Introduction to CMS

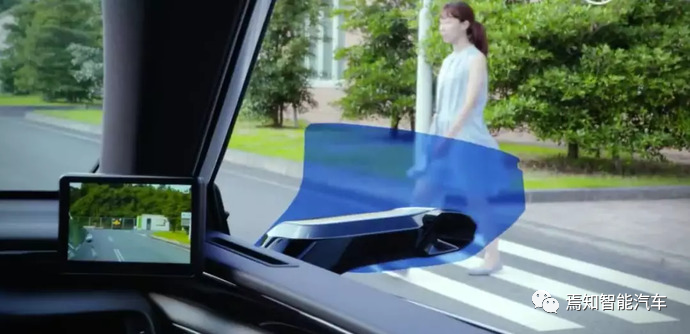

Camera Monitor System (CMS) is a product combination based on cameras and displays, which can enhance the driver’s visual perception of the vehicle surroundings and rear sides, further improving driving safety and comfort. External camera images are processed and displayed on the interior screen, and can be integrated with functions such as blind spot warning and obstacle detection.

CMS Cognition

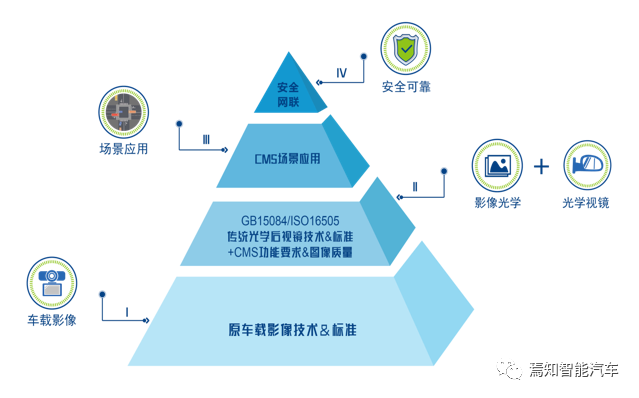

Electronic rearview mirror is essentially a system composed of a professional single-lens camera and a vehicle-mounted monitor that meets the GB15084 standard and satisfies the automotive safety level D. The cognition of electronic rearview mirrors is generally divided into four levels:

The first level is traditional imaging, which refers to the traditional imaging products that are familiar to everyone, such as reversing rearview, central control screen, recorder, and streaming media rearview mirror.

The second level is replacement relationship, where the CMS replaces the traditional optical rearview mirror and must meet GB15084. Electronic rearview mirrors are cross-industry products combining traditional optics and electronics, requiring interdisciplinary talents, especially in optics imaging, image color, and image processing. This is also the reason why international traditional optical rearview mirror enterprises and electronic enterprises jointly develop CMS.

The third level is temporary adjustment of the field of view (scene tracking). The image display of CMS is mainly combined with the vehicle attitude and driving environment, which meets the physical mirror field of view stipulated in the regulations and the temporary expansion of the field of view. Scene tracking is the soul of CMS. Electronic rearview mirrors replace traditional mirrors ten times the price, so they must provide users with value-added functions beyond traditional rearview mirrors and be able to provide temporary adjustments of the field of view in starting, driving, turning, and parking scenarios.## Advantages and Applications of CMS

The fourth layer of safety and reliability is the traditional optical rearview mirror, which is an important safety component for automobiles and the foundation of CMS products. Safety cannot be achieved in isolation and can only be truly understood and respected by strengthening the foundation of the first three layers.

Electronic rearview mirrors, also known as “smart rearview mirrors,” have been hailed as a “rearview mirror with thinking ability.” They are small, retractable, streamlined, and more high-tech, allowing drivers to obtain real-time information about the surrounding road conditions without drastically changing their viewing angles during driving. In comparison with traditional optical rearview mirrors, CMS has several significant advantages:

1. Vehicle weight reduction, drag reduction, and noise reduction:

In traditional rearview mirrors, a passenger car weighs about 1-2 kg on each side, and a commercial vehicle weighs about 5-10 kg on each side. Supporting such a large weight will inevitably increase the thickness of the door’s steel plate and the overall weight of the vehicle. According to testing data from a German enterprise, adopting CMS can reduce the weight of the entire heavy-duty vehicle by 60-80 kg, and canceling the external rearview mirror can save fuel by 2%-3%. Take the Mercedes-Benz Actros as an example. By using CMS, Actros can reduce the fuel consumption of the entire vehicle by 3%.

In addition, the CMS external device only has a camera, whose volume is up to one-third of the traditional rearview mirror at most. The overall design is more in line with the principles of aerodynamics, reducing drag by 90% and further lowering wind noise. For example, the design of the electronic rearview mirror on the Audi e-tron reduces the vehicle’s drag coefficient to 0.27, which is 0.1 percentage point lower than traditional design, thereby improving the driving range.

2. Blind spots:

The effective visible area of traditional rearview mirrors is fixed. Due to different driver heights, postures, and eye positions, the visible range also varies, and it is impossible to adjust the visible range in complex road conditions. CMS uses different cameras with different angles to capture real-time, multi-angle images around the vehicle, displaying the vehicle’s situation, blind spots, and pedestrians behind the vehicle. The viewing angle is more flexible, and the visible range is about three times that of traditional rearview mirrors, reducing blind spots by about 10% (with a wide field of view of about 50%).

3. Special Environment:

Generally, CMS exterior cameras combine physical shading and electric heating to ensure water and snow resistance, leaving the rest to post-processing algorithms and in-vehicle displays, greatly improving visibility in rainy and snowy weather, glare, poor lighting, or night driving. In addition, as technology advances, more advanced functions such as active glare reduction and night vision will be integrated, ensuring safer night driving for car owners.

4. Intelligent Experience:

To analyze the surrounding images and even access network platforms for traffic dispatch and vehicle safety management, a level L3+ intelligent driving system requires the collection of peripheral images, making the outside of the car an indispensable source of information. CMS can provide underlying hardware support for this. Although CMS may not be the ultimate information collection solution for intelligent driving, its high security and high-quality requirements for cameras will promote the overall development of the relevant supporting industry and improve the application technology. At the same time, CMS can also provide a more comfortable experience in human-machine interaction and driving process.

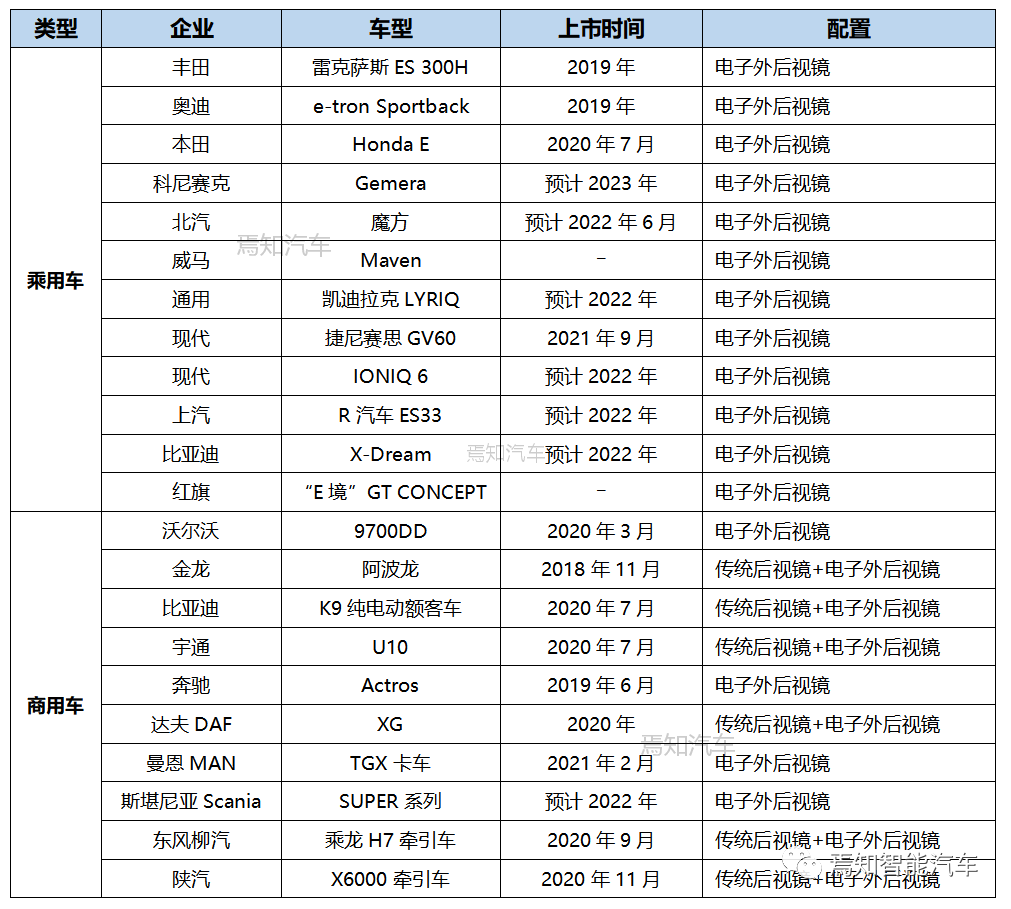

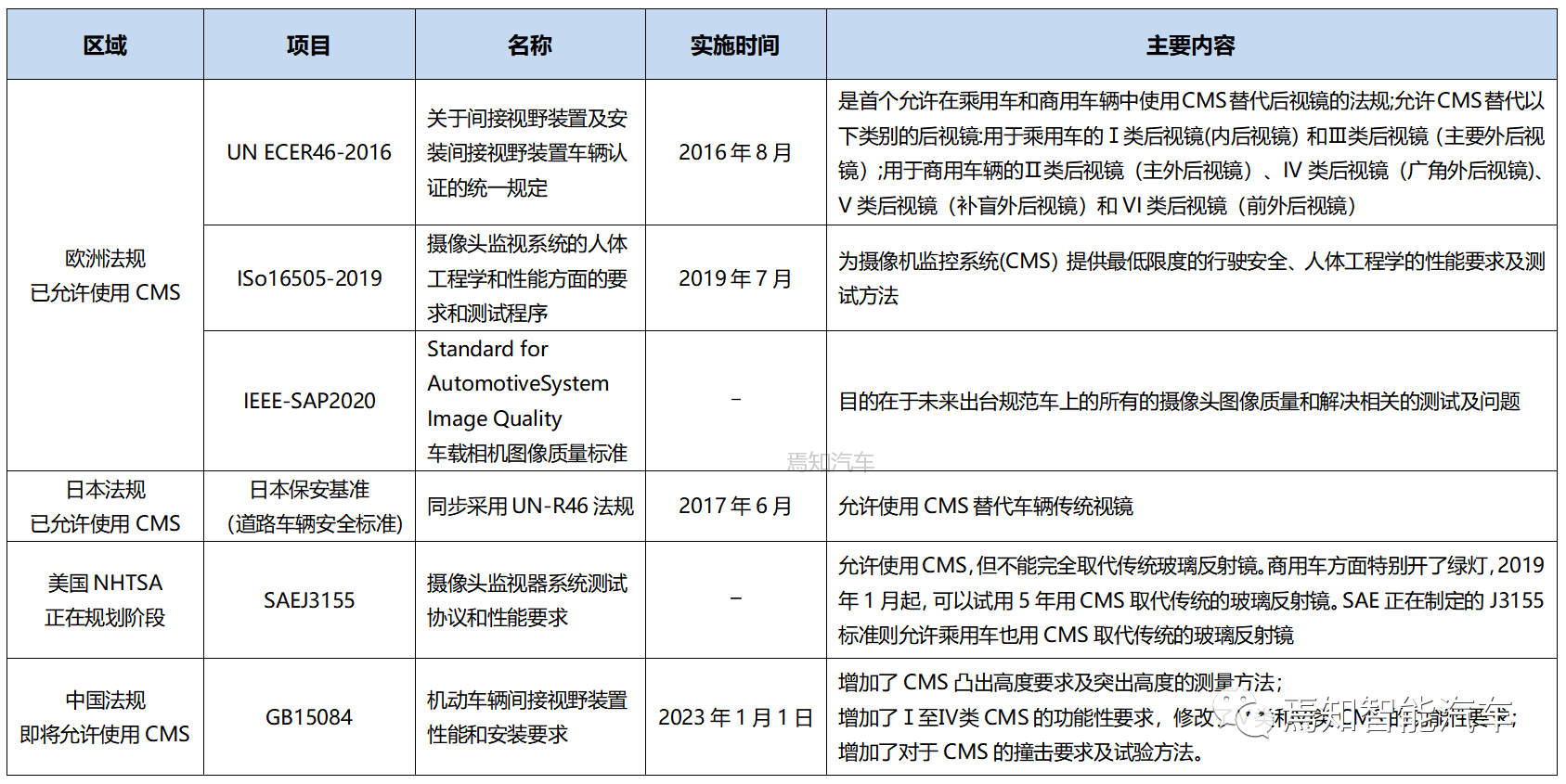

With the acceleration of the era of intelligent electric vehicles, CMS has received more attention from the industry. The EU and Japan lifted the regulatory restrictions on electronic external mirrors in 2016 and 2017, respectively, and OEMs such as Audi, Lexus, Honda, and Koenigsegg have successively launched mature applications.

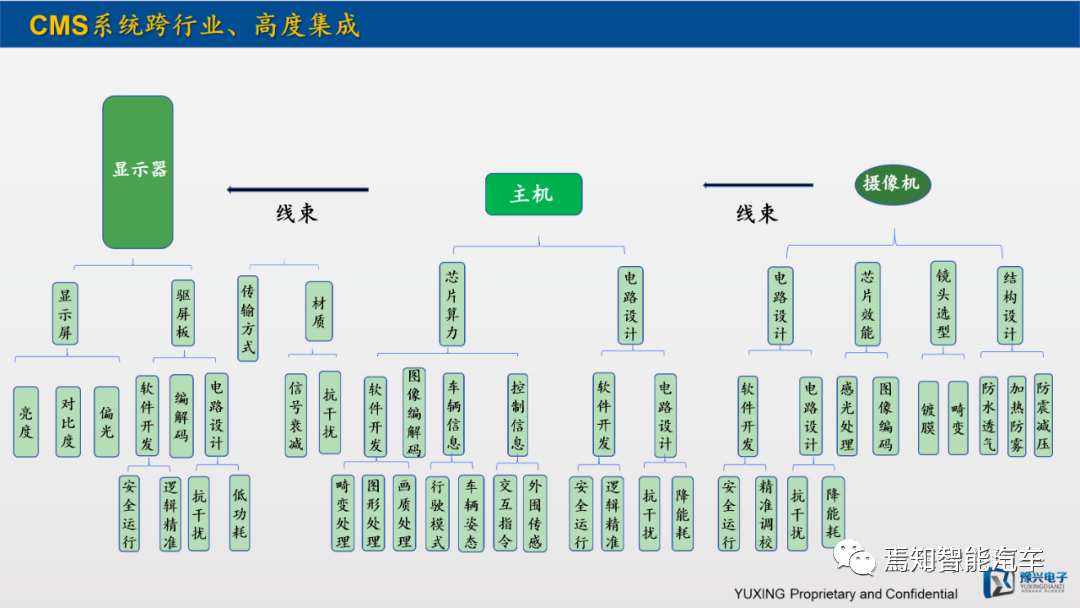

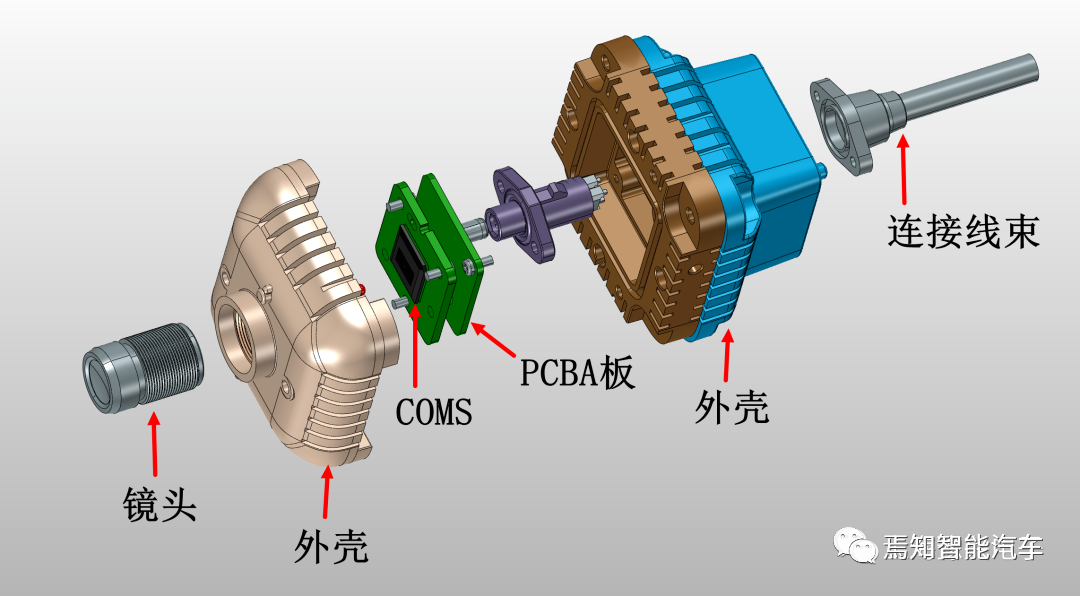

Critical Component of CMS: CameraCMS is a system consisting of a camera and a display, which is an indirect vision device that allows for the clear rear, side or front view of a vehicle within a specified field of view. This requires CMS system suppliers to possess complete design capabilities for cameras and display systems, especially in the area of lens design, chip selection, ISP/DSP system design and testing capabilities for CMS cameras, such as chip selection that meets AEC-Q100, safety design standards that refer to ISO26262, and production systems that meet IATF16949. The requirements also include the accumulation of experience in high-reliability and long-life CMS system development and design, engineering, installation, and testing capabilities.

Lens Selection

Domestic lens manufacturers for vehicular cameras started with manufacturing lenses for security cameras and generally began entering the vehicular field around 2016. Because the requirements for lens performance for current vehicular cameras are not high, there is still a significant difference between the needs for CMS lenses and what these manufacturers have accumulated in optical expertise.

1. Lens Material

Lenses consist of multiple groups of lens elements that are processed with concave-convex surface angles and combined to achieve optical design performance. The optical imaging quality and service life are determined by the materials used. Materials can be all-glass that is able to protect for many years, or resin lenses that may turn yellow and blurry within 2-3 years due to the influence of external environmental light exposure and changes in internal and external temperature.

CMS lenses have high requirements for resolving power, distortion, glare and ghosting, hydrophobicity, and low-light imaging capabilities, while also requiring excellent temperature characteristics. Generally, all-glass + metal structures are adopted.

2. Coating Technology

A critical process for lenses is coating, and the materials used in the coating have different compositions, functions and service lives, resulting in significant price differences. Good coating materials can reduce glass reflectivity, improve glass transparency, and have a greater effect on improving image quality than ordinary coating materials. Coating processes are divided into cold coating and hot coating, with resin lenses using cold coating. The biggest difference between the two coating types is their resistance to abrasion and longevity.

3. Blackening Process for Lens Barrel

The blackening process of the lens barrel determines the size of the glare and ghosting areas in the image. Oxidation blackening has the lowest cost, while special production processes are used for blackening on single lens reflex camera lenses.

4. Assembly Technology### Lens Assembly

Lens assembly reflects the production process level of the lens manufacturer, including the tolerance between lenses and lens barrels, lens fixation, and imaging adjustment.

5. CMS Camera Lens

The cost and performance of a camera depend on factors such as glass composition, spherical aberration, non-spherical aberration, coating, blackening of the lens barrel, glass fixation, and waterproof performance. CMS camera lens is equivalent to mass-produced professional SLR lenses, hence the high price.

CMOS Selection

As a safety component of smart connected vehicles, the complexity of the CMS scenario puts higher requirements on the hardware statistics and algorithm processing of the ISP signal processor, including the colorful body and the irradiation of the taillights.

Currently, many component suppliers in the market are evaluating traditional SoC chips, such as IVI central control display chips, DVR recorder devices, and even consumer security monitoring chips, to achieve CMS design. However, based on the performance of several models that have been mass-produced and equipped with CMS, traditional SoC chip solutions seem to encounter certain problems under complex lighting conditions, such as picture color deviation, dark noise, diffusion and ghosting, and excessive delay. What factors should be considered for a CMS solution that truly fits actual driving conditions? What is the ideal chip solution for CMS systems at present?

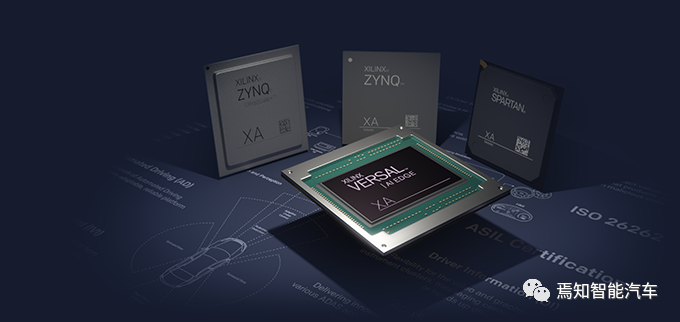

According to several industry insiders and experts from host manufacturers, FPGA solutions with low latency, upgradable hardware, and flexible adaptation are the best choice for current CMS systems, especially in the specific environment where regulatory standards are still being updated. FPGA solutions can quickly achieve fast onboarding demos and comply with regulations, without changing the original design, which can maximize the differentiation needs of different customers. Even if core materials such as screens or cameras need to be replaced, only updating logical units and core functions based on hardware characteristics is required, which greatly reduces the development cycle and cost of CMS manufacturers and vehicle factories, and speeds up the mass production of CMS products.

It is understood that AMD-Xilinx and its partner iWaySense have jointly created a core image processor IP specifically for CMS products, which is designed for CMS application scenarios and has excellent image quality while achieving extremely low latency. In addition, combining with the advanced image laboratory and debugging service capabilities of the iWayLab, as well as the localization team in China, it can further accelerate the onboarding and mass production of CMS projects for host manufacturers.In addition, some special handling is also required in the structure of the camera. For example, the outer shell of the components of the external camera design should prevent water droplets from falling on the lens. An additional waterproof coating is required on the lens. To reduce the performance degradation of the camera exposed to dust and rain, it is equipped with a built-in heater to prevent freezing or fogging. Some schemes are also equipped with light sensors that can automatically reduce glares from other car headlights.

Currently, foreign electronic outside rearview mirror suppliers mainly include Valeo, Magna, Donghai Chiray, Bosch, etc., all of which consider it as an important component of ADAS or intelligent driving systems. Domestic electronic outside rear-view mirror suppliers mainly include Shanghai Yuxing Electronics, Senpeng, Yuanfeng Technology, Huayang Electronics, Hangsheng, Desay SV, etc. Among them, Shanghai Yuxing has provided electronic outside rear-view mirror + traditional rear-view mirror integrated solutions for Yutong, and Senpeng has provided such solutions for BYD K9. In January of this year, Yuanfeng Technology officially won the XPeng Motors CMS project, and in February, Yuxing Electronics won the Deepway smart truck CMS designated project.

Chinese CMS regulations update

Since the implementation of the GB15084-2013 standard for five years, some problems have been exposed, such as imperfect test methods, outdated quoted standard versions and inability to adapt to the current development of automotive technology. To standardize the healthy development of the industry, improve technological standards and achieve the goal of aligning with international standards, to regulate and improve the development of the domestic automotive indirect vision device industry, the National Automotive Standardization Technical Committee launched the research and revision of this standard under the guidance of the Ministry of Industry and Information Technology in December 2018.

On June 3rd, 2020, the Ministry of Industry and Information Technology (MIIT) issued a draft of the mandatory national safety standard GB15084 (performance and installation requirements for indirect vision devices for motor vehicles), which added the requirements for the CMS protrusion height and the measurement method for highlighting height in the CMS section; added functional requirements for CMS from Class I to Class IV, modified the functional requirements of CMS for Class V and Class VI and added the impact requirements and test methods for CMS.

From the information currently available, the standard is expected to be released in mid-2022 and will be implemented from January 1, 2023. In the second half of 2022, automakers may begin to declare new models equipped with CMS and carry out designated experiments, and the CMS market will enter the rapid mass production phase.

Challenges and Issues Faced# CMS System Requirement

To meet the GB15084 standard and satisfy the safety level of automotive D, the technical threshold, safety level, and performance indicators of CMS system have stringent requirements, which are by no means comparable to automotive accessories such as reversing screens, driving recorders, and streaming media. According to the calculation of fully replacing the traditional rearview mirror, the domestic electronic rearview mirror for commercial vehicles and passenger cars has a market size of nearly 100 billion yuan. Although the prospect is broad, there are still some urgent challenges that need to be overcome:

1. Solving Imaging in Low-light and Complex Environments

The main challenge facing all automotive imaging systems is to improve imaging under low-light conditions while also improving resolution and the imaging dynamic range. In order to avoid image saturation caused by the headlights of the rear vehicle approaching, CMS must have good image quality, low illumination must be below 1Lux, and the dynamic range must exceed 110db. At the same time, the imaging system must have sufficient pixels to fill a monitor with high resolution, which exceeds the limitations of traditional pixel technology. The on-board camera is different from security monitoring and other video cameras. It can install a sunshade or change the camera installation position to avoid strong light sources, but how to ensure clear image quality poses a higher challenge to the system technology.

2. The Impact of Flickering Car Lights on the Camera

Another major challenge is the impact of LED car lights or street lights flickering on the current image sensor. In the display screen rearview mirror, the daytime running lights will present a flashing state due to pulse width modulation (PWM), which may cause the driver to mistakenly think that an emergency has occurred or that a police car is approaching, thus affecting safety. The PWM frequency of many daytime running lights is between 90-300Hz. When the sensor exposure is relatively low under daytime conditions, it is very difficult to image in this range.

3. Reliable Imaging for Long-term Use

The camera replaces the rearview mirror, and it is necessary to solve the problem of “whether or not” and cover the blind spots of the traditional rearview mirror. It is even more important to solve the problem of “seeing clearly”. There are other car headlights in the field of view, but still need to see other obstacles clearly. The camera that replaces the rearview mirror works as soon as the car is powered on and needs to be used even during high-speed driving. The requirements for the camera are higher, bringing higher challenges in terms of high pixel, distortion-free, wide dynamic range, low illumination, high frame rate, and high reliability.

4. Cable and Connector Selection Matching Problem

With the increase of camera sensor resolution, the cost of transmitting camera data to the display will also increase. In the case of using standard-definition camera systems, video data is transmitted together with analog composite video, which is a common camera system on the market. Because the data bandwidth is also very low, the cost of cables and connectors in this case is relatively low. With the introduction of high-definition cameras, the cost of cables and connectors will also increase depending on the type of data transmission technology used.Currently, the most common technology for high-definition video transmission in vehicles is the digital Serializer/Deserializer known as “SerDes”. The main issue with existing SerDes is the relatively expensive cable and connector types compared to analog hybrid video systems. Another challenge of SerDes is the multiple SerDes standards currently in the market (with similar functionality) that are not mutually compatible, thus OEMs and Tier 1 system manufacturers usually need to select a specific SerDes standard and stick with it regardless of whether competing standards have better features. Due to the delays caused by IP-based systems, IP cameras perform poorly in such applications. People demand mirrors to replace the system with the lowest latency possible, and analog video and SerDes can achieve this.

5. Higher computing and memory requirements

Image sensors and imaging processors need to comply with automotive standards (AEC-Q100) and their complicated testing requirements. Additionally, the problem of power consumption and heat dissipation needs attention in the design of high-definition image sensors. With more and more high-definition cameras being used in cars, numerous new applications and rich image data will come in, which also means that processors require higher computing and memory capabilities. Currently, there is an increasing demand for high-definition image sensors that traditional CVBS interfaces cannot support, and new LVDS and EthernetAVB interfaces may become the mainstream for the next generation of automotive intelligent cameras.

6. Professional division of labor

The domestic camera module professional division of labor is highly specialized, including structural design, ISP tuning, and module production. Currently, traditional rear-view mirror suppliers mainly excel in physical structure and optics but lack electronic circuits and imaging processing technology, making it difficult for them to provide CMS systems with high safety standards. Supplier offering in-vehicle infotainment (IVI) lack traditional optical mirror knowledge and technology accumulation, foundation in imaging and optical processing, and design experience for high-security systems, making it difficult for them to enter the CMS system market.

Currently, there are only a few companies that can independently grasp the terminal customer’s requirements, match COMS, lenses, and external structures according to these requirements, and have dedicated ISP engineers responsible for image calibration.

In addition, the mass production and popularity of CMS requires not only the CMS suppliers to make technological breakthroughs and provide more secure and reliable products, but also the early design matching support from the host plant and vehicle models.

ConclusionThe automotive industry is undergoing an unprecedented transformation, characterized by electrification, intelligence, connectivity, and sharing. The development of imaging and optical technologies, as well as the intelligence of automotive vehicles, makes it possible to replace traditional optical mirrors with electronic rear-view mirrors. Similar to how the advent of touch-screen phones restructured the mobile phone ecosystem, this transformation will reshape the glass mirror industry, empowering driving safety through high-quality imaging from cameras, 5G, and AI. The tipping point for CMS has arrived, and the curtain is slowly rising. Let’s wait and see who will come out on top.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.