Author: Zhu Yulong

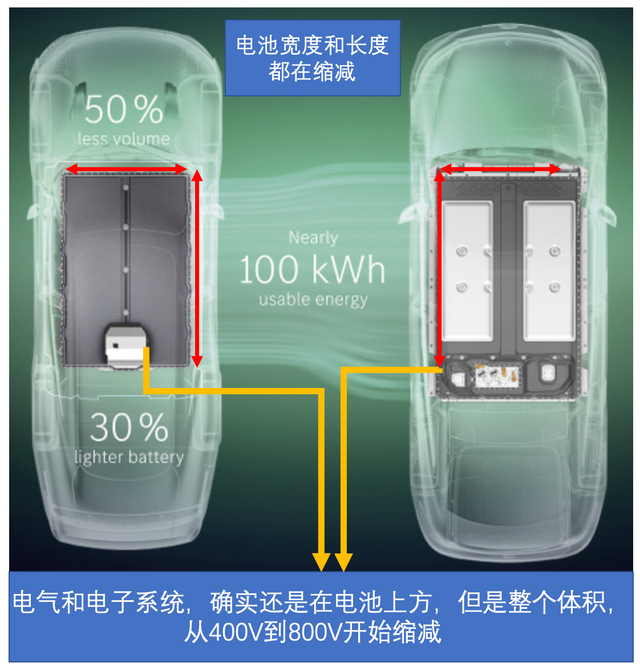

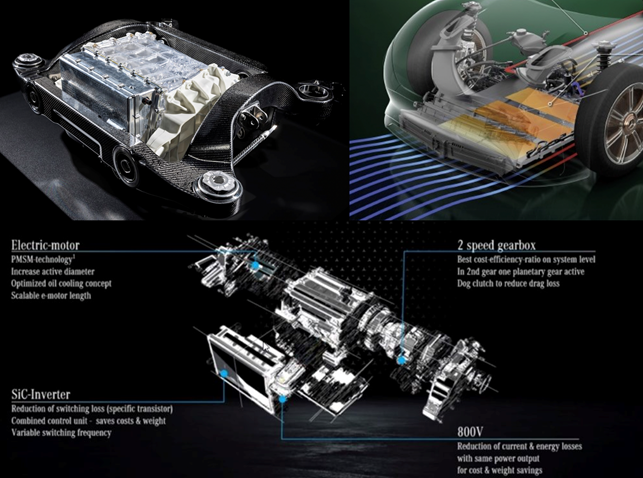

Recently, Mercedes-Benz has started promoting its next-generation electric drive and battery design in Europe, which is a complete transformation from 400V to 800V. According to the timeline we previously saw, it will be fully implemented in 2023-2024 and will require significant changes in the entire three-electric system of the VISION EQXX. Therefore, the real-world range test results under European road conditions are being heavily promoted this time (with a 100 kWh battery, the car can travel 1008 km on a single charge with 15% remaining battery capacity, which is about another 140 km).

Note: for concept cars, manufacturability can be disregarded, and the focus is on achieving the best possible range performance.

In this battery system, we can see many interesting things:

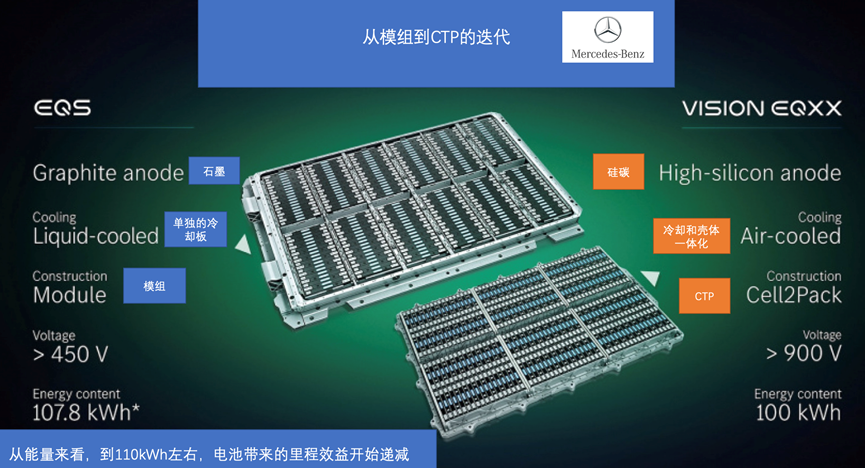

- Mercedes-Benz will switch to CTP from module design, so how the soft-pack battery cells will be used in the future, how long they will be used, and whether the previously seen design of six large battery blocks will be compatible will be an inevitable choice.

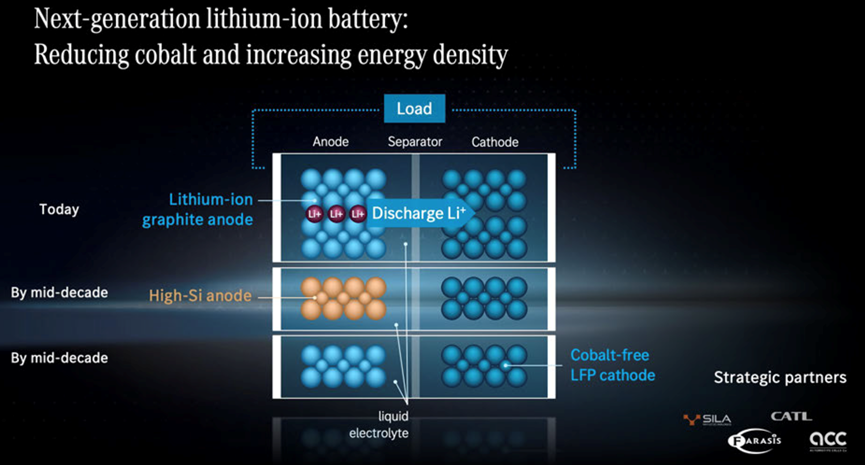

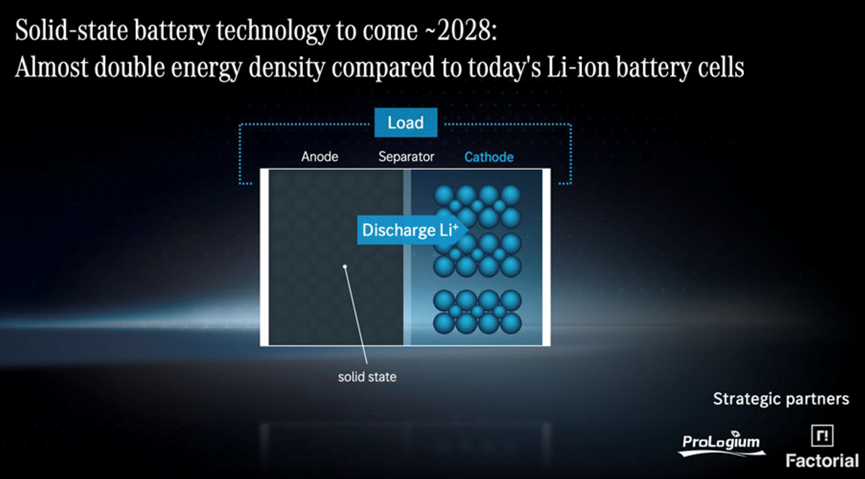

- In terms of material system, Mercedes-Benz is divided into existing technology, EQXX technology (graphite changed to silicon-carbon), and solid-state batteries, which have been described in detail in the ESG conference materials.

- Switch from 400V to 900V, which reduces the battery capacity, and the width of individual battery cells also becomes smaller. All European automakers use battery cells with a thickness of under 40mm, and this time the capacity reduction is mainly achieved by reducing the width.

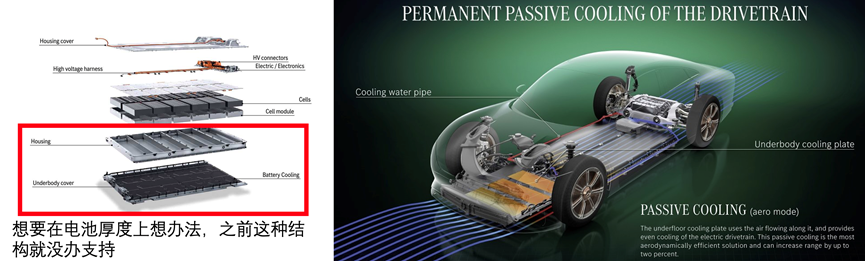

- Cooling design: This starts with the integration of the independent water-cooled plate (and the entire shell is thermally isolated) into the unified structure with the water-cooled plate and shell, but the heating method may need to be solved using high-frequency methods. Therefore, this change may also revolve around the availability of SiC semiconductors, which are more suitable for high-frequency switch hooks than IGBT.

- Of course, in terms of battery design, Mercedes-Benz has given the battery cells the largest possible space, and the electrical components are similar to a box placed on top.

Let’s take a closer look at the iteration of this battery system.

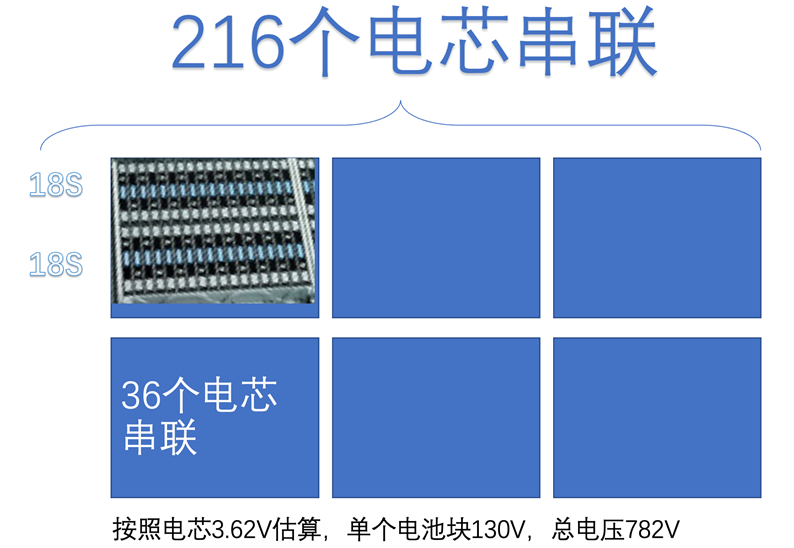

Battery System and Propulsion SystemThe VISION EQXX power battery system has a volume energy density of 400Wh/L at the Pack level (energy density of 200Wh/kg). Based on calculations for 100kWh, it corresponds to 250L. When the package is broken down according to length, width, and height, it can be estimated as 2000x1260x110mm. Similar to this capacity, the size of this pack has indeed undergone significant adjustments. Therefore, the volume has been reduced by 50% compared to the previous EQS battery pack, and the weight has also been reduced by 30% to 495kg. The working voltage of the battery pack is above 900V.

According to the above figure, I counted the number of battery cells in the module. Two sets of 18-serial modules are placed side by side. Then, I removed the beams of the entire tray here, and provided structural constraints through the side and end plates of the 6 battery blocks to achieve overall structural strength with the entire tray.

From a logical standpoint, from BYD’s blade design to CATL’s LFP batteries, the compatibility of the entire tray will be strong in the future. They are all flat-bottomed and can move towards high-pressure aluminum casting.

Now that we are in the age of electric vehicles, both cooling and heating have become a fine art, and the vehicle’s thermal management engineer needs to achieve the system requirements with minimal energy consumption by coordinating different modes throughout the vehicle. Here, the original demands on the battery engineer need to be abandoned, and the battery tray and cooling plate need to be simplified. Of course, the most important thing is that a proactive air vent is set up here, which can control whether the inside of the battery shell can be ventilated through a switch. This design is particularly interesting.

According to a predecessor from Xi’an Jiaotong University presented by Eaton, the electrical system of EQXX is likely to change the previous way of having multiple contactors through iteration. Engineers at Mercedes-Benz may really have trouble dealing with the positive and negative poles of two large modules in parallel at 400V. Through the use of circuit breakers, the previous design of the EQS can be greatly simplified and the space required reduced significantly.

In terms of the power system, Mercedes-Benz also uses a distinctive cooling method. Of course, I understand that air cooling is a mode. Compared with the high efficiency of water cooling, this mode is more like an attempt based on the heat-resistant foundation of SiC. Moreover, in non-extreme mode, air cooling can indeed achieve a speed of 60-80 kilometers per hour.

Mercedes’ Next-Generation Battery

ESG revealed some things, mainly the direction Mercedes is studying. The promotion of lithium iron phosphate dominated by CATL and BYD in Asia will begin to land globally in 2024, so the previous statement that cobalt-free is achieved in the short term is the use of this lithium iron.

In terms of investment pace, 2026-2028 is probably the time point when everyone is serious about solid-state batteries. These investments are still at the stage of solving problems from laboratory cell development to manufacturing.

Summary: In these years, the chemical system of batteries has not undergone significant innovation; innovation in the engineering and manufacturing fields has brought rapid cost reduction. However, as the global penetration rate increases, it may take 1-2 years to absorb the rising raw material prices. I feel that the battery engineering design in the past two years has reached a bottleneck, and it has become simpler and simpler. Structural engineers of batteries, you are in danger ^_^.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.