Author: Zhu Yulong

The CATL’s Sword battery aims at the 4680 cell, and some comparisons are also made on the performance of 4680 on actual vehicles.

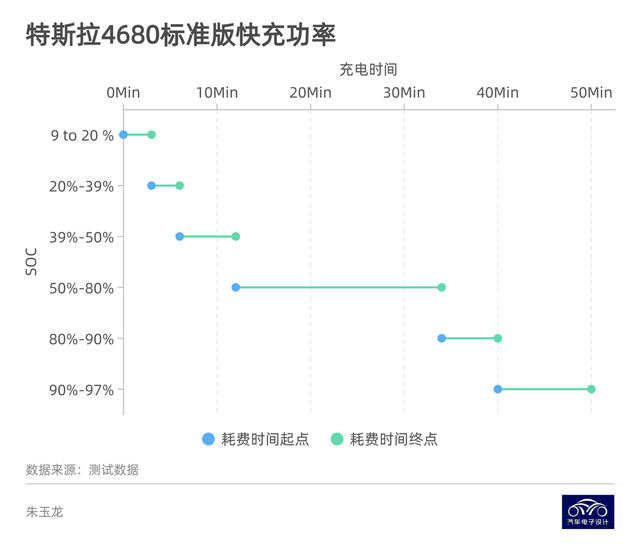

Currently, in the 4680 products delivered to consumers, the fast charging test of standard cruising range can charge 80% in about 30 minutes. The entire charging process of 4680 is recorded as follows:

-

9% to 20% in 3 minutes

-

9% to 39% in 6 minutes

-

9% to 50% in 12 minutes

-

9% to 80% in 34 minutes

-

9% to 90% in 40 minutes

-

9% to 97% in 50 minutes

Conversion of fast charging data

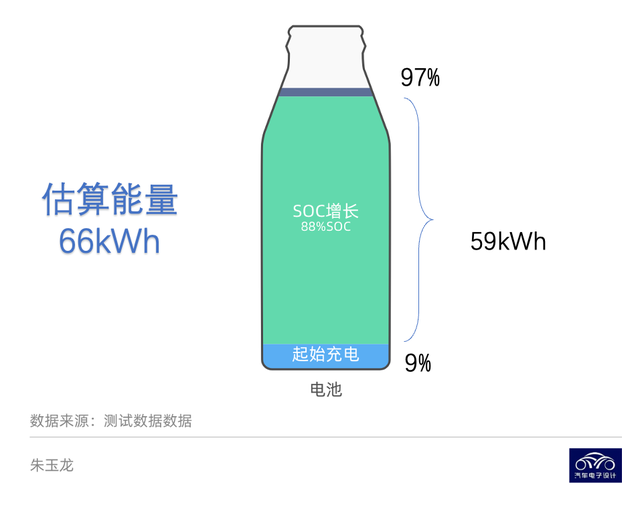

Currently, the EPA cruising range of 4680 Model Y standard AWD is 279 miles. During this charging process, charging from 9% to 97% consumed 59 kilowatt-hours. At the same time, some quick math calculations show that Model Y’s available battery capacity is about 66 kWh.

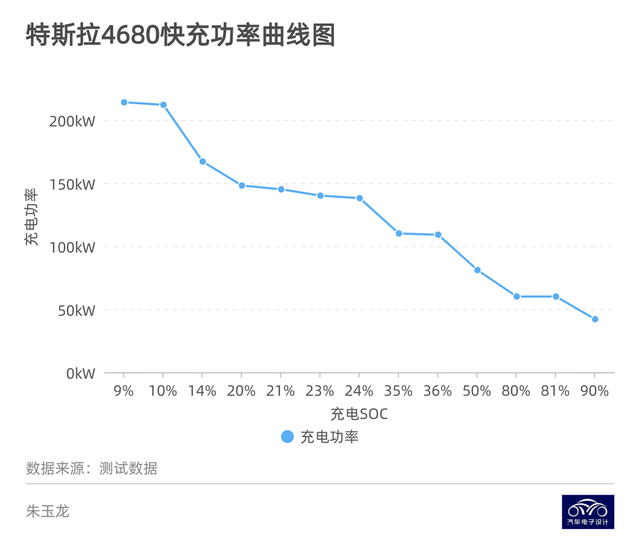

According to the data, the peak power of this 66kWh battery pack is 227kW (this data should have a deviation of around 5%). I didn’t see this data, so I drew the curve of the overall charging power myself after intercepting the screen:

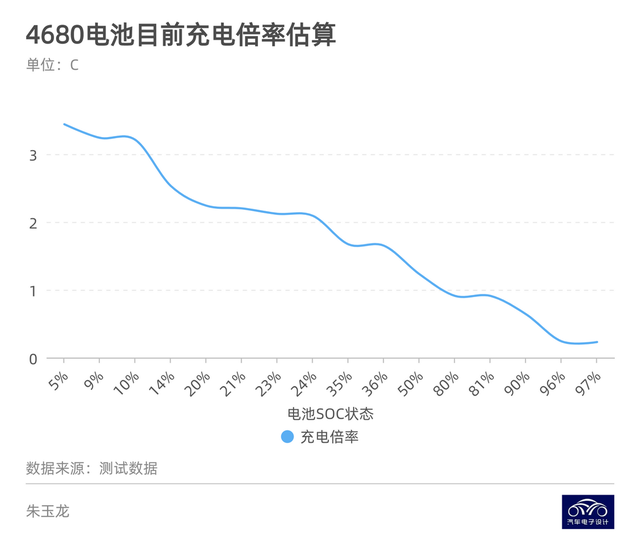

If it is converted into rate data, this graph may be clearer. There are indeed some challenges here. This is based on the consideration of instant power, and the change of rate is taken into account. The data state seems to drop a bit fast.

Due to the time effect above, I estimate that the range of the rate can be more accurate based on the time at different SOC. When describing it, I estimate that the actual 11%-20% range is only 2 minutes, and the 20% to 39% range is 4 minutes, to match the instantaneous rate above.

It seems that this data is somewhat different from our expectations. Based on the currently available information, the fast charging speed of 4680 is mainly affected by how the heat is dissipated. When designing for fast charging above 3C, not only are there many problems with the characteristics of the battery itself, but the data for heat dissipation also becomes crucial.

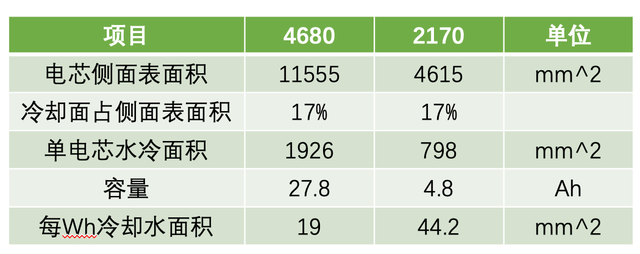

In the entire battery design, Chiba made some comparisons, which I think is very interesting: using double-sided cooling really increases the cooling surface of the whole battery, and this surface area can also be used to deduce how much cooling plate area is needed. If estimated, we can get the weight of the water cooling plate.

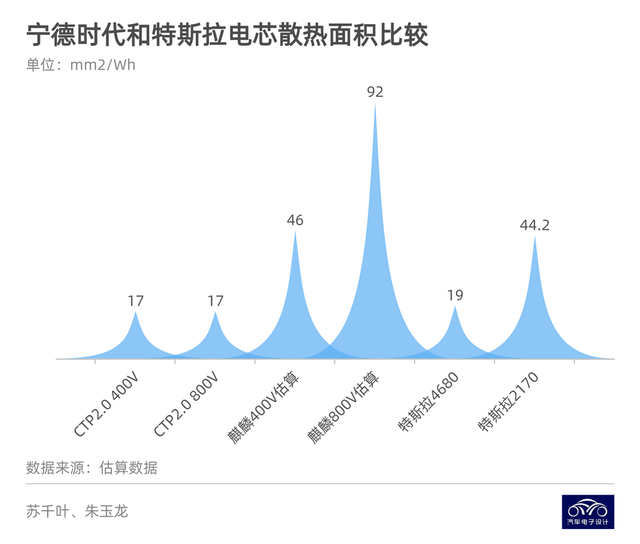

This 4x data comparison is mainly based on 800V. If the 400V system is used with a thick battery, the comparison should be about 2x.

Compared to the 2170, the cooling area advantage of the 4680’s serpentine cooling tube is offset by the increase in battery size. From the data, it is not particularly good, which is why Tesla wants to add a top water cooling plate. The cooling surface area from 2170 to 4680 is not good for single-side cooling.

Note: According to different information sources, the top of this generation of 4680 design of Texas is actually mica sheet. Due to the data below, in order to fully carry out the heat, a top water cooling plate is planned. The speed of iteration and improvement of the 4680 battery is faster than we imagined.

If we compare the cooling water area of Kirin in terms of Wh:

Summary: In Pack structure, it is interesting to consider extreme heat management. When we work on performance packages, we can verify our assumptions with actual data. Qianye has done some data calculation, and I have collected some data for reference.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.