Author: Feng Jingang

In recent years, a few new energy brands have gradually mastered the marketing skills of new energy, such as giving their battery a loud name, including “Magazine battery”, “Dayu battery” and “Qilin battery”, etc. The main purpose is to facilitate everyone’s memory and believe in the quality of the battery through these popular and powerful names, thereby forming a word-of-mouth effect.

On May 30th, NETA Motors held an online Netalks sharing session on the topic of “Tiangong battery”, which has been rapidly fermenting online for the past few days. Therefore, this is also the first time that Tiangong battery has been unveiled to the public. Taking advantage of NETA Motors’ sharing session, we can also glimpse the technical details of Tiangong battery and explore its strength.

Why is it called Tiangong battery?

This time, the introduction of the Tiangong battery was given by Zhang Honglei, whose title is the assistant president of NETA Motors and the executive deputy dean of the Automotive Engineering Research Institute.

About Zhang Honglei, he is also a relatively legendary figure in the new energy industry. He is one of the earliest engineers engaged in the new energy industry in China. He has worked for 16 years and experienced from a range of 20 kilometers to 1000 kilometers of the endurance of electric vehicle, the transformation from fuel to electric vehicles with a completely new architecture, the mass production of high-voltage electric platform and the glorious years of delivering them to Zhongnanhai…

If you still have an impression, we wrote an article about NETA Motors’ chairman Fang Yunzhou last year – “Legend“, which is roughly the same history. Fang Yunzhou and Zhang Honglei are also teachers and friends. The achievements of China’s new energy today cannot be separated from the unremitting efforts of these pioneers.

Nowadays, the stable and outstanding performance of NETA Motors’ three electric systems has a profound origin.

At the sharing session, Zhang Honglei first introduced the origin of the name “Tiangong battery”, which comes from “what nature gave us, we develop with our hands” (the name is still very “Chinese” sounding), and NETA Motors hopes to express its concept through Tiangong battery, and thus safeguarding the safety standards for batteries. To give a name to a power battery, it must be popular and powerful, and Tiangong battery undoubtedly achieves this.

Zhang Honglei said that there are two principles for Tiangong battery: never-changing user guidelines and uncompromising technical goals.

Regarding this, Zhang Honglei also said a heartfelt remark. He said, “I have been in this industry for so many years, and to be honest, working in the battery industry has always been like walking on thin ice. Why? Because the safety of users’ lives is in our hands. Therefore, problems like engine failure and battery combustion can have a huge impact on users’ lives and property. So we have always regarded safety and customer experience as the never-changing user guidelines.”

Zhang Honglei also said that NETA Motors has always adhered to the spirit of craftsmanship, and guarded the safety of batteries with the spirit of craftsmanship, turned customer expectations into its own work goals, and made them its own technical goals.Promoting the craftsmanship spirit to make batteries, in my impression, NETA Motors is the first in the industry. Regardless of the strength of Tiangong Battery, at least in the spirit of technical development and the mindset of technical naming, NETA Motors is already leading the industry.

Three key points of Tiangong Battery design

This part is the focus, it is not only the realization of Tiangong Battery technology, but also NETA Motors’ response to user demands and solutions to user pain points.

In Zhang Honglei’s opinion, for power batteries, the most important concerns of users are safety, range, and life. Therefore, Tiangong Battery must solve these problems from the design goals. It mainly includes the following three key points:

Highly integrated design with super strong protection

Regarding this point, it includes the following two items:

The first item is lightweight, highly integrated, and heavily protected mechanical and electrical design, which includes rigorous cell selection, aerospace-grade cell insulation, high-strength grid-like framework, and high-integration module construction, ensuring battery safety while also having a high energy density.

Zhang Honglei said that Tiangong Battery has gone through three development stages. The first stage is the international standardization VDA module, which is convenient for seamless replacement of different cells, but the disadvantage is that the recombination efficiency is slightly low, about 65% -70%, and the system energy density is 175Wh/kg; It has now entered the second stage-customized large module plan, that is CTP, with a grouping efficiency of 73%-76% and a system energy density of 185Wh/kg; The third stage is a high-integration solution, which includes CTP/CTC technology, with a grouping efficiency of > 85% and a system energy density of > 210Wh/kg.

Zhang Honglei revealed that for the third-generation Tiangong Battery, NETA will hold a strategic release conference, in addition to announcing CTP/CTC technology, it will also disclose cutting-edge technologies such as skateboard chassis.

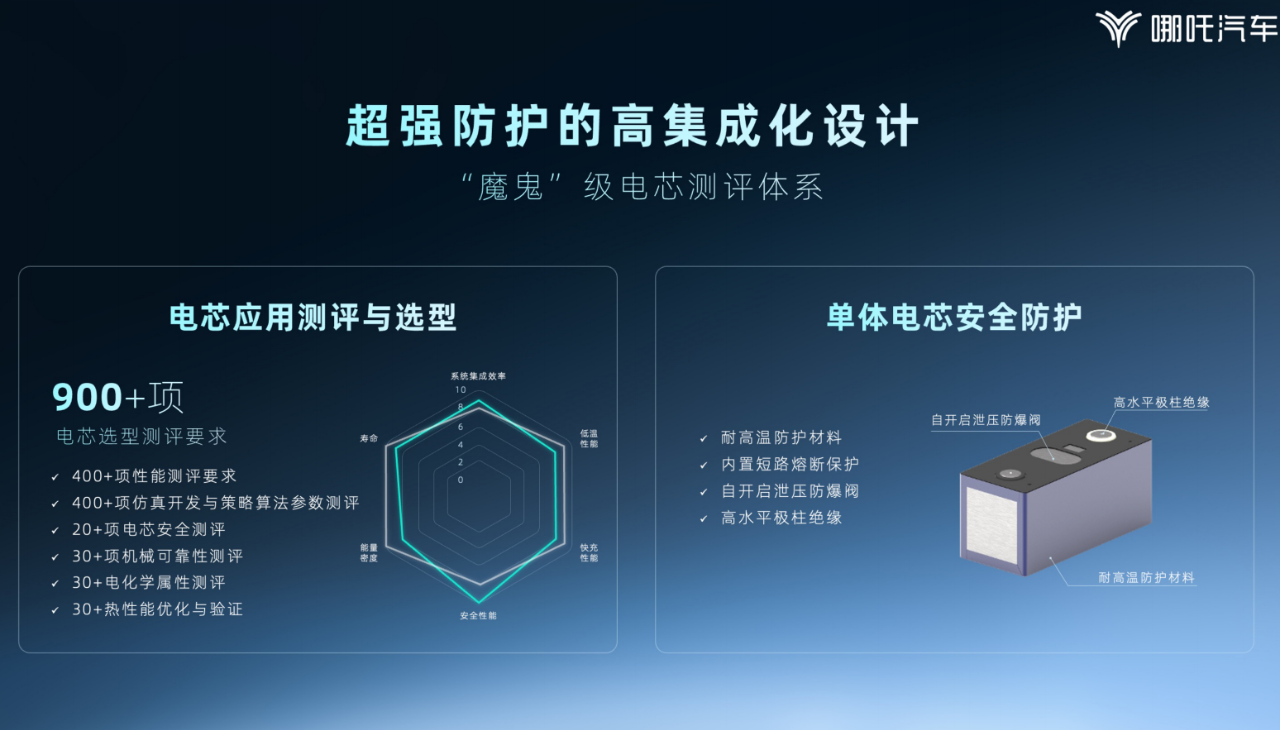

The second item is a fortress-like layered defense that cuts off all links between ignition and thermal runaway. It includes the “devil” level battery cell evaluation system (precise selection of battery cells), mesh module design (taking into account cell insulation and high energy density), and chamber-type battery pack design (realizing a reliable sealing, insulation, and ventilation system).

Regarding the “devil” level battery cell evaluation system, it includes cell application evaluation and selection and individual cell safety protection, as shown in the following figure:

As for the module design in network format, it includes three points: first, aerospace-grade insulation, which can achieve 1000+ degree Celsius insulation and UL94 V0 flame retardancy; second, military-grade electrical protection, which adopts 800V electrical insulation redundant safety design, sampling short-circuit redundant design, and module-level short-circuit redundant safety design; third, compartmentalized structure protection, including lightweight high-strength aluminum frame, 2000+N level structural safety, and highly integrated customized large module design.

As for the module design in network format, it includes three points: first, aerospace-grade insulation, which can achieve 1000+ degree Celsius insulation and UL94 V0 flame retardancy; second, military-grade electrical protection, which adopts 800V electrical insulation redundant safety design, sampling short-circuit redundant design, and module-level short-circuit redundant safety design; third, compartmentalized structure protection, including lightweight high-strength aluminum frame, 2000+N level structural safety, and highly integrated customized large module design.

Regarding the compartmentalized PACK box structure, it includes PACK compartmentalized structure design and PACK thermal/electrical safety protection, as shown in the following figure:

Zhang Honglei stated that NIO has excellent thermal simulation capabilities, and has also collaborated with CATL and Tsinghua University to develop a comprehensive simulation capability from battery cells to modules to complete pack.

Below is a simulation video made by NIO on the thermal runaway of a battery pack.

Zhang Honglei said that in addition to safety structure and heat-resistant materials, the thermal conduction of the entire exhaust channel is also a very important design element, and the most critical part of the battery pack is the thermal conduction of this part.

Ma Jiansheng, Director of R&D of NIO Power Battery, stated that with the IP68 protection level of the TianGong battery, 800V electrical insulation redundant design, and directional heat diffusion exhaust channel, it can basically achieve the goal of no thermal diffusion.

Efficient and Intelligent Temperature Control System

In order to improve the range, the simplest and most straightforward approach in the industry is to stack batteries. The more batteries are stacked, the longer the range. However, Zhang Honglei believes that this approach is not economical, and the resource allocation of such a battery pack in a vehicle is wasteful.

Zhang Honglei believes that how to improve the range experience from the efficiency of the system and the heat management solution, including the charging experience, is the focus that automakers should pay attention to.Currently, the thermal management system of Tiangong batteries has developed to the fourth generation, adopting a new heat pump system, which has better efficiency than the traditional PTC. For example, the winter range can be increased by more than 20%, the single charge can save 2% energy, and the low-temperature charging efficiency can be improved by 20%. Zhang Honglei said that Tiangong batteries should strive to achieve a charging time of around ten minutes for low-temperature charging.

Regarding the fourth-generation thermal management system of Tiangong batteries, Zhang Honglei described it as a customized and “babysitting”-style constant temperature management strategy, including smart pre-cooling and pre-heating, personalized customization, all-time-domain/territory constant temperature control, fast charging, and persistent endurance.

In terms of specific technical details, the Tiangong battery thermal management system adopts a mesh-like flow channel design, which allows the battery to control its own temperature management according to its regional differences, mainly in the following four aspects:

Firstly, intelligent feedforward thermal management control, which estimates refrigeration/heating demand according to the operating conditions and can save 2% energy per single charge.

Secondly, intelligent driving heating function, including the heat pump multi-thermal source driving heating/insulation function, and the advanced heating strategy, which can improve the low-temperature charging efficiency by 20% by preheating according to the navigation destination.

Zhang Honglei said that NETA Motors is the first brand in China to introduce energy flow pre-management control strategy.

Thirdly, efficient cooling and heating system, including constant temperature liquid cooling, with 95% temperature controlled at 15-45 degrees Celsius, high-temperature charging, with an 8% efficiency increase. The heating rate is ≥0.8 degrees Celsius/minute, and the low-temperature charging efficiency can be improved by 10%.

Intelligent and Pre-scheduled Insulation Function

The intelligent and pre-scheduled insulation function of NETA cars can preheat the vehicle before departure and ensure excellent insulation performance. Even in an environment of -20 degrees Celsius, the battery can maintain a temperature above the freezing point of the battery for more than 6 hours.

Closed-loop Management System for the Full Lifecycle of Batteries

According to Zhang Honglei, NETA cars adopt a front-end mentality and a front-end closed-loop strategy, analyze big data to comprehensively and deeply explore potential individual battery failures, and achieve closed-loop management of batteries throughout their entire lifecycle with remote diagnosis and convenient operation and maintenance.

To achieve this, NETA cars use algorithms covering the entire scenario, including SOH, lithium separation algorithm, outlier algorithm, and safety warning algorithm; these algorithms cover multiple scenarios such as driving, charging, and standing still. NETA cars have developed a large BMS ecosystem that involves developers, vehicles, and the cloud, all with the capability to cover the entire scenario and implement closed-loop management throughout the batteries’ lifecycle. By defining failure boundaries through historical data and combining them with real-time monitoring using big data models, this system supports a safe and efficient operation.

For example, the 24-hour watchdog mode adds various algorithms inside the battery pack. Monitoring values such as current, voltage, temperature, and pressure can all be used as exceptions. If an exception occurs, the battery maintenance personnel, including the battery manager, will be notified remotely, enabling them to identify thermal runaway issues effectively and promptly.

Closed-loop management of the batteries throughout their entire lifecycle is of great help for battery safety monitoring and residual value utilization. However, for the car manufacturer itself, achieving this management strategy is not simple for two reasons. First, can they obtain data from the battery production end? Second, do they have the ability to build such a large data platform?

NETA cars managed to solve these two challenges, mainly thanks to their major battery supplier, CATL, and shareholder, Ningde Times. According to Zhang Honglei, NETA cars can obtain experimental and production data of early batteries from Ningde Times, combined with the later battery pack production data, vehicle data, travel data, and final residual value evaluation. Thus, NETA cars can achieve closed-loop management of batteries.

Regarding the platform and the algorithms required, Zhang Honglei stated that after 360 acquired NETA cars, their support in big data platforms and analytics has significantly helped NETA cars.

The Voice of Electric Potential

Electric and intelligence are the two core competitive strengths of new energy vehicles (NEVs). Among them, the core of the electric side is the battery. Though most car companies do not have the ability to develop their own battery cells, this does not affect launching a battery brand, especially for car companies with certain battery development capabilities.

As battery safety becomes an obstacle for consumers to purchase NEVs, solving battery safety is undoubtedly the key to gaining user trust. In addition, compared to industry jargon such as ternary lithium and lithium iron phosphate, the names of the batteries, such as maglev battery and Tiangong battery, are more popular, powerful, and easier to be remembered by consumers; hence they create a word of mouth effect that can promote product sales.In the new forces, NIO’s three-power capability is relatively outstanding. In addition to being able to independently develop domain controllers, the overall quality is also good. However, people’s impression of NIO’s three-power technology is not deep. This is also understandable. Young NIO cars do not have too much energy to do systematic dissemination.

However, from the pure electric platform of Shan Hai released at the end of last year to the sharing of Tiangong batteries, it can be seen that NIO’s efforts and reinforcement in technology brand communication.

Of course, communication is more of a bonus to strength. Based on NIO’s three-power technology accumulation and this systematic summary, the profound strength of Tiangong batteries is beyond doubt. Therefore, the introduction of such a battery brand is currently very necessary and urgent.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.