Author: Da Yan

In the era of intelligent electric vehicles, while intelligent connected and automatic driving technologies often take the spotlight, the overall performance of the three-electric system remains the cornerstone of the entire electric vehicle.

An intelligent electric vehicle is firstly a car, and it is only then that there are many other possibilities to imagine. Therefore, similar to traditional fuel vehicles, one of the main areas of innovation for electric vehicles is still the three-electric system, which is located in the powertrain. Only through continuous innovation of the three-electric system can an electric vehicle occupy a place in the intense competition in the market, by bringing safer, smarter, and higher performance experiences.

On July 26th, SAIC-GM held an “Auton Electric Vehicle Platform Technology Open Course” at the Pan-Asia Automotive Technology Center, to provide insight into the core of the Auton platform regarding aspects such as safety, intelligence, and performance.

As the cornerstone of General Motors’ transformation to pure electric vehicles, it is not excessive to emphasize the importance of the Auton platform for this veteran automaker. In the future, General Motors will develop 30 electric vehicle models based on the platform, of which over 10 pure electric vehicle models will be launched in the domestic market.

Therefore, in the context of the era of intelligent electric vehicles, talking about the safety, performance, and intelligence of the pure electric vehicle platform is not outdated, but rather, it is a demonstration of the basic training for whole vehicle enterprises.

Safety stems from higher standards

Every scorching summer, news about the safety of electric vehicles occasionally enters the hot search list, reminding us of the importance of safety. Safety is the topic that users are most concerned about when it comes to electric vehicles, and it is also the core principle of R&D for each automaker. For the Auton electric vehicle platform, safety is the foundation of all technological extensions.

The Auton platform not only meets the highest ASIL-D level of system safety for electronic and electrical systems in the automotive industry but also develops in accordance with the four design standards of voltage, energy, physical protection, and insulation resistance of the load end of the electric power system in the Five-Star Safety Evaluation for electric vehicles. This maximizes the elimination of safety hazards for electric vehicles.

To achieve this, the Auton platform has made efforts in the following aspects.

For the power battery, various tests are essential, including drop, compression, and puncture tests. Auton has developed and tested far beyond the national standards to ensure safety.

In terms of battery cells, not only does the Altair platform adhere to 100% Direct Current Resistance (DCR) detection, but also the battery cell tests have accumulated over 3.2 million hours to ensure that all potential problems are exposed in the early verification stage. In terms of battery pack design, the Altair platform’s testing and certification standards far exceed national standards.

In terms of battery cells, not only does the Altair platform adhere to 100% Direct Current Resistance (DCR) detection, but also the battery cell tests have accumulated over 3.2 million hours to ensure that all potential problems are exposed in the early verification stage. In terms of battery pack design, the Altair platform’s testing and certification standards far exceed national standards.

The battery cell is the core of the entire battery pack, directly affecting the performance and life of the battery. Based on General Motors’ global unified safety and performance standards, Pan Asia Automotive Technology Center has developed the exclusive optimized formula of the Altair platform based on the 811 NCM basic formula in conjunction with local battery suppliers, achieving better thermal stability, lower attenuation, and longer life.

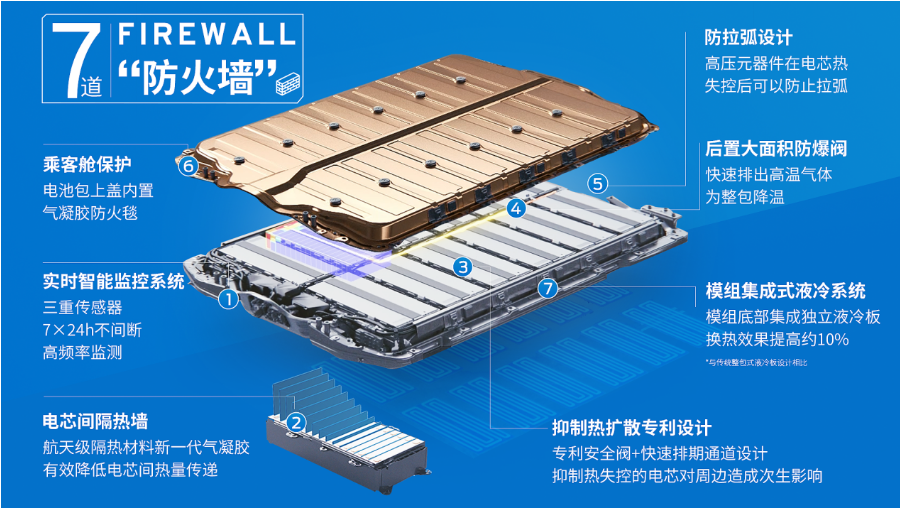

For batteries, thermal management technology is crucial. Therefore, General Motors ensures that the battery can minimize the occurrence of thermal runaway through its seven-core battery thermal management technology and multiple patented designs; even if thermal runaway occurs, heat can be dissipated in a timely manner, avoiding uncontrolled situations in the whole vehicle.

Specifically, Altair has set up seven firewalls in terms of thermal management, including inter-cell insulation walls, heat diffusion suppression technology, an integrated liquid cooling system, fire protection designs for modules and entire battery packs, combined with rear explosion-proof valves, arc-resistant shields, and a “vehicle-cloud” battery health monitoring system at both ends.

In addition to optimizing battery pack performance, the Altair platform uses a high-strength cross structure with multiple 1500MPA ultra-high-strength steel beams to create a sturdy battery pack shell that is closely integrated with the vehicle system, capable of withstanding a 300kN compression test. This stable physical protection architecture can also achieve sealing performance levels such as IP67 dust and water resistance and IP6K9K high-pressure water spray protection.

At the same time, to avoid post-collision danger, Altair can complete active discharge within 5 seconds after a collision to ensure rescue safety.

OTA for Wireless Battery Management System

As a pure electric vehicle platform in the era of intelligence, intelligence is an essential attribute.

The Better Battery (BB) platform is currently the industry’s first wireless battery management system. The wireless battery management system replaces the original wiring harness with an electrical signal to achieve internal information transmission in the battery system.

Replacing the wiring harness not only reduces the weight of the battery system, simplifies the assembly process, but also reduces the difficulty of later maintenance. Compared with the cable connection, which is restricted by wire performance and poor connection stability, the wireless signal transmission is more reliable, faster, and more secure.

After adopting wireless connection, aided by the remote upgrade function of the new generation VIP intelligent electronic architecture of General Motors (GM), the underlying architecture of the battery management system can also be updated and networked like a smartphone, providing more flexible and rapid incremental updates.

To accurately and efficiently detect the health status of the battery system, BB platform is equipped with a battery health intelligent monitoring system that integrates “car-cloud” at both ends. The main functions of this system include real-time thermal runaway monitoring on the vehicle side and cloud-based thermal runaway early warning.

The former can continuously monitor the battery pack and cell status in real-time around the clock, through the integrated triple sensors (pressure/temperature/voltage) inside the battery. Once a runaway risk is detected, it will actively wake up the battery management module to issue an early warning and automatically take prompt cooling measures to ensure the safety of the battery pack.

The latter can rely on the large database and evaluation algorithm of the cloud platform to analyze and assess the battery health status in a multi-dimensional comprehensive manner and prevent risks in advance, bringing more proactive and intelligent battery risk prevention and management.

To realize smarter use of the battery system, the BB platform is equipped with the BEV HEAT high-efficiency integrated thermal management system, which integrates a fusion-type thermal system and intelligent thermal management software strategies for air conditioning, battery, and drivetrain. It can reasonably distribute energy to the battery and cockpit based on the actual temperature of the battery, environmental temperature, air conditioning needs, and other factors to achieve the optimal solution for cabin comfort, driving quality, energy consumption, cell life, and battery safety.In BEV HEAT, SAIC-GM thoroughly considers every energy-saving scenario. For example, in winter, the charging pre-processing mode of BEV HEAT can maximize the use of the charging station’s electricity rather than the car’s internal electricity to optimize the comfort of the cabin air conditioning for users after starting the vehicle in winter, saving the power consumption of heating the battery and passenger compartment during the vehicle start-up stage, thereby increasing the vehicle’s range in cold environments.

There are many such examples on the OTEV platform.

The performance of an electric vehicle is not just acceleration

For electric vehicles, due to the inherent advantage of electric motors over internal combustion engines in terms of torque response speed, they can provide stronger power for electric vehicles. Therefore, for many people, the high performance of electric vehicles seems to be easily obtained without much effort. However, performance is not only equal to acceleration. The OTEV platform attempts to expand the definition of high performance.

The OTEV platform is equipped with a highly efficient modular drive system that has three power electric drive units for front-wheel drive main motors, rear-wheel drive main motors, and rear-wheel drive auxiliary motors. For example, the 3-in-1 electric drive unit installed in the Cadillac LYRIQ RuiGe rear-wheel drive model has a peak power of 255 kW, a peak torque of 440 Nm, and a maximum driving motor system efficiency of 96%, leading the market in various sub-segments.

In addition, the OTEV platform’s modular drive system also has unique features in terms of NVH and durability performance.

Since General Motors has set a goal of “building 30 electric vehicle models,” it is ready to allow OTEV to support a variety of battery and electric drive combinations. OTEV’s electric vehicle platform can cover products with different ranges, driving styles, and performance levels, and can support the creation of various styles of models including sedans, SUVs, MPVs, pickups, etc., with different wheelbases and sizes.

In terms of batteries, OTEV’s battery pack can be combined with eight, ten, and twelve modules and can also simultaneously support lithium iron phosphate, ternary lithium batteries, and future lithium-metal and solid-state batteries.

Charging has always been a big pain point in the use of new energy vehicles. OTEV has made improvements in power supplementation. Based on OTEV’s platform, on the one hand, the model can mark charging stations with problems proactively through charging-related data, avoiding customers falling into the pit. On the other hand, it can also better compatible and supplement power to poorly stable charging stations, providing users with a better charging experience.## A complete testing and certification system

Shanghai General Motors was founded in 1997. In the same year, SAIC and General Motors, the shareholders of SGWM, jointly established the Pan Asia Technical Automotive Center. As the engineering and technical center of SGWM, PATAC has not only undertaken a large number of GM localization projects in the past 25 years, but also formed a positive development capability from platform to complete vehicle. At the same time, PATAC has deeply understood GM’s testing and certification process.

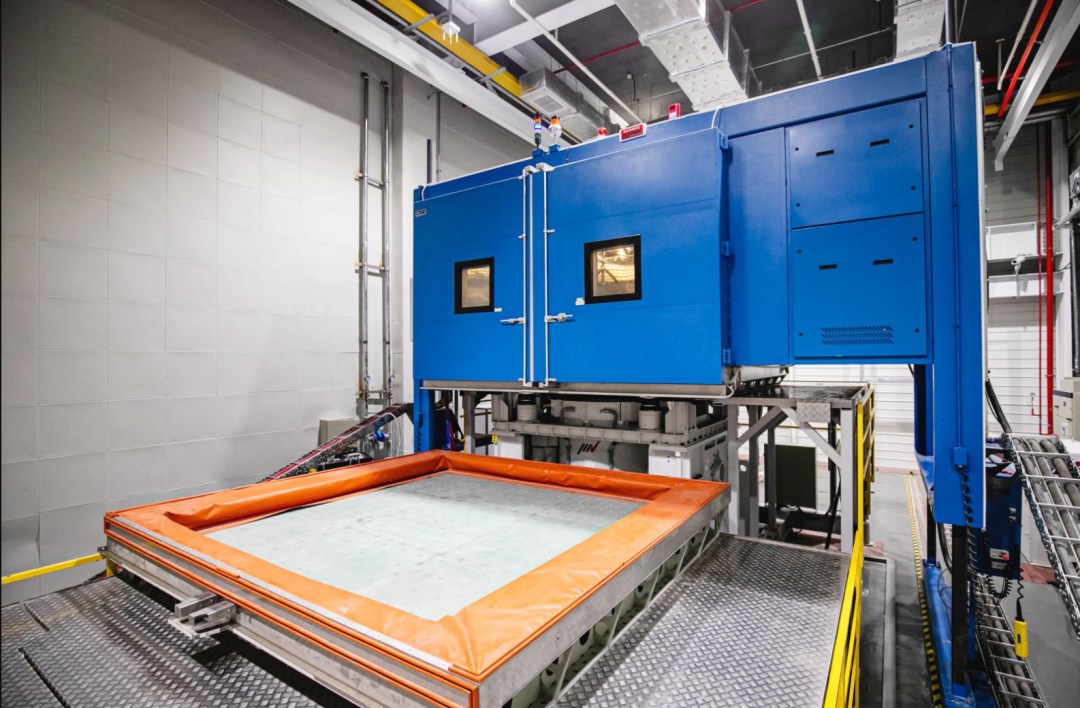

In terms of the testing and certification of the three-electric systems, SGWM relies on PATAC to build two major “three-electric” technology testing centers, the PATAC New Energy Testing Building and the Guangde Battery Safety Testing Laboratory. It has established the ability to test and certify the whole process of key components of the three-electric system, including battery vibration testing systems, battery performance testing systems, electric drive transmission testing systems, electric control development testing systems, and complete vehicle charging and discharging environmental chambers. Combined with the accumulated experience of complete vehicle testing and certification process of PATAC, it ensures that SGWM can deliver electric vehicles and new energy vehicles to users at the highest level.

Last but not least

With General Motors announcing its plan to ban the sale of fuel vehicles by 2035, and the rapid development of the domestic electric vehicle market, SGWM will also hit the accelerator in the smart electric vehicle market.

Based on the Ultium platform, Cadillac LYRIQ Ruige has demonstrated its strong product power: the four-wheel drive version has a maximum power of 375kW and a peak torque of 710N·m; the minimum cruising range can also exceed 600km; in terms of energy supplement, the battery can be fast-charged for 10 minutes and can travel for 96km, and it also supports fast charging throughout its service life.

All of these are enough to make the market have high expectations for this new Cadillac, and full of expectations for the transformation of SGWM and even General Motors as a whole.

Looking back on the 25 years of development of SGWM in China, integrating the hundred-year manufacturing experience of General Motors with the actual situation of the Chinese automobile market, and tailoring more suitable models for Chinese consumers, is the key to SGWM’s long-term position in the top tier of the domestic market. This not only requires the strong support of both shareholders, but also the solid support provided by PATAC.

In the next 25 years, based on the successful model and the powerful product power of the Ultium platform, SGWM will bring a better electric vehicle experience to domestic consumers.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.