Author: Mu-min

Many people may still remember the famous biological concept proposed by Darwin, “Survival of the Fittest.” In a specific environment, only the species best suited to that environment can be the most effective in reproducing. The same species that spreads to different geographic locations gradually shows different forms due to different environments.

Such biological evolution concepts can sometimes be perfectly replicated in the differences in the form of cars. In Europe, where there are many mountain roads and highways are not wide, the heavy truck head has always been dominated by flat heads, which are shorter in length and have a better observation view. A shorter front also means a larger trailer space.

For the vast and resource-rich, low-cost fuel, wide and straight roads of North America, larger engines and greater comfort are two dominant requirements, and long-nose heavy-duty trucks have naturally become the favorites of North American truck drivers.

With the advent of the new energy era, the “head style” of trucks has once again embarked on the path of evolution, and this evolution may be a convergent evolution. Because no large engine means a more compact front end design, and switching from fossil fuels to batteries also means a decrease in energy density, improving efficiency has become a top priority.

The New Milestone of Domestic New Energy Heavy-duty Trucks: DeepWay Mode

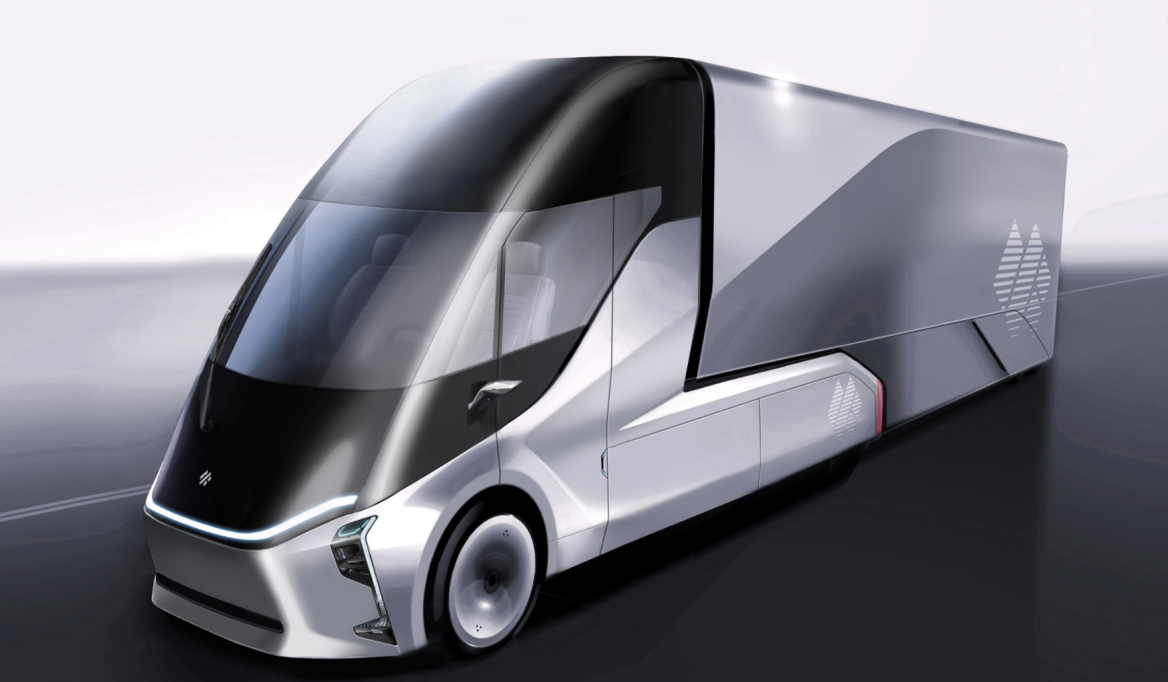

DeepWay, a generation of deep stars, is the third form born under the background of embracing sustainable energy and intelligent transformation-“wedge-shaped front”.

As a unicorn of Baidu and Shi Qiao’s joint incubation of automatic driving trunk logistics, DeepWay aims to redefine the track of new energy truck racing.

More specifically, it is an intelligent logistics operation service for trunk lines powered by battery-swapping and hydrogen-powered intelligent new energy heavy truck products and empowered by automatic driving.

Before DeepWay, the automatic driving start-up path of trunk logistics can be roughly summarized as the following two types:

- Serving as an algorithmic technology supplier role for OEMs.

- Self-built fleet mode.

For the former, commercial vehicle automatic driving start-up companies clearly lack the dominance of products, making it difficult to form differentiated product competitive advantages, and the contextual adaptation of hardware itself is also difficult to iterate quickly; for the latter, compared with the logic of creating new travel modes in the C-end market such as ride-hailing, attempting to cut into this existing cake in the To B market in a heavy-asset manner poses significant challenges to platform efficiency and early-stage price competitiveness, and the profit model is difficult to run quickly.

As a leading digital logistics management platform for complete vehicle transport in China and a strategic partner and investor of DeepWay, Lionbridge provides advantages for DeepWay to integrate Baidu’s intelligent driving from the bottom up by developing vehicles on its own. Meanwhile, it introduces BaaS (Battery as a Service) and battery bank models to create intelligent new energy long-haul logistics vehicle products and value-added services throughout their entire life cycle. The former means that replaceable batteries are made into giant rental power banks, changing the charging mode of vehicle-on-board purchase. On the other hand, electric vehicle batteries belonging to the operator can be packaged as ABS fixed-income financial products and sold through financial platforms.

As a leading digital logistics management platform for complete vehicle transport in China and a strategic partner and investor of DeepWay, Lionbridge provides advantages for DeepWay to integrate Baidu’s intelligent driving from the bottom up by developing vehicles on its own. Meanwhile, it introduces BaaS (Battery as a Service) and battery bank models to create intelligent new energy long-haul logistics vehicle products and value-added services throughout their entire life cycle. The former means that replaceable batteries are made into giant rental power banks, changing the charging mode of vehicle-on-board purchase. On the other hand, electric vehicle batteries belonging to the operator can be packaged as ABS fixed-income financial products and sold through financial platforms.

DeepWay’s self-developed approach to car manufacturing centered around its core technology can be said to be the first of its kind in China and has taken the lead position in the new energy heavy truck race.

Recently, DeepWay, which has always been low-key, has made new progress and launched the first white body of its product Deepway Star Journey.

The Story Behind the White Body: Superior Aerodynamics

As for commercial vehicles, the truck shape of the past lacks sufficient distinction compared to passenger cars. For example, “family design,” which has been popular in passenger cars for nearly 10 years, has been a long-standing fixed design approach in the truck industry.

In response to this problem, DeepWay made a breakthrough choice: to commission Italy’s famous car design company Pininfarina to design the first product of its brand.

As a top design agency famous for designing many sports cars, such as Ferrari and Lamborghini, Pininfarina has given the DeepWay Star Journey an unforgettable elegance and strong modern lines.

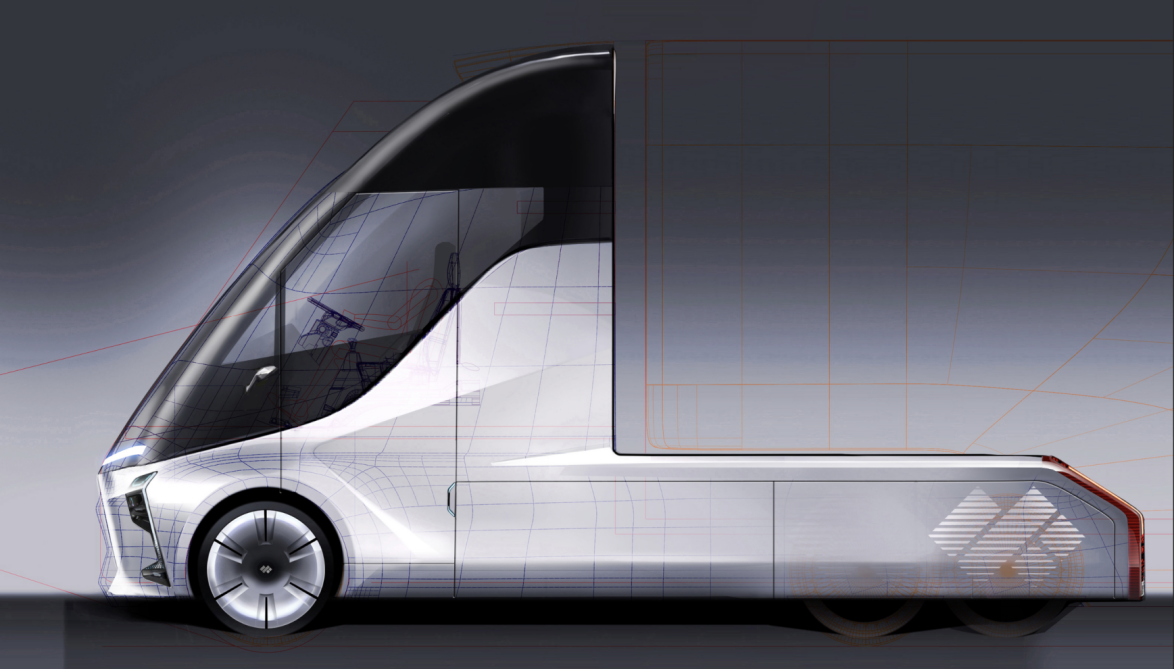

Iconic wedge-shaped front end, electronic rearview mirror, larger A-pillar inclination angle, and bottom flow plate together outline the technological sense and high-efficiency attributes of this car.

For pure electric vehicles with higher energy efficiency but lower energy density, the coefficient of drag is more important than for traditional petrol vehicles because a lower coefficient of drag directly means lower average power consumption and, therefore, actual driving range. Moreover, during high-speed driving, more than half of the energy used will be spent on overcoming air resistance, so a lower drag coefficient is always better for any vehicle focused on efficiency.This comparison chart shows the drag coefficients of DeepWay Star Journey, diesel trucks, and Bugatti Veyron. It can be seen that a large truck can have a lower drag coefficient than a supercar, reaching 0.35.

Of course, in order to bring the aerodynamic performance and design aesthetics of the 3D model into the real world, DeepWay’s styling team and engineering team still need to find the intersection of theory and reality in countless clay model evaluations.

One of the most beautiful parts of this car should be the wheel arches, which are different from the traditional flat shape of trucks. DeepWay Star Journey has a wheel arch with a sports car-like rise, which brings a sculptural sense of biology to the car’s design. However, this stunning surface design also brings a new problem: it is impossible to install door hinges.

This is a typical contradiction between “design and engineering”. Regarding this contradiction, DeepWay’s chief engineer Tan Changyu said: the team has considered changing the surface design of this area to a flat style, but the flat design greatly destroys the beauty of the original design. For the DeepWay design team that pursues perfection, this is obviously unacceptable. Fortunately, the entire team is not bound by convention and perfectly solves this problem through hinge placement. It not only retains the functionality of the doors but also preserves the most classic design elements.

There are several advantages to hinge placement:

- Meet engineering requirements. In the development of an excellent product, engineers always have to find a balance between design and engineering, which DeepWay has found.

- Meet the aerodynamic requirements. Many people may think that aerodynamics are not very important for a large commercial truck with a huge windward surface. But this is not so. One of the biggest needs of commercial truck users is to reduce operating costs. Under the premise of low energy consumption, how to complete the most tasks in the shortest time and at the lowest cost is the key.

- Meet the requirements of design aesthetics and fluid side lines. Commercial trucks have always been tool vehicles, and few manufacturers really care about whether a car has beauty. Like Rolls-Royce, hinge placement allows DeepWay Star Journey to have a pair of rear-opening doors that support electric opening. With the help of the electric execution structure, the cumbersome truck doors can allow drivers to enter and exit the vehicle more elegantly.

In addition to these advantages, there are other advantages of self-developed white bodies.

DeepWay’s white body also extensively uses high-strength steel, accounting for about 65%, compared to the common car models in the market with a high-strength steel ratio of about 30%-40%. However, this strength cannot support the huge impact of truck collisions in the forward and lateral directions, resulting in a higher fatality rate in truck accidents than in passenger cars.

65% high-strength steel means a stronger body, which can better protect the cabin from collision intrusion. In the figure below, in addition to the main anti-collision beam below the front of the car, the two horizontally arranged beams above also have a certain energy-absorbing effect when a collision happens.

DeepWay uses a large amount of aluminum alloy in places such as doors and front covers, and the greatest advantage of using aluminum alloy in special positions is that it meets the collision requirements and protects the safety of drivers and passengers. Another advantage is lightweight, which can improve vehicle energy consumption and reduce the owner’s operating costs.

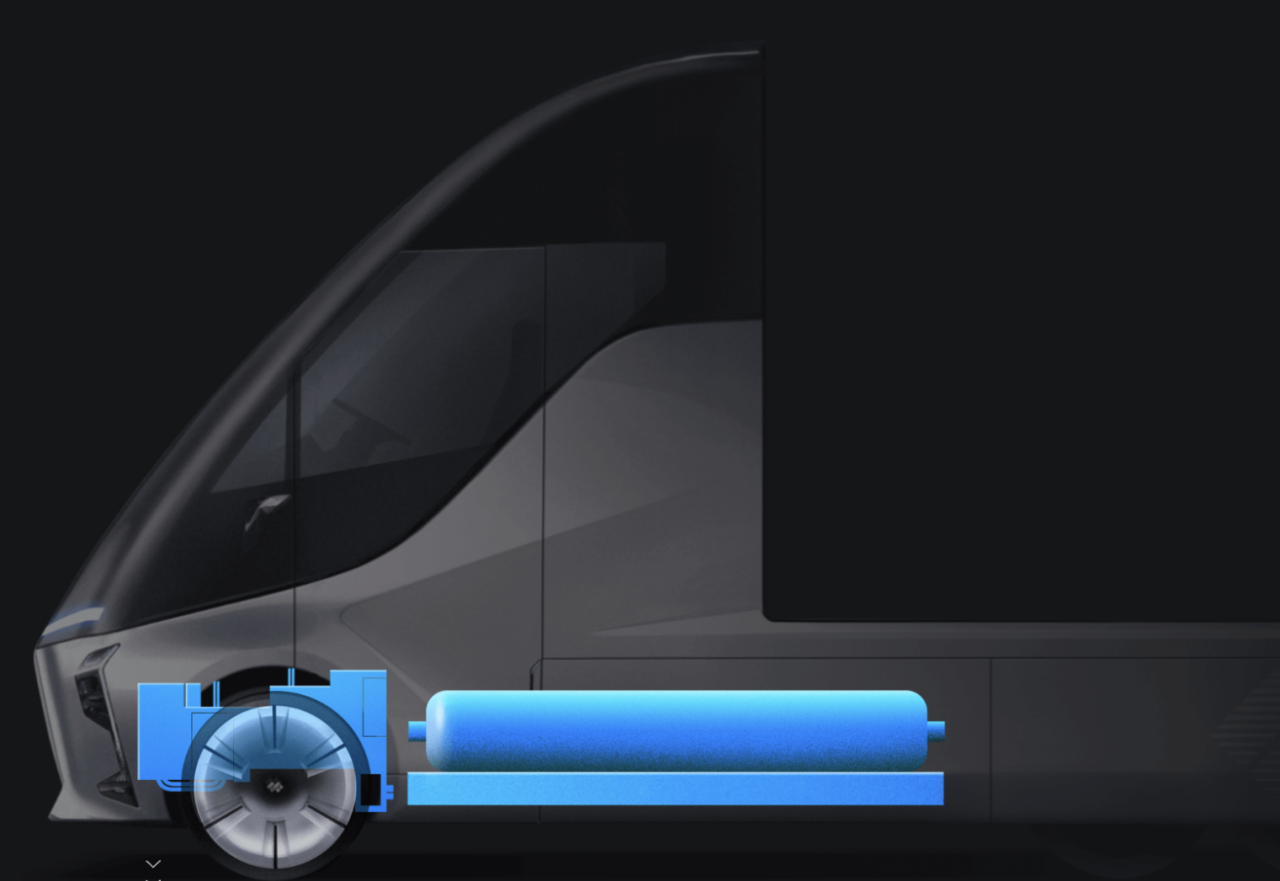

In addition to improving collision strength, there is also one thing that differentiates new energy trucks from traditional trucks: the weight of the battery puts a requirement on the vehicle structure.

We all know that new energy trucks require much higher battery capacity than passenger cars, because in addition to the weight of the vehicle itself, the weight of the battery and the weight of the goods being towed must be considered.

Although it is most reasonable to hang the battery under the vehicle in terms of space utilization, there are also macroscopic problems. The connection between the battery and the frame cannot be a rigid link. Especially when fully loaded, the truck’s frame must have a certain degree of flexible deformation to disperse stress, while the battery pack must ensure that it does not deform at any time, otherwise catastrophic consequences may occur.

If the battery and the frame are rigidly linked, the battery will twist and deform with the frame, which challenges battery safety.

DeepWay’s chief engineer Tan Changyu stated that:

“To solve the problem of connecting the battery and the frame structure, DeepWay used a high-stiffness aluminum alloy battery frame. This frame is first installed on the frame, and the connection between the frame and the frame is a soft link through rubber suspension.”

“The rigidity of the aluminum alloy frame is very high, but its connection with the frame is soft. This deformation compensation can meet the safety of the battery and support the frame’s need for elasticity. For this reason, DeepWay has also applied for related patents.”

This technology is currently used in the battery-swapping version of the model, but there will be a chassis integrated structure solution in the future, which is already in the pre-research stage.

For trucks, improving the cabin strength, reducing wind resistance, having a flexible link between the battery structure and the frame, and reducing weight are not simply for showing off, but more importantly, to allow you to carry more goods within the maximum weight limit of 49 tons and to ensure the safety of every driver.So, we only see passenger car manufacturers making technological improvements for users, but in the commercial market, DeepWay is also doing the same thing. Companies that focus on “user benefits” to develop technology, though every step is longer, are also valuable.

Another benefit of positive research and development is the ability to determine sensor configuration and layout in the design concept stage. For example, DeepTek Xingtu First Generation integrated ADAS cameras and millimeter-wave radar sensors in the electronic rearview mirror, and perception components were better integrated into the body.

The aesthetics brought by this positive research and development are evidently of a higher level, with no sense of incompatibility with after-installation, and it helps to increase flatness and achieve excellent aerodynamic goals.

Without an engine, there are no protruding parts that take up space inside the cabin. This truck has good advantages in cabin floor flatness and height, and its 1-meter-wide bunk bed provides a more comfortable resting experience than the more common 900mm bunk beds in other models.

Hydrogen + electricity, two powertrain systems

Taking advantage of positive research and development, the DeepTek Xingtu First Generation still achieved a hydrogen fuel cell vehicle on the same platform. Compared to the BEV model, it is obviously a product designed for longer zero-emission travel range.

But from the current infrastructure perspective, the BEV model with a 466-degree capacity battery pack and 300 km of range is the product that will be delivered in larger quantities in subsequent mass production. Therefore, the speed of battery swapping directly affects the time cost of long-distance trunk transportation trips.

DeepWay will use AGV unmanned handling vehicles to achieve battery swapping installed under the frame to achieve faster energy supply.

Stepping into the unmanned zone

One of the most important indicators in the freight industry is TCO (Total Cost of Ownership). For long-distance logistics heavy trucks, in addition to the purchase cost, there are also operating costs and maintenance costs, all of which are what a freight company needs to account for.

If calculated based on 35L of fuel consumption per hundred kilometers for a 49-ton heavy truck, the cost of fuel per hundred kilometers is about 210 yuan. The reason why the fuel price is set at a lower 6 yuan per liter is because this calculation also considers the possibility of refueling with cheaper third-party diesel along the way.Based on the energy consumption of 150 degrees per 100 kilometers and an average electricity price of 1.3 yuan per kilowatt-hour, the energy cost per 100 kilometers for DeepWay Xingtu’s first generation electric truck is 195 yuan, which is a reduction of 8% compared to diesel trucks.

For vehicle maintenance, electric powertrains essentially eliminate the need for powertrain maintenance, and regenerative braking can reduce brake usage and extend the replacement cycle for consumable parts. Additionally, the Battery-as-a-Service (BaaS) model means that end-users do not have to bear the depreciation caused by battery wear and tear.

On top of having a purchase cost no higher than traditional diesel trucks, DeepWay Xingtu’s first generation electric truck also has a 8% advantage in operating costs and significantly reduced maintenance costs due to its electric powertrain and battery swapping technology. These advantages are tangible benefits to users.

Of course, in addition to user benefits, solid technological development, strong in-house capabilities, reasonable scenario definition, rigorous profit models, and excellent management teams are all crucial factors. According to DeepWay’s official statement, they are about to complete Series A financing, which also proves that its performance in the above-mentioned areas has been recognized by the capital market.

Will DeepWay Xingtu’s first generation electric truck create its own glory like Steyr 91 did in the 1980s and open up a new chapter for Chinese commercial vehicles? The answer will slowly emerge after the start of mass production in June 2023.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.