Global Automotive Industry Drives towards Centralized Electrical and Electronic Architecture

Author: Zhu Yulong

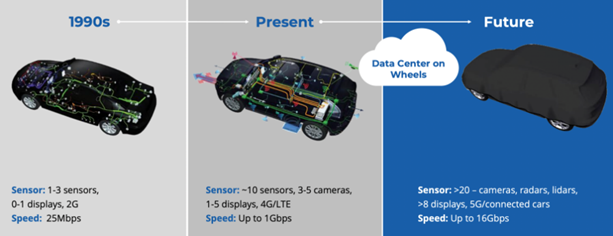

In previous articles, we spent a lot of space exploring the development of the global automotive industry towards centralized electronic and electrical architecture. Currently, it is expected that by around 2023, designs centered around domain controller architecture will transition to cross-domain fusion architecture in flagship models. By around 2025, they will gradually move into complete computing platforms.

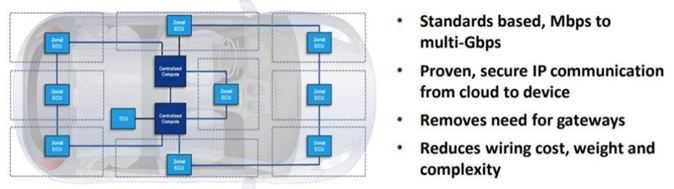

The main feature of the next-generation architecture is an architecture with regional controllers cooperating with a computing center. In order to achieve this goal, the automotive industry must upgrade the two main connection types of automobiles:

- Sensor to ECU connection – large one-way bandwidth, small reverse bandwidth (asymmetrical)

- ECU to ECU connection – large bandwidth two-way transmission (symmetrical)

From an evolutionary perspective, we can call all non-standard vehicle Ethernet controllers Zonal ECU because this controller will be integrated with many functions in a differentiated manner during the standardization process.

ECU-to-ECU Connection

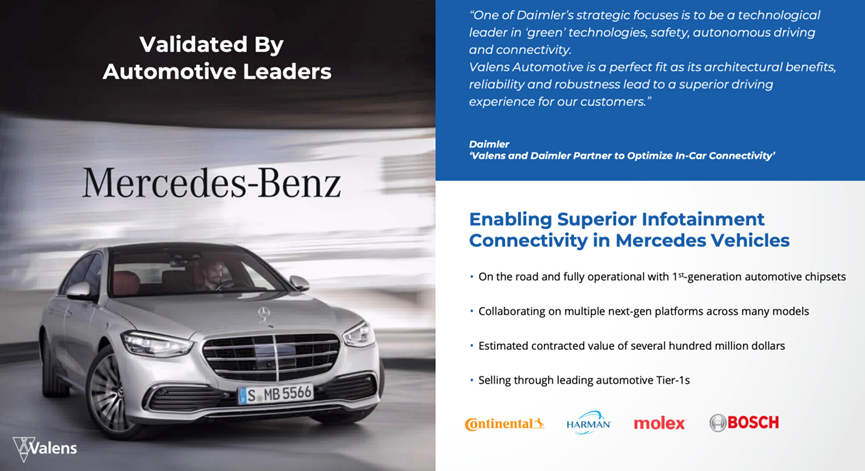

With the popularization of autonomous driving and intelligent cabins, companies that develop high-speed connection solutions have found their place. For example, Valens, a traditional company that develops audio and video and high-speed connection solutions, has also entered the automotive field. Valens’ latest chip, VA6003, can use simple and low-cost cable harnesses to achieve high-bandwidth and symmetrical vehicle signal links, providing a solution for transmitting high-bandwidth signals on unshielded channels. Some global automotive companies are also evaluating whether this chip can be used in the latest automotive domain controllers and computing platforms.

The VA6003 chip provides an efficient solution for Ethernet connections in the current automotive industry, including a series of unique features:

- 1.5Gbps/1.5Gbps symmetrical bandwidth

- Extremely low power consumption and error rate

- Able to transmit Ethernet high-speed solutions on low-cost unshielded cables, greatly reducing system costs.# VA6003 chip supports multiple signal transmissions on a single unshielded cable, such as Ethernet, audio and control data. This chip series has been validated by several German Tier-1 suppliers and endorsed by Mercedes-Benz. The VA6000, the early model in this series, has been installed in many Mercedes-Benz production models, providing higher efficiency and cost-effective solutions to meet various entertainment applications and customer needs.

VA6000 is applied in the latest entertainment cockpit system of the Mercedes-Benz S-Class, providing quick communication connections.

Valens products are in line with the current trend in the automotive industry and are able to meet the demand for symmetric transmission applications, such as connections between ECU to ECU. For asymmetric transmission applications, such as connections between sensors and ECU, the VA7000 series (chipsets compliant with the A-PHY protocol) can be used.

Link between Sensor and ECU

Valens recently released its VA7000 series, which is the world’s first product compliant with the new automotive sensor connection standard A-PHY.

Since the release of A-PHY by the MIPI Alliance at the end of 2020, high-speed automotive connection standards have made significant progress in the industry. In 2021, the IEEE Standards Association adopted A-PHY as one of its own standards. Automotive Tier 1 and Tier 2 suppliers (including some Chinese suppliers) have been committed to integrating it into the next generation of advanced driver assistance systems (ADAS) solutions.

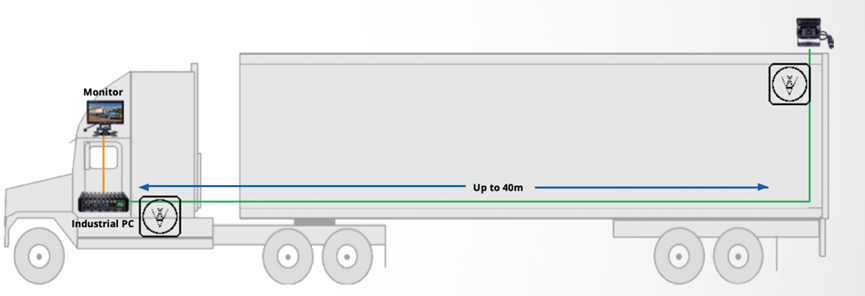

Valens’ technology has been best demonstrated in heavy-duty truck applications, where it can connect sensors over long distances in heavily challenging electromagnetic interference environments, connecting rear-view cameras from the back of trailers to driver-side displays, and its performance also meets real-time requirements of automakers.In the field of commercial trucking, the lack of remote sensor connections has affected millions of trucks on the world’s roads, severely limiting the driver’s rearward visibility. Valens is researching a long-distance connection solution capable of providing a unique solution to this difficult application, enabling video connections of up to 40 meters and solving significant safety concerns. This technology solution allows for effective data transmission in commercial vehicles.

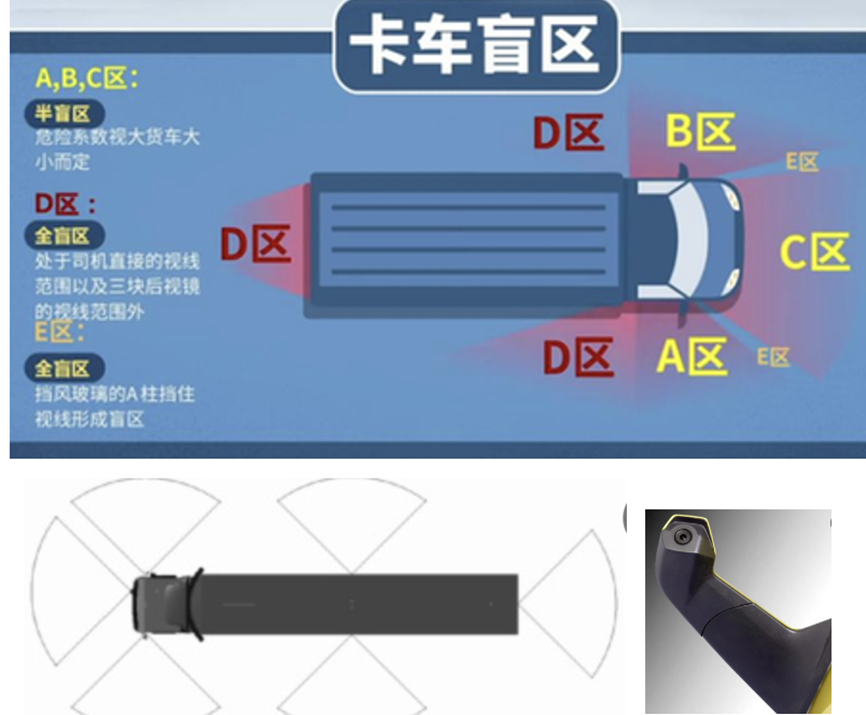

Large trucks have blind spots both when parked and in motion. Due to their size and dimensions, the driver’s field of vision is limited, creating blind spots. If other vehicles, pedestrians or obstacles are present in these blind spots, a driver’s limited visibility can lead to incorrect judgment and choice of operation, resulting in serious accidents.

By collecting images from multiple cameras and stitching them together into a 360° panoramic image, drivers can be assisted in understanding the surrounding environment through an active display system while driving the vehicle. Machine vision is used to detect pedestrians and obstacles in the blind spots on the left, right, and rear of the vehicle, with audio or visual alerts given if there is any danger. This enables drivers to passively understand the situation in the blind spots and improve driving safety.

To obtain a panoramic image, different numbers of front, left, and right cameras are arranged based on the size of the heavy truck, with reversing cameras used to capture the image.

The principle is easy to understand, but due to the long length of the truck and the need to connect across the cabin and trailer, existing transmission solutions cannot reliably transmit the rear camera image to the driver’s cab. Valens’ goal is to develop a long-distance connection solution that can transmit high-quality, zero-delay, and zero-error video.

In the commercial vehicle sector, Valens is collaborating with Stoneridge to develop a solution for connecting heavy trucks and trailers in terms of vision and safety systems, tackling safety concerns in the trucking industry.

In conclusion, the automobile industry is upgrading its two main types of vehicle connections – ECU to ECU connections and sensor-to-ECU connections. Companies like Valens that offer advanced solutions for these two applications will be at the forefront of the industry transformation.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.