Author | Tian Hui

Editor | Zhu Shiyun

To become the “leader of new energy vehicles”, BYD not only needs to have the highest sales volume, but also a top-tier brand image.

In mid-May, Li Yunfei, general manager of BYD’s automotive brand and public relations division, announced a new brand plan for BYD: four sub-brands, Ocean, Dynasty, Tang, and a high-end brand.

BYD’s high-end brand and logo will be launched in the third quarter of this year, with the first new car launching in the fourth quarter and vehicle deliveries beginning in the first half of 2023. As for the price, Li Yunfei has set a target pricing range of RMB 800,000 to RMB 1.5 million.

Entering the third quarter, more and more information has been revealed about BYD’s high-end brand:

-

The first car model is an SUV over 5 meters in length with a non-load-bearing body structure, offering plug-in hybrid and pure electric power modes. It will be the first to debut with four-wheel independent drive, wheel-end motor, and advanced chassis domain controller technology.

-

BYD’s second high-end model will be positioned as a supercar, with only a pure electric version and will launch in 2023.

From the first car, we can see the initial glimpse of how BYD plans to build its high-end brand: technology, and product power.

BYD’s Chairman Wang Chuanfu said in 2013, “we can build a Tesla in minutes.”

Now, it’s his chance to shine with the high-end brand.

Wheel-End Motor Drive, Turn On The Spot

Cars can now go off-road like a tank.

BYD’s high-end brand SUV will use four-wheel independent drive technology, providing “tank-like” turning ability.

The so-called “tank turning mode” has been demonstrated on the Mercedes-Benz EQG concept car, allowing the car to rotate on the spot around the center point of the vehicle.

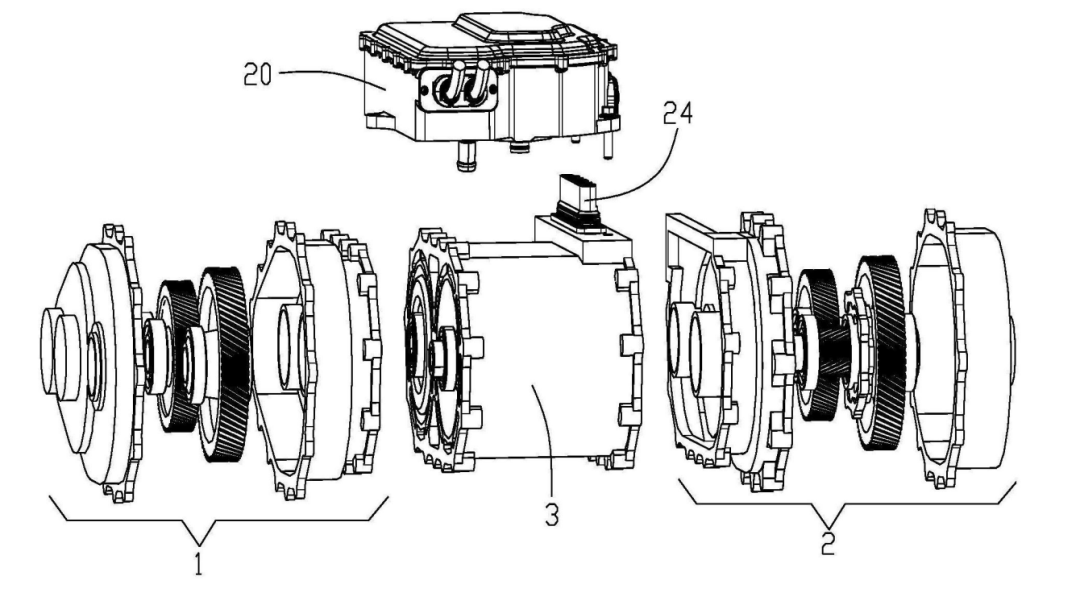

BYD’s high-end brand SUV will also achieve such a function, but using its own technical solution: wheel-end drive and four-wheel independent electric drive control.At the end of June, a new patent titled “Wheel-drive assembly and vehicle” was added to BYD’s patent pool. According to the information obtained by Electric Vehicle Observer, this technology patent is designed for BYD’s high-end brand off-road vehicles.

BYD has been deeply exploring wheel-hub motor technology for many years, and has achieved mature applications in commercial vehicles such as buses. However, it is the first time that BYD has used wheel-hub motor technology in passenger cars.

The advantage of using wheel-hub motor is that the power output is more direct, there is less transmission loss, and the motor output efficiency is high, but the disadvantage is that it takes up a lot of space. Therefore, this technology was first applied to commercial vehicles such as buses that are not sensitive to space, but to apply it to passenger cars, certain changes and upgrades are required depending on the type of vehicle model.

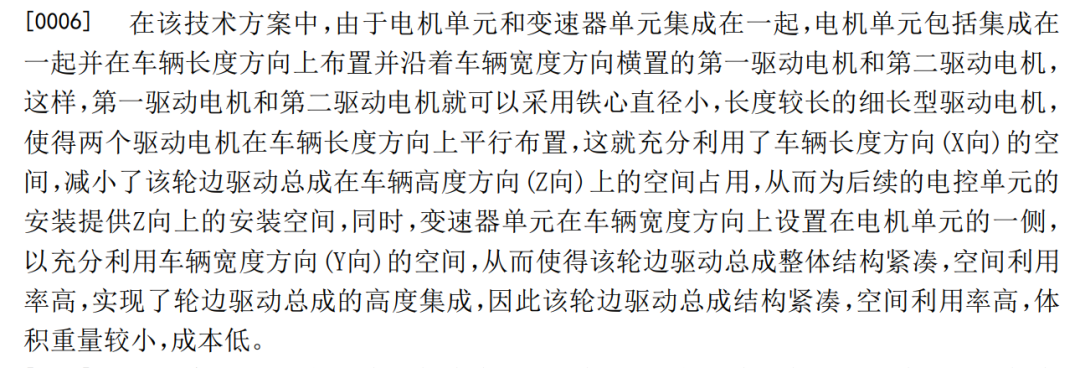

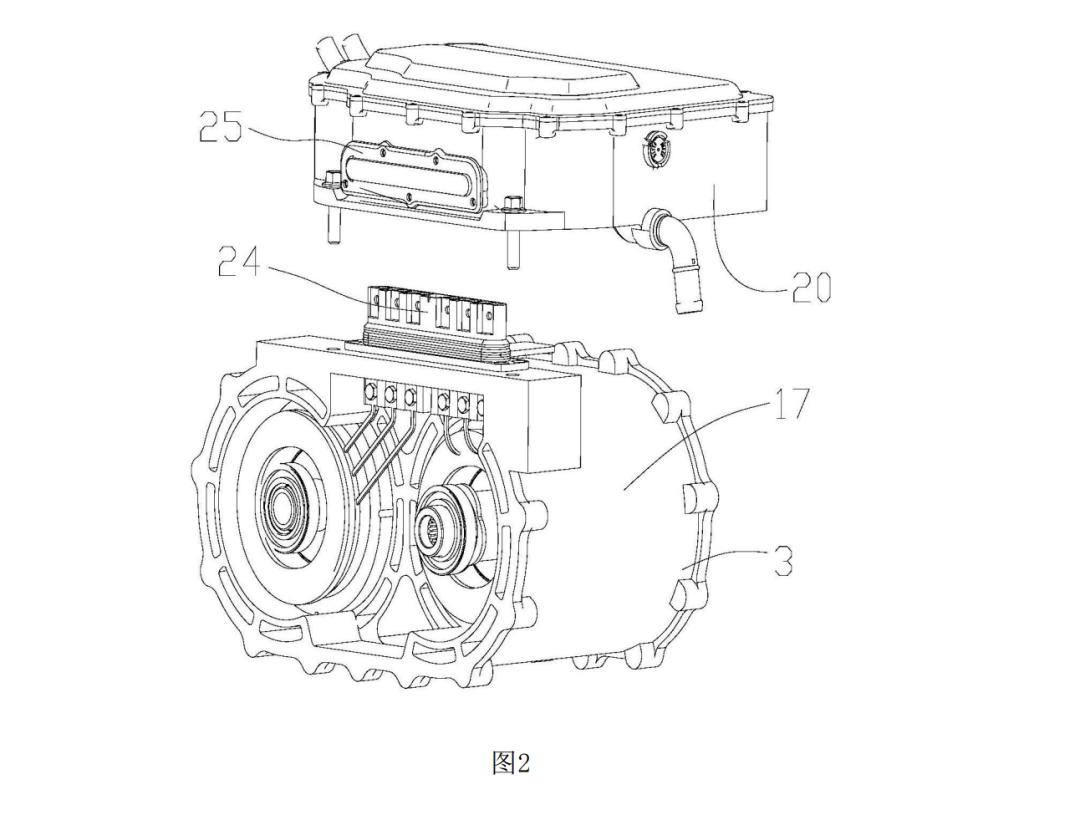

In BYD’s high-end off-road vehicle, the motor controlling the wheels on both sides is arranged parallel to each other in the direction of the car’s forward movement, and the motor is a tubular-shaped driving motor with a small diameter iron core and a large length.

After this arrangement, the outer shell of the space between the two motors and the motor cooling pipeline can be shared, achieving a huge improvement in power density volume.

This method is also related to the off-road working conditions that off-road vehicles need to face. The motor needs a higher ground clearance to reduce collisions. For off-road vehicles, improving transmission efficiency is not the top priority. Ensuring safety under off-road working conditions is the first priority, so this method is appropriate.

Currently, there are already cars with four-wheel independent motor control, such as the pickup truck model sold by American company Rivian, while the Mercedes-Benz EQG concept car has not yet entered mass production.

Compared to Rivian, BYD’s four-wheel independent motor scheme uses a drive shaft due to the need to meet off-road conditions. However, BYD’s motor layout is more compact and better suited for passenger cars.

For BYD, achieving a “tank turn” in an off-road vehicle is not the most difficult part of the motor layout, but rather the difficulty lies in the coordination of the four motor systems. In other words, the difficulty lies in writing the electric control software.

In theory, with a vehicle that uses four electric motors, any single motor driving a wheel could get the vehicle out of stuck positions in off-road conditions. However, any incorrect power output from a wheel while driving at high speeds could cause the vehicle to overturn.

“How to synchronize the driving status of the four wheels and output power correctly under different road conditions” is the problem that BYD needs to face.

A 2-meter-long “soft blade” battery

The blade battery will evolve again for high-end brands.

In the currently available BYD models, the blade batteries for pure electric and plug-in hybrid versions are not the same, meaning that their technical solutions for energy and power blade batteries are not the same.

Inside the power blade battery are multiple soft pack cells connected in series, forming the blade battery which can be viewed as a module in a traditional power battery pack.

According to Zhu Yulong, editor-in-chief of the “Automotive Electronics Design” magazine on Weibo, the blade battery prepared by BYD for high-end brand models has a length of over 2 meters and a structure that includes multiple soft pack cells connected in series and parallel, which is referred to as a “long soft blade” structure by netizens.

The advantage of this structure is that a single long soft blade cell can increase the voltage level and meet the high voltage level requirements of the entire vehicle by connecting several single-unit soft pack cells in series and parallel.

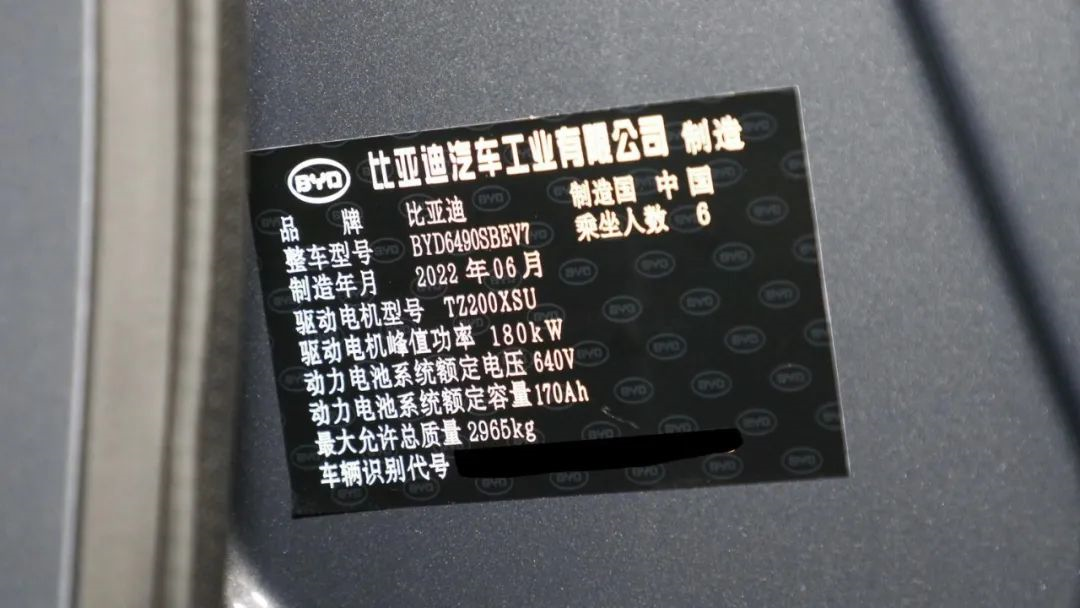

Currently, the rated voltage of the power battery pack on the pure electric version of the Tang EV already meets the high voltage level requirement, reaching 640V, which is similar to the rated voltage of the power battery pack used in the Porsche Taycan with an 800V voltage platform.

Therefore, in the future, BYD’s high-end brand off-road vehicles will definitely use power batteries based on high-voltage platforms, but there is a slight suspense whether BYD will use SiC silicon carbide MOSFT modules on power batteries to further improve the efficiency of the three-electric system.

Therefore, in the future, BYD’s high-end brand off-road vehicles will definitely use power batteries based on high-voltage platforms, but there is a slight suspense whether BYD will use SiC silicon carbide MOSFT modules on power batteries to further improve the efficiency of the three-electric system.

After increasing the voltage level, the input and output efficiency of the power battery pack is improved, which directly improves the fast charging capability of the whole vehicle and increases the acceleration performance of the whole vehicle.

In terms of power battery capacity, BYD has already mass-produced a 108.8kWh power battery pack, and the capacity of the battery pack used in high-end brand models in the future may reach the level of 150kWh.

Completely Decoupled Chassis and Body?

Whether it is possible to achieve the complete decoupling of the chassis and body is the biggest suspense of BYD’s high-end brand off-road vehicles at present.

The non-load-bearing body structure used by off-road vehicles itself has the characteristics of decoupling the body and chassis hardware. The upper body of a traditional fuel vehicle and the non-load-bearing chassis are connected by bolts and other methods, and the vehicle body can be removed separately for repairing structural components such as the body or engine when needed.

However, traditional off-road vehicles cannot achieve the decoupling of the steering mechanism. After the car body is removed, the steering mechanism still remains on top of the vehicle body.

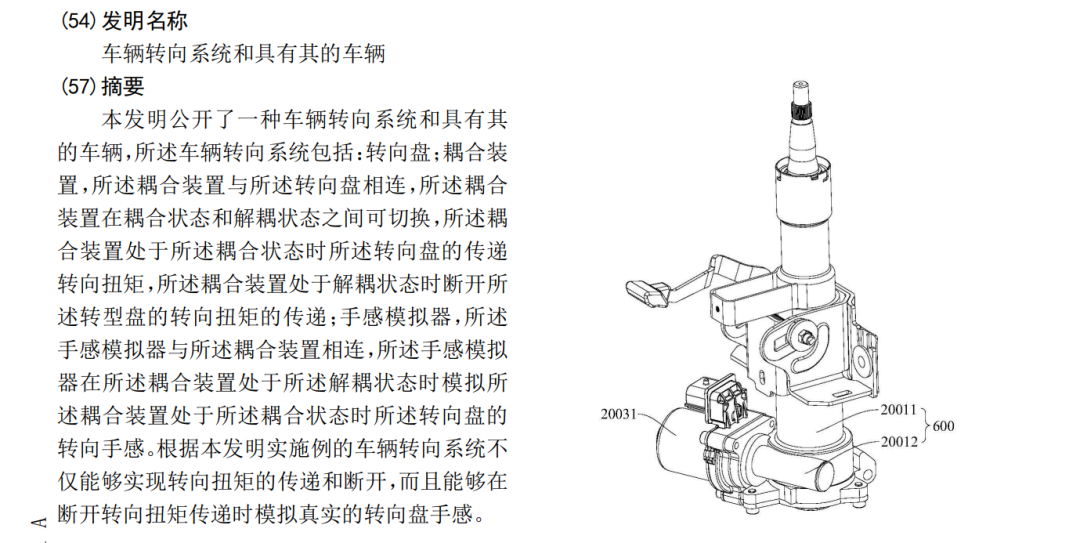

In July, BYD applied for a new patent called “Vehicle Steering System and Vehicle with the Same”, which can achieve the hardware decoupling of the steering wheel and wheels. When turning the steering wheel, the wheels can move with it or not.

Combining this wheel-side motor patent with the steering decoupling patent, what BYD wants to achieve in high-end brand off-road vehicles is to provide a new chassis solution for the future. This solution can not only be applied to off-road vehicles, but also to other types of vehicles by swapping the upper bodies.

The development rhythm of the chassis domain controller will be the key control point for whether BYD’s high-end brand off-road vehicles can achieve their development goals as scheduled.

Why Off-Road Vehicles?

BYD is not short of technology or products, but it lacks a high degree of brand recognition in the minds of consumers.

BYD: Developing High-End Models to Build Its Brand Strength

BYD, a pioneer in new energy vehicles with its leading technology and rich product variety, has seen positive feedback in terms of sales. However, its brand strength still lags behind its sales volume, partly due to its reputation being dragged down by traditional fuel vehicles in the past. Now, with the discontinuation of its fuel vehicle products, the brand image of BYD has significantly improved, and its sales performance has reached new highs, indicating its leading position in the new energy vehicle market.

Nevertheless, any large automobile group is a complex entity, and both Toyota and Volkswagen, for example, have models that are both sales leaders and well-known models.

BYD’s high-end brand must therefore undertake the role of “traffic star,” just as Bentley is to Volkswagen, Rolls-Royce is to BMW, and G is to Mercedes-Benz. A large automobile group must have its own top flagship model.

The off-road vehicle and supercar planned by BYD’s high-end brand are highly topical models. The first model will be equipped with numerous state-of-the-art technologies. This not only provides excellent product power but also satisfies consumers’ expectations of BYD. Building high-end cars that apply cutting-edge technology can help transform the traditional automobile industry.

The reveal of BYD’s high-end brand car technology, such as four-wheeled independent electric motor drive, a long soft knife battery, and chassis domain controller, has unveiled the technical veil of its high-end brand cars. These features have always been BYD’s strong suits. The greater challenge is how BYD can create the value of its high-end brand through marketing and service.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.