Author: Zhu Yulong

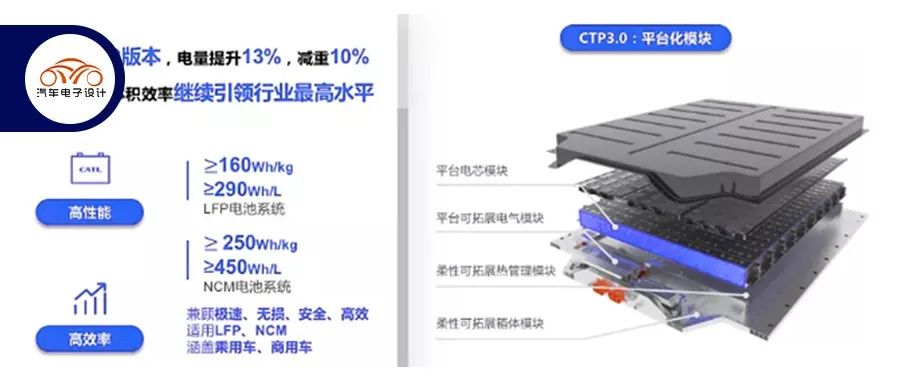

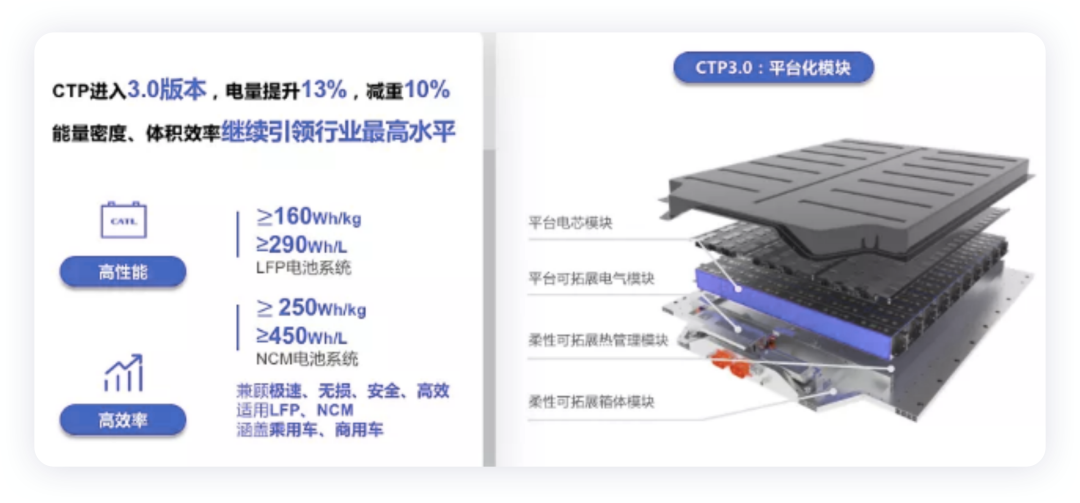

A few days ago, Wu Kai, the CEO of CATL, confirmed at the 2022 World Battery Conference that CATL will soon release the CTP3.0 battery (Kirin battery), which has been mentioned repeatedly and will soon become a product available to the market. In this article, I will discuss the design of this product and its characteristics, such as high speed, lossless, and safe performance, as well as its relationship with the 4680, blade, and magic cube batteries.

Design of Kirin Battery

We have already introduced the basic information regarding this product:

Kirin battery is a flat platform cell module that is compatible with both LFP and NCM, and it is also compatible with the subsequent manganese-based M3P. When the energy density of a 300Wh/kg battery pack is increased to 250Wh/kg, the matching rate can reach up to 83.3%. In reality, the cell’s energy density can reach about 285-290Wh/kg, which means the matching rate can be as high as 87.7%.

From the information released so far, the Kirin battery uses a flat tray with no longitudinal or transverse beams, low-expansion cells, and a cell body for the structure’s requirements.

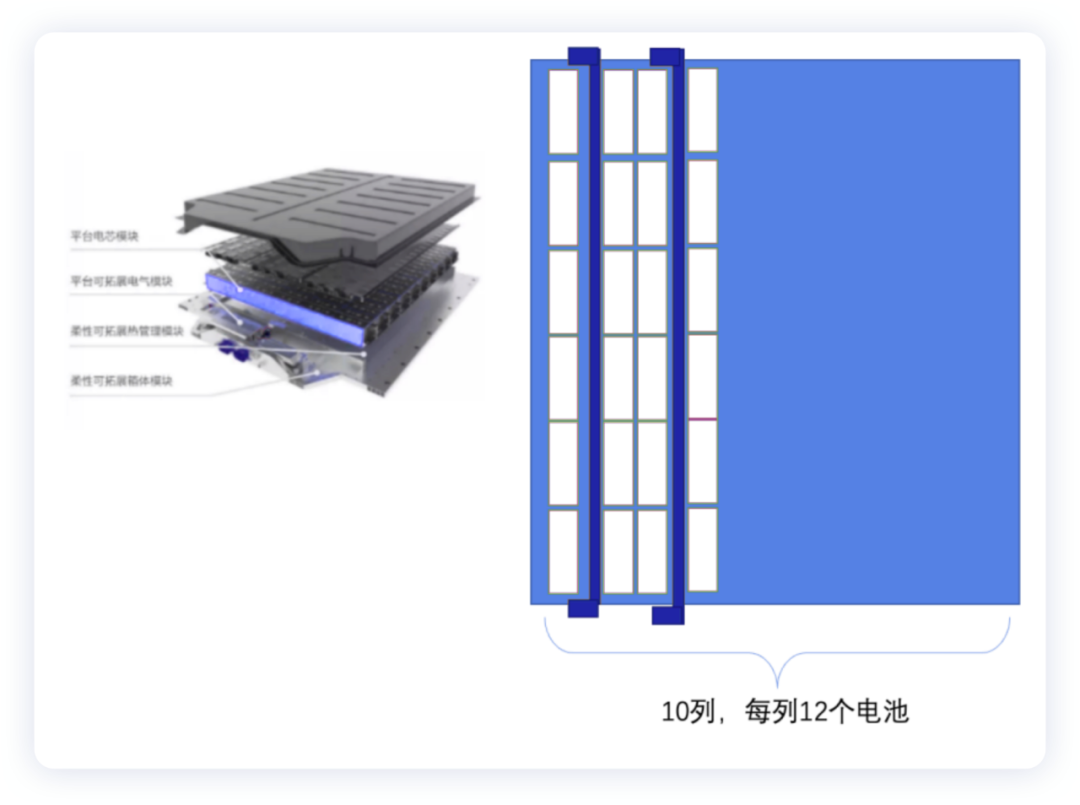

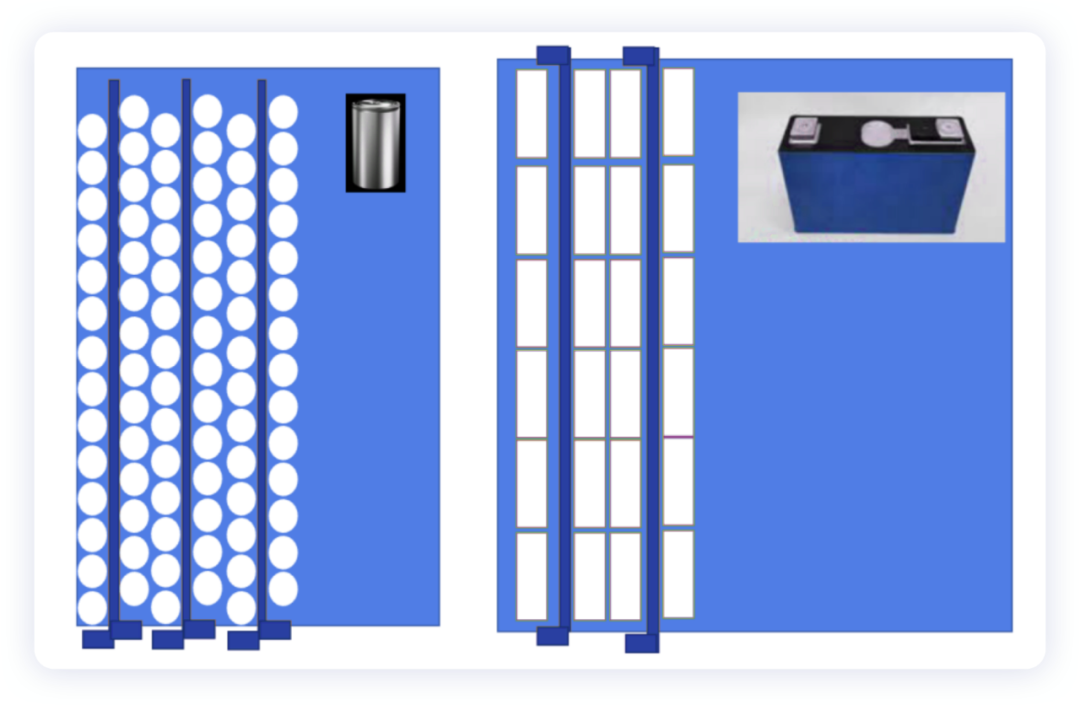

According to the current schematic diagram, the design shows 10 columns and 120 individual cells with water-cooled plates added in between two cells to reduce heat conduction between adjacent cells and avoid thermal runaway. This design is somewhat similar to the layout of the 4680 battery, and we can display the design commonality of the two batteries very clearly when placed together. I am curious to know if the square-shell battery also requires aerogel insulation on the side due to the use of an air gap for the 4680, but with direct contact with the water-cooled plate, it can withstand more heat after thermal management is activated. The effect of the entire design under the high-nickel doped silicon system may only be visible after the battery is launched, which is highly anticipated.

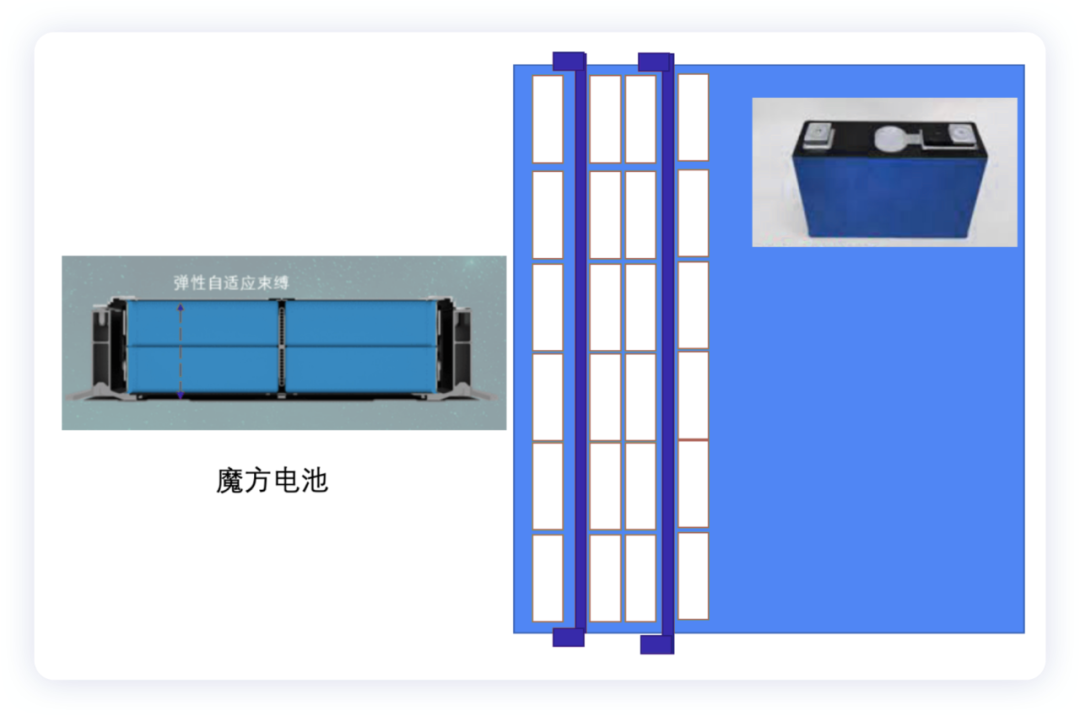

In terms of thermal runaway, Kirin battery, like the magic cube battery, can sacrifice up to two cells, and side insulation is a more mature solution.

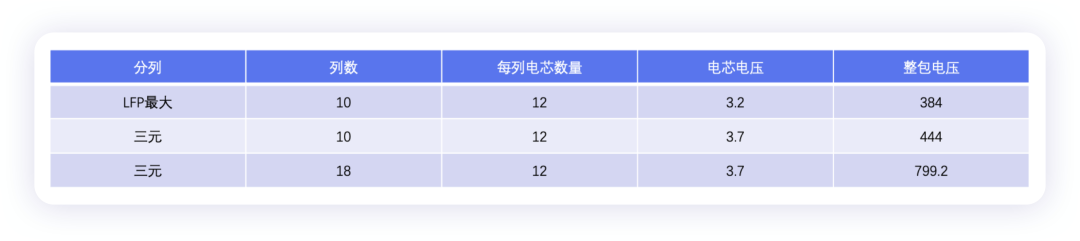

And we can also consider both 400V and 800V. In the case of 800V, the thickness of the battery can be reduced by half, and a similar design can meet high-voltage fast charging, and 4C charging is not difficult. We can see it in the market next year. However, if we consider the 800V design, the number of columns may have to increase to 18, which means that the battery cells need to be thinner and more water-cooled plates need to be added as shown in the table below. And under 4C, it may be necessary to continue to maintain the design of the water-cooled plate at the bottom in order to effectively reduce heat dissipation.

And we can also consider both 400V and 800V. In the case of 800V, the thickness of the battery can be reduced by half, and a similar design can meet high-voltage fast charging, and 4C charging is not difficult. We can see it in the market next year. However, if we consider the 800V design, the number of columns may have to increase to 18, which means that the battery cells need to be thinner and more water-cooled plates need to be added as shown in the table below. And under 4C, it may be necessary to continue to maintain the design of the water-cooled plate at the bottom in order to effectively reduce heat dissipation.

From a lifespan perspective, since the batteries do not directly contact each other, the lifespan of the batteries can be greatly improved, and the water-cooled sheet metal serves as a cushion. This has already been attempted in the Magic Cube battery. Two batteries are pressed together through the bottom plate and the top cover. As long as the lifespan expansion is considered to be 8%, the design of the Kirin battery is similar, with water-cooled plates used as partitions.

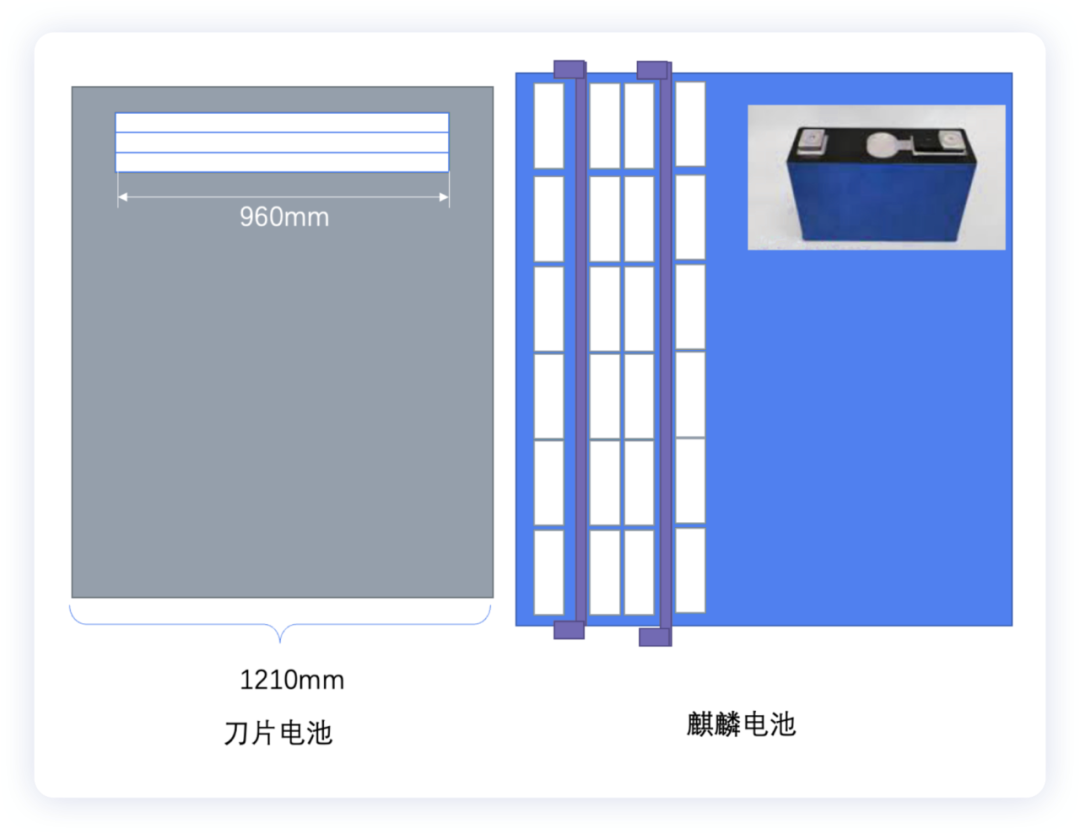

Of course, from an energy efficiency perspective, four is higher in specific energy, and the Kirin battery can improve space utilization. The energy density of the lithium iron phosphate system is 160wh/kg, and the ternary high-nickel system can reach 250wh/kg, with 13% more energy than the 4680 battery if calculated by volume. I actually think that the current design of the Kirin battery is like cutting the blade battery into six pieces, and then sticking them together with glue and water-cooled plates, achieving the strength of the battery pack in a “fish-like” structure.

Currently, the domestic short-knife and long-knife have generally cancelled the beam and rely on their own long shells to stick together. However, the Kirin battery widens the width of the battery and it can be approximately 1.1m in effective layout distance. The width of the battery cell is about 183mm after calculation.

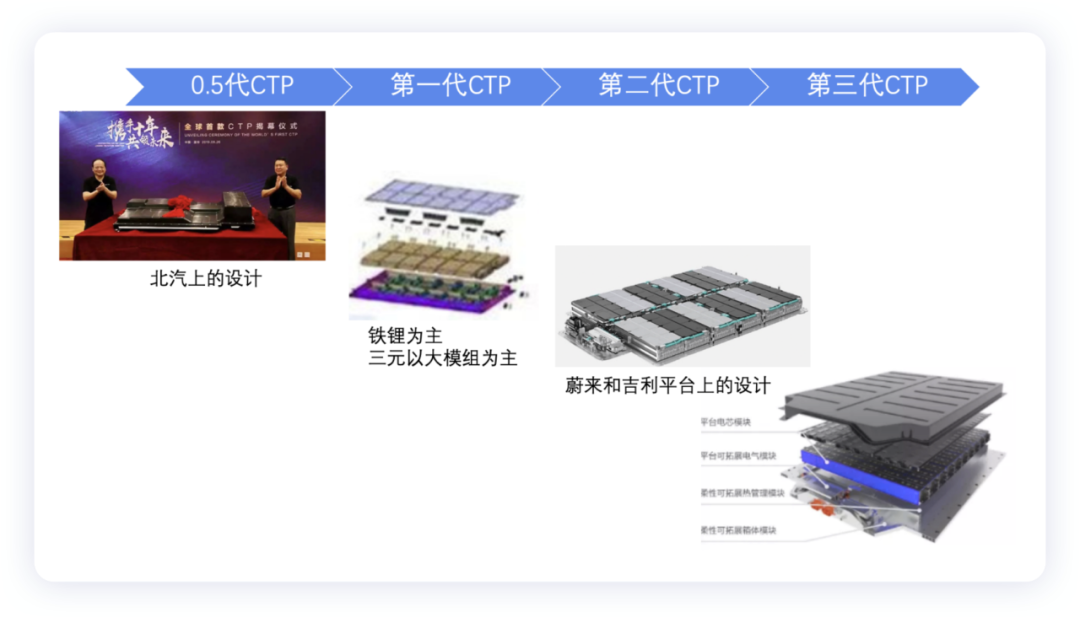

Design Iteration of CATL

Let’s take a look back at the third-generation CTP of CATL:

- The prototype of the 0.5-generation CTP: It was first released on Beiqi and did not seem to have good performance.- The first generation of CTP (passenger cars) refers to the solution adopted on buses, which is somewhat similar to the custom large module (subverting the VDA355 module), by reorganizing the size of the original module structure, removing the side plates of the module, and replacing them with straps, which can reduce weight and improve grouping rate.

- The second generation of CTP optimizes the two end plates of the module (which play a role in pressurization), and uses the longitudinal and transverse beams on the battery box to replace the end plates, making the best use of existing structural design without destroying the strength of the battery shell.

- The third generation of CTP is the Kirin battery.

Summary: Ningde Times has the most engineers and cell engineers among global battery companies. I think having so many customers has advantages and disadvantages. The advantage is that many common design elements can be effectively transferred to create better solutions. Of course, the biggest feature here is to grasp the main points and let go of the details.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.