Author: Zhihao Liang

New energy transformation pains, is it just about charging?

I find that every time we introduce new energy vehicles, there are always people in the comments section who say “the pollution from scrapped batteries is huge” and “new energy vehicles are not environmentally friendly”. Indeed, for the general public, the battery degradation and scrapping of new energy vehicles are always major concerns.

Even if a company like NIO spends a large amount of money on building battery-swap stations, the disposal of waste batteries is still a major concern for people. However, caring about environmental protection is certainly not wrong, but have you ever thought that the main pollution caused by electric vehicles may not come entirely from waste batteries, but rather from the most inconspicuous – tires.

Tire pollution is becoming more prominent

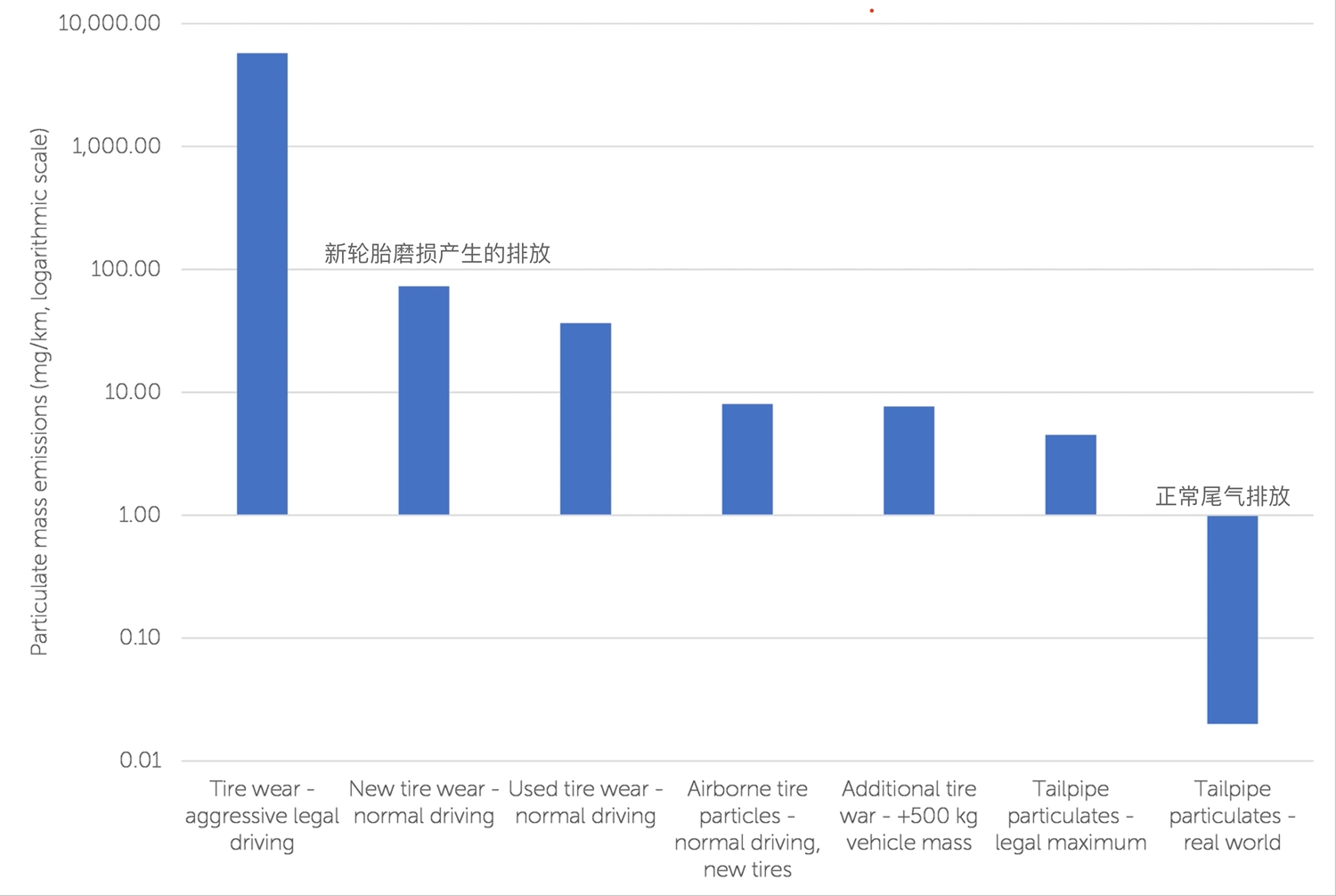

As new energy vehicles rise in the world, peripheral research on new energy vehicles has gradually become more mature. As early as two years ago, a foreign research institution released a study stating that the pollution caused by tire wear and braking on new cars is even 1850 times more serious than the exhaust emissions from gasoline/diesel vehicles.

Isn’t this a bit alarmist? Not really.

Today, new energy vehicles have an increasingly high market share worldwide, and the reason why they are so popular is, of course, partly due to policy support, but there is no doubt that the rapid power and smooth driving experience of electric vehicles have an irresistible appeal to consumers who don’t have to worry about charging.

But what we cannot ignore is that in the era of new energy vehicles, the weight and power of cars have made a leap forward. For example, a BYD Tang EV AWD has a total weight of 2.56 tons, and even with a few pieces of luggage and passengers, the total weight can easily exceed 2.8 tons. However, it can still complete the 0-100km/h acceleration in just five seconds, and easily stop from a speed of 100km/h within 40 meters when braking… and this almost insane energy conversion is completed by its four tires engaging with the road surface.

However, the large weight and strong power of Tang EV are not exclusive features, as long as the electric car is slightly higher-end or has longer endurance on the market, the curb weight can often easily exceed 2.2, 2.3 tons.

Even some models with lower positioning will also have a significant increase in curb weight after electrification. For example, the Volkswagen Golf 1.4T model with similar positioning and vehicle performance as ID.3. The former has a curb weight of only 1.36 tons, while the latter weighs 1.76 tons. This also means that when completing the same acceleration, braking, and turning actions, the pressure that the latter’s tires have to bear is much higher than the former.

Although material science is advancing every year, it is obvious that the explosive growth of electric vehicles has exceeded the expectations of some tire manufacturers. This has also led to the fact that, for quite a long time, electric vehicles could only forcibly “use” ordinary tires. Some brands have used SUV-specific tires with stronger load-bearing capacity on heavy electric sedans for the sake of safety or helplessness.

However, this cannot fundamentally solve the problem, and many consumers have also reported that the tires of their purchased electric vehicles wear much faster than when using fuel vehicles. Some aggressive drivers may have serious tread wear on their tires after only 20-30,000 kilometers.

And these worn-out rubber particles are not only an important source of PM2.5 in the air, but also a major culprit for various respiratory diseases, even cancer.

With the exhaust gas treatment of fuel vehicles becoming increasingly strict and complete, pollution from tire wear has become a major problem faced by environmental protection agencies in various countries because it is difficult to handle properly.

Special Tires for New Energy Vehicles are NecessaryIn such a case, launching special tires for new energy vehicles is necessary for car manufacturers, consumers, and tire manufacturers alike. As the issue of tire wear has received increasing attention in recent years, many major tire manufacturers have also attempted to introduce various models of special tires for new energy vehicles. For example, Michelin has launched the e・PRIMACY series, and Bridgestone has the eContact series.

In addition to these international big brands, even domestic tires have begun to explore this area. For example, the electric tires developed by Qingdao Senkeer, which are the original equipment adapted tires for many models under GAC Aion, and the Pulin tires in Shandong, which directly claim that their brand is “born for the electric era”, indicating a desire to seize the opportunity of the new energy vehicle tire market.

However, whether it is a big brand tire costing thousands of yuan, or a domestic tire costing six to seven hundred yuan, the most important product features for those targeting “electric vehicles” are mainly these few: 1. Low rolling resistance to increase range; 2. More wear-resistant; 3. Reduce tire noise, improve ride comfort.

For example, Michelin’s e・PRIMACY series claims to reduce rolling resistance by 29.1% and increase range by 8% by using low heat-generating rubber and optimizing the internal structure. The optimized tire structure can increase the contact area, and reduce tire wear when facing high torque electric vehicles. The soundproof cotton attached to the inside of the tire and the acoustic structure on the tread can also effectively reduce tire noise.

On the surface, this indeed solves a major pain point for electric vehicle tires, but there is a cost involved. From an e-commerce platform, we can see that a set of Michelin e・PRIMACY tires equipped with all the “high-tech” features mentioned above, is priced the same as the same size Michelin PS4S tire.

Yes, it is indeed necessary to have special tires for electric cars, but for me, at the same price, the PS4S, which is the “benchmark of street tires,” is more attractive…

Yes, it is indeed necessary to have special tires for electric cars, but for me, at the same price, the PS4S, which is the “benchmark of street tires,” is more attractive…

Of course, I am not “denigrating” electric car tires. After all, not everyone will buy such expensive tires. On the contrary, I believe that it is quite necessary to popularize special tires for new energy vehicles. Even from the perspective of car owners in the long run, it can reduce the number of tire replacements, which is also an economical deal.

However, before this happens, whether it is an automaker or a relevant department, they should do some related knowledge popularization among car owners so that everyone can understand that there are actually many differences in the use of new energy vehicles compared to traditional fuel vehicles, except for charging.

Only when car owners understand this, will they actively choose new energy-specific products when replacing tires. As for whether they choose a two-thousand-dollar Michelin or an eight-hundred-dollar Senkairen, it actually doesn’t matter at all.

Conclusion

In this era of transition and collision between traditional fuel vehicles and electric vehicles, more similar pain points and difficulties will gradually emerge in the future. Especially in the new energy era, power has become cheaper. In order to fit more batteries, cars are becoming bigger and heavier. After tire dust pollution, the next problem may be the parking space that cannot keep up with the expansion of the car body or the roads that were constructed according to past standards.

If you have noticed, you will find that after the bus entered the new energy era, the damage to the pavement of the station is more serious than before.

The pains of energy transformation are more than just charging.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.