BMS 的计算包括以下内容:

-

SOH:状态健康度,即判断电池的健康程度。

-

SOC:电量状态,是电池电量的衡量标准。

-

剩余续航里程:通过计算当前 SOC 及行驶时产生的能量,模拟出剩余能够行驶的里程数。

-

动力系统效率:通过统计车载电池系能量流向作出的工作与热耗的比值,评估电池的恢复能力。

-

动能回收:将动能转化成电能并储存于电池中,缓解了制动能量消耗所带来的影响,延长了续航里程。

- 通讯(保护)

BMS 还需要对整个电池系统进行通讯和保护,具体包括以下:

-

与车载电脑、充电桩之间的通讯,实现车载电池信息的汇报和控制。

-

保护电池系统安全,比如防止过充、过放、短路等问题。

-

保护整个车辆,防止由于电池事故而引起的火灾和安全事故。

总的来说,BMS 是电动车电池管理系统中必不可少的一部分,它起到了统筹各个电芯状态,精确汇总成为具有参考意义的 SOC 或者是续航历程的作用,同时保障电池系统的安全性。Talking about “calculation” is actually very general. The most crucial thing here is to combine the detection data with the SOC (State of Charge), which is the state of charge of the battery, commonly known as remaining power. And the remaining mileage is actually another way of presenting it.

Don’t think that this thing is very simple, because the state of the battery is constantly changing in real time, with thousands of battery cells and tens of thousands of parameters. The industry is improving its accuracy of estimation. Most of the core algorithms in this area are controlled by battery manufacturers, such as CATL, SVOLT, Panasonic, and LG.

However, in recent years, semiconductor giants have also deeply involved in this field, such as Texas Instruments, Analog Devices, Renesas Electronics, Infineon, NXP, and ON Semiconductor.

For the mainstream nickel-cobalt-manganese ternary batteries in China, the estimation accuracy error of SOC is about 3%, and that of lithium iron phosphate is about 5%. The current integration method, discharge test method, open circuit voltage method, Kalman filtering method, neural network method may be used, but that’s not to be discussed here. You can search for it on your own.

In addition, there are also SOH (State of Health) battery health condition and SOP (State of Power) battery power state, sometimes also called SOF (State of Function), these two are also commonly used calculation results.

- Communication (Protection)

After obtaining the detection data, the vehicle needs to input these data into the ECU or domain controller for calculation, and finally display them on the HMI or send them to other places that need this data.

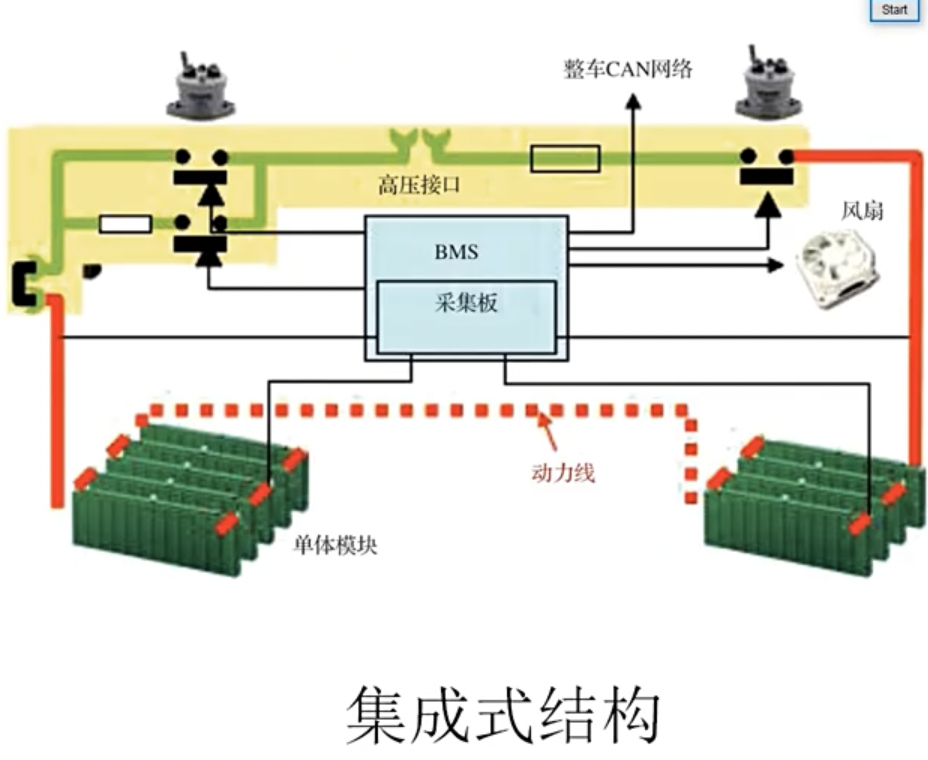

The topology structure of BMS is generally divided into centralized and distributed.

- Centralized

As the name suggests, the centralized BMS processes the collected data through a main control chip and bus, and sends out instructions, divided into high-voltage and low-voltage parts.

Although this structure is relatively simple, the length of the harness is generally longer, and the voltage difference is caused by the inconsistent harness length, which further affects the “calculation” function. Moreover, the centralized BMS layout is difficult to expand the battery size due to the limited number of channels. Therefore, it is commonly used in products with low capacity, low total voltage, and small battery volume and capacity.

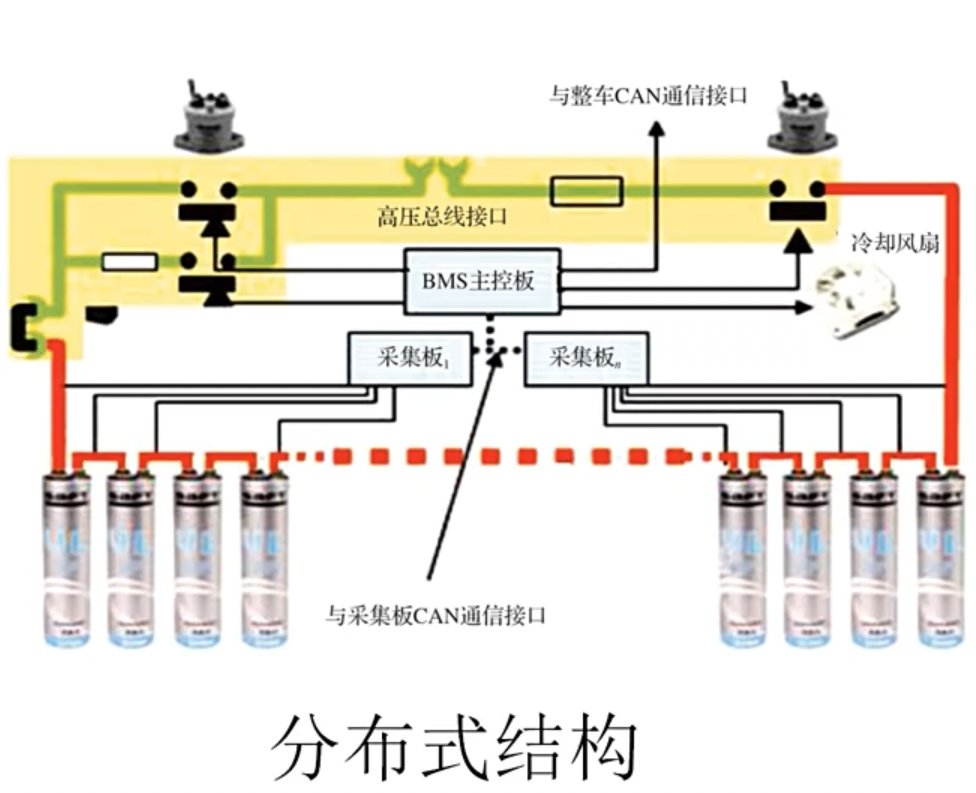

- Distributed

As the centralized architecture is not conducive to the volume and capacity changes of batteries in modularized vehicle platforms, most car companies use a distributed topology structure.## Distributed BMS

The distributed structure can be arranged by more flexible master control chips to reduce wire harness length and meet flexible battery size requirements. The disadvantage is that the cost is relatively higher.

For example, Tesla’s Model 3 has multiple battery control modules and multiple collection boards, which is a typical distributed BMS structure.

Wireless BMS

You’ve probably heard of the well-known Ultium platform from GM, right? One of the core technologies of this modular electric drive platform is wireless BMS, which can be understood as a further development of distributed BMS.

Due to the further reduction of communication wire harnesses, wireless BMS has gained greater flexibility and lower power consumption.

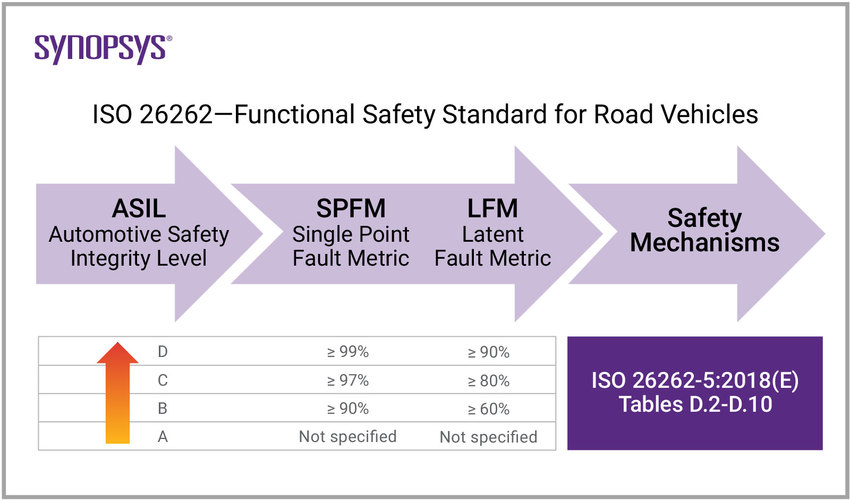

In March 2017, Analog Devices (ADI) demonstrated the industry’s first wireless battery management system (BMS) installed in the BMW i3 concept car at electronica China in Munich. The Ultium platform uses the technology of this company with ASIL-D safety level.

Texas Instruments (TI) also released its own BMS solution in January 2021, while Sensata and Honeycomb Energy signed a memorandum of cooperation for wireless communication BMS in 2019.

Protection

After having a complete communication system, the BMS directly notifies the battery-related systems whether to work. For example, if the BMS senses that the battery is warming up and needs to be cooled, it will start the cooling fan to lower the battery temperature. Another example is the charging preheating function in winter, which also notifies the PTC or heat pump to warm up the battery.

BMS and Regenerative Braking System

The working principle of regenerative braking is explained in my previous article, “What is Regenerative Braking? – 42 Garage”. Simply put, the VCU will comprehensively judge whether to activate the regenerative braking function by obtaining the signal of the brake pedal.

The current generated here will flow back to the battery after conversion, which requires the function of the BMS. For example, by comprehensively judging the percentage of SOC, it can determine how much regenerative braking should be given. It can be said that the good decoupling between the BMS and regenerative braking can effectively optimize the energy consumption performance of the entire vehicle.

Conclusion

From the perspective of consumers, here is a simple way to judge the quality of BMS. You can refer to the ISO 26262 standard commonly adopted by automobile manufacturers, which is divided into 4 safety levels from A to D, that is, Automotive Safety Integrity Level (ASIL), with D being the highest level. Normally, B/C is used, and a better one is ASIL D.

From the perspective of consumers, here is a simple way to judge the quality of BMS. You can refer to the ISO 26262 standard commonly adopted by automobile manufacturers, which is divided into 4 safety levels from A to D, that is, Automotive Safety Integrity Level (ASIL), with D being the highest level. Normally, B/C is used, and a better one is ASIL D.

In summary, it is clear how important BMS is for electric vehicles. From a safety perspective, it can greatly reduce the occurrence of battery accidents and thus reduce casualties. From a consumer perspective, BMS can also improve battery life, reduce energy consumption, and more.

From the overall trend, the wireless and flexibility of BMS is a long-term goal. With the emergence of new types of power batteries such as semi-solid-state batteries, solid-state batteries, sodium ion batteries and the further promotion of battery swap mode, the requirements for BMS capability will be further improved.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.

![[Popular Science] It turns out that BMS is so important!](https://upload.42how.com/en/2023/03/20230313050902213.png)