On November 7th and 8th, Tesla’s Shanghai factory opened its doors to the outside world for the first time. As one of the first invited media groups, Garage 42 visited Tesla’s super factory in Shanghai, which was built in 10 months. Besides experiencing the factory, they also test drove the domestically produced Model 3 for more than 100 km.

This article will be divided into two parts – the factory and the vehicle. Those who are interested in the changes of the domestically produced Model 3 can skip to the second half directly.

Setting Sail of the “Fearless Ship”

On January 7th, 2019, Tesla’s Shanghai factory was established, and on November 7th, the first domestically produced Model 3 trial assembly car officially rolled off the assembly line after 10 months of construction, equipment installation, debugging, and trial assembly. This construction speed is unprecedented in the world.

Let’s first review the legendary construction process:

On July 10, 2018, Tesla signed a cooperation memorandum with the Shanghai Municipal Government to build a wholly-owned electric vehicle manufacturing factory, Gigafactory 3, in Shanghai.

On October 17, 2018, Tesla announced that it had acquired an 860,000 square meter plot of land in Lingang for the construction of Gigafactory 3.

On December 6, 2018, the land leveling work was completed and construction was about to begin.

On January 7, 2019, Elon Musk visited China to participate in the groundbreaking ceremony, and the Tesla Shanghai factory officially started construction.

On April 3, 2019, construction of the main structure of the Tesla Shanghai factory began.

On May 20, 2019, the Tesla Shanghai factory began to take shape and internal construction began.

On June 16, 2019, production equipment began to be installed inside the factory.

On July 24, 2019, Tesla released internal pictures of the Shanghai factory for the first time in the second quarter financial report, showing that a large number of manufacturing equipment had been installed.

On August 20, 2019, the Tesla Shanghai factory’s infrastructure construction entered the final stage and obtained the first comprehensive acceptance certificate.

On August 26, 2019, pictures of white car bodies being produced in the factory were exposed for the first time.

On September 19, 2019, the Tesla Shanghai factory passed its comprehensive acceptance inspection.

On October 17, 2019, the Tesla Shanghai factory was approved to start production of the Model 3.

Behind the extraordinary construction speed, apart from essential government support, there is also experience gained from Gigafactory 1 and Tesla’s flat management system.

Experience from Gigafactory 1

At the beginning of its construction, Gigafactory 1 was defined as a worldwide leading battery production facility that was replicable, scalable, and quickly iterative. All knowledge learned during the product development process can be shared with the Giga 3 factory construction team, so that a factory of similar capacity can be built with less than half the investment.

Flat Management System

At the same time that the Tesla Shanghai factory started production, SAIC Volkswagen’s MEB electric vehicle factory with a production capacity of 300,000 vehicles per year also announced that it had started trial production. People are curious, aside from the unparalleled construction speed, what is the differentiated core of Tesla’s factory in comparison to the industry?The core competitiveness of Tesla Shanghai factory remains the efficiency of execution brought by the extremely flat organizational structure advocated by Elon Musk and the culture of rapid iteration.

A subtle detail is that Zhu Xiaotong, the president of Tesla’s Greater China region and the director of the Shanghai factory, has no independent office in the factory. A small office area accommodates all functional departments from the top level to the front line, facilitating the whole process of identifying and solving “major” issues, from reaching the upper level within 24 hours, to discussing and making decisions, and finally, to implementing solutions.

What about “non-major” issues? When there is a conflict between efficiency and the power chain of transmitting orders, Tesla’s answer is: efficiency comes first.

Any front-line employee can initiate cross-departmental and cross-level communication at any time, including sending messages directly to Zhu Xiaotong or even Elon Musk if necessary.

This is a miraculous company that was founded 15 years ago and still maintains a Day 1 mentality throughout the company. It is now about to engage in a close combat with the industry giant Volkswagen Group which possesses strong capabilities in research and development, manufacturing, and supply chain management.

The rapid pace of the Tesla factory may be attributed to the government’s green light, which is indispensable of course. But behind all this is the construction team of the Shanghai Construction Group and the hard work of Tesla staff day and night. It is the combined efforts of the three parties that made the fearless ship set sail on time!

Now let’s take a look inside the factory. As the factory has not been fully completed and is not open to the public, we will briefly introduce it through the official PPT.

Currently, only phase 1 of the Tesla Shanghai Super Factory has been built, with a planned annual capacity of 150,000 vehicles. This is only one-fourth of Gigafactory 3. Once the entire Gigafactory 3 is completed, the annual production capacity can reach 500,000 vehicles.

Two noteworthy details:

Firstly, the body welding production line of the Tesla factory can work with three robots on the left, right, and top sides simultaneously. Compared with the left and right robots, the coordination difficulty of the numerical control software of the robotic arm is greater, but the production efficiency can be further improved.Secondly, the general assembly workshop of Tesla factory is arranged in a straight line shape, which is more efficient in the assembly line production process. As an integration link for all components, the general assembly workshop will gather a large number of parts from all over the world. On one side of the factory is a container unloading area arranged in a straight line, where all parts can be delivered to the production line in the first place.

This is the current situation of the whole Tesla Shanghai factory.

Any Changes with the domestic Model 3 rolling off the production line?

Before seeing the domestic version of Model 3, in addition to excitement, I had some concerns. I hope that after domestic production, Model 3 can touch more users with lower prices, let more people feel what intelligent cars are and what growing cars are, and change more people’s cognition and views of traditional cars. However, I worry about the changes in the mechanical quality of the vehicle after domestic production.

Fortunately, my worry is unnecessary. It is still the familiar Model 3.

- About workmanship

Let’s take a look at a set of detailed comparison pictures.

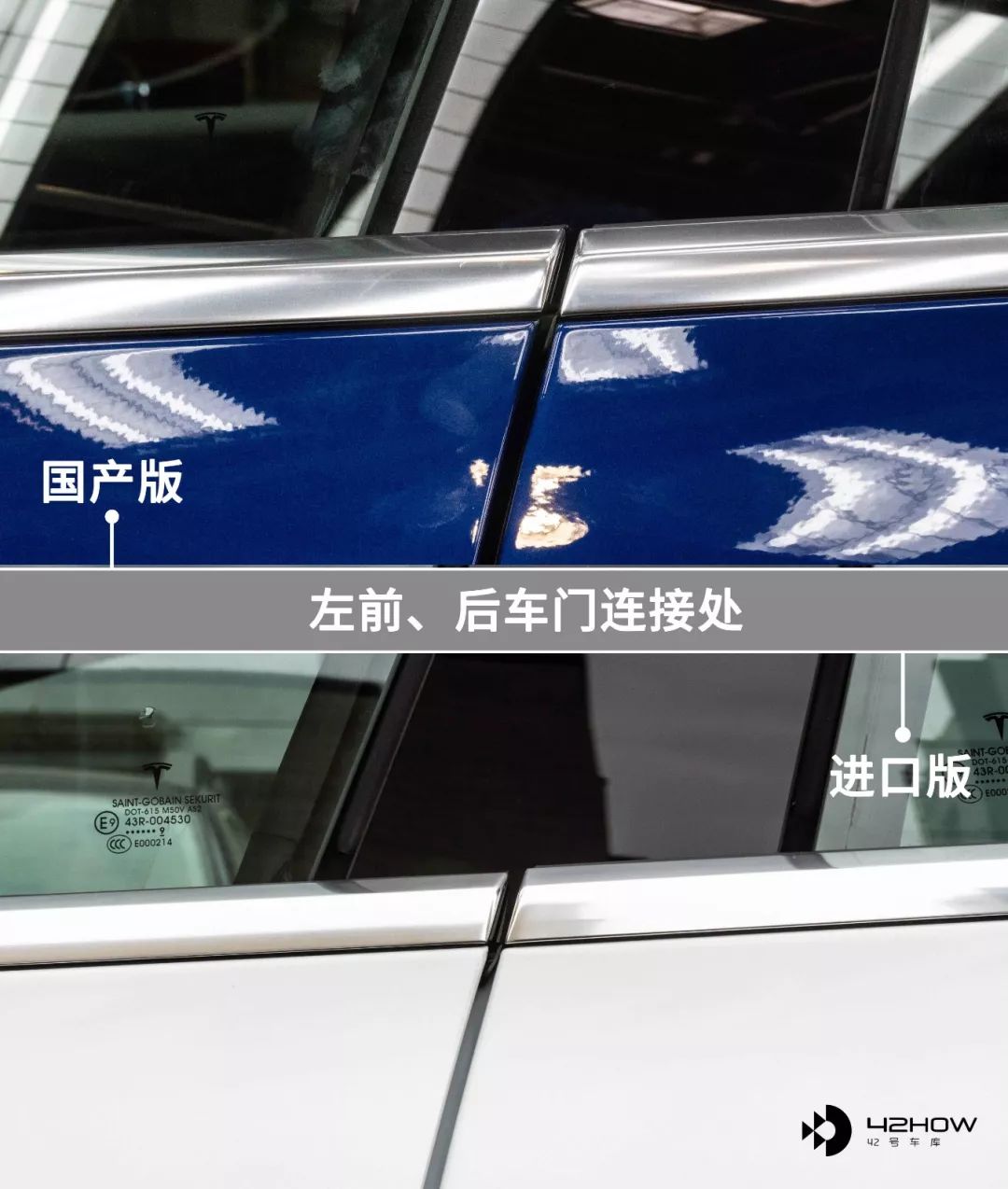

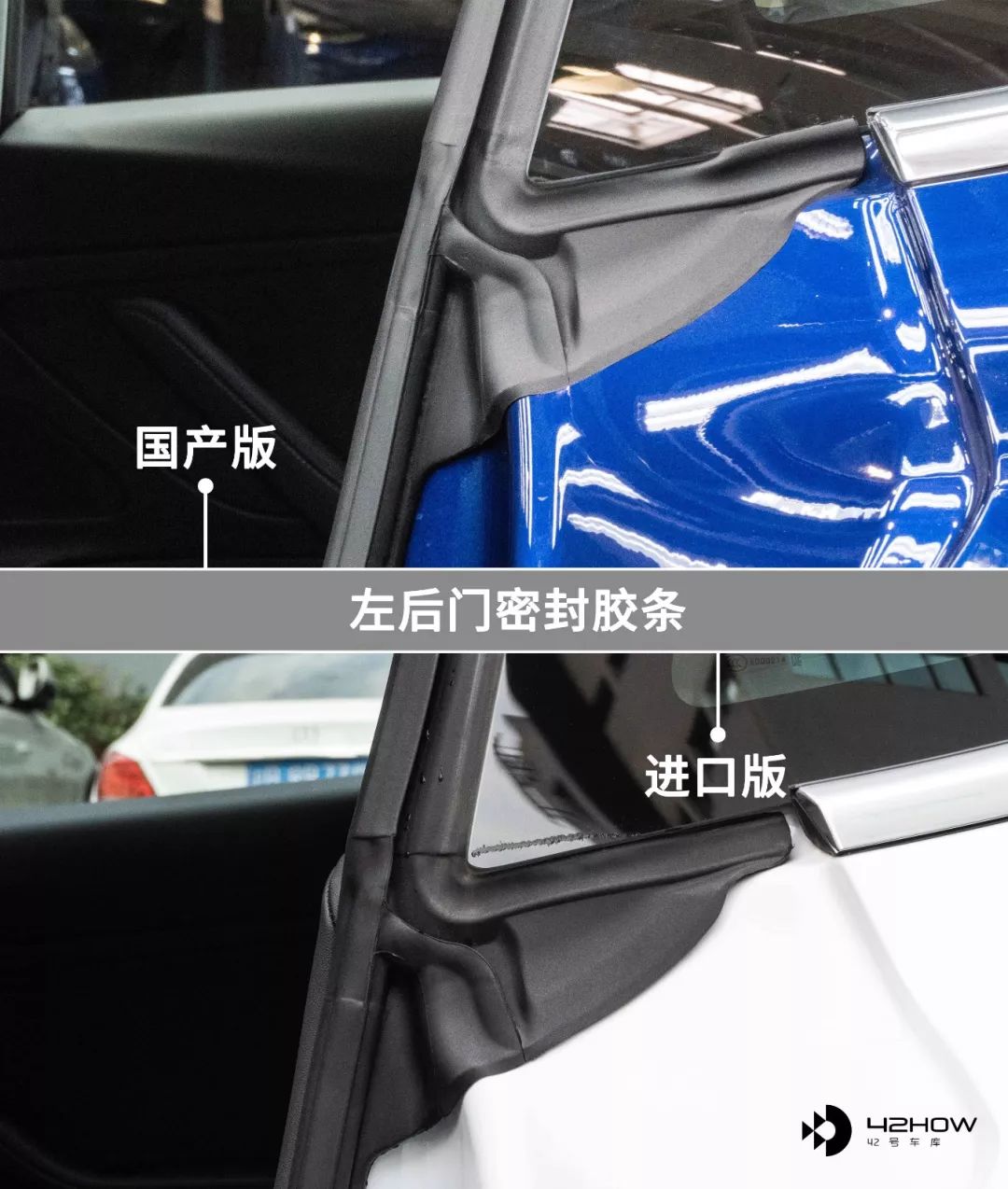

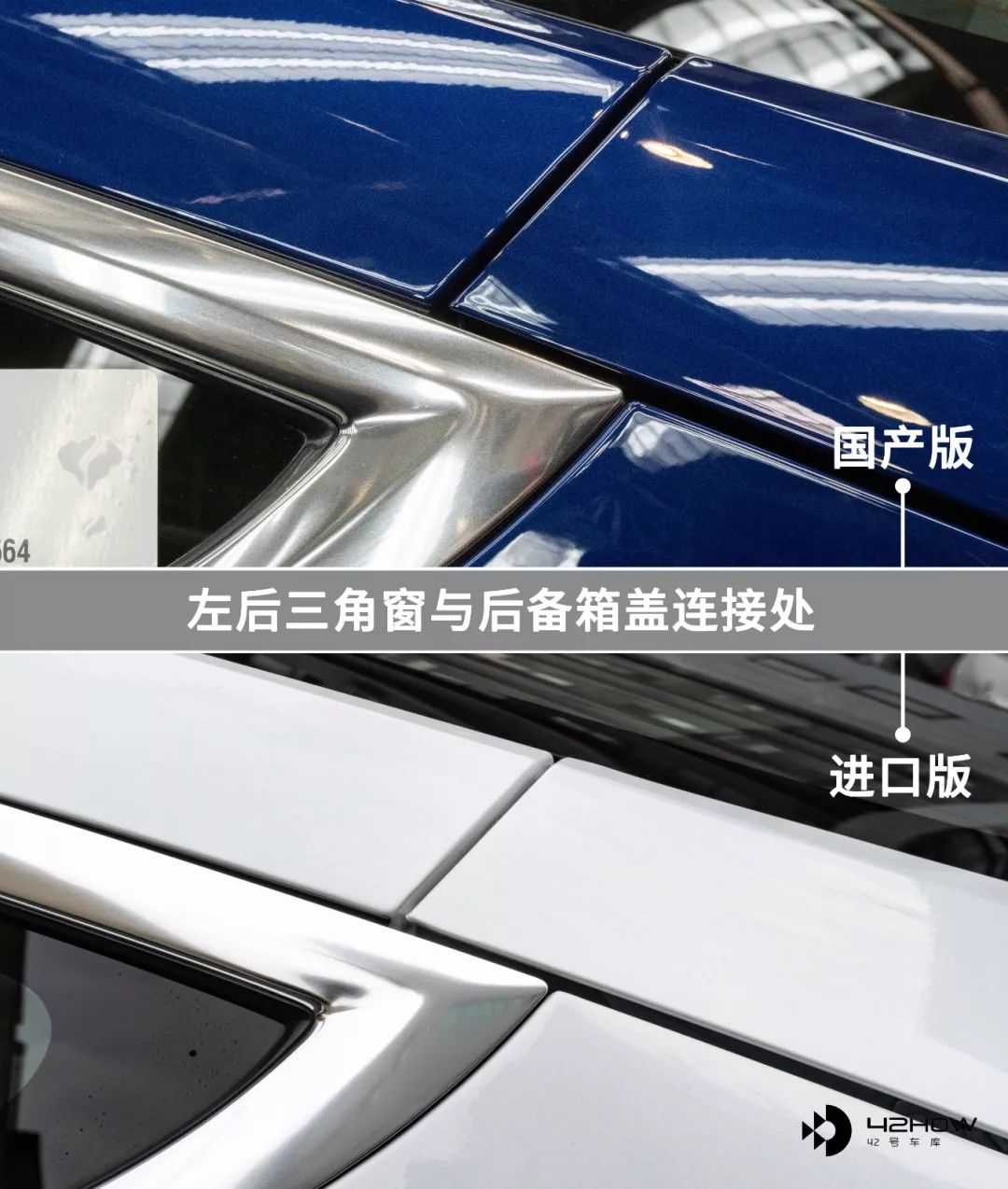

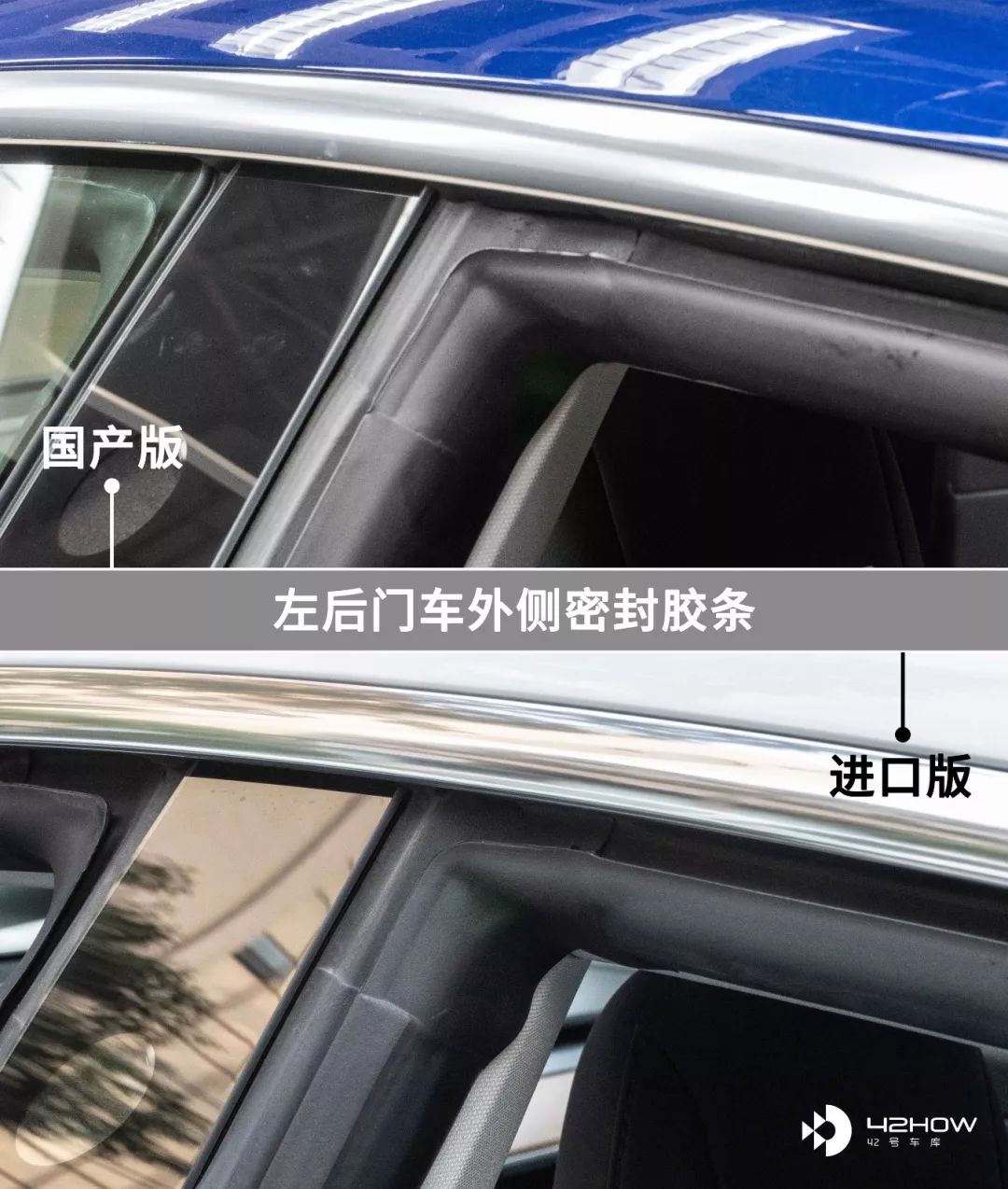

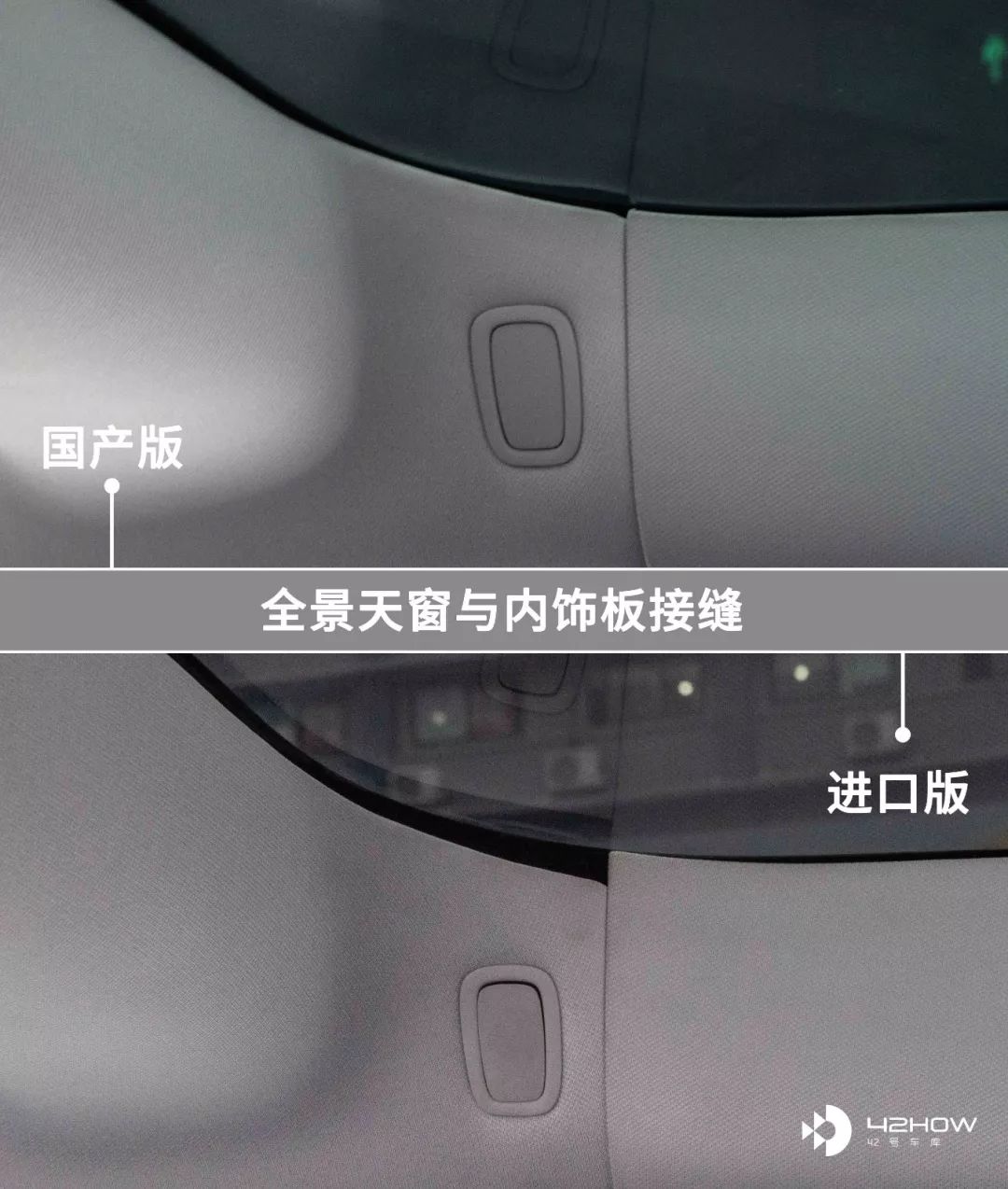

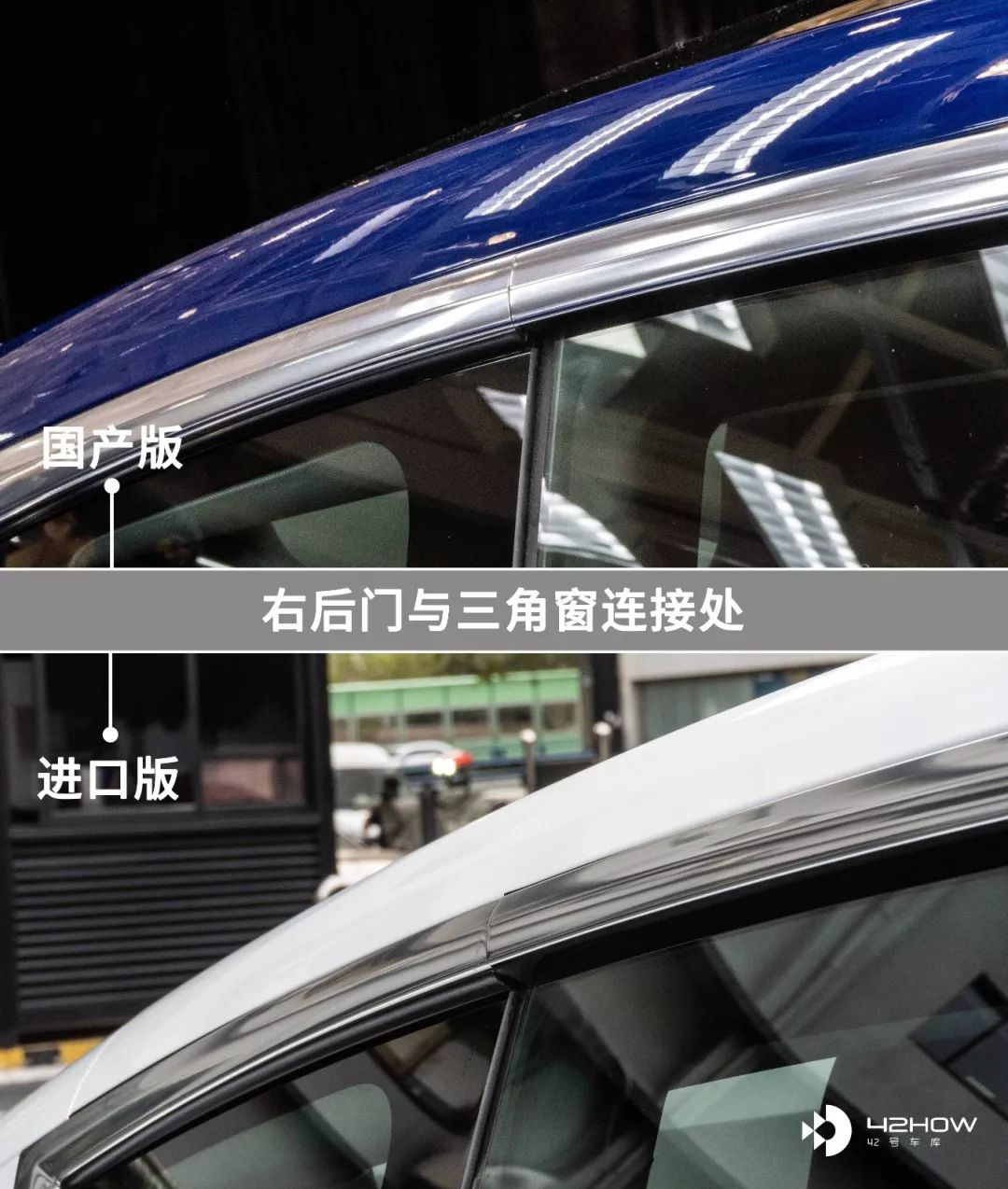

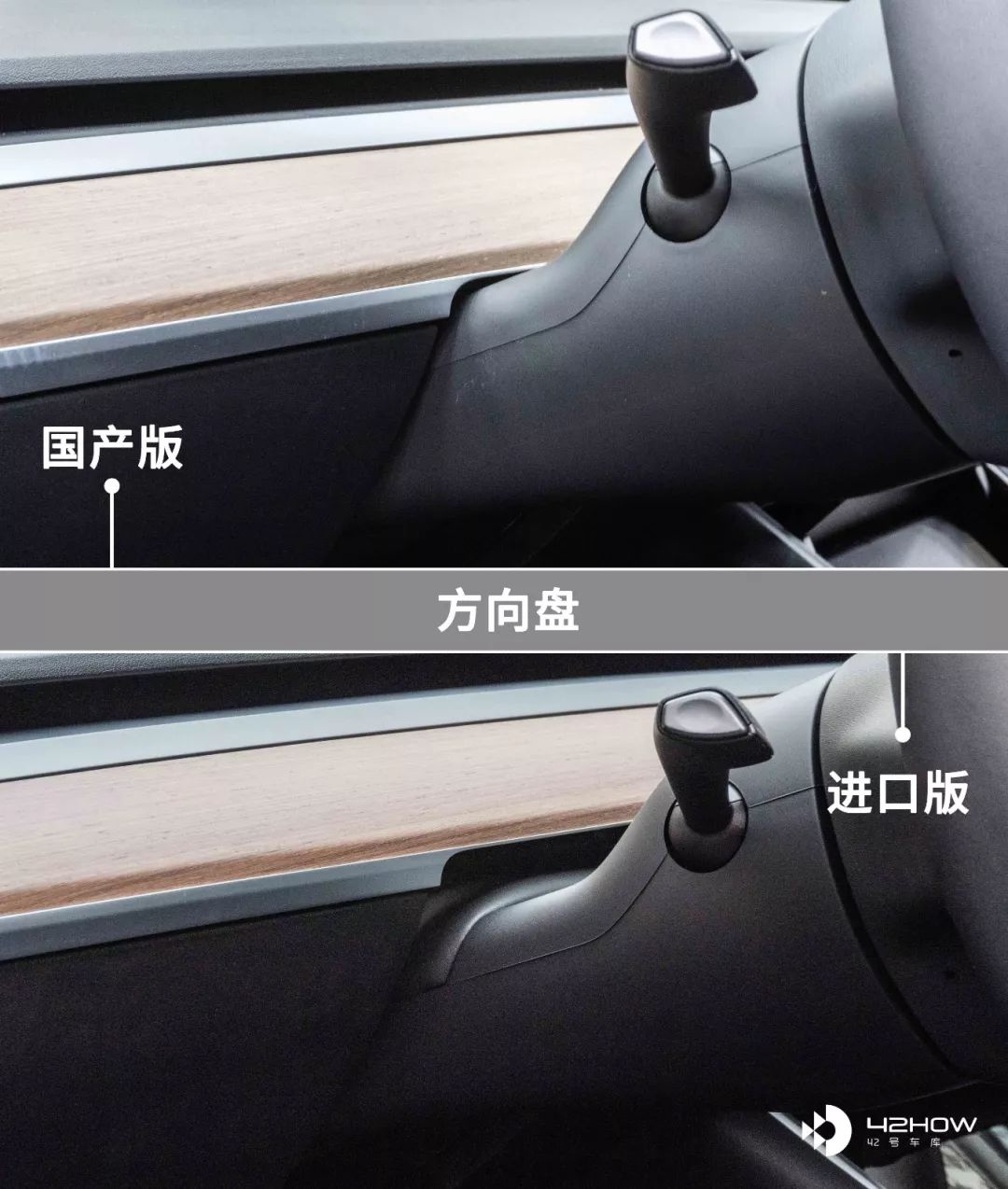

The blue one is the domestically produced Model 3 that has just come off the factory, the white one is the imported Model 3 purchased by Garage 42 in March this year. From the comparison of details, the seams of the body panels of the domestically produced Model 3 are slightly smaller, but the overall difference is not significant. After we published this set of pictures on Weibo, many people thought there was no difference at all.As one of the few who have touched it by hand, I have to say that although the difference in gap size is small, the smoothness of the two covering parts is much better than that of the imported model. The seam between the trunk lid and the C-pillar can be obviously felt in the imported model, while the domestic model is basically on the same plane.

In terms of interior workmanship, the improvement is much more obvious than the exterior. The joints of the interior trim panels are smaller, and the rubber strips on the doors are more uniform.

The quality of the first batch of vehicles produced by the Shanghai factory is beyond our expectations, as we analyzed in the article “Getting to Know the Domestic Tesla” (source). The improvement of craftsmanship requires time and experience accumulation, especially for a company like Tesla that prioritizes efficiency.

According to a Bloomberg survey of 5000 Model 3 owners on October 29th, when Tesla delivered the most vehicles in February 2019, the most problems also occurred. However, as more and more vehicles have been produced, the number of problems has decreased. So this is just the beginning of the Shanghai factory, and as production increases, craftsmanship will continue to improve.

Regarding production and components, the earliest rumor was that Tesla’s Shanghai factory would achieve mass production of first batch vehicles through CKD/SKD assembly, but today’s event revealed that the four production processes of Tesla’s Shanghai factory have been run through, entering directly into full-process production. The vehicles that have been produced are made by Tesla’s Shanghai factory.

In terms of appearance, the stamping parts of the car body are all manufactured by the Shanghai factory, and the window glass has been changed from Saint-Gobain imported version to Fuyao.

- About the battery

The current offline vehicles still use imported Panasonic batteries. Whether Tesla will replace them with other brands of cells after domestic mass production remains unclear. According to foreign media reports and our analysis of LG Chemical’s investment direction and technological development, once the LG Chemical plant in Nanjing is completed and put into operation, Tesla’s Shanghai plant will use LG Chemical’s cells to manufacture vehicle power batteries.

- About the driving experience

This time, I specifically drove an imported version of the Model 3 to participate in the test drive of the domestic version. The most intuitive feeling is that there is almost no difference in driving experience between the two vehicles, and they are still smooth to accelerate, extremely precise in steering, tight in chassis, and easy to drive.

In terms of noise, after our actual measurement, under the same road conditions and the same speed (60 km/h), the noise of the domestic version of the Model 3 is between 62-63 dB, while the noise of the imported version is between 64-65 dB, and the domestic version feels better as well.

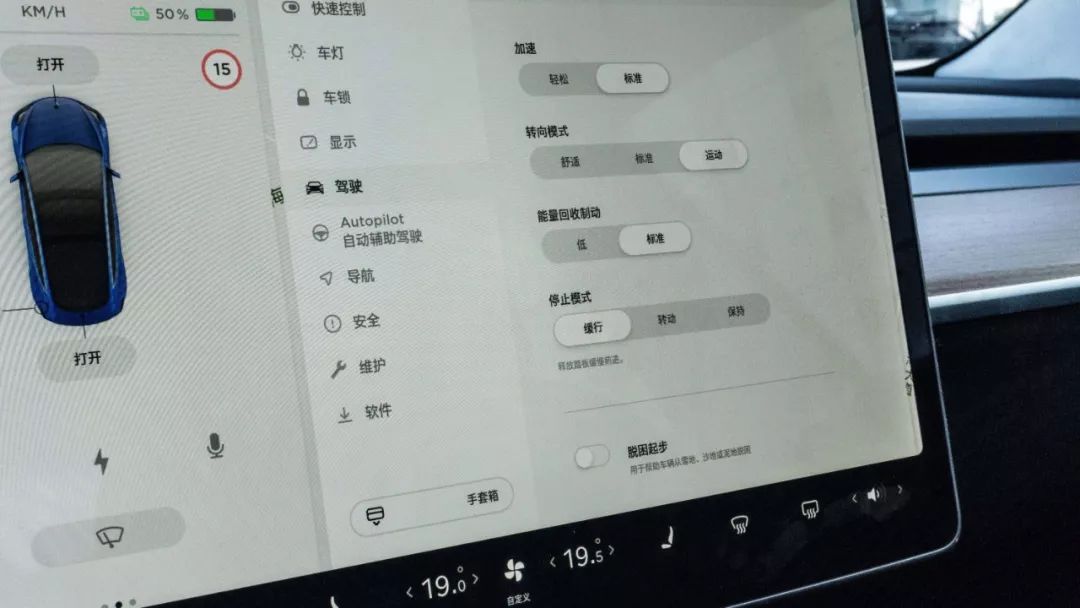

- About new software features

The batch of vehicles offline from Tesla’s Shanghai plant are the first to be equipped with version 2019.36.1 of the software, which has two new features: cone recognition and the ability to stop with a single pedal.

Cone recognition: The previous versions of Autopilot have 0 ability to recognize cones, which has caused accidents both domestically and internationally.The improvement of Tesla’s assisted driving system in recognizing traffic cones was once again demonstrated during the brief test drive. In total, we encountered two traffic cones, one on the highway and the other in a parking lot.

Even at a speed of 120 km/h on the highway, the vehicle could accurately identify the traffic cones on the road. Unfortunately, we did not have the opportunity to test whether the vehicle could actively avoid the traffic cones while in Autopilot mode. We will conduct corresponding tests as soon as the software is updated.

In the parking lot, I tried driving the vehicle around the traffic cones, and the display on the instrument panel changed smoothly according to the dynamic changes of the vehicle’s position with the traffic cones.

After the test, the only feeling is that Tesla is too flashy, please push the new version of the software as soon as possible.

The “One-Pedal Driving” mode with regenerative braking: In this mode, when the accelerator pedal is released, the vehicle will be decelerated to a complete stop by regenerating kinetic energy, realizing full one-pedal operation. The regenerative braking is fully utilized, not only maximizing the energy recovery, but also reducing the wear of brake pads.

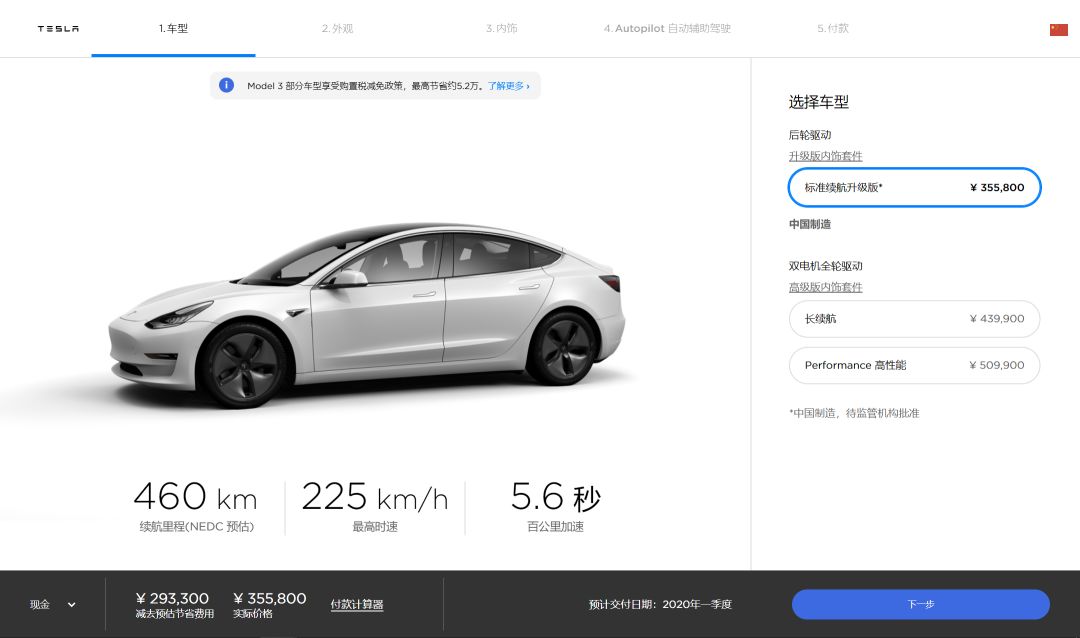

- About the Parameters and Prices of the Chinese Model 3

The power parameters and vehicle size of the Chinese Model 3 are exactly the same as those of the imported models, with the only differences being the NEDC range and the price.

Currently, the NEDC range displayed on the official website is still estimated to be 460 km, while the NEDC range of the imported standard range plus model is 480 km, a difference of 20 km. The official statement indicates that the Chinese version is undergoing corresponding tests in China and the results will be updated as soon as they are available.

The price is not surprising, which is 355,800 yuan, including the basic Autopilot. As for whether there is room for this price to decrease, you can refer to our previous article on the Chinese Tesla pricing, which provides a full interpretation of pricing policies (http://mp.weixin.qq.com/s?_biz=MjM5NTIyMjA2MQ==&mid=2656753385&idx=2&sn=0d98c7e3168aaf812074f283c4bc1ad2&chksm=bd55b1ab8a2238bd6ad9e9b94b76f923d117ddcce5f3d0da1f178ac3c53fc3f2b03316c9dfbd&scene=21#wechatredirect).

The price is not surprising, which is 355,800 yuan, including the basic Autopilot. As for whether there is room for this price to decrease, you can refer to our previous article on the Chinese Tesla pricing, which provides a full interpretation of pricing policies (http://mp.weixin.qq.com/s?_biz=MjM5NTIyMjA2MQ==&mid=2656753385&idx=2&sn=0d98c7e3168aaf812074f283c4bc1ad2&chksm=bd55b1ab8a2238bd6ad9e9b94b76f923d117ddcce5f3d0da1f178ac3c53fc3f2b03316c9dfbd&scene=21#wechatredirect).

- About the Production Planning of the Shanghai Factory

From the confirmed news that has been published, the Shanghai factory will currently only produce the standard range upgrade version of Model 3. After the Model Y is launched, the Shanghai factory of Tesla will also produce it synchronously.

As for the long range version and Chinese extended range version of Model 3 that many people are looking forward to, the official has not made any response. As far as we know Tesla, as long as there is demand in China, the Chinese long range version is entirely possible, but it may not come as quickly as expected. The possibility of an extended Version of Model 3 is very small. Friends who have space needs may want to wait for the Model Y.

Finally, let’s return to this picture at the end of the article. The eye-catching Tesla logo on the tailgate declares itself as a Tesla produced in China to the world. More importantly, there is no FAW, no SAIC, and no GAC in front of the word “Tesla”. This is the first wholly-owned car company in China, an intelligent electric vehicle production company.

After nine years of continuous new energy policy subsidies, the Chinese market needs fresh energy. Under the leadership of Chinese Tesla, more people will learn about intelligent electric vehicles, accept them, and promote the development of domestic new energy vehicles.

The world is developing towards sustainable energy, and the entry of Tesla into the Chinese market will only accelerate this process.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.