Author: Zhang Yi

On June 23, with a total investment of 15 billion yuan and an area of 2.9 million square meters, BMW Lida factory officially opened. Lida factory is BMW’s third complete vehicle factory in Shenyang, and also the largest single investment in BMW’s history in China, demonstrating BMW’s practical action and great ambition of “being at home in China”.

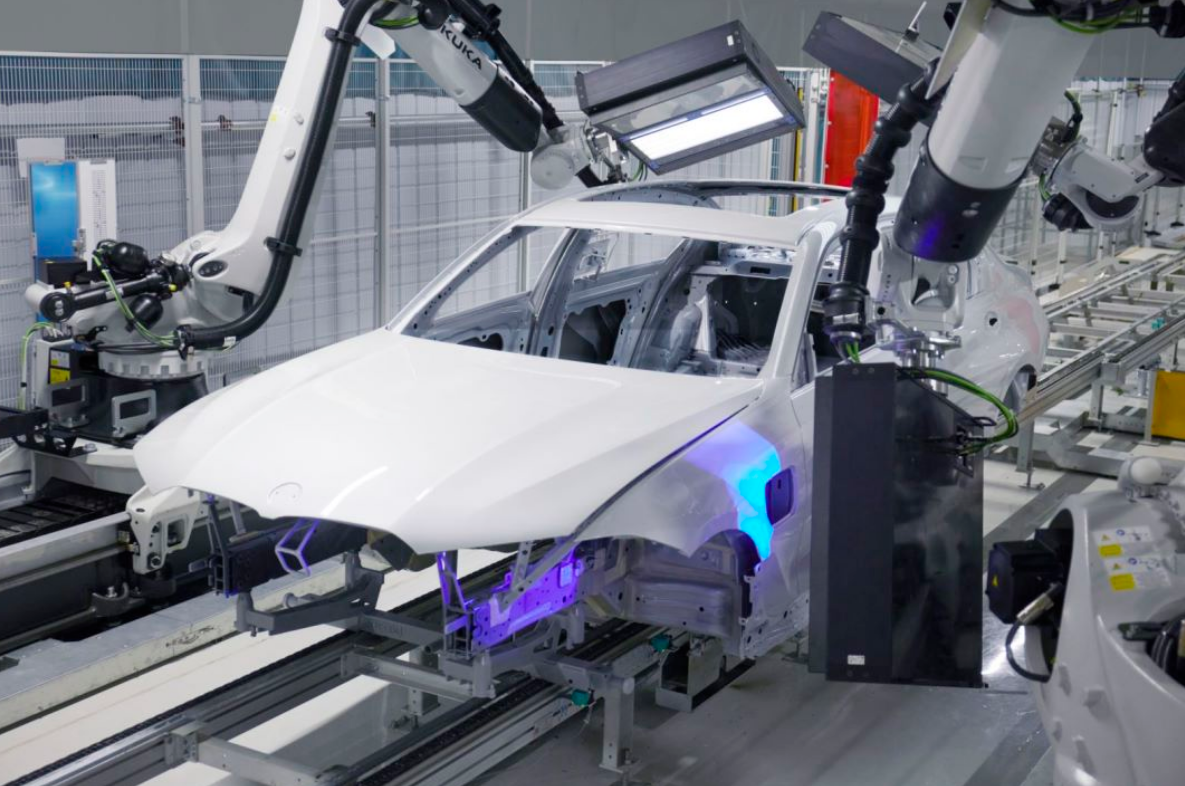

From the three dimensions of “lean, green, and digital”, BMW has transformed Lida factory into a new paradigm for automobile production. Lean production is naturally the standard configuration for BMW as a luxury car brand, and green emissions are the responsibility that BMW as a global company must shoulder. However, what is most surprising and amazing in Lida factory is BMW’s digitalization!

Based on BMW’s iFACTORY strategy, the digitalization of Lida factory is no longer the traditional physical three-dimensional digitalization, but the virtual intelligent industrial metaverse digitalization!

Entering the Industrial Metaverse

For most people, metaverse may still be a new and unfamiliar thing, let alone industrial metaverse! But in fact, the industrial metaverse is a conceptual branch of the metaverse and essentially is still the metaverse.

If it is a metaverse, it must have an immersive experience; if it is a metaverse, it must be decentralized. However, the immersive experience and decentralization in the industrial metaverse are not only related to users, but more importantly to the immersive work of designers and producers and modular production.

Compared with traditional factories, production in the industrial metaverse will undergo earth-shaking changes.

First, from user reverse-driven to user forward-driven. In the traditional design and production process, all starting points must be based on user needs. However, it often takes several years from the design of a car to its production, and there is a big question mark as to whether the design from that year can still meet today’s user needs.

However, such problems will no longer exist in the industrial metaverse. Firstly, in the industrial metaverse, users can also participate in the design and experience on the platform. For example, BMW released a cloud-based mobile game called “BMW iFACTORY Experience Tour”, where players can choose a role and visit every part of Lida factory, observe the production of every component, and experience the design of automotive products. With the deep participation of users, BMW can grasp the latest needs of users.Second, industrial metaverse breaks the restriction of geography, which allows virtual and real spaces to collide and inspire more spiritual inspiration through human-machine interaction and multi-person collaboration. It can produce designs that meet or exceed user requirements. With the help of virtual scenes and interactive experiences, the final design effect can be achieved. Therefore, design in the industrial metaverse will greatly improve the efficiency of design and save design costs.

Of course, the improvement of efficiency and cost saving are the benefits that the industrial metaverse brings to BMW. For users, deep participation can deepen their understanding of the product, reflect on their own needs, and experience multidimensional online and offline experiences.

Second, algorithms are used to break through the boundary from design to production. In the initial launch of a new product, production often slows down or defects occur because the production process does not meet the process requirements of the product. Production operations cannot keep up with changes in user demand, resulting in frequent complaints. Therefore, it must go through a difficult production ramp-up period. In BMW’s LEP factory, artificial intelligence computer vision system can take 100,000 photos and perform deep learning within 100 seconds, recognize defects on the product.

In addition, the industrial metaverse can enable intelligent simulation of the production and operation process, which can more intuitively discover problems and solve them in a timely manner. In the LEP factory, products, people, and processes are connected through the Internet of Things (IoT), and high-precision tracking of the production process is implemented. Possible risks and problems are avoided and the technical quality of each process is guaranteed.

The moment the boundary from design to production is broken, the road to the user becomes shorter and shorter.

Third, the uncertainty of delivery is reduced. Under the double blockade of the epidemic and the chip crisis, waiting for delivery for many users is often very painful.

BMW’s solution is still to use the industrial metaverse to simulate it accurately. BMW is the first to use the yard management system, which combines real-time logistics data with 3D models, to simulate various logistics scenarios in an all-round way, generate more reasonable yard planning, and more scientifically mobilize personnel and container management.

The epidemic and the chip crisis may be uncontrollable, but controllable factors still need to be firmly grasped.

Finally, it is worth mentioning that the LEP factory itself is a product of the industrial metaverse. From factory planning, building design, production line layout to equipment debugging, they all happen in the industrial metaverse. With an area of 2.9 million square meters, it only took two years from design to production. The industrial metaverse greatly improves the construction efficiency of the LEP factory.

Through the construction of the industrial metaverse and production in the industrial metaverse, the LEP factory can be said to have come and gone from the industrial metaverse.## Forge Ahead with Industrial Metaverse

It is undeniable that BMW’s current electrification products have encountered certain issues, with low market recognition and unsatisfactory sales. Thus, to salvage BMW’s reputation in the electric car market, the Lunda factory, which is oriented towards electric car production, may play a significant role in turning the tide.

It is reported that the brand new BMW i3 has already been put into production at the Lunda factory. The future of the BMW i3 remains uncertain, but even in the past, the i3, while under the blue sky and white clouds of BMW, could only rely on continuous price cuts to barely achieve sales of over 100 units per month.

Therefore, BMW has chosen the brand new BMW i3 as the first batch of models to be produced at the Lunda factory, perhaps with the intention of standing up from where they fell. Thanks to the new production methods and concepts of the industrial metaverse, the brand new BMW i3 may have some new changes in smart experience, design and handling performance.

Guo Le, President and CEO of BMW Greater China, stated: “For BMW Group, ‘Home in China’ is not only a commitment but also a concrete and continuous effort. The electrification strategy is the key to achieving our sustainable development goals, and the Lunda factory will play an important role in accelerating the transformation towards electrification.”

In addition to the brand new BMW i3, BMW will also launch four pure electric car models, including the iX3, i4, iX, and i7, in 2022. With the gradual release of production capacity at the Lunda factory, BMW’s production in China will surge to 830,000 vehicles. This means that opening up the electric car market as soon as possible has become the top priority for BMW Brilliance Automotive.

Starting from the industrial metaverse, can BMW remove its inherent label in the electric car market and continue its glorious history in the fuel car market? The riddle is written by BMW, and the solution will be revealed by you and me!

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.