Author: Turbocharged Fatty

Yesterday, the autonomous driving company Qcraft held the first QCRAFT DAY, a brand upgrade event. During the QCRAFT DAY, Qcraft mainly released:

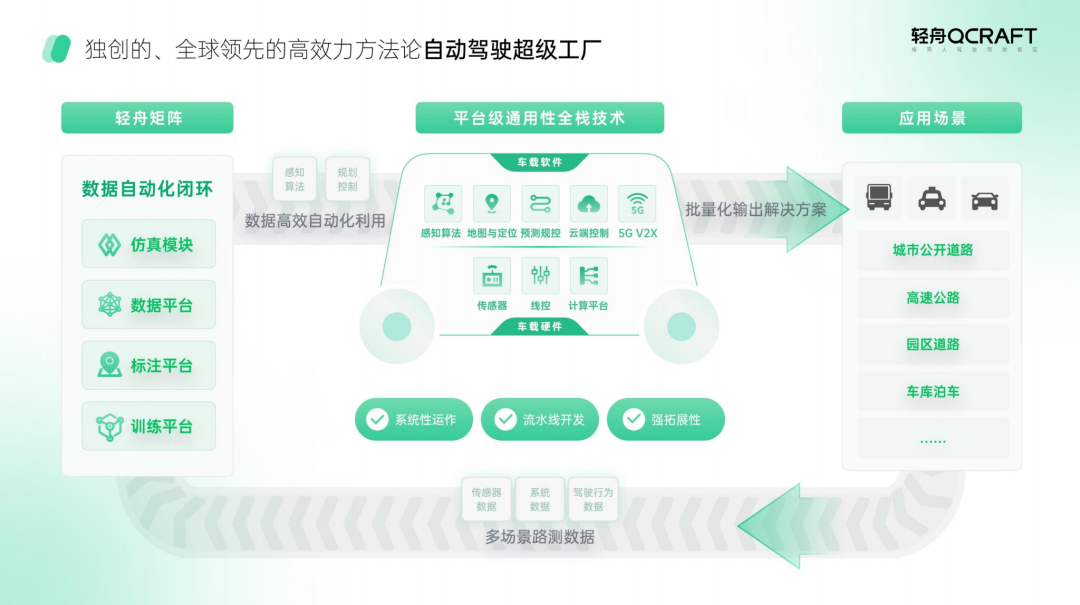

- An “autonomous driving super factory” efficient methodology;

- A “dual-engine” development strategy;

- A mobile travel space solution “Dragon Boat SPACE”;

- The fourth-generation mass-produced vehicle-class autonomous driving solution “DBQ V4”; and

- An autonomous driving development toolchain “Qcraft Matrix”.

In addition, Qcraft also reached strategic cooperation with Volcano Engine, T3 Travel and Horizon Line.

Choosing between Bus and Taxi

In the context of the commercialization of autonomous driving, Robotaxi is significantly more popular, but Qcraft did not choose to follow the Robotaxi route from the beginning.

Now that the Robotaxi market has entered the second half of its battlefield, Baidu Apollo and Xiaoma Zhixing have also obtained the “main driver automatic” test license in Beijing. Nevertheless, in the short term, Robotaxi’s development remains difficult to surpass the operating capacity of cruising taxis and ride-hailing platforms.

Meanwhile, Robotaxi is mainly based on sedan and SUV models, with small passenger capacity and limited operational capability. In contrast, Robobus can carry more passengers and has greater operational capability, to some extent replacing the function of urban public transportation. At the same time, because of lower speed, Robobus has a higher safety factor and fixed routes are easier to manage.

But this does not mean that Qcraft will always stick to Robobus. As the scale of commercialization of Robobus continues to expand, it will be easy to switch to the Robotaxi mode when routes and stops become more widespread.

Building Rockets instead of Ladders

On the technology roadmap to achieve autonomous driving, Qcraft seems to have a different understanding.

If we describe the landing process of autonomous driving as “exploring the moon,” what kind of “tools” should be built?>If the “build a ladder” strategy is chosen at the beginning, you can see the people still on the ground one step ahead. When the ladder reaches its limit and cannot meet the needs of “moon exploration”, it is necessary to return to the ground and build new tools;

>

On the other hand, if the “build a rocket” strategy is chosen from the beginning, although it requires higher technology, higher costs and more time-consuming, it will not only exceed the limits of building a ladder, but also meet the needs of “moon exploration”.

The core of the process of the scale landing of autonomous driving is “data and data-driven”. This not only includes simulated data, but also road test data. Whoever has a large and complete dataset and can thoroughly “activate” these data, will have a hope of leading the forefront of autonomous driving.

Road test data: Many people choose to produce L2/L3 products first to achieve product scale landing, and then gradually upgrade, evolve and iterate towards L4 through accumulated data. However, the requirements of L2/L3 software and hardware and application scenarios are very different from L4, and it is difficult to exchange data with L4, and it is also difficult to improve the data loop.

Simulated data: Some people choose to land products as the first requirement, conduct a large number of road tests, and collect a large amount of road test data. However, they later found that road tests alone cannot fully cope with unpredictable road scenarios, so they realized the importance of simulated data.

And Quicktron has chosen the way of “building a rocket instead of building a ladder” from the beginning to achieve the landing of autonomous driving. It is also based on this concept that Quicktron has created the highly efficient methodology of the “Autonomous Driving Super Factory”.

This is a systematized and automated autonomous driving infrastructure that is based on “data-driven” and “efficiency improvement”. It creates a data automation loop and strives to make the entire loop rotate faster, providing support for Quicktron’s technology, products, and autonomous driving solutions research and development.

Quicktron initially regarded the simulation testing platform as a key core capability, and also paid attention to “automation”.

By applying semi-supervised learning, self-supervised learning, and data synthesis in the perception field, the dependence on manual labeling is reduced, and the data labeling cost is greatly reduced. Enhance the interpretability of AI data, replace manual operations with machine automation, and convert engineer time into machine time, forming an “automated mass production factory”.

In addition, the industry now widely adopts the “time and space separated planning” scheme, but its ability to cope with road changes is very limited, often resulting in sudden stops and continuous braking. Relying on the “autonomous driving super factory”, QZ Intelligent Navigation has also created the “time and space joint planning”.

The “time and space joint planning” system of QZ Intelligent Navigation endows vehicles with more sensitive timing control ability, enabling them to complete continuous obstacle avoidance in complex road problems, and the product riding experience is also smoother and more comfortable.

Power + Innovation = the Boosting Engine of Autonomous Driving

The autonomous driving industry is ushering in a golden turning point of development, with more friendly policies and regulations, stronger technology algorithms, sensors and computing moving towards the direction of vehicle-level, and more industry supporters.

In the face of such a historic opportunity, QZ is committed to continuously investing in both vertical technology depth and horizontal scenario width, and always adheres to the development philosophy of both technology and commercialization, promoting the continuous landing of high-level autonomous driving technology in a wide range of scenarios.

To this end, QZ Intelligent Navigation has proposed the “Dual Engines” strategy:

-

The “Power Engine” gradually achieves fully autonomous driving ability in more scenarios with the public road L4 automatic driving software and hardware solutions it builds;

-

The “Innovation Engine” is built with a freely configurable automatic driving front-loading mass production solution to help users innovate with a safer and more cost-effective high-value proposition, and achieve the large-scale landing of autonomous driving technology;

-

The two engines “rotate in parallel” under the autonomous driving super factory, with data symbiosis and sharing.

Two sets of solutions + one set of toolchain

Based on the autonomous driving super factory methodology, QZ Intelligent Navigation has released three products under the “Dual Engines” strategy: Longzhou SPACE, DBQ V4 and QZ Matrix.

Longzhou SPACE

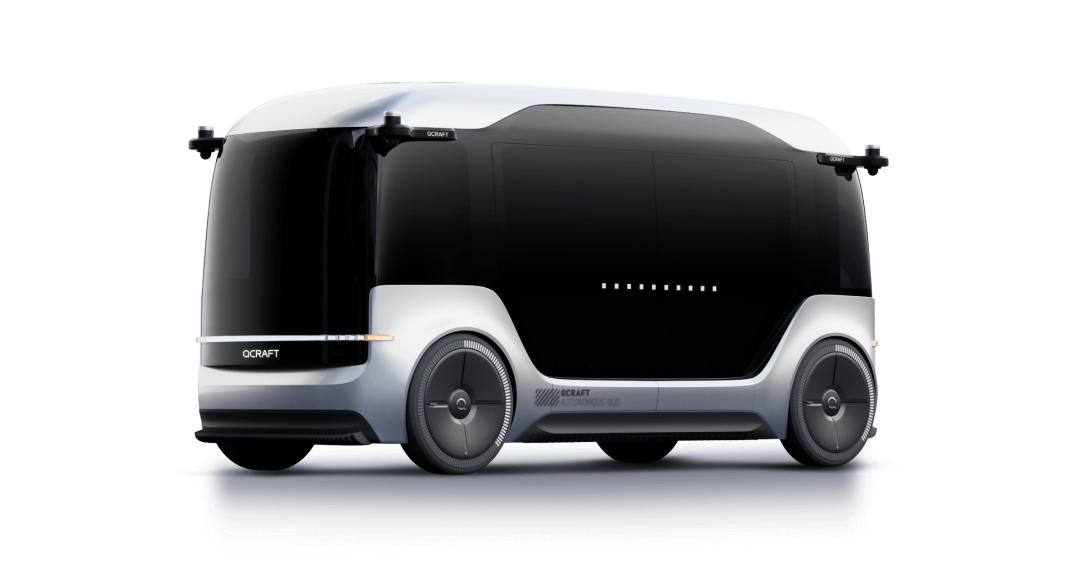

Longzhou SPACE is a set of mobile travel space solutions that can operate on complex public roads, adapt to various vehicle models, meet seamless connections from long-distance to short-distance, and the space can also undergo multiple transformations to cover different scenario needs.

Last year, QZ Intelligent Navigation and Dongfeng Yuxiang took the lead in launching Sharing Bus, based on Longzhou SPACE, which has landed in many cities such as Wuhan and Dali. QZ Intelligent Navigation and Dongfeng Yuxiang will gradually realize the commercial operation of 300 unmanned vehicles nationwide.

Sharing Bus is based on QCraft’s Driven-by-QCraft automatic driving solution and can achieve 360-degree sensing around the vehicle with a sensing distance of more than 200 meters. It is mainly applied to fixed-line medium and low-speed scenarios with operation speeds between 20km/h and 50km/h.

In addition to basic functions such as pedestrian and vehicle avoidance, automatic lane changing, automatic steering, and traffic light recognition, it can also cope with various complex traffic scenarios in cities, such as intersections with mixed pedestrian and vehicle traffic, vehicles cutting in from behind, and surveillance cameras.

DBQ V4

DBQ V4 is QCraft’s fourth-generation mass-produced autonomous driving solution, which integrates the company’s self-developed automatic driving hardware and software technology. It can be realized with domestically produced configurations and can flexibly select different configuration schemes based on different customer or OEM requirements. At the same time, a set of technical stacks can meet the application requirements of different vehicle models and scenarios.

QCraft mentioned:

DBQ V4 can achieve 99% of L4 capability with only 10% of the cost, and the cost of mass production is as low as RMB 10,000.

“Mass production cost as low as RMB 10,000” sounds somewhat exaggerated. At least from the official information, DBQ V4 is equipped with lidar, and no matter which brand and model of lidar product is used, the cost will still account for several thousand yuan at the very least.

Even if QCraft’s current L4-level autonomous driving algorithm is not included in the cost, the hardware portion still needs to consider the cost of high-performance autonomous driving chips that meet L4 requirements, multiple high-definition cameras, multiple millimeter-wave radars, etc.

The Lightboat Matrix

No matter how it is trimmed and combined, what will a set of L4-level autonomous driving systems bring with 10,000 yuan?

The Lightboat Matrix is one of the core components of autonomous driving super factories, which is an autonomous driving R&D tool chain with simulation at its core. Its primary functional points are data annotation and deposition.

The Lightboat Matrix connects data processing, annotation, training, large-scale simulation, and technical output, which is an important support for Lightboat’s autonomous driving super factory’s “data-driven” and “efficiency improvement” strategies, realizing efficient utilization of autonomous driving data and driving efficient iterative technology development.

This set of Lightboat Matrix autonomous driving R&D tool chains has also been officially opened to the public, assisting customers in building their own “autonomous driving super factories.”

Final Words

The advent of Robobus has opened the era of urban micro-circulation autonomous driving, solving the problem of users’ last three kilometers of travel. It initially focuses on middle- and low-speed scenarios with fixed routes and creates a city-level autonomous driving mobility space, establishing a micro-circulation system in urban roads.

Compared with Robotaxi, the Robobus model and product are more easily accepted by urban managers.

However, it is apparent that Lightboat Intelligence cannot escape the “commercialization” path. The scale and development speed of Robobus alone cannot fully satisfy Lightboat Intelligence’s “appetite.”

Therefore, Lightboat Intelligence has chosen a parallel route for Robobus and the passenger car pre-installation solution.

The mature L4-level autonomous driving solution’s software and hardware are “trimmed,” and the dimension is lowered and put into the L2-level assisted driving solution for passenger cars. Choosing a larger passenger car market will accelerate Lightboat Intelligence’s commercial capabilities and speed.

Most importantly, Lightboat Intelligence now has enough technological reserves and front-loading production capabilities.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.