Author: French Fries Fish

“Hurry up! Leapmotor is having a new product launch again!”

When there is a fan of a certain brand in the company, you will never miss out on the news of this brand. Fortunately, I have such a colleague.

Three months ago, our CTO Mr. Mie became a fan of Leapmotor after the event “the bladder couldn’t hold on against the endurance of C11”. For details on how he was persuaded and impressed, interested readers can click the video below to review.

As an automotive company with a strong engineering culture, Leapmotor has already told us about their attitude towards self-developing technology through various product launches.

And this time, Leapmotor brings “mass-produced CTC battery chassis integration technology.”

The power battery is the core component of an electric vehicle. Improving the power battery naturally becomes the goal of every technology-seeking car company.

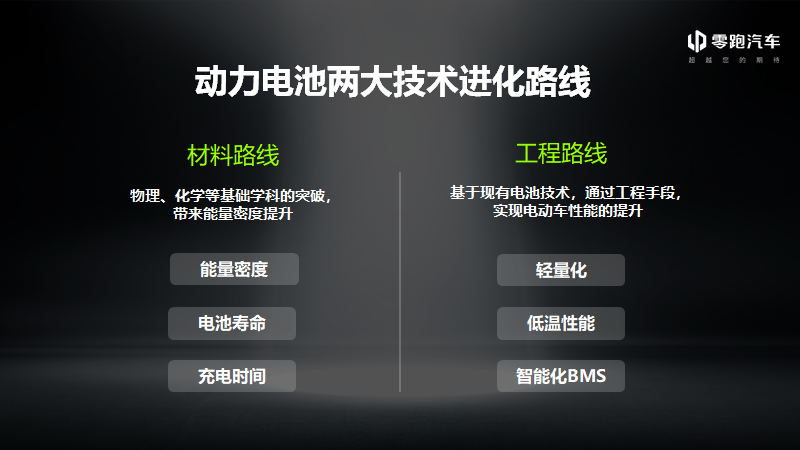

From the current perspective, there are two evolutionary routes for power batteries. One is the material route, which improves the battery energy density by finding breakthroughs in basic disciplines such as physics, chemistry, etc.; the other is the engineering route, which achieves better battery performance through engineering methods such as battery pack structure adjustment, and battery management technology.

It is obvious that Leapmotor has chosen the more realistic engineering route.

If you are not particularly interested in electric vehicles, you may not know what CTC battery technology is.

In response to this, Song Yineng, the general manager of Leapmotor’s battery product line, gave a definition:

“CTC technology, namely cell-to-chassis, refers to the cutting-edge technology that integrates battery, chassis, and lower body design to simplify product design and production processes.”

The core of CTC technology is to couple the redesigned battery-carrying pallet with the chassis of the vehicle, thereby reducing the redundant structure and number of parts, and obtaining more battery space. This is what Song Yining called “Less is more”.

The core of CTC technology is to couple the redesigned battery-carrying pallet with the chassis of the vehicle, thereby reducing the redundant structure and number of parts, and obtaining more battery space. This is what Song Yining called “Less is more”.

For electric vehicles, battery safety is of the utmost importance. In the past, fewer redundant structures and more battery safety were seen as contradictory. The core challenge of CTC technology is how to use “Less” structure to ensure “More” strength.

The hardware solution is to use a dual-skeleton annular beam as the body and chassis structure of the vehicle, which can also be reused as the battery skeleton structure, that is, the chassis structure and the battery skeleton are combined into one.

Note that structural strength is not always “1 + 1 = 2”.

In terms of component quantity, the new structure has fewer components, but its strength is higher than that of the original chassis and battery skeleton, thus achieving higher structural efficiency.

On the software side, Leap Motor has integrated artificial intelligence into the BMS battery management system. With the help of the on-board network, the new BMS will monitor the battery status in real-time on the vehicle end and upload battery big data to the cloud. The cloud will use AI deep learning to analyze massive battery information, and provide feedback to the vehicle end with battery charging and discharging strategies suitable for the current battery status, thus ensuring battery safety and achieving better battery performance.

What impressed me most at this press conference was how Leap Motor used specific quantified numbers to explain these abstract concepts. For example, “higher structural efficiency” means increasing the vertical usable space by 10mm, the battery layout space by 14.5%, and the vehicle torsional rigidity by 25%; and “better battery performance” means an overall endurance increase of 10% under various operating conditions, charging for 5 minutes, and continuing to travel for over 200km.

The CTC new hardware and BMS new software together form Leap Motor’s intelligent battery technology. Combined with the previously released intelligent electric drive technology, the release of the intelligent battery will complete Leap Motor’s “Leapmotor Power” intelligent power technology.In the era of “Internet celebrity culture,” manufacturers are constantly trying to cater to their audience’s interests, and it seems that a press conference without some sort of special feature or “One More Thing” is just not enough.

Luckily, ZERØ RUN did not disappoint. After showcasing their cutting-edge technology, they unveiled their first mass-produced sedan with CTC technology: the ZERØ RUN C01.

During the unveiling of the C01, “self-developed” was the phrase I heard the most from ZERØ RUN.

From multi-sensor fusion perception algorithms, planning and decision-making algorithms, control algorithms, AD control units and sensors for intelligent driving, to operating systems, upper-layer applications, and intelligent cockpit control unit and cockpit interaction system for intelligent cockpit technology, to the complete control system, thermal management system, intelligent electric drive system, and the intelligent battery system that was debuted today, these are all the latest products made with ZERØ RUN’s in-house research and development.

This self-developed technology both bolsters my expectations for the C01 as well as causes concern for whether ZERØ RUN is capable of maintaining full control over all of these aspects of the car, after all, an automobile is a systemic engineering project, and any shortcomings in any one sub-field could negatively impact the overall driving experience.

Of course, whether this is good or bad, we will have to wait for a true experience in the C01. ZERØ RUN announced that the C01 would soon be available for pre-orders.

But wait, there’s more to come…

“Tech innovation is a crucial variable, core technology is the key to winning in the game,” ZERØ RUN CEO Zhu Jiangming proclaimed during the press conference.

“The new technology shouldn’t be a barrier, but rather a ladder to drive the industry forward,” he went on to say.

At the end of the press conference, Zhu Jiangming, the chairman of ZERØ RUN, who comes from an engineering background, announced that they would be opening up their CTC technology to the industry for free sharing.

As he said, “One person can go faster, but a group of people can go further.” We sincerely hope that the Chinese automobile industry can win more and go further in the second half of the intelligent automobile era.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.