Dyson Abandons Smart Electric Car Project

The British consumer electronics giant Dyson made a huge splash in the car circle today as James Dyson, the CEO, announced that the company is terminating its intelligent electric car plan which has been in progress for years, which caused a stir of discussions.

A Weibo user named @哲伦班长 commented that Dyson has limited the losses quickly. However, some people hold different opinions, saying that Dyson’s car-making plan, which has caused such a sensation, is either a strategic transformation or a boring hype since they announced the termination of the project without even revealing a prototype.

Today, we are going to talk about how Dyson’s intelligent electric car went from a start-up to being abandoned.

Radical and Different

“I have been committed to finding a solution to air pollution around the world. I believe that electric cars will solve the pollution problem. Dyson is developing a brand new battery technology, and we have been tirelessly innovating in fluid dynamics and heating, ventilation, and air conditioning. Now, we finally have a chance to integrate all of Dyson’s technology into one product.

“Today, we have the opportunity to solve the pollution problem at its source. I am announcing that Dyson has begun developing electric cars, which are expected to be launched in 2020.”

In September 26, 2017, Dyson’s founder, James Dyson, introduced Dyson’s original intention for making cars in a company-wide email.

Does this mean that Dyson started to make cars in 2017?

As early as January 2015, Dyson officially launched a code-named Project E electric car project. After the project was launched, Dyson began to frantically recruit people. In addition to British car makers such as Jaguar Land Rover, Mini, and Aston Martin, Dyson also recruited a large number of professionals from Mercedes-Benz, BMW, and Tesla.

By 2019, the size of Dyson’s car-making team had grown to nearly 500 people, many of whom had aristocratic backgrounds. These people played a significant role in promoting the progress of Dyson’s car project.

If you are careful enough, you will find the clues of Dyson’s car-making project in James Dyson’s company-wide email. On February 28, 2017, Dyson announced the acquisition of a training base previously owned by the British Royal Air Force in Bristol, which will be used for “expanding a new technology center”.

This news is quite intriguing. As a consumer electronics company, it is illogical for Dyson to need a 517-acre open space for a technology center. What product of Dyson requires such a large testing ground? But Dyson is determined. After an investment of £84 million in the first phase of reconstruction, Dyson announced that it will increase investment in the future. It is expected that the cumulative investment in the new technology center will reach £200 million.

In September 2017, James Dyson officially announced that he would invest £2 billion in developing intelligent electric vehicles. One year later, Dyson announced that it has selected Singapore as the location to establish an electric vehicle factory, stating that “where batteries are produced, electric vehicles should be produced, and the world’s center for power batteries is in Asia.”

As for the product itself, Dyson has shown absolute confidence. In an interview with the media, Dyson mentioned that Dyson’s electric vehicle will be “radical and different.”

Who gave Dyson the courage?

Obviously, Dyson did not rashly enter the automotive industry solely for “unremitting innovation in fluid dynamics and HVAC.”

First of all, Dyson has achieved great success in the consumer electronics field. James Dyson has successfully established a high-end brand with global influence.

Anyone who understands Dyson’s development history knows that Dyson has always been a product-driven company with innovation as its core competitiveness.

G-Force, the world’s first bagless vacuum cleaner developed by James Dyson, was tested in more than 5,000 prototype models during the R&D stage.

Supersonic hairdryer, which became popular in China in 2017, was developed by a team of 103 engineers and invested £50 million over a period of 4 years. Over 600 prototypes were designed and tested with a total length of real hair used for prototype testing exceeding 1,600 kilometers.

The Dyson Airwrap curler was developed by a team of 230 engineers and scientists over 6 years, with 642 prototype machines produced at a cost of £24 million.

…

This unique and unparalleled brand image of innovation gives Dyson’s automotive project a strong topic effect. In August 2017, James Dyson mentioned that the production of Dyson’s first electric vehicle model would be limited to a few thousand. As for the product itself, he said: “Our product (electric vehicle) is unique, and following or copying others is meaningless.”The brand effect has brought a high level of attention to the Dyson car project in terms of promotion. Fast Company, an innovative media that focuses on business and technology, used the following headline when the Dyson car project was first announced:

This high level of expectation and attention is what any new Chinese car company’s marketing department dreams of but cannot easily achieve. Compared with new brands, high net worth users naturally have a better impression of the Dyson brand.

In fact, Dyson does plan to replicate its successful product strategy in the consumer electronics field. When interviewed by The Guardian, James Dyson stated clearly that Dyson’s car could be very expensive depending on how much of your savings you are willing to give up.

Secondly, there is Dyson’s healthy operating status and research and development accumulation.

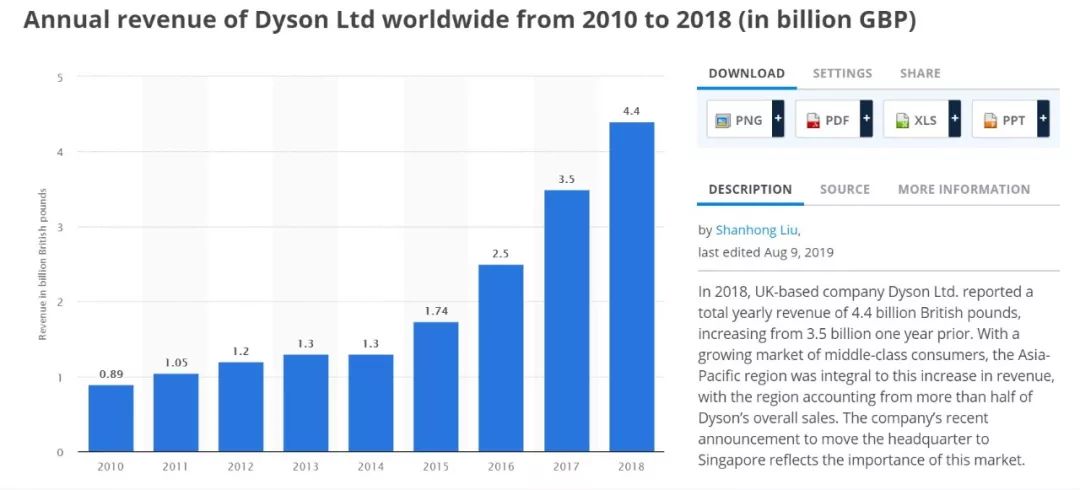

Two years ago, in 2017, Dyson’s revenue grew 40% to £3.5 billion, and profits increased 27% to £801 million. In 2018, Dyson’s revenue increased by 28% to £4.4 billion, and profits increased by 33% to £1.1 billion.

While supporting a 400-500 person auto project team and investing in factories in Bristol, UK and Singapore, Dyson still maintains a very healthy financial position.

In terms of research and development, Dyson’s situation is even more complex. Who would have thought that a vacuum cleaner manufacturer would attract scientists in the field of artificial intelligence? Dyson did.

The “years of practice for one sword” product model requires a strong talent pool to support it. In 2018, Dyson had a global team of about 12,000 people, including 5,853 engineers and scientists, covering energy storage, robotics, battery chemistry, motors, and artificial intelligence.

This is also why James Dyson said that entering the automotive field “provides an opportunity to integrate all of Dyson’s technologies into one product”.## Failures of Solid-State Batteries?

Why did James Dyson halt the investment of hundreds of millions in the fledgling automotive project?

In March 2015, Dyson initiated its first external investment and provided $15 million of funding to solid-state battery startup Sakti3. Despite its status as a leading consumer electronics enterprise, this investment did not attract widespread attention. However, seven months later, Dyson again invested $90 million to acquire the remaining shares of Sakti3 while announcing a $1 billion investment to build solid-state battery factories.

Sakti3’s solid-state batteries feature superior safety performance and a high energy density far superior to other battery suppliers, including Tesla. In the 2015 sample exhibition, the company’s battery energy density reached an unprecedented 400Wh/kg.

In addition to Sakti3, Dyson also developed another electrochemical team in-house that has been committed to the commercialization of solid-state batteries since 2010. James Dyson stated that the two teams’ technological pathways accelerate the commercialization of solid-state batteries through competition, matching Dyson Automotive’s 2020 market launch.

However, in February 2018, the Financial Times reported that insiders said Dyson was considering using ternary lithium batteries in its first model instead of solid-state batteries, although Dyson had not made a decision yet.

Here’s some context: The consensus in the power battery industry is that solid-state batteries will be commercialized by about 2025.

It seems that the battery has brought down the Dyson Automotive project?

Forget Smart EV, It’s Just a Black Hole

If the whole project was stopped due to the battery factor, I think Dyson should “thank” the underdeveloped research and development of the battery team.

How many steps are needed to create a smart EV?

From a project management perspective, design, engineering development, production, supply chain management, inventory and logistics management, and more; from a corporate operations perspective, finance, brand, marketing, public relations, sales, operations, after-sales, and more; from a technical perspective, motors, power electronics, batteries, intelligent cabins, ADAS, EE architecture, and more…

Starting in 2003 and still deeply entrenched today after sixteen years of existence and raising over $10 billion in financing, Tesla has struggled to control every aspect of this process. As a super outsider, what is Dyson’s bargaining power in the automotive industry?

The threshold of the automotive industry is so high, as demonstrated in the most brutal and distinct case of the Chinese market: Three years ago, the grandiose new car movement has already passed the elimination round, and each new car company’s core issue has shifted from focusing on the future to surviving.

In conclusion, we must admire Sir James Dyson’s courageous decision. As he mentioned in his open letter, although the Dyson Automotive project team “developed an excellent car that was innovative and faithful to Dyson’s philosophy,” it was “not commercially viable,” and everything was just empty talk.

And finally, James Dyson’s open letter encourages every newcomer to the automotive industry to bring new blood and new vitality to this century-old industry:

Since day one we have taken risks and dared to challenge the status quo with new products and technologies. Such an approach drives progress, but has never been an easy journey – the route to success is never linear. This is not the first project which has changed direction and it will not be the last.

I am looking forward to our future adventures together.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.

*

*