The Evolution of Electronic Stability Control System under Intelligent Chassis

Author | Panjiang

With the development of the automotive industry, cars are getting heavier and faster. These changes not only demand higher basic braking capabilities but also present higher challenges to vehicle stability. Research on auto safety has shown that about 10% of road accidents are caused by vehicles deviating from the predetermined path or skidding during braking. It’s well known that improving the braking performance of the chassis is a crucial measure to reduce traffic accidents, and actively intervening in the braking is the key to optimizing the braking performance.

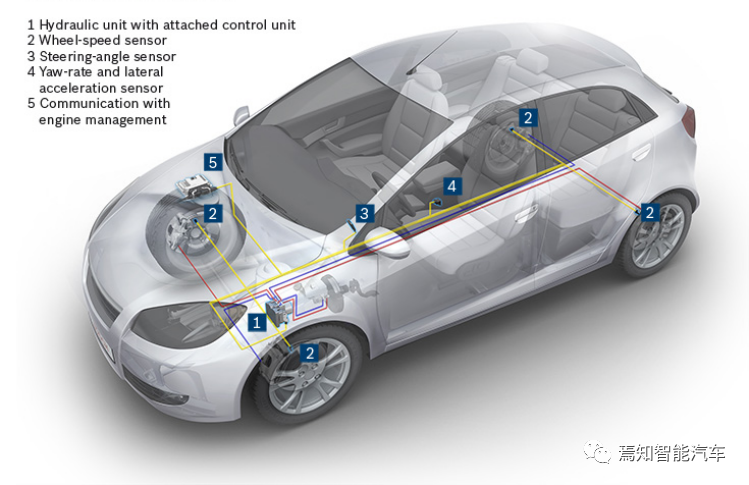

Although the theoretical research on actively intervening in the braking system to improve vehicle stability has been conducted early on, the actual application is dependent on the timely development of relevant technology. The widespread application of hydraulic brakes replacing traditional mechanical brakes and the development of mechatronics technology provides a technical foundation for implementing active braking intervention, and even makes it possible for active intervention in driving and suspension. Thus, from the initial Anti-lock Brake System (ABS) to today’s Vehicle Dynamic Control (VDC), the evolution of the chassis electronic stability system has begun.

However, the evolution of the chassis electronic stability system has not stopped. The new E/E architecture of intelligent chassis has brought new optimization directions to the chassis electronic stability system. For example, under the control of the chassis domain controller, the co-working of each subsystem can achieve faster stability control. The topic of intelligent chassis and electronic stability system is becoming a hot research area for mainstream automakers and suppliers.

Against this background, the following issues will discuss the evolution of the electronic stability system and the new direction brought by intelligent chassis based on the following structure in the coming periods.

-

Part1: The Working Principle of ABS: Anti-Lock Brake System

-

Part2: The Working Principle of TCS: Traction Control System

-

Part3: Powering ESP: A Revolutionary Product

-

Part4: The Further Evolution of Electronic Stability Control System under Intelligent Chassis

Intelligent Chassis and Electronic Stability Control System

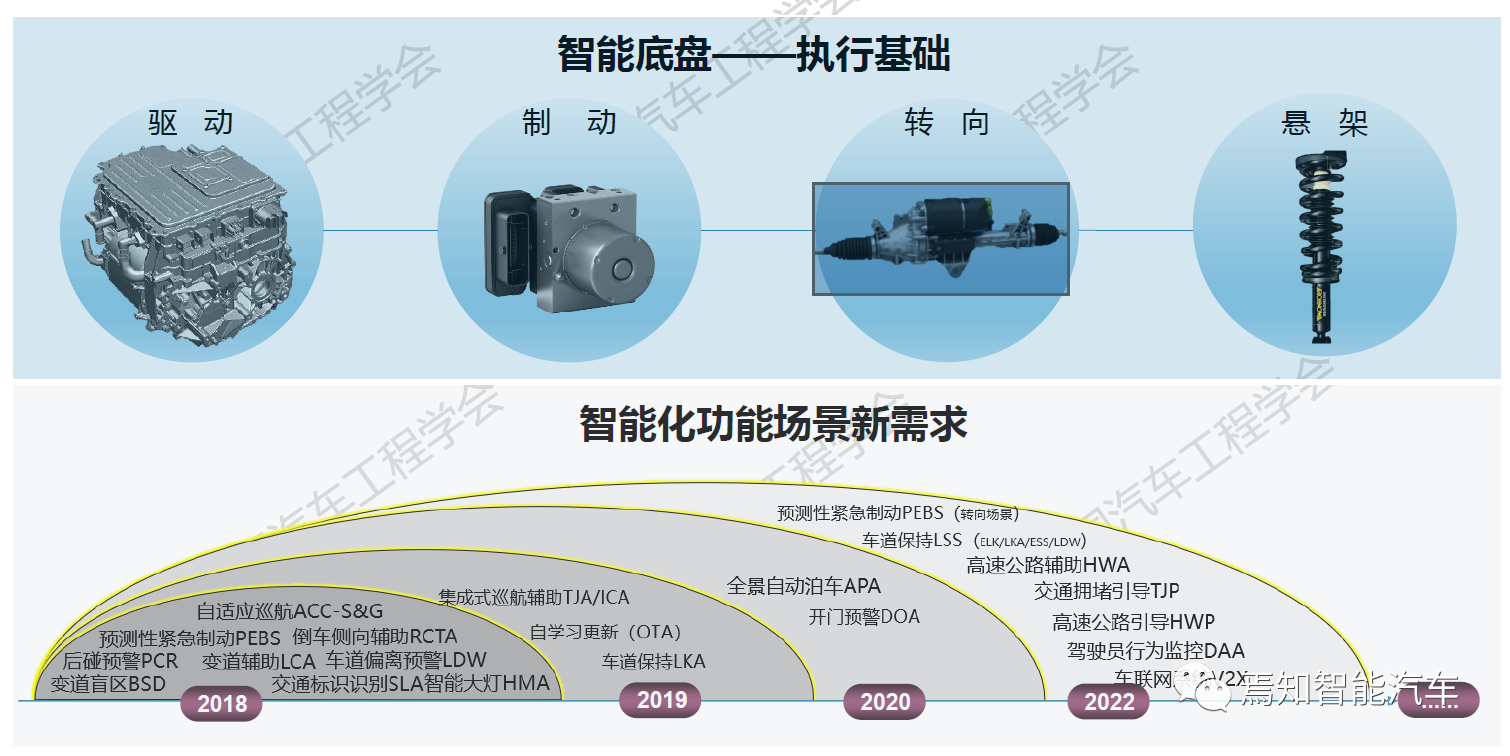

Under the current trend of electrification and intelligence in the automotive industry, traditional power systems are upgraded to three-electric systems, the mechanical components of the chassis system are simplified, and the degree of electric control is increasing. At the same time, with the increasing popularity of ADAS systems (such as ACC, AEB, etc.) and the gradual implementation of autonomous driving systems, new demands for increasingly diverse intelligent scenarios have emerged.On the other hand, the positioning of cars in the consumer market is also changing. End consumers no longer view cars as just transportation tools; instead, cars have become carriers of improved quality of life and space. This consumer trend means that while the industry is pursuing intelligent cars, it also needs to further improve the comfort and driving quality of cars to provide consumers with a more enjoyable driving experience.

Under this trend, cars are demanding higher requirements for chassis systems, and a more intelligent chassis is needed to adapt to the development needs of car electrification and intelligence.

The new requirements for intelligent chassis can be summarized into four categories:

- Personalization: Providing customized services based on customer driving habits

- High performance: Faster and more accurate system response

- Scalability: The system has self-learning ability and supports OTA upgrades

- Safety: Multiple security guarantees for product and information security

Although the current market performance shows that chassis systems are still in the electromechanical hybrid period, the trend toward intelligent chassis is already evident.

Firstly, the popularity and evolution of wire control technology in cars. Wire control technology originates from aircraft control systems, which convert the pilot’s manipulation commands into electrical signals and transmit them directly to autonomous servos through cables. The biggest advantage of wire control technology is its precise and rapid response, which has been inherited in wire control technology for cars. Currently, almost all chassis control subsystems have achieved wire control.

With the evolution of autonomous driving, the role of drivers has been weakened, and the roles of steering wheels and pedals have gradually diminished. The electronic control system and driver mechanical interface are decoupled, which can more flexibly adjust the characteristics of the chassis system to meet the personalized needs of different customers. This is another advantage of wire control chassis.

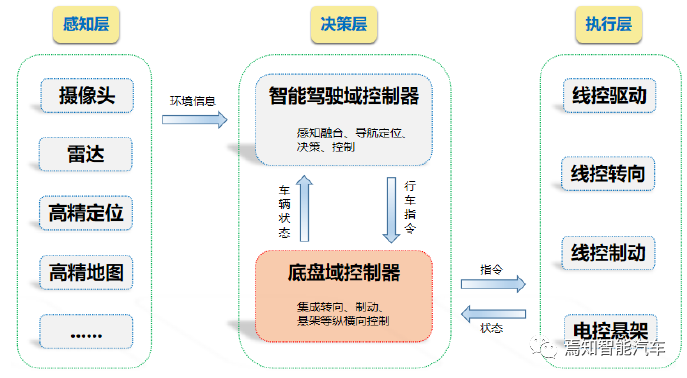

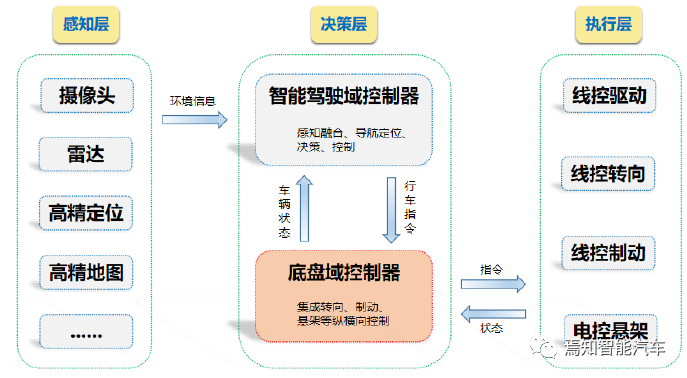

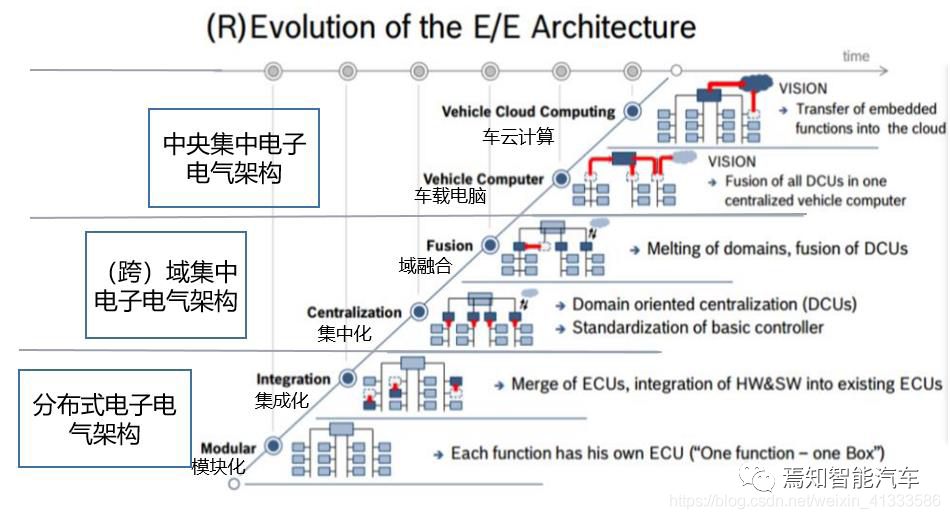

Secondly, the transformation of the intelligent driving system E/E has also spurred the evolution of the intelligent chassis E/E. In the electromechanical hybrid period, the E/E architecture of the chassis system consists of simple subsystem ECU stacking, and although cooperation exists between the subsystems, these cooperations are only reflected in the information sharing level. The subsystems still “mind their own business”, and their function controls are constrained by each other, resulting in slow response and failing to reflect the effect of “1+1>2”.The performance of the Vehicle Dynamic Control (VDC) system introduced in the previous article is constrained by the limitations of traditional E/E architectures. The VDC relies on inputs from the steering and braking systems to determine whether the vehicle is experiencing understeer or oversteer tendencies, and makes corrections to the wheel-end braking force to control the yaw rate and bring the vehicle back to stability. Although the steering system has a direct impact on vehicle stability, the VDC does not directly intervene in the steering wheel angle control, so the performance of the steering system during this process affects the speed of stability control adjustment in real-time, but its impact can only put the braking system in a “remedial adjustment” loop. In other words, the steering system cannot play an “active assist” role in stability control.

In the new E/E architecture based on the Chassis Domain Controller, the intelligent control core functions are centralized in the domain controller, and real-time coordination control of each subsystem is carried out precisely and quickly, breaking down the barriers of simple subsystem functional stacking.

For example, in the same VDC system, the domain controller can synthesize the vehicle states feedback from each subsystem and intervene in control before the vehicle reaches its dynamic stability limit, quickly making corrections to braking, steering, and even suspension. As compared with traditional controls, it has shifted from “remedial control” to “prevention control”, which is not only safer but also more comfortable for drivers.

It is foreseeable that with the evolution of the intelligent chassis, the electronic stability system will undergo a revolutionary transformation, with trends being primarily toward “cooperative cooperation”, “remedial to preventative” and “fast and precise”. At the same time, the electronic stability system will no longer be provided by a single supplier but rather as a complex system involving multiple controllers, and the degree of coordination between various subsystems will directly determine the performance of the electronic stability system.

- Case: dTCS (Distributed Traction Control System)

Currently, major OEMs and suppliers are developing towards domain-centralized E/E architectures, but it will take some time before they are widely implemented, and currently, distributed E/E architectures are still predominant.

However, it has gradually become evident during the exploration in the industry that each sub-system has been strengthening the trend of “collaboration and cooperation”, even under the distributed E/E architecture, solutions have been developed to improve the performance of electronic stability systems. The distributed traction control system (dTCS) jointly developed by BYD and Bosch, which made its debut on the pure electric vehicle, Han, is a successful example of the coordination and cooperation between the braking system and the power system.

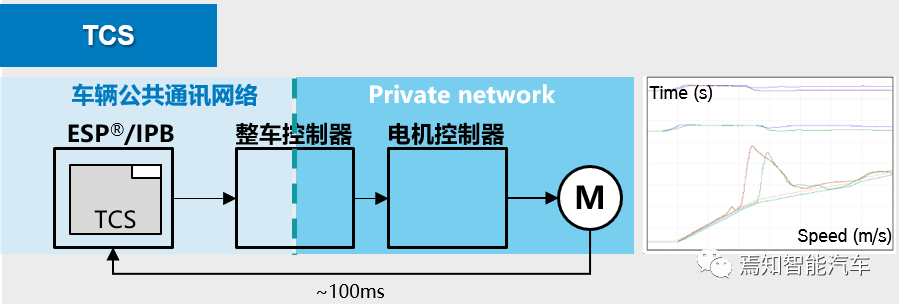

In the sixth article, we introduced the role of the traction control system (TCS). TCS mainly ensures that the vehicle can suppress wheel slip and start smoothly on an icy surface or a separated road surface (one side has a low adhesion coefficient and the other side has a high one) by restricting the engine torque and adjusting the braking pressure of the wheel end.

For pure electric vehicles, the driving motor replaces the traditional engine. Because the driving motor responds quickly and has a small rotational inertia, new energy vehicles are more likely to exceed the road adhesion limit when starting on an icy surface, and it becomes particularly important to adjust the driving torque accurately and quickly to achieve smooth starting.

The control cycle of the traditional TCS system is 20ms, and with the delay of the communication network, it takes about 100ms for the torque closed-loop response to adjust the driving torque output from wheel slip. During the closed-loop control process, the characteristics of fast response of driving motor torque and small rotational inertia increase the amount of wheel slip when starting on an icy surface, which requires TCS longer time to adjust to the target torque, resulting in a negative impact on the TCS adjustment time.

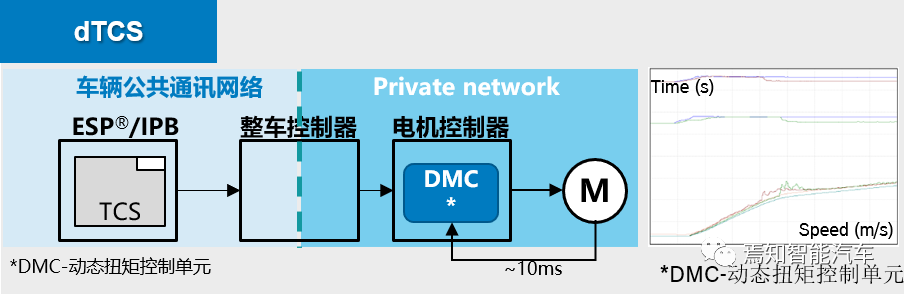

On the other hand, the control cycle of the driving motor controller MCU is much shorter than that of the ESP or IPB ECU relied on by the traditional TCS system. The latter is on a millisecond level, while the former is on a microsecond level. If the torque control module is moved from the ESP/IPB ECU to the motor controller MCU, which will greatly shorten the control time of TCS, the disadvantage will be turned into an advantage. This is the core idea of the dTCS system.

To achieve this goal, the key is to separate the Dynamic Motor Control unit (DMC) from the traditional TCS system and integrate it into the MCU software. In the collaboration between BYD and Bosch, Bosch provides the IPB system and DMC software, while BYD is responsible for integrating the DMC software into the independently developed motor controller and jointly debugging it on the Han EV Four-Wheel Drive version. This has increased the wheel drive torque response by about 10 times, greatly reduced the wheel slippage, and maintained good road grip, thus greatly improving driving safety.

The dTCS system reflects the huge space for evolution of the electronic stability system under the intelligent chassis. It can be foreseen that the implementation of the domain controller will create more space for coordinated cooperation among various subsystems, and the electronic stability system will face greater evolution.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.