Author: Zhu Yulong

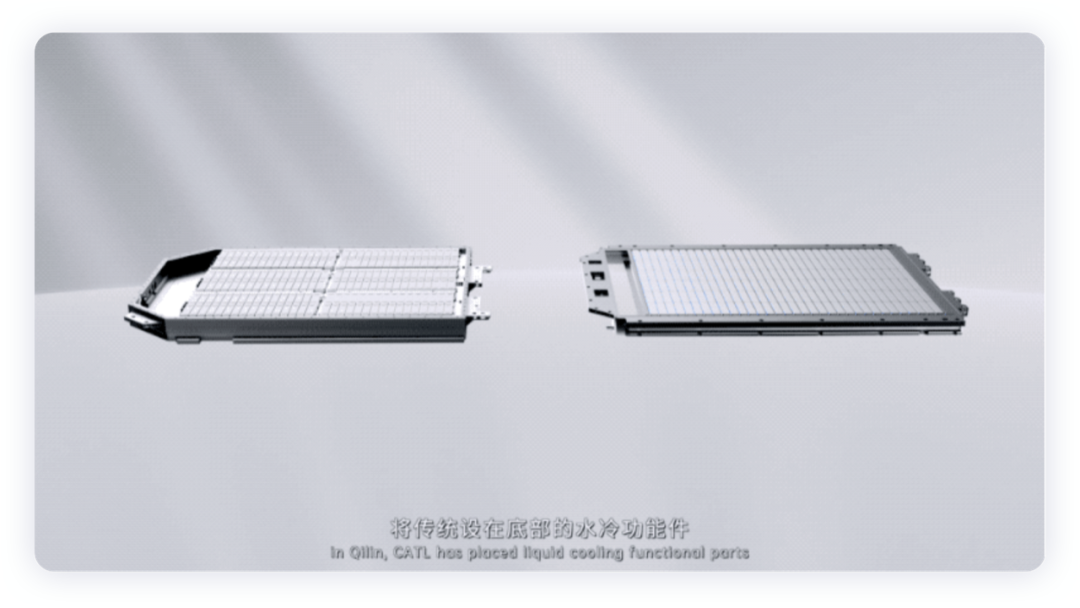

Yesterday was really unexpected! CATL has announced its “true” Kirin battery, which, amid no significant differences in overall parameters, is characterized by the emergence of the inverted bat battery. Now CATL has already included various poses of shell batteries.

-

Standing battery

CATL VDA, 590 module, CTP1.0, CTP2.0 all

-

Lying battery

Designed by SAIC Roewe plus CATL

-

Inverted battery

CTP3.0 true Kirin battery

The true Kirin battery was originally planned to replace the layout diagram of the CTP3.0 platform module standing on the background of Bairenhui. Let’s take a look at the characteristics of this battery system according to the information I received.

Design Concept

Firstly, the third-generation CTP true Kirin battery has a volume utilization rate of over 72%, an energy density of up to 255Wh/kg, and a mileage of 1000 km. Let’s focus on its characteristics.

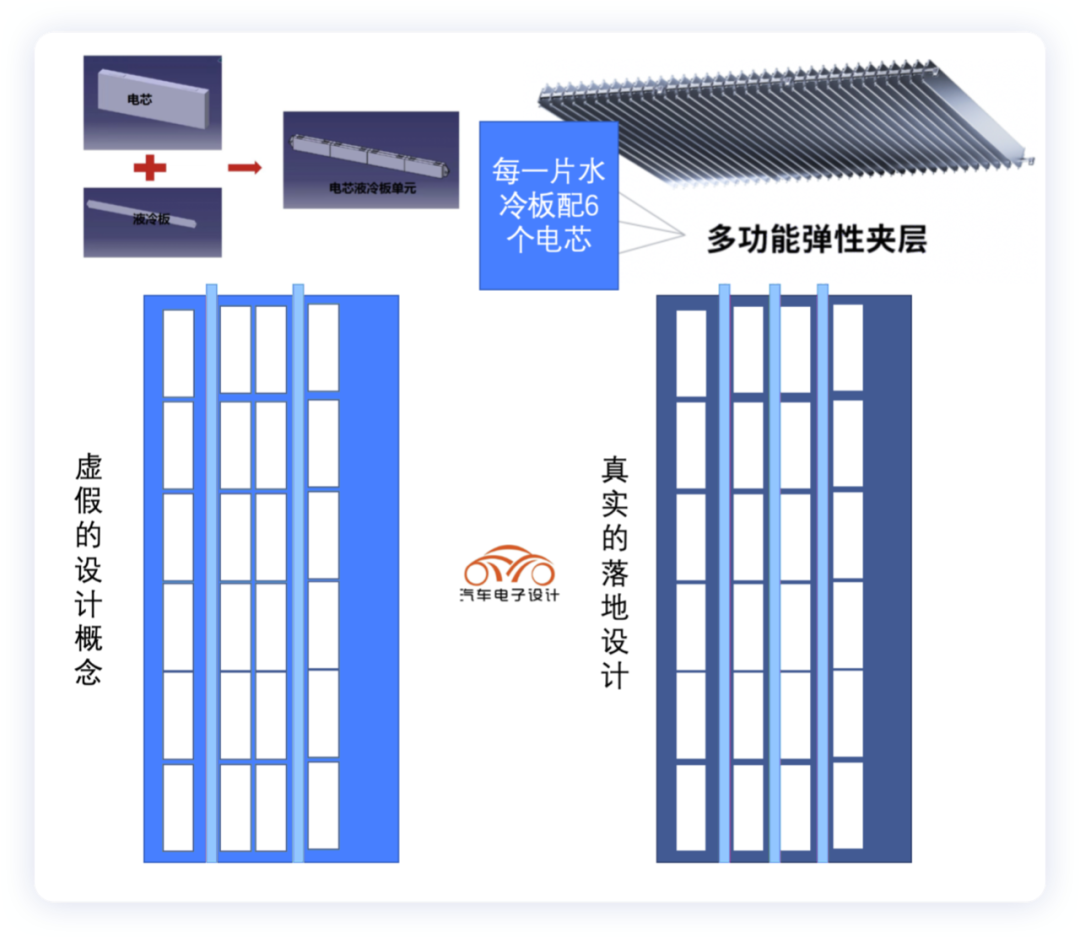

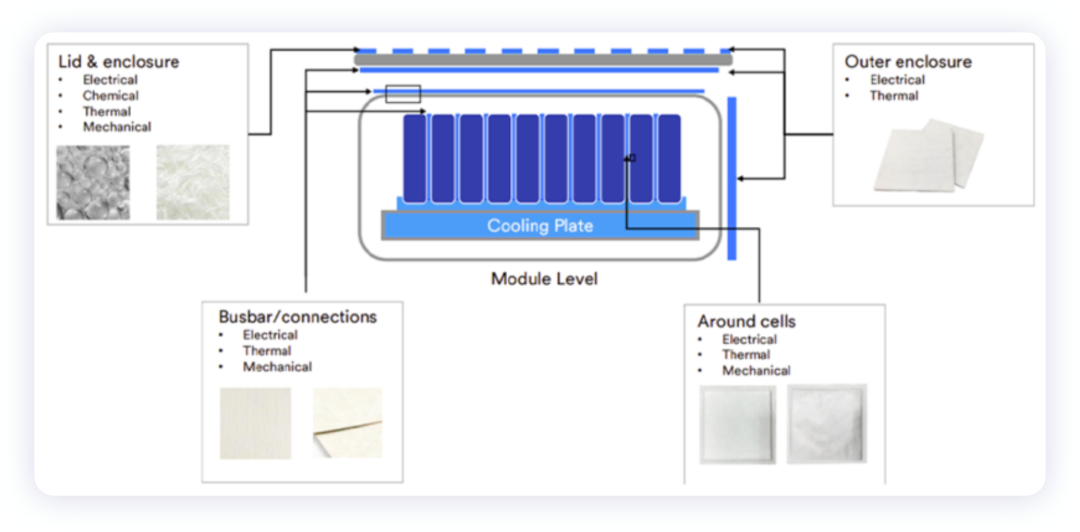

Water Cooling Plate

The Kirin battery integrates the transverse longitudinal beams, water cooling plates, and insulation pads into a multifunctional elastic interlayer. The interlayer is equipped with micrometer bridge connection devices, which can flexibly cooperate with the cell respiration to freely extend and improve the reliability of the cell during the entire life cycle. The integration of cells and the elastic interlayer into an energy unit improves the stability of the force structure in the direction perpendicular to the travel direction, and enhances the battery pack’s vibration and impact resistance.

My question is whether the same design applies to both high-nickel and iron-lithium batteries. Assuming the LFP version of the Kirin battery uses the same design, is this dense water-cooled plate with iron-lithium necessary?

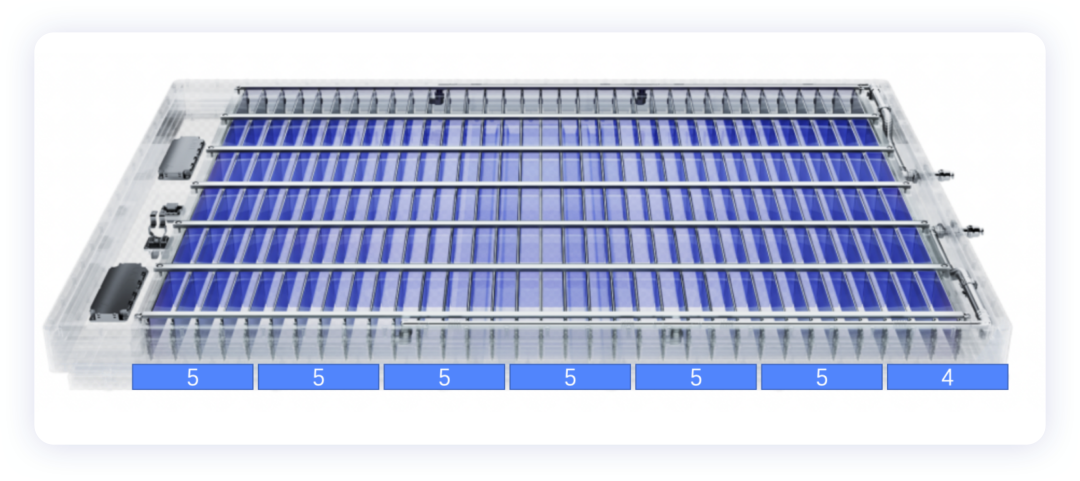

If calculated by 6*34=204 cells, according to a design of about 3.62V for ternary high-nickel + silicon-carbon, the system voltage is 738V. The number of water cooling plates seems a bit excessive.

### Reshaping the Structure in Z Direction

### Reshaping the Structure in Z Direction

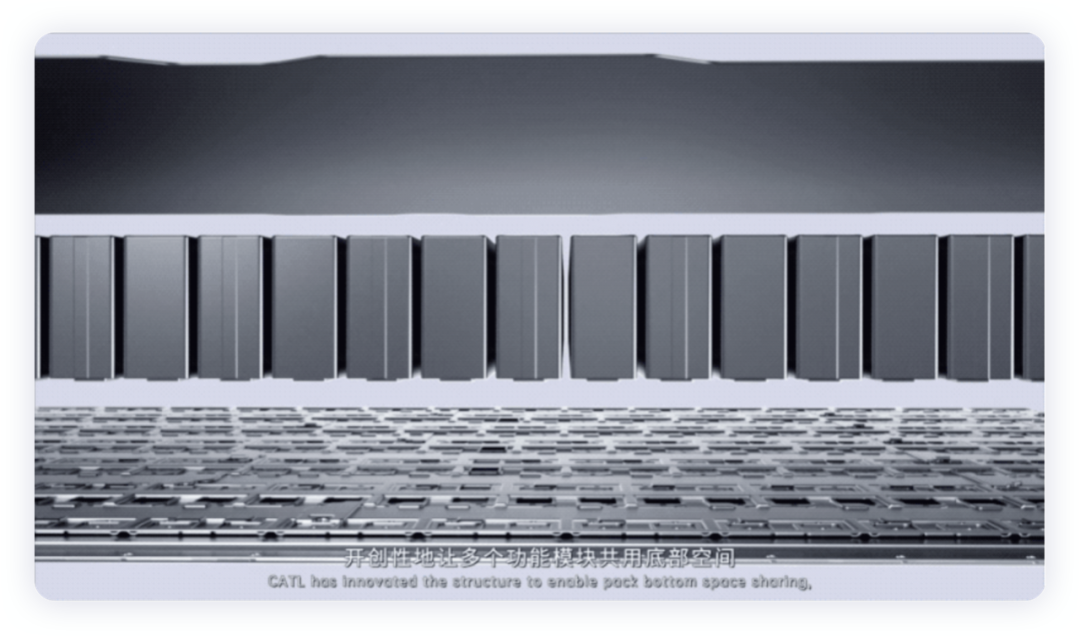

The biggest differentiation and variable in this design lies in the Z direction. In order to find a way to utilize the Z direction, as the height of the Z direction needs to be broken down into tray thickness, bottom water-cooling plate, cell height, cell tabs, CCS (Busbar), air gap (smoke channel), and top cover, the effective volume layout of the traditional square shell cell is improved in the Z direction. The volume utilization rate exceeds 72%, and the most important breakthrough of 6% is to turn the battery upside down.

By inverting the battery and making it stand upside down like a bat, the bottom space can be shared to achieve an intelligent distribution of structural protection, high-voltage connection, and thermal runaway venting modules, which releases 6% of the energy space. It can meet the safety test requirements for bottom ball impact and other national standard batteries.

The part that I am particularly curious about here is in the process of thermal runaway venting of the cell. If we consider how to quickly release high-temperature molten slag and smoke, where will the smoke go if the space below is compressed?

Due to the need for traditional square shell cell design to provide space for CCS and cell venting, the loss of Z-directional height has a significant impact.

This inverted battery was originally designed to be used for CTC, so that the upper battery can bear pressure and the upper cover can be removed.

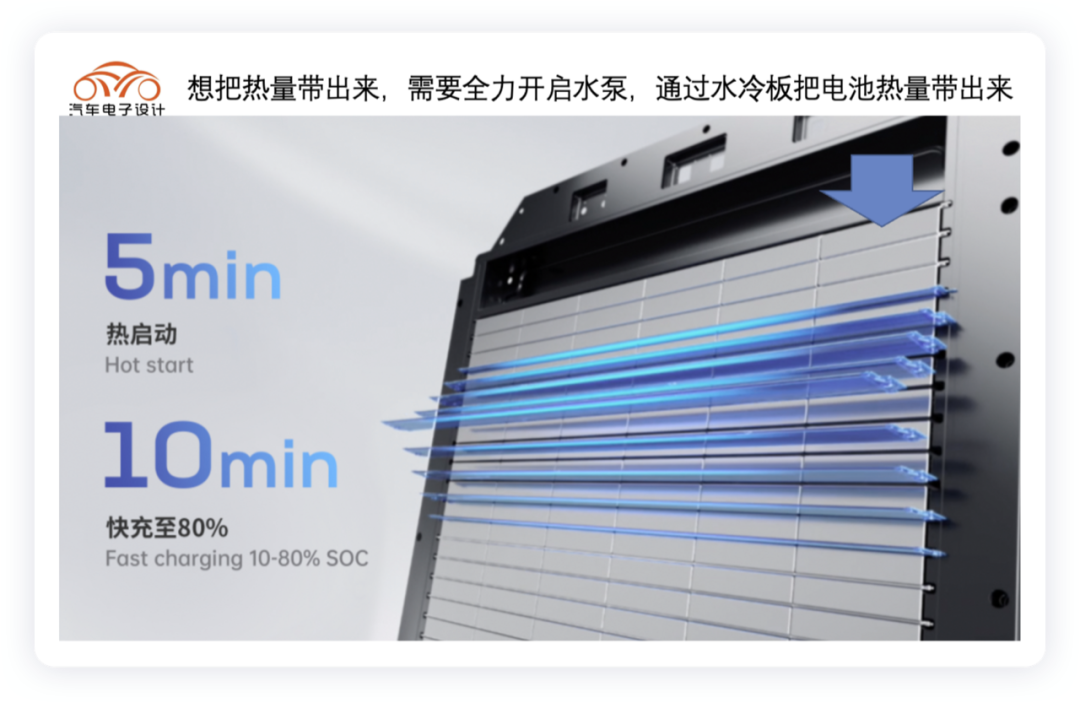

Consideration of Heat Dissipation of Water-Cooling Plate

In the fast charging design, the cell enjoys two large cooling surfaces at the same time, by placing the water-cooling function between the cells, the temperature control time of the cells is shortened by half, supporting 5-minute rapid start-up and 10-minute fast charging. In the case of thermal runaway of the cell, the cell can rapidly cool down, effectively blocking the abnormal heat conduction between the cells. However, due to the large number of heat dissipation plates, is there a need to handle the external water pump, and does the external detection mechanism need to operate the water pump immediately after the cell vent is opened?

Personal View on CATL Battery

As per my assessment, (of course, this is also based on the CATL’s official image and concept battery).

-

LFP does not require so many water cooling plates, which is to say, the design of these 34 water cooling plates is mainly for high nickel content to achieve 255Wh/kg; due to the height of the battery cell could be further increased to above 102mm, the transformation rate is mainly achieved by inversion.

-

How to improve the specific grouping rate of LFP, also depends on utilizing the Z-height of 6%? Let’s estimate that the 6% of 120mm is about 7.2mm, which is similar to the effect of canceling the floor. Therefore, I am quite curious about how much energy can be accommodated in the seal vehicle of Hippopotamus. The current focus of competition revolves around how much energy can be contained in a battery pack of the same size, including CATL’s Blade Battery, BYD’s Blade Battery, and the subsequent Honeycomb Energy’s Short Blade Battery.

Conclusion: My personal thoughts are not important, what we need to observe is to what extent the intense competition between CATL’s 4680, and the blade batteries will go. Being a battery company is not easy, so let us take it easy.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.