuits and metal parts exposed, walked steadily and waved to the attendees below the stage.

In the demonstration video, Optimus can not only walk independently but also help Tesla office staff move parcels, lift water bottles and water plants.

On the other hand, Optimus also played the role of an honorable workshop worker in Tesla’s factory.

This was also what we analyzed before this AI Day, that the first-generation Optimus could undertake the most common and representative work. In other words, the first batch of Optimus’s large customers is likely to be Tesla’s Gigafactories around the world.Please find below the English Markdown text, which retains the HTML tags:

However, the figure seems to be in a transformed state and not in the standard form of Optimus that left the laboratory. The screen splits again, and Optimus, with its shell fitted, appears to be surrounded by three stout members of the Tesla team.

Compared with its predecessor, this version of Optimus has a higher level of completion in terms of appearance, which is probably closer to the mass production state than the prototype: it looks more humanoid and has a higher degree of freedom.

If we apply the terminology of mechanical evolution in the Gundam world, it seems to be called a pilot production model. No, it seems to be still far away. This prototype still needs several more weeks to be able to walk on the ground normally.

In fact, even though the Tesla robotics team worked more than ten hours a day and seven days a week for the past year, Optimus is still in the very early stages, and there is still a lot of room for improvement before it hits the market.

According to Musk, Optimus’s development will mature in the next three to five years. When the Tesla robotics business reaches a production scale of millions of units, the unit price will be much lower than that of cars, and the expected price will not exceed $20,000 per unit—note that this is much lower than the unit price of less than $40,000 for Tesla Model 3’s standard range upgrade version.

Those who are familiar with Musk’s language system know that this roadmap does not need to be taken too seriously. This is not a mockery but a reminder to keep expectations reasonable.

Let’s focus back on the topic. With a well-presented introduction, we now come to the efficacy, like what one would say when selling medicine.

Musk said that the purpose of Tesla AI Day is to demonstrate the coolest technology and attract the most talented technical professionals to help mass-produce the results and improve the lives of millions of people together.

“Make it happen”.

Similar rhetoric appears densely in the first phase, with Musk reminding aspiring individuals to join Tesla in his distinctively American style and strive for excellence.Translate to English:

Next, the technical leaders of Tesla's robot team took turns to introduce the details and progress of Optimus.

Let's forget about the cyborg image unveiled at AI Day 2021 last August, as the first appearance of Optimus is essentially a development platform for basic functions. The "brand new version" that looks more complete will continue to be improved.

- The complete Tesla humanoid robot "Optimus" weighs 73 kg;

- The power consumption when stationary is 100W;

- The power consumption during fast walking is 500W;

- The whole body contains more than 200 degrees of freedom, including 27 degrees of freedom in the hand.

Since its initial release, Optimus has undergone three iterations.

The core of Optimus's sensor array is a camera similar to that of Tesla's FSD system. The core energy supply component is a 2.3kWh battery pack, and the entire power distribution and calculation system is integrated into the "body", specifically the torso. To be more precise, in this cross-sectional view, the blue part is the electronic system inside Optimus, and the orange part is the motor.

This design is intended to minimize the number of wire harnesses, as much as possible, influenced by Tesla’s mature car design.

The current version of Optimus has a total of 28 motor actuators throughout the body, which can be understood as human joints. This is more than a quarter fewer than the previously announced 40, and for a simple reason, which is to reduce overall power consumption.

This can be easily understood. Just like the battery life of a smartwatch, which can last for one to two weeks with a single charge during normal use, after a single day of not charging, it would simply stop working like a plaything.

After being fully charged, Optimus can operate for a full day. The technical lead did not clarify whether this “operation” refers to regular use or extreme high-intensity labor such as carrying heavy packages at the dock.

To make its “brain” more “clear,” Optimus uses a Tesla-developed SoC as a key component of its intelligent central system, which supports WiFi and LTE (4G) network connections. Considering the huge differences between the environment of the robot and that of a car, wireless network, audio input, and other support are necessary components for protecting both human users and Optimus.

As Optimus’s legs are not yet very agile, one of the Tesla robot team leaders stated that they used the same predictive model for collision safety testing used for electric cars on Optimus to predict its performance under various postures and working conditions, including falling.

To protect the body, optimization of the structural foundation has become a focus of the team’s work, with an energy-absorbing area set up in front of the chest. This not only helps the robot avoid damaging critical components such as the arms and joints when it falls but also prevents it from being “stunned” directly.

These are a bit like the physiological structural characteristics of human beings and a series of physiological defense mechanisms adopted reflexively at the moment of falling. After all, whether it is human treatment and rest or robot maintenance and inspection, they are quite expensive in various senses, aren’t they?

Speaking of being human, the Tesla robot team incorporated the concept of bionics into the design of Optimus. For example, the joint of the robot’s knee was divided into four motors, mimicking the configuration of the human knee joint.The premise of this approach includes a series of precise calculations. The team simulated the collected data from various experiments by means of calculus to fine-tune the power of the motor. On the one hand, it reduces the power consumption of the movement, and on the other hand, it avoids potential dangerous issues such as imbalance due to excessive force.

One of the keys to cost savings is that only six different designs were adopted from the 28 motors in Optimus, as mentioned earlier. Using a minimalist platform design to increase production capacity while simultaneously reducing maintenance costs, it has a Tesla-style industrial feel, doesn’t it?

Among these key motors, the load capacity of the critical parts is so great that a single component is enough to lift a grand piano. As the most sophisticated component of the human body, the control and flexible application of hand muscles can be said to be one of the key factors in human evolution. In this regard, the Tesla robot team designed small and precise motors for Optimus, which not only has the ability to move heavy objects but also can skillfully handle work with high accuracy requirements.

In order to help Optimus achieve basic movements, motion capture system was also used to learn the motion trajectory of humans when moving objects, combined with the structural characteristics of the body to plan the entire body posture control.

Although Optimus uses many Tesla car technologies, it is very different from manufacturing robots. After all, cars only need to consider running on the road, while the scenarios for bipedal robots, as imagined, are much more complicated. Walking is only the basis, and tasks such as going up and down stairs, squatting and standing up, turning around, moving objects, twisting screws, drilling with a drill, and so on are all heavy responsibilities that Optimus needs to face.

Speaking of which, let’s also take a look at ED-209, the villainous robot from the 1987 version of “Robocop,” whose firepower and martial prowess were abundant but still tumbled down the stairs.

Before becoming useful, Optimus took five months from stumbling and staggering in April 2022 to walking normally in September. Fortunately, Musk is talented enough in creating life, and I believe he will cultivate artificial intelligence at a pace faster than his peers, just like raising a child.

Why does Tesla have to design its production robots in humanoid form?

First, because it’s challenging. Designing and implementing a humanoid robot is much more difficult than designing a non-humanoid robot. But realizing it would be much more significant for Tesla.

Second, it’s more likely to be used. There are already many robots applied to various industries in the real world. For example, many of us have seen food delivery robots carrying dishes shuttling around restaurants, or information kiosks with screens meandering around hospital lobbies.

All of these are designed for single scenes. Humanoid robots with a form and movement similar to humans have greater possibilities for use cases than their “predecessors” of various shapes and are better suited to enter human life.

Tesla wants to create useful robots, not just play with technology.

Musk has stated on multiple occasions that Optimus, the humanoid robot, will be Tesla’s most important product development project, even more valuable than its automotive business and FSD plans.

Initially, Tesla robots were designed to replace people in repetitive, dangerous tasks. However, to make them go further, cooking at home, trimming lawns, and taking care of the elderly are the basic scenarios that will make Tesla robots a true reflection of human life.

Despite the never-ending hours of AI Day this year, Musk did not forget to go live and interact with fans as soon as the event was over. In fact, he even said that there will be a catgirl version of the Optimus robot in the future.

To be honest, if Tesla has time to spare, I hope they will also release a Daft Punk version in the future, as it might better complement Musk’s black leather jacket.

FSD Iteration Accelerates 80 Times in One Year

Compared with the humanoid robot prototype that was first unveiled, FSD has become a household name. As an old friend, FSD may not see any revolutionary technological leaps, but there have been plenty of hardcore optimizations.

Firstly, the test scale has expanded. Currently, FSD Beta autonomous driving testing has 160,000 customers, 80 times more than the 2,000 in 2021. A larger test scale means FSD can provide a continuous stream of high-value data as “nutrients” for the vision-based FSD algorithm.

The development process of the FSD autonomous driving algorithm involves using auto-annotation and simulated training data to train the FSD main algorithm framework composed of recognition algorithms and environment modeling algorithms, which completes the entire iteration process.

At last year’s AI DAY, Tesla revealed that it used the Occupancy Networks neural network model in its autonomous driving technology, which directly transforms 2D image planes to 3D BEV space in the neural network, improving the accuracy and stability of multi-camera perception. This year, the entire closed-loop process has been further optimized.

At last year’s AI DAY, Tesla revealed that it used the Occupancy Networks neural network model in its autonomous driving technology, which directly transforms 2D image planes to 3D BEV space in the neural network, improving the accuracy and stability of multi-camera perception. This year, the entire closed-loop process has been further optimized.

For example, to improve efficiency, Tesla has established an “automatic labeling machine” that uses intelligent labeling instead of manual labeling. With the help of automatic labeling, other clips can be used to fill in the images when the camera display is unclear, and video frames can be more intelligently selected to improve frame quality while reducing the quantity, increasing the training speed by 30%.

Similarly, the efficiency and quality of simulation simulation have also been optimized. Based on the real information collected by the vehicle, the reconstruction simulation environment that usually takes several weeks to complete manually can be completed in less than 30 minutes.

Currently, the FSD deep neural network has reached one million parameters, 150,000+ neural network layers, and 375,000 links. In the past year, engineers have trained 75,000 neural network models, all of which are the results of optimizing the training model.

Not only have the training models been optimized, but the decision-making has also been improved. Tesla’s engineers specifically mentioned the epic challenge of unprotected left turns in autonomous driving, and improvements have been made to recognize and predict behaviors, as well as identify dogs when making unprotected left turns.

In fact, in recent FSD updates, reducing aggressive “extreme operations” and making unprotected left turns more natural has been a trend, making autonomous driving more and more like human driving behavior.

Of course, after optimizing FSD, Musk has come to “put satellites” again, “from a technical point of view, we have the ability to enter the global market by the end of the year.”

It’s hard to count how many times FSD has been fully opened, but regulatory policies in various regions outside of technology are the key to whether domestic car owners can experience FSD.

Dojo Supercomputer: Targeting NVIDIA, Coveting Amazon.When Dojo made its debut at AI DAY last year, it received immense attention due to its potential to surpass the leading chip manufacturers. This year, Dojo is directly compared with the NVIDIA A100.

The single training module of the Dojo supercomputer is composed of 25 Tesla self-developed neural network training chips – D1. Since each D1 chip is seamlessly connected together, with extremely low delay between adjacent chips, the training module maximizes bandwidth retention.

Compared to its inaugural launch, Dojo’s design is more integrated. This makes one Dojo training module equal to the performance of 6 general-purpose GPUs, while energy consumption and costs are only equivalent to 1 GPU.

In comparison with the NVIDIA A100, Tesla’s engineers published results of ResNet-50, a classic image classification model, and showed that Dojo can achieve a higher frame rate than A100. Additionally, Dojo’s performance is doubled while running neural network model, Occupancy Network. The final goal is to have 4.4 times the single-chip training speed of the A100, along with even lower energy consumption and cost.

Of course, with the powerful Dojo, Musk’s expectation is not only for Tesla to use it for themselves, but also for external commercial use. He stated they will “consider using it in a way similar to AWS.”

It seems that Dojo’s competitors are not limited to NVIDIA, but also Amazon Web Services.

In the first quarter of 2023, the first Dojo Exa POD will be completed and presented. The most direct application for most people is likely to significantly improve the speed of FSD data processing.On the day before AI DAY, Musk announced on social media that the purpose of this event is to recruit engineers in the field of artificial intelligence and robotics.

I wonder if the geeky engineers were “hooked” by this all-hardcore AI DAY?

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.