Author: Lingfang Wang

Editor: Kaijun Qiu

When it comes to battery safety, forward-looking automakers all have their own solutions, and SAIC is no exception.

On August 10th, battery technology experts from Jienen Company of SAIC Innovation Research and Development Institute conducted a battery analysis live class, offering an in-depth interpretation of the secrets of the “Magic Cube Battery”.

The “Electric Vehicle Observer” simply summarized the characteristics of this battery pack as “lying, side spraying, and high flexibility”. These three characteristics mainly target safety, efficiency, and durability. Of course, the connotations underlying these three features are quite rich.

Of course, the magic cube battery can also meet the demand for ultra-fast charging. It only takes 30 minutes to charge 30-80% of the remaining battery capacity and 40 minutes to charge 5-80% of the remaining battery capacity.

Lying: High utilization rate of vertical space

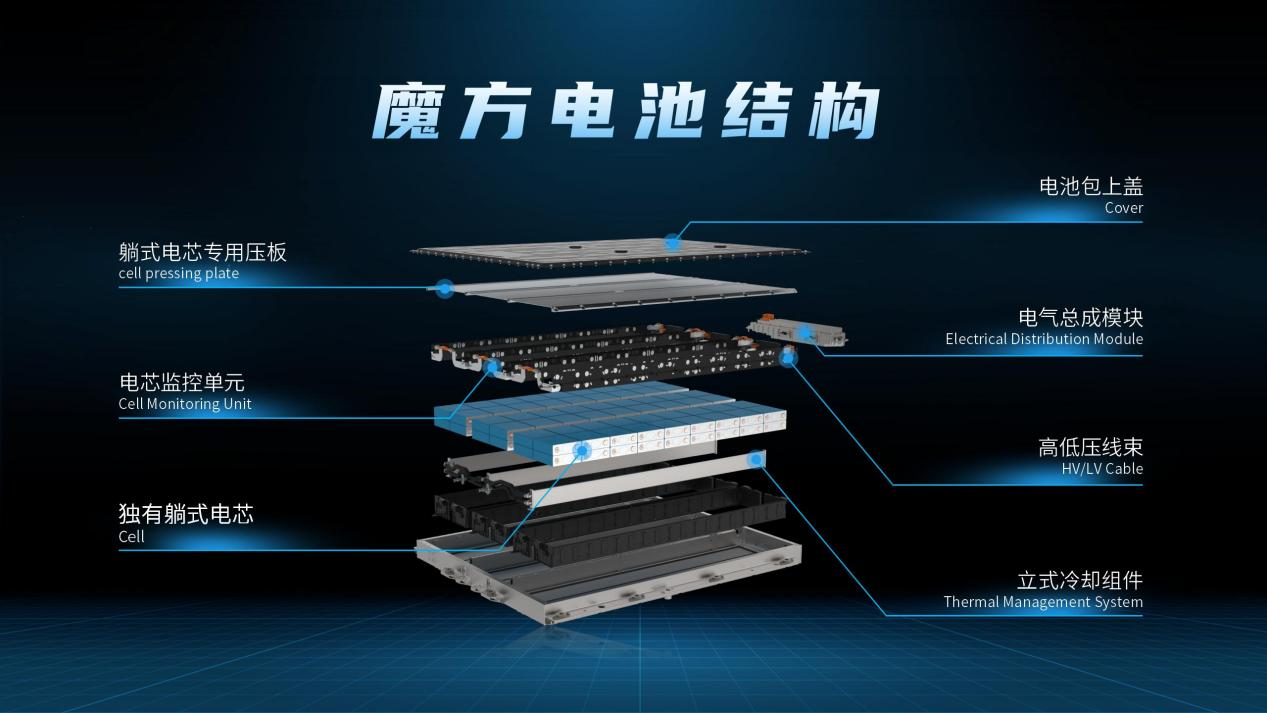

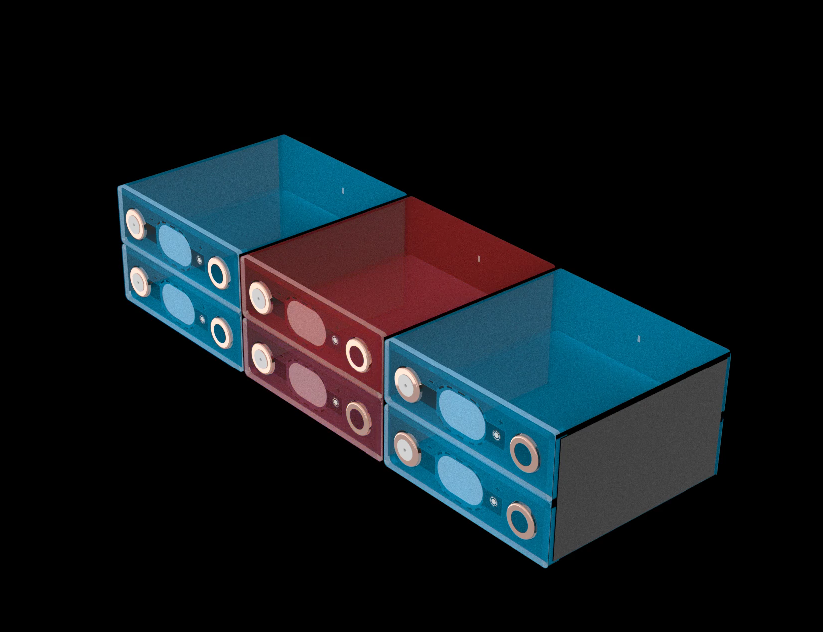

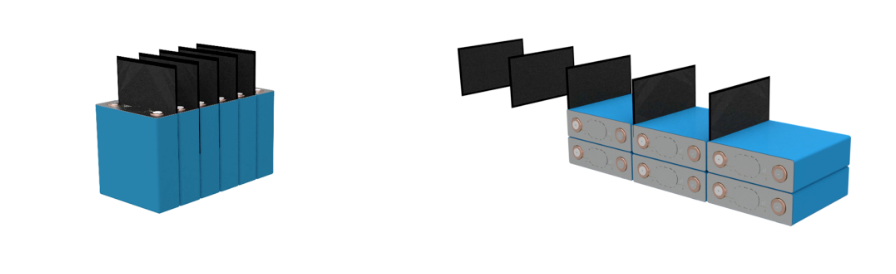

Completely different from the traditional battery pack with vertical battery cells, the biggest characteristic of this battery pack is that the cells are lying flat.

After the cells are laid flat, the most obvious benefit is that the vertical height of the battery pack is significantly reduced, which can release more interior space for passengers and ensure the passage of the chassis.

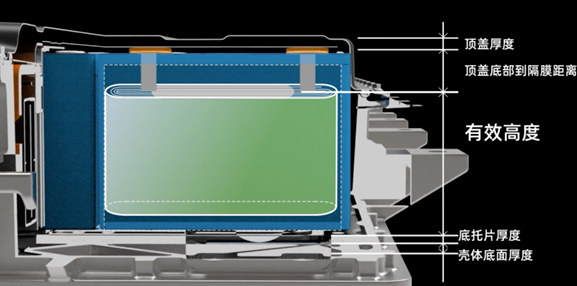

The utilization rate in the height direction is generally not high in vertical cells, which are usually occupied by the top cover thickness of the cell case, the distance from the bottom of the top cover to the diaphragm, and the thickness of the bottom support plate.

The laying of the cells in Magic Cube greatly improves this situation. Not only is the height of the battery pack fully utilized, but the proportion of active materials in the battery is also greatly increased, thereby significantly improving the volume utilization rate.

The length and width of the Magic Cube battery pack are fixed-1690mm*1300mm; there are three different heights: 110mm, 125mm, and 137mm.

You can imagine that the length of the battery is equivalent to the height of an adult man, and the thickness of the battery pack is equivalent to a can of cola-like a large Pad.

According to data provided by SAIC, based on CTP, high voltage, ultra-thin substrate and other technologies, the energy density of the battery system of 90kWh Magic Cube battery reaches 195Wh/kg, which can achieve a CLTC range of 550-570km. The energy density of the 5-series cells can be achieved using an 8-series cell and the CTP grouping efficiency reaches 79.6%.

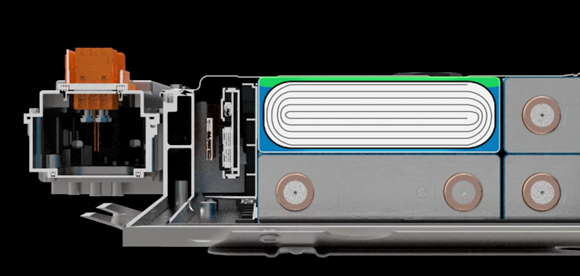

Side spraying: Higher safetyAnother advantage of laying the battery cell flat is that the explosion vent is no longer facing upward, but instead sprays sideways onto the bottom tray structure.

Generally, the strength of the battery cover is not too great, with a thickness of only 1-2mm. With the vertical battery cell layout, should a thermal runaway occur, there is a certain safety risk to passengers inside the car. The flat battery cell layout solves this problem.

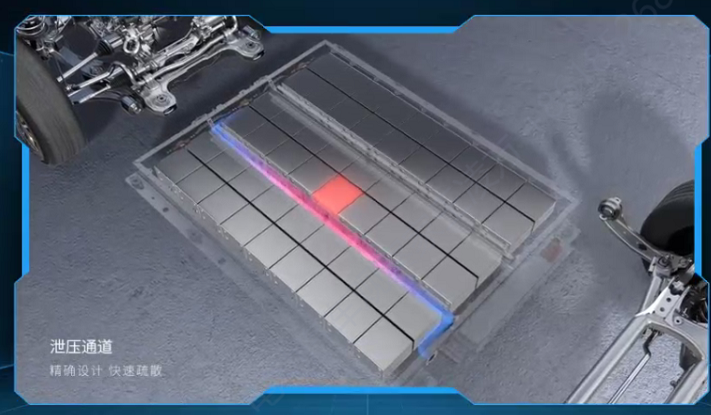

In addition, the horizontal battery cell arrangement reduces the effective contact area between battery cells and decreases the heat transfer channel. The cube battery pack has only two layers of battery cells, so once a battery cell experiences thermal runaway, it will only spread to the adjacent battery cells with a large contact area above and below it, and the heat will be dissipated through the water-cooling system.

The battery cells on the left and right sides have a small contact area and are protected by thermal insulation material, so the likelihood of thermal runaway is greatly reduced. Thus, the overall thermal runaway of the battery cells is controllable and will not cause a domino effect.

This flat layout can also maximize the saving of thermal insulation materials. For example, a pack that used to require six pieces of thermal insulation material now only needs two. Most of the space can be used to accommodate effective electrochemical materials.

In summary, the safety of the cube battery pack mainly relies on the following five secrets:

Pre- 7x24h remote monitoring system: The self-learning function enables early detection of thermal runaway, preventing accidents before they occur.

Guide- Early cooling system: Once thermal runaway is detected remotely, the maximum power cooling system is activated.

Lay – Unique flat battery cell design: Reducing the effective contact area between battery cells and decreasing the heat transfer channel.

Isolate- Aerogel flame retardant material: Physically isolating the heat and ensuring that the thermal runaway of a single battery cell does not affect adjacent battery cells.

Disperse – Automatic pressure relief and explosion-proof valve: It automatically releases pressure inside the battery pack, reducing the temperature of the overheated gas and preventing gas ejection.

Flexibility: Increase cycle life

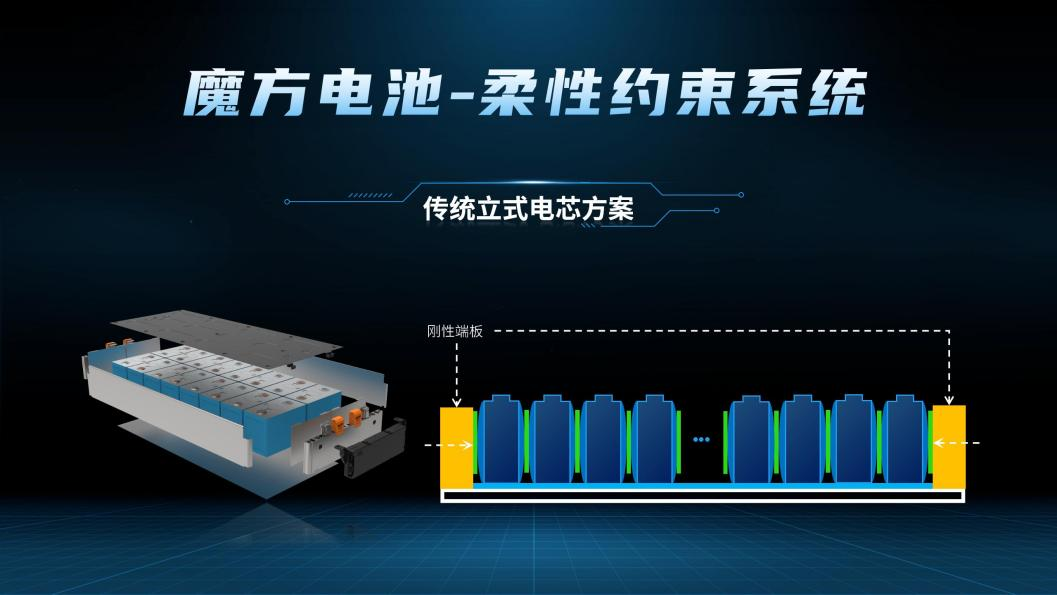

In traditional vertical battery cell packs, the battery cells are placed in a rigid framework called an “iron cage.” As the battery cells age and expand, the stress conditions will deteriorate rapidly, and the battery cells can only bear greater clamping force within a limited space.

The cube battery uses flexible constraints as its structure, mainly completed by the upper and lower layers of thin-wall flexible pressure plates and flexible structural adhesive to constrain the battery core together. This is like putting a “highly elastic bodysuit” on the battery core, which can adapt to the battery core’s expansion, greatly reducing the force on the battery core and extending the battery core’s cycle life.

The cube battery uses flexible constraints as its structure, mainly completed by the upper and lower layers of thin-wall flexible pressure plates and flexible structural adhesive to constrain the battery core together. This is like putting a “highly elastic bodysuit” on the battery core, which can adapt to the battery core’s expansion, greatly reducing the force on the battery core and extending the battery core’s cycle life.

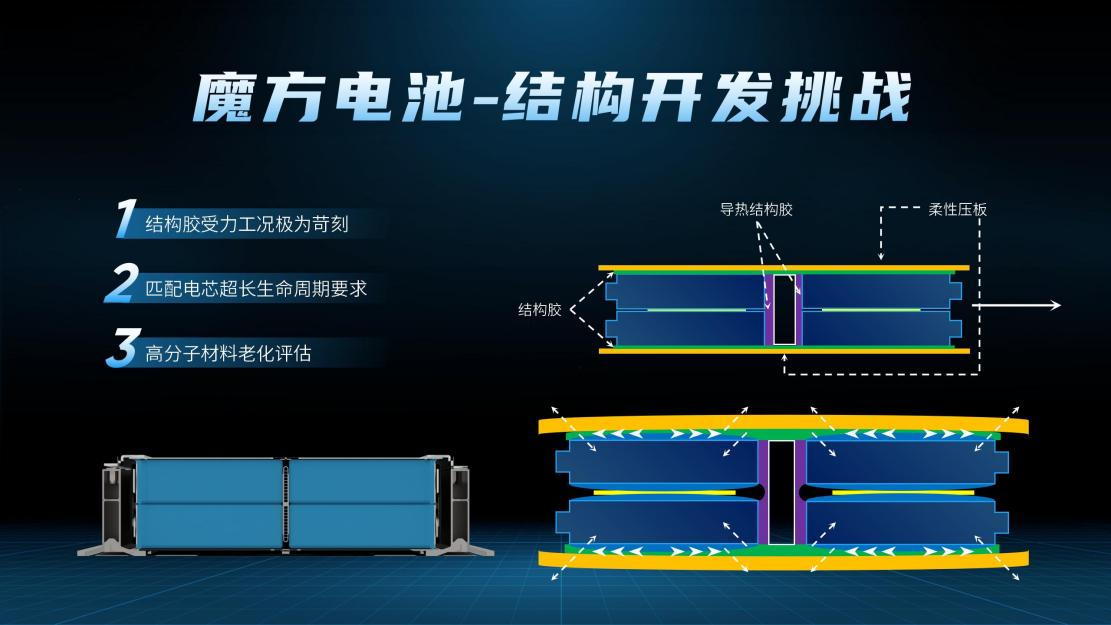

According to SAIC, the birth of this “super tight bodysuit” is extremely challenging as there are three major obstacles to be overcome.

First is the extremely harsh working conditions of structural adhesive. The structural adhesive is subject to completely different working conditions at different positions of the battery core. The “super tight bodysuit” needs to be cut into small parts and designed according to the needs of different parts.

Second is the need to match the battery core’s entire life cycle. The volume of the battery core will expand significantly in the later stages of its life, and this “super tight bodysuit” also needs to adapt to the changes in the battery core. Simply put, it should fit even when a lean person with a waist circumference of 70 becomes a fat person with a waist circumference of 100.

Third is the aging evaluation of the ultra-high molecular weight material. As SAIC’s relevant person in charge put it, the entire flexible solution can be said to be the art of using adhesive. The SAIC team needs to solve the aging problem of the adhesive.

Therefore, SAIC partnered with Dow Chemical to develop and match exclusive structural components for the laying battery core. They jointly developed and tested more than 1,000 formulations of structural adhesive and performed more than 20,000 hours of reliability verification before finally determining the structural adhesive formula.

In addition, SAIC’s unique battery core electrolyte drainage design makes the electrolyte flow smoother, and the combination of these factors increases the battery core’s cycle life.

With the help of these technologies, the cube battery has successfully passed the nail-piercing test. When the steel nail punctured the battery pack and triggered thermal runaway, the punctured battery pack emitted smoke but did not catch fire, explode or exhibit thermal spreading.

In summary, the most obvious feature of the cube battery is that it uses a laying battery core to make the battery pack thinner, further increasing the utilization of internal space. The safety has improved, and the potential danger of the upright battery core spraying upwards has been solved by the lateral spray.

Of course, there are additional advantages to the ultra-thin battery, such as the car achieving a super low center of gravity and uniform distribution, which can effectively suppress the lateral tilt during high-speed driving. In extreme driving conditions, the car’s control is better, ensuring a purer driving experience.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.