Author: Zhu Yulong

In light of the recent CTB fire incident with BYD’s seal lion, I think it is necessary to explore some of the core logic in this field. The logic in battery development has come from several facets in the past few years:

- Battery cells:

The proportion of compressed inactive matter is continuously decreasing in copper foils, aluminum foils, diaphragms, and other materials. Within the same chemical system, the density of compressed materials is increasing to enhance the energy density in battery cells.

- Battery system:

The improvement in pack-level energy density is also focused on the conversion rate between battery cells and packs, which is the integration efficiency. Almost all teams have explored the limits of how to remove redundant structural components in battery packs.

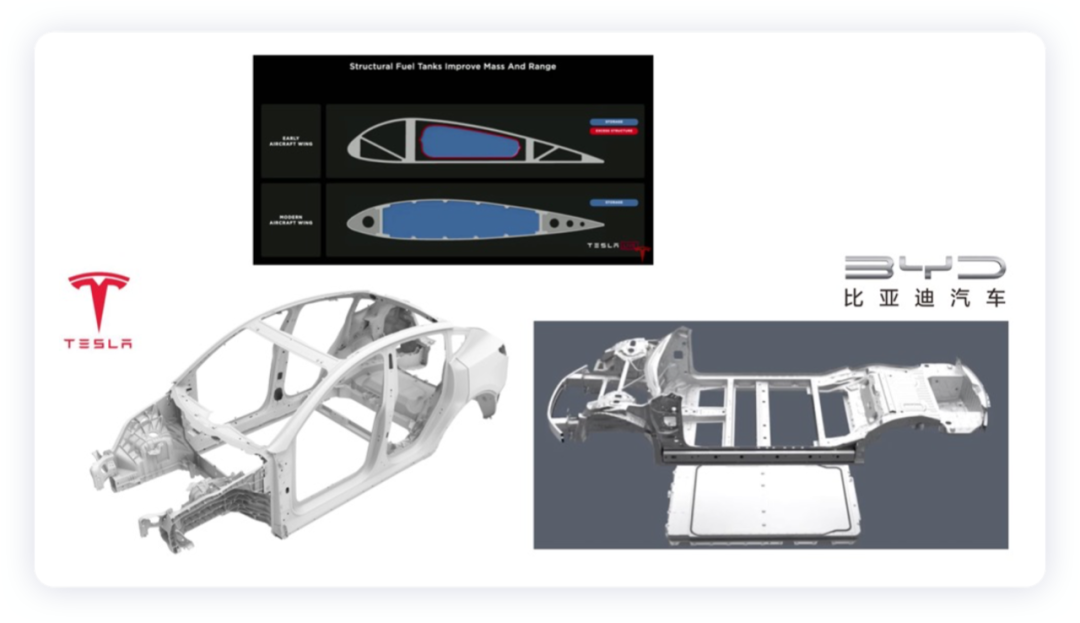

- Structural battery:

Following Elon Musk’s airplane fuel tank example, the fuel tank of the airplane transformed from wing + tank to wing = tank. Therefore, more space and structural coupling should be considered in the entire vehicle design to enable the combination of the car body and battery pack. The battery cell’s shell structure becomes an integral part of the overall load-bearing structure.

As a result, the entire vehicle’s early design, integration, and after-sales services need to come into play, and the existing logical division of labor has changed. Car companies that can work collaboratively on both the electric vehicle and battery end have become the first group to successfully launch this type of design, which is entirely reasonable.

I have collected a lot of Tesla’s repair information to see some findings.

Tesla’s Structural Battery and CTB of Seal Lion

The following picture is what we saw during the open day of the Tesla Texas factory. In terms of this structure, the load-bearing capacity of the battery shell mainly includes:

-

Two front seats

-

The feet of the members in the front seat

-

The feet of the members in the rear seat

Note: According to the disassembly situation, the fixing structure of the rear seat is unrelated to the battery pack.

In the seal lion’s design, both the front and rear seats are supported through a central cross beam, and the load-bearing capacity of the battery pack mainly relies on the stepping points of the members on top.

There is one more thing to note. Above the battery, there are mainly HVAC air ducts and compartments. The air duct mainly runs through the middle, and there is a certain buffer between the surface of the battery casing and the air ducts through a partition. The picture below shows the metal surface, which is the top cover of the battery pack.

There is one more thing to note. Above the battery, there are mainly HVAC air ducts and compartments. The air duct mainly runs through the middle, and there is a certain buffer between the surface of the battery casing and the air ducts through a partition. The picture below shows the metal surface, which is the top cover of the battery pack.

Just like the front row, Tesla’s rear row is also supported by the battery floor, with the white part being the air duct connected to HVAC. In the picture below, we can see that Tesla has made all the support parts into parts of the battery shell.

When the entire battery is removed, viewed from the top, the entire center is completely empty. To disassemble the battery pack, you need to remove the center console armrest, both seats, and all components of the middle air duct. It is indeed possible to repair, but it is very, very difficult.

We have not seen much of the structure of the seal body, but the basic logic is similar, that is, when disassembling the battery, the front seats do not need to be removed, which will be relatively easier, and the overall structure is completely the same.

Tesla’s shell design

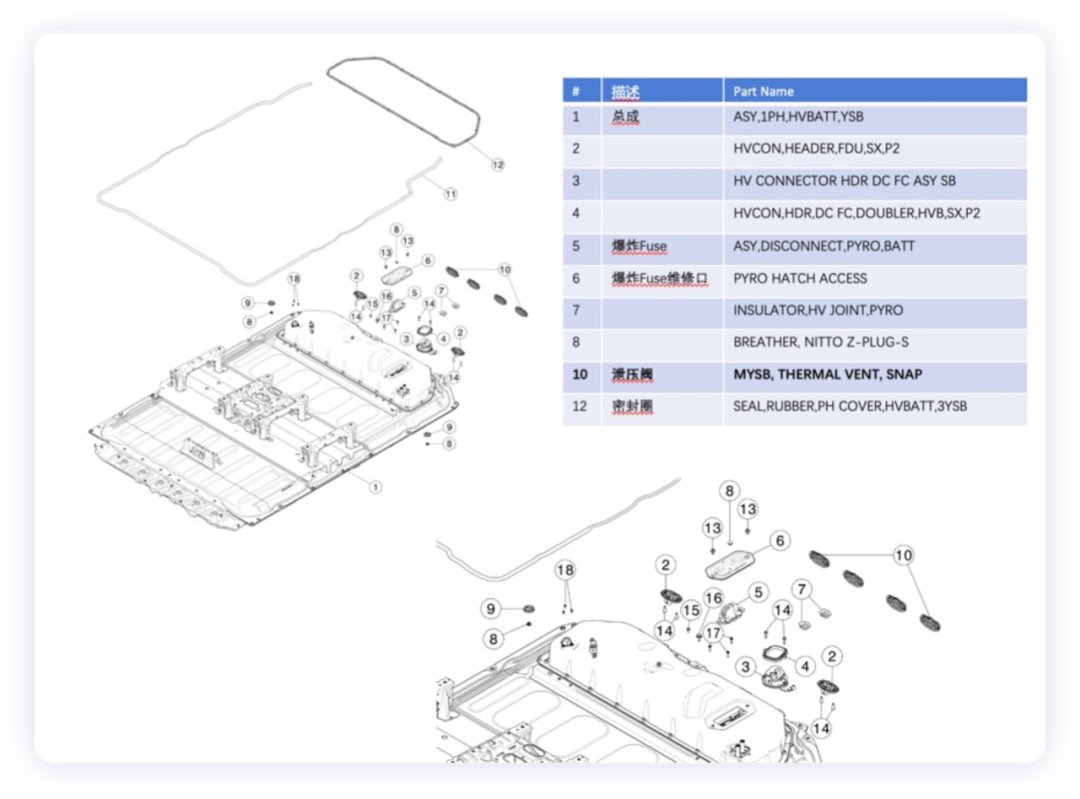

Because it is difficult to disassemble, Tesla’s maintenance strategy this time is mainly divided into three considerations:

-

Maintenance of Pyrofuse. There is a plastic cover above the battery pack. If this is a problem, you only need to disassemble some components of the rear seat and directly replace it.

-

Maintenance of electrical components. This is more difficult, but it is also disassembled from the second row seats, and the electrical components are repaired under the entire maintenance window.

-

Entire maintenance. This is when the battery cell is completely faulty, and the battery is replaced.

The sporadic issues that recently occurred in Shanghai can be resolved through replacement. LFP batteries from the Shanghai factory and NCA batteries from North America have both experienced sporadic quality control issues and require post-replacement.

The sporadic issues that recently occurred in Shanghai can be resolved through replacement. LFP batteries from the Shanghai factory and NCA batteries from North America have both experienced sporadic quality control issues and require post-replacement.

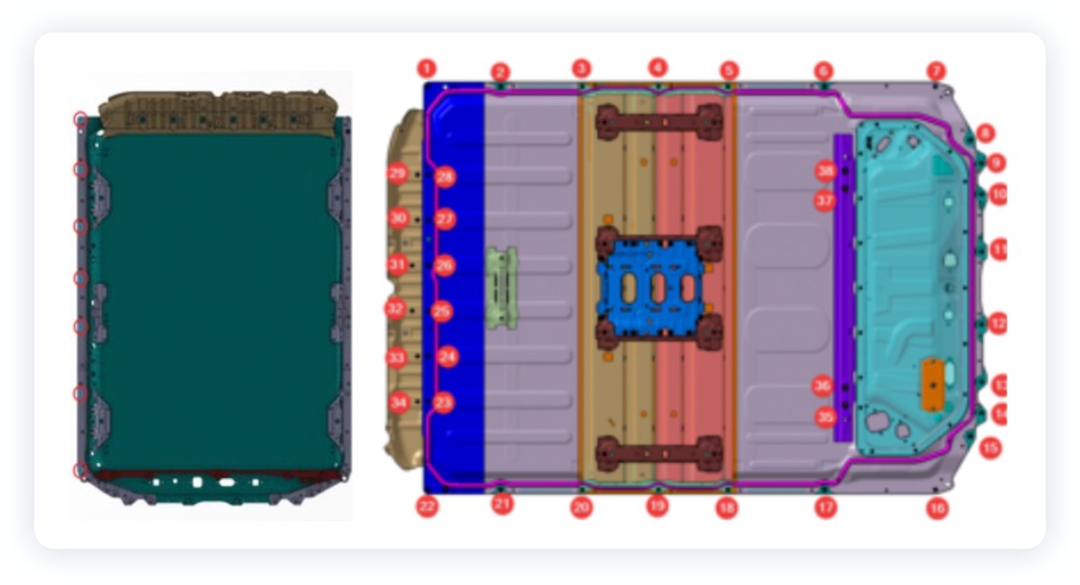

As illustrated in the picture below, there are many bolt connection points in this battery pack, including 38 bolts. This mainly consists of 14 bolts on each side, 7 on one side, 6+6 on the top with an additional protective plate, 4 hanging points for electrical components, and 8 hanging points at the end of the battery.

In the CTB state, the battery’s shell may revert from the existing welded shell to a sheet metal tray. According to different information channels, there are two possible paths for the two trays. One option is to use sheet metal for cost considerations, while the other is to use high-pressure cast aluminum (whether the aluminum strength is sufficient and how it matches the internal structural design is a challenge).

Conclusion: Looking at the overall structure, we need to consider the overall space requirements. Core competencies have evolved from giving space to batteries to vehicle space for batteries, which is currently the core interest of everyone. Addressing the overall arrangement space dimension or the Z-direction dimension is a point of interest.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.