Author | Banjiang

Depending on the different types of braking actuators, Brake-By-Wire (BBW) system can be divided into Electro-Hydraulic Brake (EHB) and Electro-Mechanical Brake (EMB). EHB is based on traditional hydraulic braking system, replacing some mechanical components with electronic devices. It uses brake fluid as power transmission medium and has hydraulic backup braking system, which is currently the mainstream technology. EHB can be divided into Two-box and One-box according to the degree of integration.

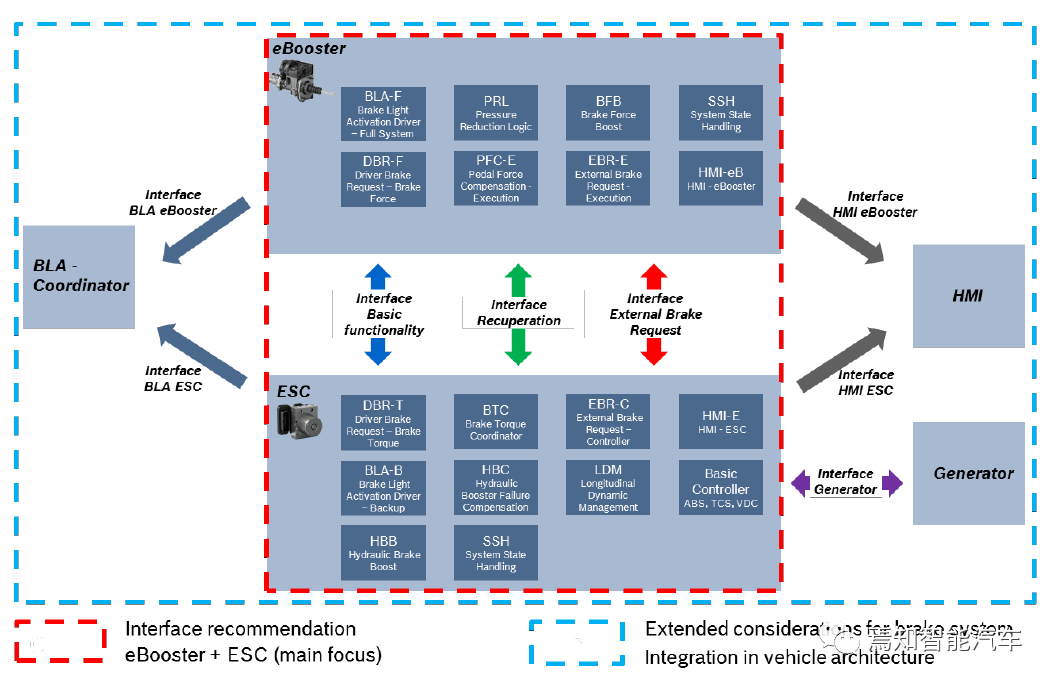

With the expansion of the new energy vehicle market, the combination of “eBooster+ ESC” has become the most mainstream Two-box solution in the market. This solution not only realizes the basic brake assist function and stability control function, but also coordinates and cooperates to ensure consistent pedal feel during the switching between electric and hydraulic braking while realizing brake energy recovery. In addition, with the popularization of advanced driver assistance systems and automatic parking systems, “eBooster+ ESC” also plays a role in realizing brake redundancy.

In the previous issue, the system architecture and degradation strategy of the “eBooster+ ESC” combination were explained. This issue will introduce the implementation of basic braking functions of the combination.

- Driver brake control

- External ECU brake control

- Brake light control

Driver Brake Control

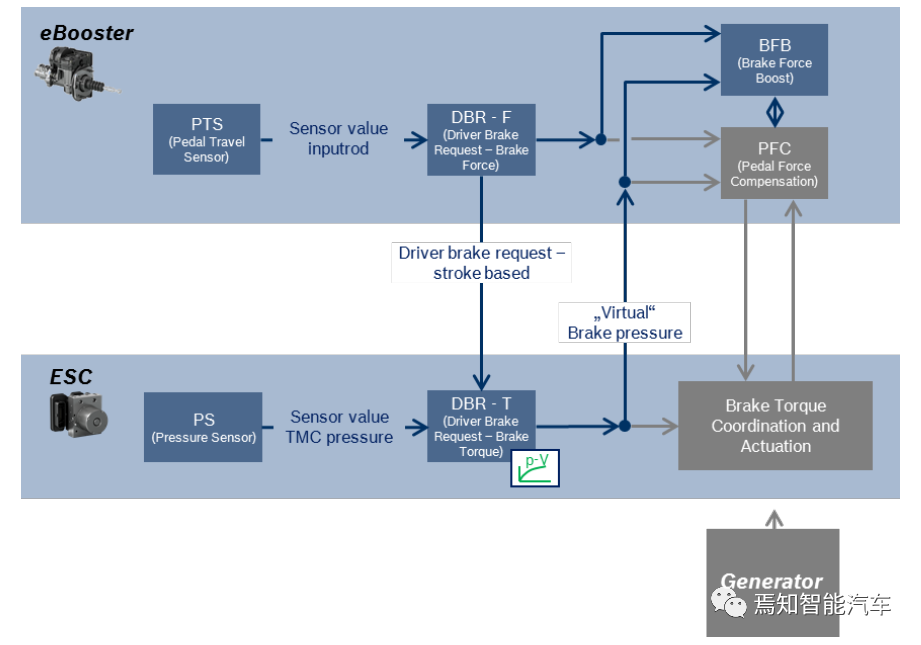

To achieve the driver’s brake assist function, eBooster first needs to correctly detect the driver’s braking intention. The pedal travel sensor installed at eBooster pushrod detects the depth of the driver’s pedal depression and feeds it back to the DBR-F (Driver Brake Request-Brake Force) module of eBooster for driver intention judgment.

After determining the driver’s braking intention, eBooster does not provide direct assistance, but feeds back the driver’s braking intention through network communication to ESC, which allocates hydraulic braking force and motor braking force.As a stability control system for vehicles, the main purpose of ESC in brake force distribution is to ensure that the distribution does not cause the risk of vehicle instability. For example, when the driver encounters a strong gas pedal condition that causes the wheels to lock up, the ESC system will stop requesting the braking force from the driving motors and instead fully adjust the brake hydraulic pressure to stabilize, while activating the ABS.

In addition, brake force distribution by ESC can achieve the function of brake energy recovery. With the popularity of new energy vehicles, the function of brake energy recovery has also emerged. With the function of brake energy recovery, in addition to the hydraulic friction brake force generated during the vehicle braking process, the cooperation between the high-voltage battery and the driving motor, the negative torque generated by the driving motor provides part of the brake force, and the negative torque generates reverse current to charge the high-voltage battery. Finally, part of the kinetic energy of the vehicle during braking is converted into chemical energy stored in the high-voltage battery, which is used for the next vehicle driving. This achieves energy recovery and reduces energy consumption and emissions.

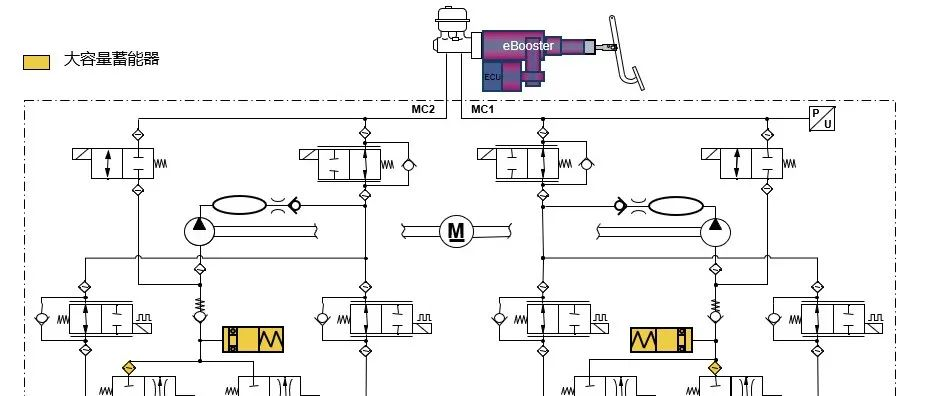

To achieve brake force distribution, ESC’s hardware first needs to be able to release the “direct correlation” between the master cylinder brake fluid and the wheel cylinder brake fluid, which is achieved by the ESC’s large-capacity accumulator and control of the wheel-end solenoid valve. With the support of the large-capacity accumulator, when the driver presses the brake pedal, the eBooster controls the hydraulic pressure of the master cylinder to enter the wheel cylinder to generate brake force, while the brake force of the driving motor slowly increases with the depth of the brake pedal. During this process, the braking fluid from the master cylinder does not directly flow into the wheel cylinder but is temporarily stored in the accumulator. The braking fluid in the accumulator does not generate brake force, thus achieving dynamic coordination and control of the electric motor brake force and hydraulic brake force during the braking process.

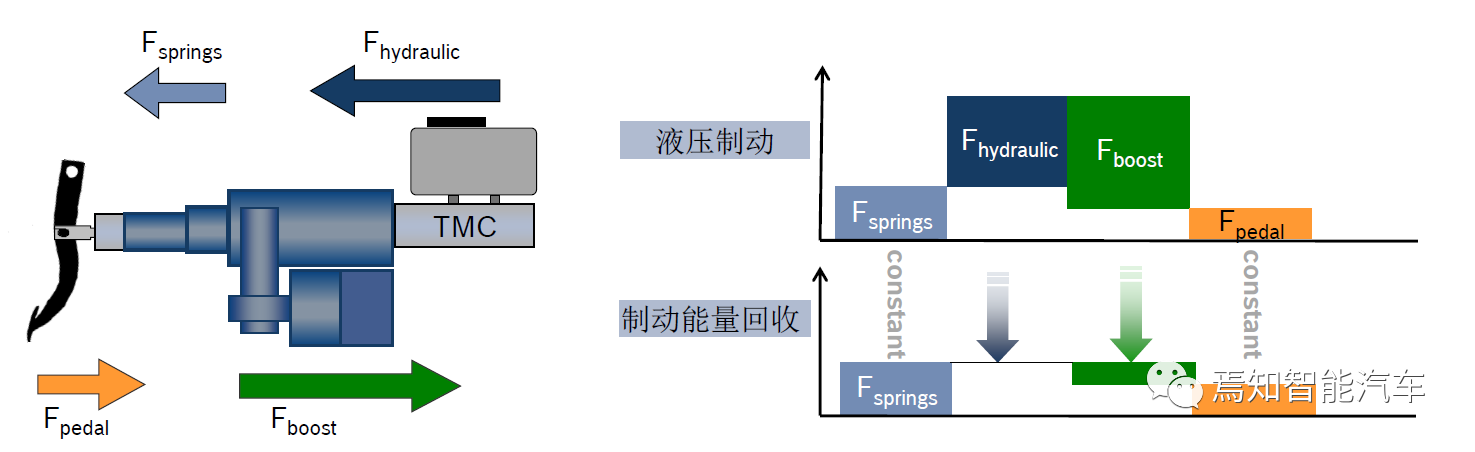

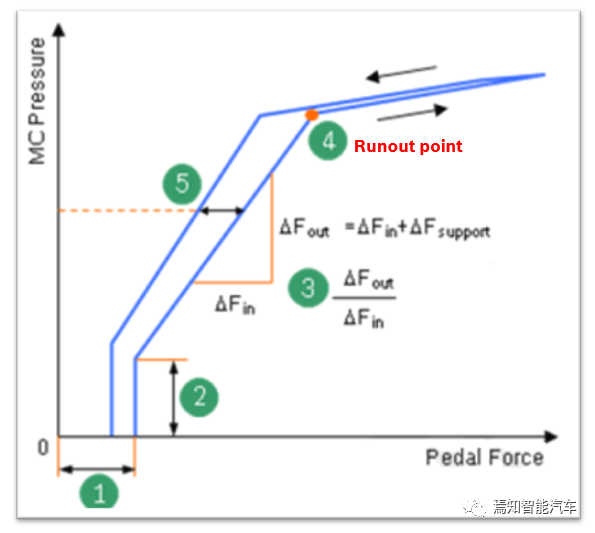

However, the “separation” of the master cylinder brake fluid and the wheel cylinder brake fluid caused by the dynamic distribution process of ESC braking force will cause changes in the driver’s brake pedal feel. The PFC (Pedal Force Compensation) module of eBooster can ensure consistent pedal feel. Its core principle is that during the driver’s braking process, eBooster controls the size of the power assistance (as shown in the figure below) to ensure that the reaction force of the pedal felt by the driver’s foot is constant at the same pedal depth. This allows the driver to not feel whether it is electric motor braking or hydraulic braking, thus achieving consistent pedal feel and bringing the most comfortable experience for the driver.

In the above figure, the spring force Fsprings is constant. In order to achieve a constant pedal force Fpedal at a certain pedal depth, the PFC module needs to know the size of the braking force Fhydraulic that can be generated by the current hydraulic energy, so as to adjust the appropriate boost force Fboost. At this time, due to the influence of accumulator liquid control and wheel-side electromagnetic valve control in the braking force distribution process, the main cylinder pressure value collected by the master cylinder pressure sensor in the ESC system cannot correspond to the actual hydraulic braking force generated. Therefore, ESC needs to send a “virtual” main cylinder pressure value to eBooster to determine the size of Fhydraulic. The virtual main cylinder pressure value is obtained by looking up the pre-calibrated pv curve in the DBR-T (Driver Brake Request-Brake Torque) module of ESC, and is fed back to the PFC module of eBooster through communication to determine the assist force size that needs to be output by the assist motor to achieve the target pedal feeling.

External ECU Brake Control

Because the dynamic response speed of eBooster’s pressure building is faster than that of ESC’s active pressure building, and its NVH performance is better, eBooster is the main execution mechanism for the brake system when requested by external ECU (such as ADAS ECU), which can also reduce the load of active pressure building during the entire lifecycle of the ESC system.

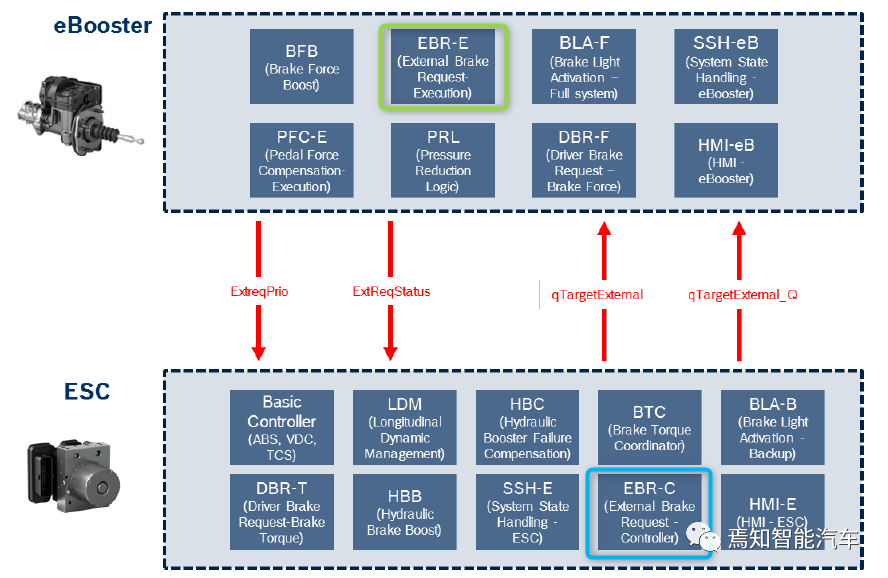

The EBR-C (External Brake Request-Controller) module in ESC is responsible for receiving brake requests from external ECU and converting the brake requests into target master cylinder pressure values, which are sent to the EBR-E (External Brake Request-Execution) module in eBooster through the communication network, and then eBooster calculates the target assist force value to achieve the braking request.

During this process, eBooster also provides real-time feedback of the actual output pressure value to ESC. For example, when the assist force capability significantly decreases after eBooster reaches the Runout point (see the figure below), ESC performs brake compensation by active pressure building.

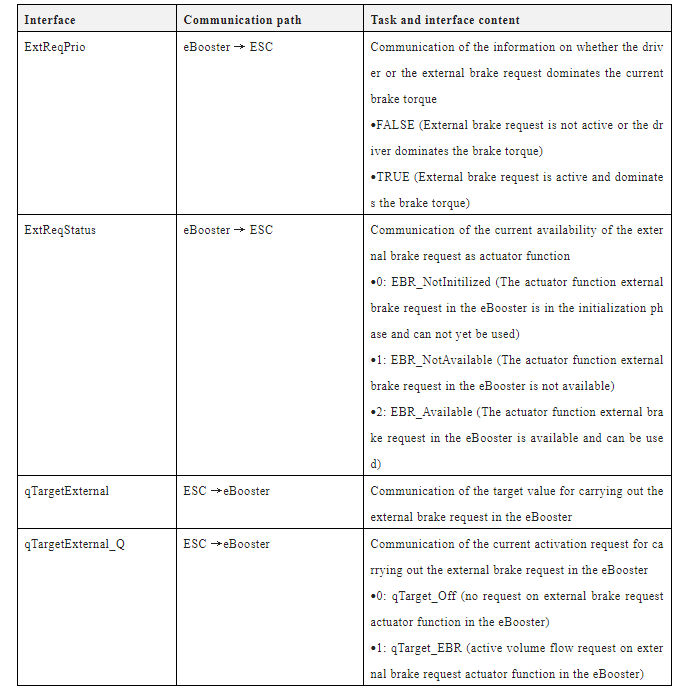

The table below summarizes the main interaction signals and purposes of ESC and eBooster when external ECU brakes are implemented.

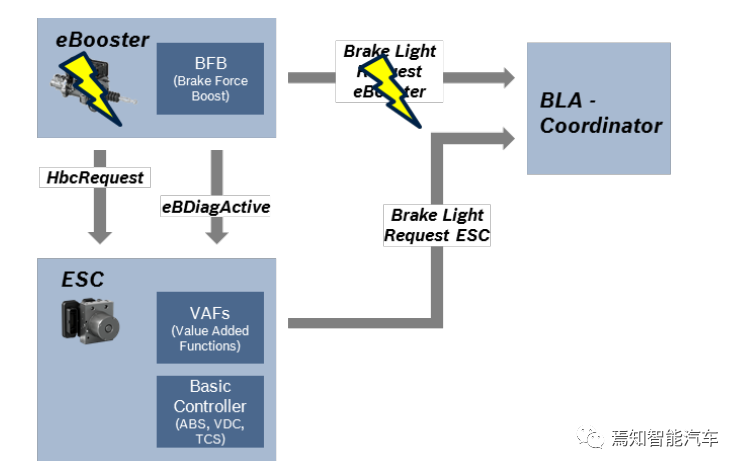

Brake light control

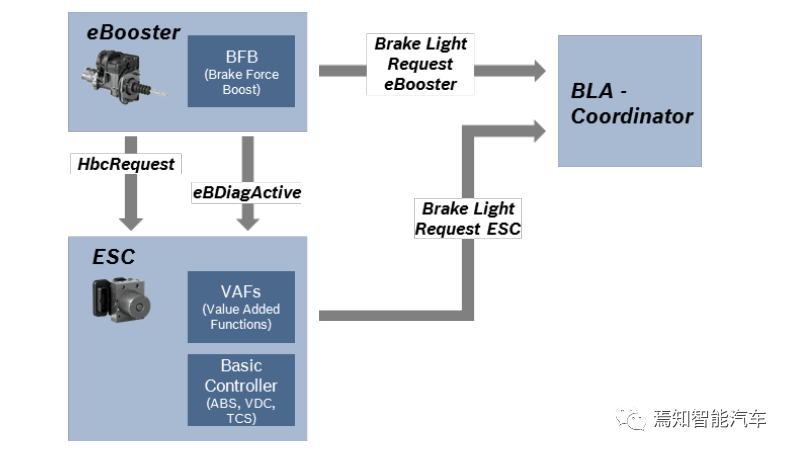

The brake light control strategy is related to the degradation status of the eBooster system.

When the eBooster is in full function, the brake light is controlled by the eBooster system according to the state of the driver’s pedal. At this time, ESC requests to light up the brake light only when the stability function or auxiliary function that does not depend on driver braking is activated by actively generating pressure.

When the eBooster power assist function fails, the eBooster requests the activation of the HBC function. At this time, the driver’s braking request is implemented by ESC actively generating pressure, and all brake lights under all conditions are controlled by ESC, including the driver’s braking conditions and the stability function and the auxiliary function actively generating pressure conditions.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.