After preheating of the Magic Cube battery, SAIC unveiled the Nebula pure electric exclusive systematic platform.

In 2011, SAIC launched the Roewe e50, and in 2015, it released two major technical brands, BlueCore and GreenCore. Whether it’s the time or the effort, SAIC’s sensitivity and actions in entering the electric vehicle race are not small. However, from the results, the Chinese electric vehicle market today is a battlefield where “Wei Xiaoli” teamed up with BYD to confront Tesla.

Although SAIC has already laid out the four major brands “Zhi Ji, Fei Fan, Roewe, and MG” to compete, as a big player in the Chinese automotive industry, at the critical node of the scale of the electric vehicle industry, SAIC has neither the time to establish a brand like “Wei Xiaoli” one car at a time nor the room to breakthrough, like BYD with one technical line after another.

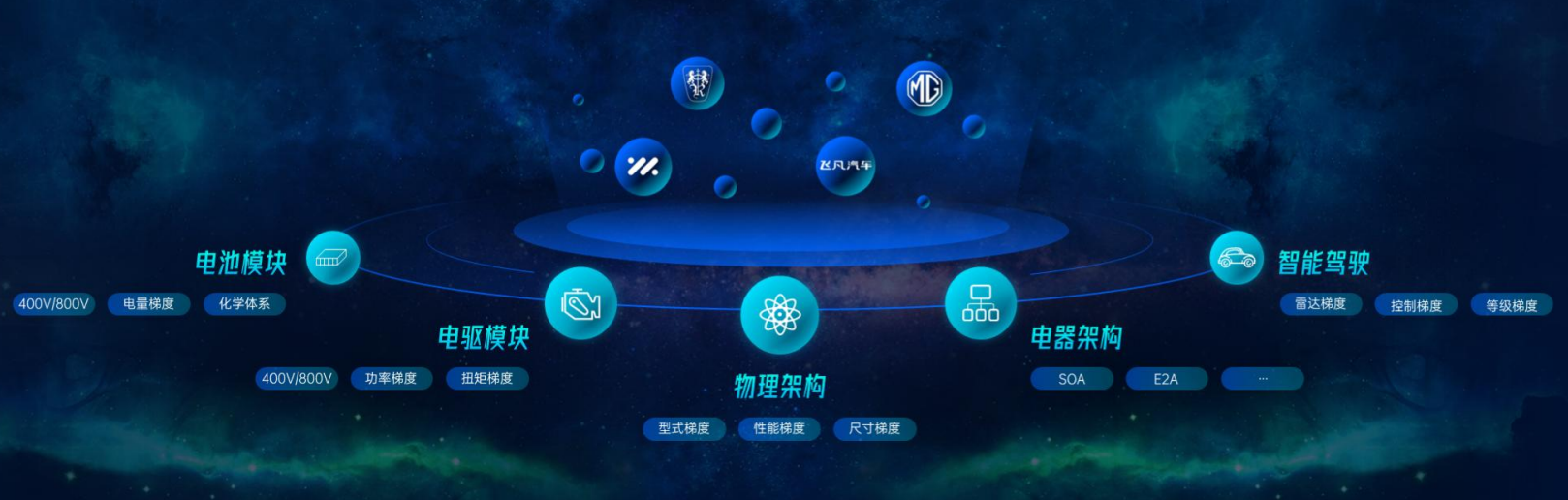

Therefore, SAIC has put out its own technical solution — the seven major technical bases led by the Nebula platform to meet the group’s demand for intelligent electric vehicle product quantity, quality, and differentiation.

How does SAIC’s Nebula platform compare to other platforms? Behind Nebula, how does SAIC solve the diversified needs of the group and its subsidiary brands from the research and development mechanism?

Nebula: Covering Four Major Brands and Five Major Businesses

Today, no platform is embarrassed to call itself a mature automaker. However, SAIC Nebula is different from all the platforms that have already mass-produced, and the only one that can be compared may be Volkswagen’s SSP architecture, which will be officially mass-produced in 2026.

The fundamental reason is that SAIC Nebula needs to become the technical foundation that supports SAIC’s four major brands and five major business lines.

In 2021, SAIC clarified the four major brands of Zhi Ji, Fei Fan, Roewe, and MG, covering mass-produced, personalized and luxury series markets, as well as five major business sectors of vehicles, parts, mobile travel and services, finance, and international operations. This means that on the one hand, SAIC Nebula supports a wide range of brands and car models and, on the other hand, needs to achieve a balanced integration of different requirements for each business.

Currently, only the SSP architecture that supports Volkswagen Group from Porsche to SEAT has been announced to support such a broad platform and business line.

“All platform companies are most afraid of insufficient bandwidth and gradient of the platform. After finishing a platform, they find that the next car coming requires more resources. This is quite annoying.” Lu Yong, Executive Vice President of SAIC Innovation Research and Development Institute, stated to “Electric Vehicle Observer,” “To meet demand, one must have great foresight and inclusiveness for the market. This platform often requires certain time and quantity support to make investment more efficient.”Lu Yong said that in just 2022-2023, the Nebula platform will produce as many as 16 electric vehicles. “We also see that the electric vehicle market will be a straight line upward from 2022 to 2025, so (introducing the Nebula platform) is the right time.”

According to the plan, by 2025, SAIC Group will achieve sales of over 8.4 million vehicles worldwide (based on calculations). Among them, independent brands will account for more than 55%, and intelligent electric vehicles will account for 20%. This means that SAIC’s independent intelligent electric products will be at least around 920,000.

At the same time, SAIC Nebula is also a change in the SAIC R&D system.

“The essence of the Nebula platform is a graded modular library, which all brands can choose from, can demand module combinations or even add some of their own modules to form competitiveness, and charge intellectual property fees when other brands reuse the combinations.”

Kang Huaping, Deputy Director of Innovation Research and Development Institute of SAIC, told the Electric Vehicle Observer: “Our modular library has a concept of a technical shelf, which currently only controls more than 70 key modules and reduces constraints on brands. In the future, as long as there is demand from brands, the R&D Institute will continue to iterate and upgrade this shelf.”

The “shelf concept” has always been the basic model for car companies’ systems and platform engineering. But before, most of them only applied services to a few similar product lines and brands.

In essence, the “shelf” can serve as many types of customers, on the one hand, depending on whether it has enough technical accumulation to cover a wider range of car models, brands, and markets; On the other hand, it depends on whether it has enough market size to amortize platform development costs and achieve profitability.

Volkswagen Group’s MEB platform mainly covers Volkswagen brands and downgraded brands, with plans to achieve global sales of 15 million units by 2028. The SSP platform that will cover all brands and segmented markets is expected to produce and sell over 40 million units.

Nebula Platform: Gradient, Expandable, and Upgradable

Can the Nebula platform bring the same scale effect to SAIC as the Volkswagen SSP platform and serve different brand characteristics and subdivided market demands? This depends on the width and breadth of its technical coverage.

“The development concept of the Nebula platform is gradient, expandable, and upgradable,” Kang Huaping said. “Based on this gradient, we can derive pure electric architectures of different levels, and series products with performance, intelligence, and cost gradients.”

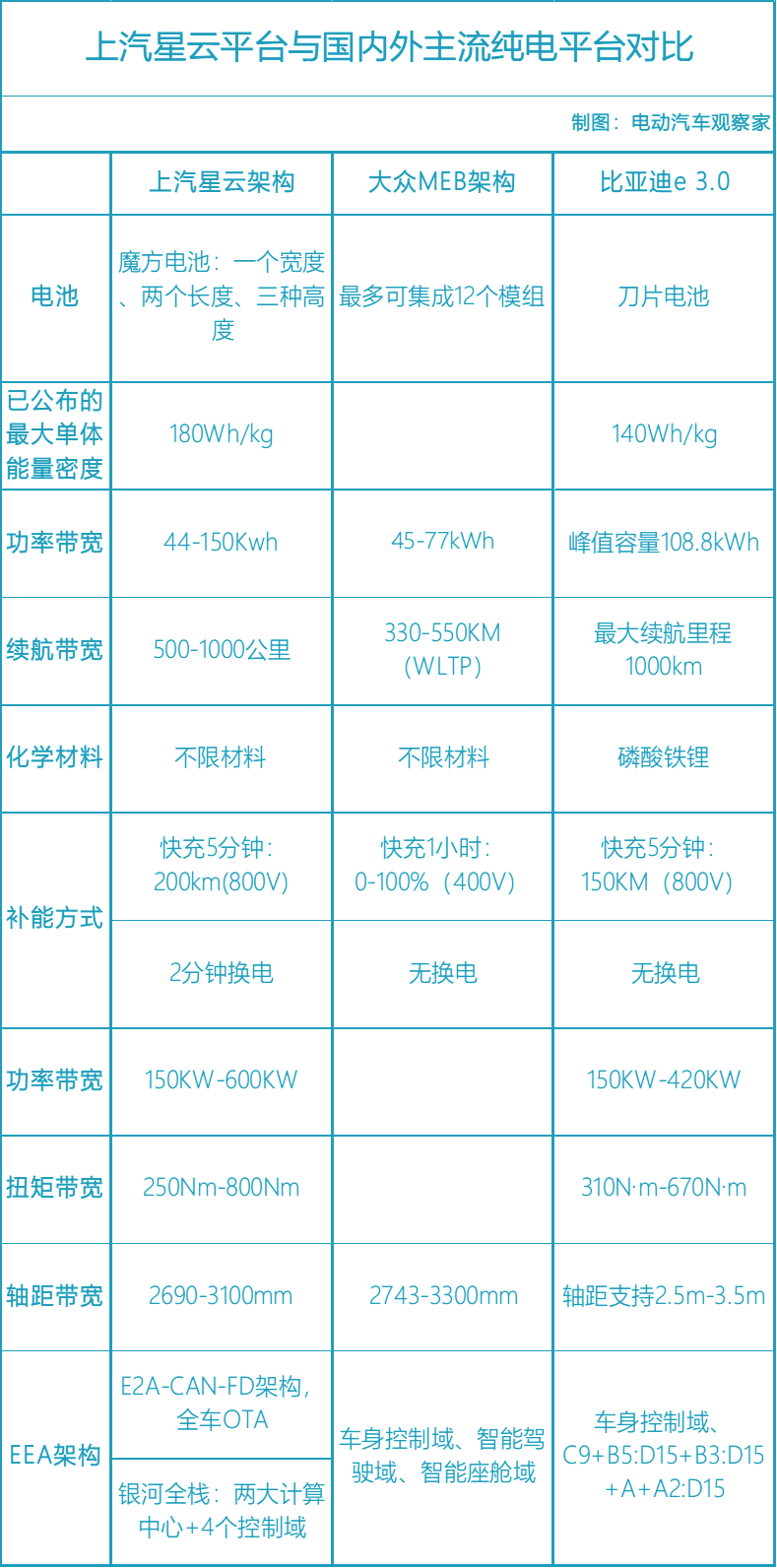

The pure electric platform is mainly composed of three modules: battery, electric drive, and chassis, and is controlled by the EEA electronic and electrical architecture. In these four levels, the Nebula platform has significant differences from current mainstream pure electric platforms.

SAIC Star Cloud Platform Compared with Mainstream Pure Electric Platforms at Home and Abroad

Battery Module Gradient

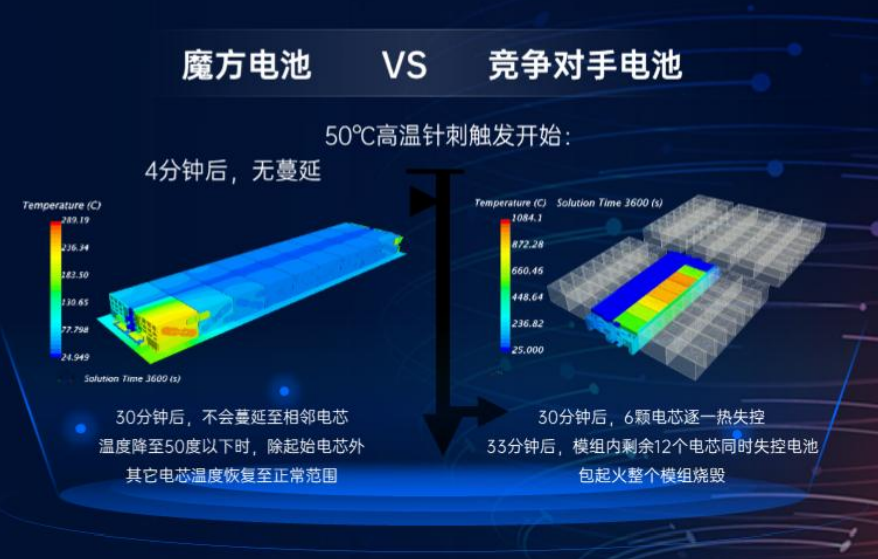

The Magic Cube battery can cover a variety of chemical systems such as lithium iron phosphate, ternary lithium, and semi-solid, providing 10 gradient energy levels ranging from 51 degrees to 135 degrees. The battery size covers different vehicle types including sports cars and 7-seater cars.

In addition, the Magic Cube battery provides gradient energy replenishment methods such as fast charging and battery swapping. Its 5-minute fast charging can provide 200 kilometers for 800V and 100 kilometers for 400V; battery swapping can be completed in only 2-3 minutes.

In comparison, there are some gaps between the Magic Cube battery and the blade battery of BYD 3.0 e platform, the cartridge battery of GAC GEP 2.0 platform, etc., in terms of coverage of chemical systems, product standardization, and charging and swapping mode.

The Volkswagen MEB platform still uses battery modules in the form of pouch cells, and can only increase the vehicle’s battery capacity by using different chemical material cells. The maximum range is currently 550 kilometers (WLTP). However, Volkswagen also announced at last year’s Battery Day that 80% of its models will use standardized battery cells.

Electric Drive Module Gradient

The electric drive module used in the Star Cloud platform is the GreenCore Drive System that SAIC has accumulated over the past decade, providing two voltage platforms of 400V and 800V.

On the 400V voltage platform, the A, B, and C three electric axles of 150kW, 180kW, and 250kW can be freely matched or used separately.

On the 800V voltage platform, the output power of Axle A, B, and C are 200kW, 350kW, and 400kW, respectively.

Therefore, the power options for rear-wheel drive vehicles range from 150kW to 400kW, and the power options for four-wheel drive vehicles range from 330kW to 600kW.

As a result, the four-wheel drive mode of SAIC’s vehicle can achieve 0-100 km/h acceleration in 3 seconds, and the two-wheel drive mode can achieve it in 5 seconds.

By comparison, the Volkswagen MEB platform born in 2019 only provides a 400V voltage platform.

Interestingly, the domestic secondary electric drive system used by MEB was jointly developed and produced by Magna and SAIC Huayu for vehicles with a power of less than 250kW, and will be launched in Asia, Europe, and North America.# BYD e-platform 3.0 offers 400V and 800V voltage platforms with peak power of 150kW and 270kW for front and rear drives respectively, slightly lower than the Green Core system in terms of data.

Chassis Module Gradient

The chassis module of the StarCloud platform supports from A to D level vehicles.

Front suspension module: MacPherson and double wishbone, configurable air springs and CDC.

Rear suspension module: Five-link for wide and narrow track, configurable air springs and rear-wheel steering.

Steering module: BD for large vehicles; DP for medium and large vehicles.

Optional steel or aluminum subframes.

As the results show, the turning radius of StarCloud platform vehicles is smaller, ranging from 13.6 to 14.7, while MEB is 14.7 and BMW3 is 14.6. The lateral acceleration that reflects the limit grip performance is close to 1g. By comparison, the lateral acceleration for regular vehicles is greater than 0.8g, for luxury vehicles greater than 0.85g, for high-performance vehicles greater than 0.9g, and for racing cars greater than 1g.

“The smallest mechanical space and the largest riding platform are the core developed by StarCloud,” said Kang Huaping. “For the series of StarCloud platform vehicles, the platform is over 200mm larger than that of the fuel vehicle platform of the same length.”

Larger riding space is one of the characteristics of pure electric platforms. For example, the ID.3, which uses the MEB platform, has a wheelbase 134mm longer than that of the e-Golf, despite its body length being 10mm shorter than that of e-Golf.

EEA Gradient

As a “latecomer,” SAIC StarCloud platform provides two sets of electronic and electrical architecture gradients to meet the current mainstream vehicle OTA needs and the high-level intelligent driving assistance needs of L3.

Among them, the E2A architecture uses CAN FD bus with variable transmission rate up to 8Mbps. It supports up to 64 bytes of data length and more frame formats, enabling whole vehicle OTA online upgrade capability and various mainstream vehicle networking capabilities.

The other is the third-generation “Galaxy Full-Stack System Solution,” which uses the “central computing + regional control” mode. According to official SAIC data, it has two central computing centers and four control domains, supporting L3+ advanced intelligent driving capability, “cloud, management, and end” data-driven system.Currently, most intelligent leading automakers in the industry still use domain control mode. In contrast, SAIC’s Galaxy Full-stack has taken a direction towards a higher degree of cross-domain integration.

In addition, the “cloud-management-terminal” digital-driven system is essential to achieve the end-to-end data system required for data-driven intelligent driving self-iteration. Currently, Tesla and XPeng are leading the way ahead of mass-produced automakers.

Scalability

Beyond the gradient of multiple systems, the scalability of technology is the key feature that sets the Nebula Architecture Platform apart from other mass-production platforms.

According to Lu Yong, SAIC’s integrated solid-state battery technology is already in progress, and the experimental verification vehicle will soon be seen. The integrated die-casting technology is in the project initiation stage, CTC prototype cars will be exhibited this year, and the wire-controlled chassis is currently in the process of breaking through. Scene-based autonomous driving based on the cooperative communication between the vehicle and the road, as well as data application, is also in development.

The Nebula Architecture reserves positions for the application of these technologies, thus achieving continuous iterative growth.

Exploration of SAIC’s R&D Center Platform Mode

This year, the Nebula Platform was one of the seven major technical foundations that first appeared at SAIC’s shareholders’ meeting. It includes three major vehicle technology foundations (“SAIC Nebula” pure electric systematic platform, “SAIC Zhufeng” mechanical and electrical integration architecture, “SAIC Xinghe” hydrogen energy-specific architecture) and four major key system technology foundations (“Lanxin” powertrain system, platform-based “Magic Cube” battery system, “Lvxin” electric drive system, “Yinhe” full-stack intelligent vehicle solution).

Along with the appearance of the seven major technical foundations is the brand new “SAIC R&D Center,” which has become a vital step for SAIC to explore innovative mechanisms in the technology R&D field.

Since 2000, SAIC has established new energy-related research institutes/technology centers and a series of innovative science and technology enterprises, such as software centers, cloud computing, and artificial intelligence, according to different technology directions. “The Innovation Center aggregates all resources in the innovation and technology fields of our (SAIC).” Lu Yong said:

In the process of going from “dispersion” to concentration, the Innovation Center has also completed the transformation from cost center to value center.

Lu Yong stated that the Innovation Center is primarily located in three areas.

First, it is the integrator of the whole vehicle product., jointly founded the creation center with IM and RisingAuto to carry out the R&D of the whole vehicle products of the four brands under the SAIC group. The technology needs to be vertically integrated within the system, and the horizontal integration between different technical systems needs to be realized to produce more competitive products.

Second, it is the source of forward-looking technology.## The Third is the key technology development base

“Through the development of key technology base, we can achieve the maximum efficiency of sharing, greatly shorten the development cycle of (various brand whole vehicles), share more of our development investment, and improve the conversion efficiency of the entire group’s R&D investment.”

Lu Yong said that based on the three positioning of whole vehicle integration, technology foresight, and commercialization conversion, the SAIC Innovation Center is facing three major tasks.

First, as a relatively neutral and independent R&D platform, under the concept of SAIC, it provides corresponding R&D services for various brands.

At the same time, solve the problem of incentive mechanism. The Innovation Center currently has more than 5,000 R&D personnel, and will increase talent investment in software and overseas digital security in the future.

To better motivate talents, the Innovation Center is exploring ways to convert incubation, virtual equity, and project conversion as value incentives.

Specifically, market-oriented incubation of team entrepreneurship and technological innovation achievements of Innovation Center engineers, as well as personal intellectual property conversion.

Through virtual equity binding and joint creation of value with IM, FF, and MG, incentives are provided for the R&D team when joint creation brings about market value or value improvement.

Third, the integration of internal and external technologies is upgraded again to accelerate research speed in integrated circuits, artificial intelligence and other areas.

Lu Yong said that for a series of technology innovation companies under SAIC, the Innovation Center will include technology integration in overall management, create a closed loop of SAIC’s technology innovation ecology through unified landing and planning of whole vehicle projects.

For example, the Cube Battery, GreenCore Electric Drive, and Galaxy Electronic Electrical Architecture are all technical achievements from various R&D teams of the SAIC Group. The Innovation Center integrates these three major technologies into competitive modules “commodities” through the Nebula platform, providing them to internal brands of the group, allowing them to scale up to products far beyond the “each to its own” mode.

Electrification and intelligent transformation are fundamentally a sustained and intense technological innovation competition. Early accumulation is SAIC’s advantage, and the core technological advantage of the Nebula platform is a result of more than ten years of previous accumulation by SAIC.

However, to achieve sustainable iterative upgrading of later-stage technologies, it is necessary to adapt to the institutional promotion of innovation. And innovation system is the weak link of SAIC as a state-owned enterprise. The Innovation Center is a starting point for SAIC to respond to the mechanism from the bottom level.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.