Author: Zuo Chenggang

This article is the third one published by the author on Jiu Zhang Zhi Jia. The first two were “Kill the Fuses and Relays for Safer Autonomous Driving” and “Why does Tesla want to ‘kill’ fuses and relays?”

Introduction

The intelligence of vehicles will inevitably drive the intelligence of the electrical architecture, and the intelligent electrical architecture will in turn accelerate the development of vehicle intelligence. This future will be implemented by our generation of automotive professionals.

This article will take autonomous driving technology, or more specifically, the challenges that intelligence brings to the traditional commercial vehicle electrical architecture as a starting point, to analyze how intelligence drives the development of commercial vehicle electrical architecture, and how the intelligent electrical architecture as the foundation infrastructure of the vehicle will bring impact to the commercial vehicle industry. For example, the improvement of OEM software capabilities and brand value, and the promotion of OEMs from vehicle manufacturers to service providers.

Those who are engaged in autonomous driving for commercial vehicles may have been focusing on sensors, chips, algorithms, and so on, but they may not have much understanding of the commercial vehicle electrical architecture. The article will popularize some basic principles of truck electrical principles, including distribution boxes, electrical controls, wiring harnesses, and so on, so that readers can have a better understanding, and at least not be seen as ignorant when in technical communication with OEMs. It can also be considered as a value of this article.

Nowadays, articles about vehicle electronics and electrical architecture are abundant in the automotive industry, but most of them are theoretical and less practical. Many of them are based on Bosch’s diagram and always mention computing power, 10G Ethernet, and central computing. It seems that without these, the architecture cannot be implemented.

In addition, the commercial vehicle architecture seems to be selectively ignored by everyone. The author has always believed that the first high-level autonomous driving technology to land will be commercial vehicles, not passenger cars. In the previous article “Why does Tesla want to ‘kill’ fuses and relays?” the traditional and intelligent distribution technology were analyzed in depth, although it involved some commercial vehicles, the focus was still on passenger cars, while this article will focus on the electrical architecture of commercial vehicles.

Vehicle electronics and electrical architecture, EEA (Electronic Electrical Architecture), generally refers to the combination of network topology, electrical topology, and logical structure. Traditional electrical architecture only focuses on electrical topology. Based on MOS technology, intelligent electrical architecture can integrate network and logical topology, which further blurs the boundaries between electronics and electrical.Talking about the electrification of vehicles. The electrification and electronicization of vehicles are both underway. The electrification is the first step towards intelligence, as it must be electrified before it can be electronicized, and then intelligentized.

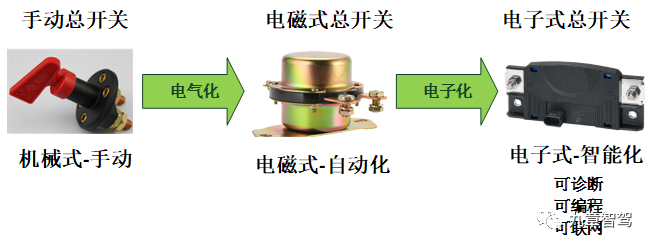

In fact, the essence of intelligence is controllable, perceptible, and evolvable. In professional terms, it is controllable, diagnosable, programmable/configurable, and networked. From the cable control of airplanes to the electromechanical control of today’s popular wire control chassis, the overall development concept remains consistent. All the foundations of intelligentization and networking are based on electronicization. Let’s take the power switch of a truck as an example.

In the future, anything that can be electrified will be electrified, and anything that can be electronicized will also be electronicized. The boundary between electronics and electricity will become increasingly blurred, and they will overlap. However, the direction of intelligentization remains unchanged.

Let’s get back on track. According to convention, when analyzing something, we must first understand its history. We will first introduce the basic features of commercial vehicles, to help readers understand, and then examine the development history of commercial vehicle electrical architecture.

Basic Features of Commercial Vehicles

Readers who specialize in passenger cars may be unfamiliar with commercial vehicles. The overall electronic and electrical technology of commercial vehicles is lagging behind that of passenger cars. The author has summarized some characteristics of commercial vehicles:

Long Operating Time

Although the design life cycle is 15 years, the operating time of commercial vehicles is much longer than that of passenger cars. Commercial vehicles are used to make money. If the vehicle is parked, it cannot earn money, and many are bought on loans. Over 70% of trucks in China are owned by individuals, and drivers take turns driving long distances with minimal rest time.

High Reliability Requirements

If a passenger car breaks down, it is delayed. If a truck breaks down, it delays making money.

Wide Range of Models, Low Single-Model Volume

Globally, the volume of commercial vehicles is less than half of that of passenger cars, and in China, it is about a quarter. In addition, commercial vehicles have a large number of models. Take Dongfeng Tianlong as an example. Dongfeng Tianlong has sold 1.04 million vehicles in the past 15 years, with 1,172 sub-models, averaging less than 900 units per sub-model and less than 60 per year.Because it is difficult for Tier 1 to cooperate with new developments due to the small volume, this will create many problems. For example, the design cannot be customized like a passenger car and can only use generic products. “Generic” in this context means “usable, but not ideal”, which means it can only be used as a makeshift solution since different car models have significantly different requirements and there are many places where design changes are needed. For example, if a signal designed for generics is high and needs to be changed to low, Tier 1 cannot make the change for you and you don’t have enough time to do it, so it is better to add a relay to quickly switch it.

Large electrical design margin, high cost

Because the design considers the variety of car models, versatility and compatibility design is critical, which will result in a large design margin and corresponding cost increase.

The commercial vehicle’s wiring harness design takes into account mechanical strength and reliability, generally not less than 0.5mm2 and starting at 0.75mm2 for buses. Wiring harness cost accounting is less detailed, and the level of refinement is not enough. Since wiring harness is a labor-intensive product and there is small volume and frequent changes, the wiring harness factory cannot account for the cost accurately; they may just calculate it based on weight.

Coarse electrical design

Because of the variety of models, load types, and high uncertainty, it is impossible and there are no conditions for refined design. Some load types are unclear even to suppliers themselves.

Multiple whole-vehicle components and demands

Commercial vehicles, especially trailers, have more whole-vehicle components than passenger cars. They have more lighting fixtures alone, and there are many components and requirements that passenger cars do not have, such as retarders, engine preheating, and post-treatment. Like many friends who may see urea for sale at a gas station and wonder what it is used for, it is actually used for trucks’ post-treatment.

High demand for user modification, electrical safety hazards

Commercial vehicles, especially trucks and buses, have high demand for user modification. It is routine to add a parking air conditioner or change lights.

Slow application of new technology

The commercial vehicle’s overall electrical environment is complex and inferior to that of a passenger car. It is less electronic and less intelligent, resulting in slow applications of new technology. For example, the common PEPS in passenger cars is rare on trucks.

Short modification cycle, heavy tasks

The modification cycle for a new model can be only a few months, and verification work is extensive. Here, we sympathize with the small partners who work in commercial vehicles. The hardship they endure is something that people who work with passenger cars cannot experience, and we hope that future intelligent electrical architectures can be a salvation for them.

Traditional Electrical Architecture for Commercial Vehicles

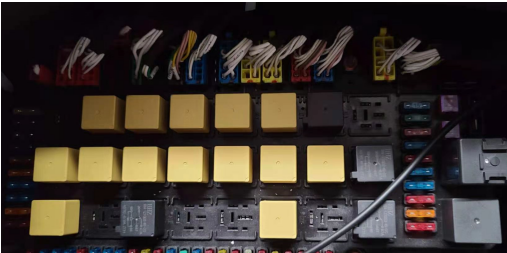

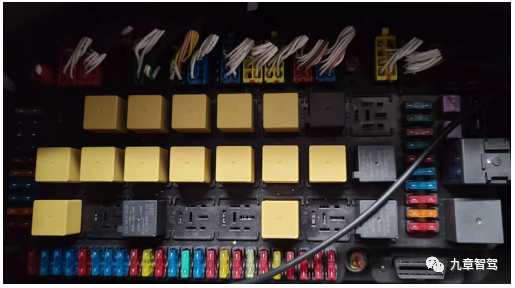

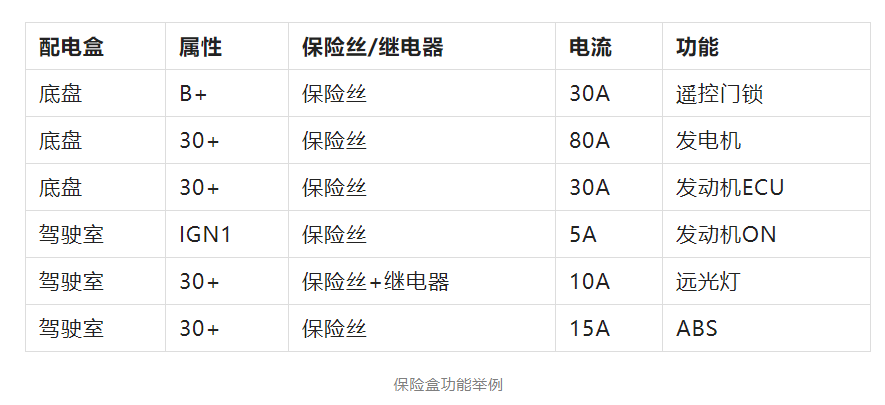

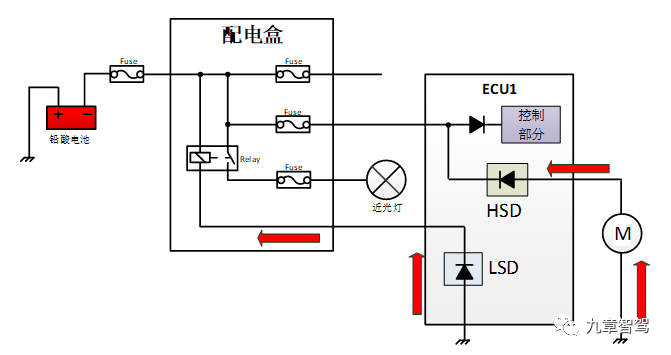

Now that everyone has a preliminary understanding of commercial vehicles, let’s take a look at the traditional electrical architecture for commercial vehicles. Its main component is the power distribution box. As usual, let’s start with a picture so that everyone can have an intuitive understanding.

Do you feel that there is no technology content at all? It’s easy to construct with a simple design, a bunch of fuses and relays that can be bought on Taobao for about 100 yuan, including shipping. But don’t underestimate it, almost all the power and control of the whole truck come from here. Let me give you some examples:

Do you see it? If any of them goes wrong, your truck won’t be able to run.

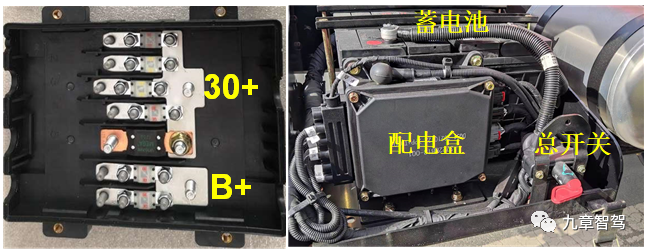

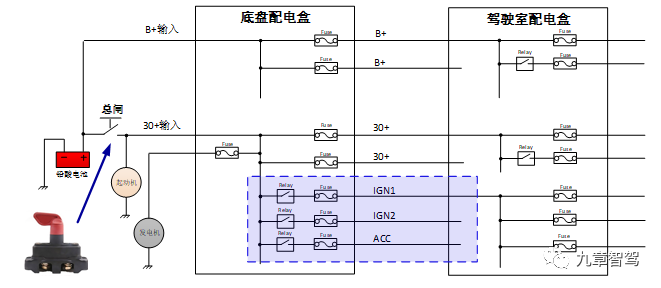

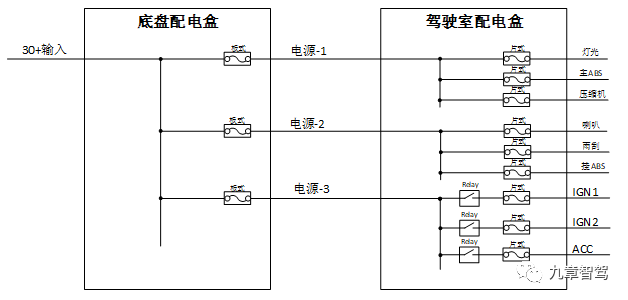

The distribution box of a truck is similar to that of a passenger car, generally divided into two levels: one is installed next to the battery, usually with a manual power master switch. If you park for a long time, you need to turn it off to avoid power consumption; otherwise, the battery will not be able to start next time. The second distribution box is installed in the cab, also called the cab distribution box, or central distribution box.

Next, let’s take a look at its electrical principle. As long as you haven’t returned your physics textbook to your teacher in middle school, you should be able to understand it.

Let’s explain the basics:

-

There are generally two types of commercial vehicle battery power sources, one is directly connected to the battery, called B+, also known as constant electricity, similar to the constant electricity KL30 of a passenger car, which always has power and cannot be turned off unless the battery is removed;

-

The one controlled by the power master switch is called 30+, also known as the main brake electricity or controlled electricity. When the power master switch is turned on, there is power, and when the power master switch is turned off, there is no power. Tier 1’s colleagues should not confuse this with the KL30 of passenger cars. If you want to have power after parking and the OEM drawings indicate 30+, then you need to confirm again.

-

Because the chassis distribution box of commercial vehicles is far away from the cab, many ignition lock gear (OFF, ACC, ON, START) relay (blue dotted box in the figure) switches are placed in the cab distribution box, so they are closer to the ignition lock, and the wires are pulled closer.

-

Compared with the engine compartment distribution box of passenger cars, the chassis distribution box of commercial vehicles generally has fewer components, mainly consisting of large plate-style fuses, and many do not have relays. Of course, this varies depending on the make and model. If the chassis function is more complex, the distribution box will be more complicated too, and cannot be generalized.“`

-

There will be many power lines, including B+ and 30+, when the chassis power distribution box is pulled into the cab. Considering the current and intensity, they are generally 4mm2~6mm2, which then split out to power the load with different fuses and relays. The chassis power distribution box is like the power distribution cabinet in a residential area, while the cab power distribution box is like the low-voltage distribution box in a house. The power line entering your house is only one 4-squared wire, but there are many in the cab.

After analyzing the electrical architecture of traditional commercial vehicles, you may feel that this is not an architecture, but rather just power distribution. Yes, if you have this feeling, then you’re right.

As we said before, technology needs to advance step by step and things should be done gradually. Therefore, do you think we can start with advanced architecture and central computing? Definitely not! Based on the current electrical architecture of commercial vehicles, we need to first build some infrastructure, and the electrical architecture is one of the infrastructure components.

What kind of electrical architecture does autonomous driving require?

Alright, we have analyzed the traditional electrical architecture (let’s just call it architecture for now), but can it meet the requirements of future intelligence? What kind of electrical architecture does autonomous driving need?

You might say, “Isn’t this obvious? We definitely need intelligent electrical architecture.” As I said before, all technologies that are not driven by real functional requirements are rogue technologies. We cannot pursue intelligence for the sake of intelligence, functional requirements must be the first driving force.

Let us switch roles and look at the core requirements of autonomous driving from the perspective of autonomous driving. Ultimately, you will find that there are only four words: safety and controllability. Safety and controllability are basic requirements, and controllability also includes functional requirements. Because there are people in the car and on the road, “safety and controllability” can be referred to as the “elementary requirements” of autonomous driving, and based on these requirements, we can deduce the following requirements:

- In order to achieve safety, redundancy needs to be added, including power redundancy and control redundancy;

- In order to achieve safety, safer new technical solutions may need to replace existing technical solutions;

- Real-time monitoring is required for reliability, and the more dimensions that can be monitored, the better;

- With monitoring, fault warnings and diagnosis are required. In order to achieve these, networking is necessary;

- In order to achieve safety and reliability, controllability is needed, such as timely disconnection and isolation of fault lines, as well as automatic function recovery after faults are resolved;

- For the sake of controllability, things that did not require control before now require it;

- In order to support continuous functional iterations, OTA upgrades are also required;

- In order to meet potential functional uncertainties, the loop needs to be controllable independently, so as to support configuration, programming, upgrades, and iterations.Okay, now that we have analyzed this, have you noticed that this is essentially the same as what we extracted from “electrification -> electronification -> intelligence”, which is “perceptible, controllable, and evolvable”? If an architecture possesses these characteristics, then we can call it a “safe and intelligent electric architecture”, since no one wants to experience a power outage at 120km/h.

Now that we have specific requirements, let’s continue to analyze how to implement this intelligent electric architecture.

The conventional method is usually based on the existing electrical architecture and how to upgrade and modify it to meet our needs. We have already analyzed the existing electrical architecture, now let’s see how to upgrade and modify it:

- Redundant power supply: add an extra fuse;

- Redundant control: add extra relays;

- Independent controllability of circuits: add relays as needed;

- Real-time monitoring: add voltage and current monitoring function for fuses and relays;

- Fault diagnosis: add diagnostic function;

- Networking: add communication;

…………………….

If you are an electrical engineer, you will definitely go crazy after this, pulling wires today, adding relays tomorrow, and changing functions the day after tomorrow. “Today’s change affects five lines, tomorrow it affects ten lines, and then in one night we can rest easy. But when we wake up the next day, there’s the product manager again.” Although the existing electrical architecture can struggle for another three to five years, the complexity will get higher and higher as the modifications progress, causing more pain for electrical design engineers. In the long run, such a modification path is not feasible.

Just like someone in the 19th century asking for a faster carriage, adding more horses to make it faster will not work in the long run. But it is also impossible to remove the wheels, add wings and turn it into an airplane because reality does not permit it. Therefore, we must upgrade and modify based on the existing electrical architecture, “keeping the wheels” and improving on this foundation.

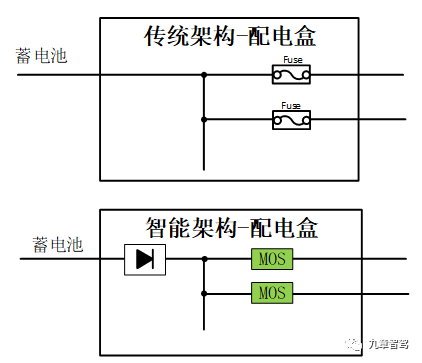

Let’s see how we can modify the existing architecture:

- Maintain the current part: retain the design of front and rear distribution boxes for chassis and driver’s cabin respectively; battery and generator/DC-DC directly connect to chassis distribution box, with no change in the connection method;

- Upgraded part: electronic devices replace fuse and relay technologies for control and protection, and electrical design becomes electronic design; after electronic adjustment, add diagnostic and networking functions, integrating some input signal detection, and OTA upgrades become straightforward.

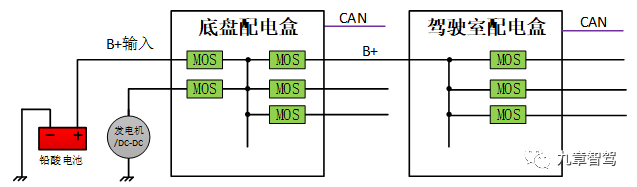

Based on these assumptions, we present a way to achieve an intelligent electric architecture for commercial vehicles. Let’s take a look at the new architecture:

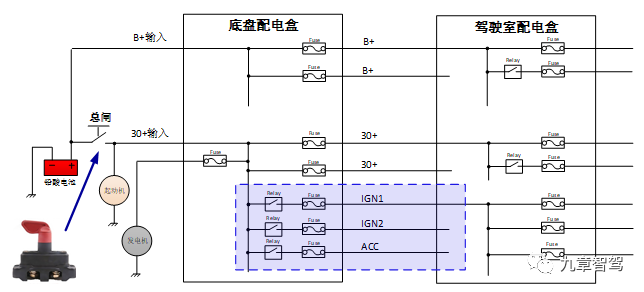

To facilitate comparison, let me show you the traditional architecture again.

Have you noticed that if the traditional architecture electrical diagram still requires some “middle school physics knowledge”, the intelligent architecture doesn’t even need that. Without the beauty of relay logic and complex power distribution, the intelligent electrical architecture is so monotonous, boring, and uninteresting. It’s like a smart phone without a beautiful mechanical keyboard, as dull as a brick.

Now, let’s compare the differences between the intelligent electrical architecture and the traditional architecture:

- Each circuit is separately controllable, which means that each line can support separate programmable control, laying the foundation for the logical architecture.

- After each circuit is separately controllable, power consumption control and energy management are no longer a problem, so the main power switch can be canceled (GB7258 regulation prohibits buses larger than or equal to 6 meters from canceling the main power switch).

- There is no longer any distinction in power supply characteristics; all lines can be defined as any power supply property. The reason for defining power supply properties in the past was for ease of management, but now it is no longer necessary.

- The B+ power supply of the cab distribution box remains unchanged, but it has been changed from multiple wires to a single wire. For example, if it used to be 4 4mm2 wires, now one 10mm2 wire may be enough.

- A communication network has been introduced. The old distribution box did not have a network, but now you can’t live without a network.

- It is monitorable and diagnosable. The old distribution box contained only passive components without status monitoring and fault diagnosis, like a black box, but now it can be perceived and is even part of the overall vehicle network.

Now, this electrical architecture looks a bit like “architecture,” doesn’t it? Electrical topology, network topology, and logical architecture can be added to it. The distribution box of the intelligent electrical architecture is actually a specialized area controller, which AMP calls the PDC. According to the level of autonomous driving, AMP believes that a smart car typically needs 2 to 6 PDCs, such as the three distributed area controllers used in the Tesla Model 3 for the front, left, and right sides.## Value Brought by Intelligent Electrical Architecture

Direct Value

The direct value brought by the intelligent electrical architecture mainly focuses on three aspects: product functions, reliability, and maintenance costs. Specifically —

- Product Functions

(1) Each circuit can be controlled independently.

(2) Protection functions not only include short circuit, but also overload, overvoltage, open circuit, etc.

(3) Each circuit can be monitored and diagnosed, not only for voltage, but also for current, temperature, etc.

(4) Devices that need to remain in operation during sleep can be set.

(5) After troubleshooting, the system can automatically or as required recover.

(6) The system can be connected to the Internet, and information can be uploaded in real-time.

(7) Control logic can be programmed and updated over-the-air.

(8) Monitoring of the power status in autonomous driving state.

(9) Remote power management for unmanned driving vehicles. Accurate power management and controllable power timing are the foundation of intelligence, including the power management for future new energy heavy-duty trucks, which is of great significance.

- Reliability

(1) High reliability can be achieved through dual power supply and dual terminal block input.

(2) MOS devices themselves have high reliability.

(3) The protection level is increased, which also improves safety. For example, the original protection level may only be up to IP54. Now the distribution box can be fully sealed and achieve IP67 or IP69, meaning that it is impossible to enter water. This is also very valuable for commercial vehicles in harsh operating environments.

- Operating Costs

(1) Maintenance reminders and fault warnings can prevent vehicle malfunctions during operation and reduce commercial vehicle operating costs.

(2) Long service life and maintenance-free. This value is much greater for commercial vehicles than for passenger vehicles. High reliability and less maintenance mean fewer breakdowns and less downtime, allowing for more profits.

It supports the vehicle electrical architecture requirements for future new energy trucks, high-end unmanned driving technologies, including basic functional requirements and functional safety levels.

Indirect Value

- Network Management NM Design Optimization

There is a question that I don’t know if you have thought about it deeply. Anyone involved in automotive electronics cannot do without the CAN bus, and thus will come into contact with the CAN bus AUTOSAR/OSEK Network Management. Why do we need network management?I estimate that you will be confused for a moment and then say, “We need to control the ECU’s sleep and wake-up modes” – but if you continue to investigate, you will find that the ultimate goal is actually to control the entire vehicle’s power consumption. The related ECU nodes should be activated only when necessary to conserve energy.

As we have discussed earlier, there are only a few types of power sources in the car, but the actual application demands vary greatly. Therefore, power management (on/off timing) and energy management become very complicated. However, it is not possible to control every power supply circuit with a relay. After all ECUs have been connected to the CAN bus, people have thought about using network management based on the CAN bus for energy management, as power management alone is far from enough.

To this end, even more complex PN (Partial Networking) functions have been developed, but they are rarely used to this day because many traditional ECU CAN transceivers do not support them. Even if the transceiver is replaced, the MCU hardware may still not support it. It is virtually impossible for Tier 1 to replace the MCU since it will have a broad impact and high cost.

However, in the intelligent electrical architecture phase, people have found that some of the previous practices seemed to be a bit superfluous. Not only were they too complicated, but they also seemed to be neglecting the fundamental purpose. For example, we have set up a very complicated CAN network management system, but in the end, we found out that it was all about saving power! Wait a minute, did you say you want to save power? Isn’t that the basic function of intelligent electrical architecture? The most basic function of intelligent electrical architecture is to achieve individual control of each circuit’s power supply.

To get to the point, let’s first take a look at the current CAN network management system. According to the wake-up method, ECU network node types are generally divided into two categories: local wake-up and remote wake-up.

Local wake-up methods use KL15 or other hardwire, sensor, and other signal wake-up methods. In this case, wake-up signals can be directly connected to the intelligent power distribution module to enable the module to collect external signals and execute the wake-up logic, because KL15 and other signals are originally generated by the power distribution module. Even KL15 can be canceled and changed to a virtual KL15 (ACC, KL30, etc.).### Translated Text

For remote wake-up, support for PN (Partial Networking) will be better, but for network segments that do not support PN functionality, all ECUs will sleep and wake up together, so the network management can play a limited role. Therefore, for functions that do not demand high sleep/wake-up speed, we can consider directly cutting off power supply instead, and let the intelligent electrical architecture directly manage ECU power, thereby transferring most of the original CAN network management functions to the electrical architecture level, reducing the network management nodes significantly, and optimizing the network management to a great extent. Workload can also be greatly reduced, and design changes become simpler since logic has moved. For example, if the power is cut off when certain conditions are met, such as vehicle speed exceeding 20KM/h, the seat control ECU function will be disabled. If there is a need for delayed power off function after parking, the electrical architecture can also perform the power sequence control.

Therefore, based on the power supply and energy management strategies of intelligent electrical architecture, it is possible to achieve some of the existing CAN network management functions, thereby optimizing the design of the entire vehicle network, and reducing the network communication load (if commercial vehicle network management is not done well, the load rate is easy to be problematic). Of course, this design concept is relatively subversive, and OEM and Tier 1 need to explore together how to optimize network management, and then reduce the complexity of the entire design.

- Guide vehicle design optimization and enhance OEM brand value

As an industry with a history of over 100 years, many designs in the automotive industry are inherited with a relatively low level of change. Similar to the phrase “the ancestral law cannot be violated” often seen in palace dramas, there are a lot of wisdom from previous generations, because our predecessors were not fools. They must have tried and failed a lot before setting the rules. Therefore, it is highly probable that there will be no problem to continue using it since everyone has been using it without any feedback.

For example, if you ask OEM’s electrical engineer why the generator insurance is equipped with 125A, he is likely to say “we have been using it this way all the time”, and there has been no feedback on “burning”, it is an inherited design. If you ask him why the harness is only 16 square when it should be 25 square for 125A according to the manual recommendation, he will probably say “this is our experience, it is okay, don’t worry”.

You can see that inherited design and experience design are actually the best solution when there is a lack of effective data support, theoretical calculative analysis, and simulation. Just like when we are designing a circuit, if the worst-case analysis of WCCA fails to compute, if you can prove that it works in practice, or if you have application cases and reliability data support, then it can still be considered as valid.

When it comes to traditional design, we tend to stick with it without much modification because it is a summary and precipitation of the experience and wisdom of our predecessors, achieving a balance between cost and reliability. However, everything has changed since the advent of intelligent systems. With real-time monitoring, diagnosis, data and network, cloud computing, big data, and AI algorithms, we can achieve a higher level of precision, granularity, and real-time capability.

For example, the original energy management system of the vehicle was quite crude because it was difficult to measure and network wasn’t available, so the electricity use was estimated. However, with digitalization and network connectivity, we can now improve data granularity and quantity, and take advantage of big data and AI algorithms. Just as with the widespread adoption of smart meters, the police can use big data analysis to catch drug dealers by detecting unusual water and electricity consumption; community services can detect the risk of falling for elderly people who live alone by detecting unusual water usage.

After digitalization and network connectivity, OEMs can obtain real-time data on the current of every load and module on the vehicle, and the total current of the entire vehicle through the back-end system. They can also analyze this data from different dimensions (the specific dimensions can be found in my previous article), which can guide vehicle design, such as:

(1) Guiding the design of the vehicle’s energy balance;

(2) Guiding the design of the vehicle’s energy management;

(3) Guiding the design of the vehicle’s power-on and power-off timing;

(4) Guiding the design of the battery, generator, DC-DC converter;

(5) Optimizing the selection of loads, wire diameters, and protection current matching design to reduce costs;

(6) Establishing a database model (load dimension, functional application dimension, etc.) for pre-made modeling and simulation design;

(7) Guiding the design of the vehicle’s electrical system, shortening the development cycle and reducing development costs;

(8) Establishing a seasonal weather environment model for simulation and design.

Moreover, by improving data dimensionality, granularity, quantity and real-time capability, OEMs can use big data and AI algorithms to achieve intelligent energy-saving or offer advice to users on how to improve fuel efficiency.

At this point, OEMs can use an app to provide users with driving suggestions, maintenance reminders, and other services, which can be considered a part of the brand value, a marketing highlight, or brand premium. Therefore, in a sense, intelligent electrical architecture can also be considered “hardware embedding,” laying the foundation for “software payment” in the future.

- Accelerate Cross-Domain Integration and Function Iteration

In the intelligent electrical architecture, after the integration of control and execution, the distribution box becomes a specialized area controller and the distribution architecture becomes a part of the functional logic architecture, which is the basis for achieving cross-domain integration and zone architecture.For example, Tesla’s FBCM has done a lot of thermal management work, including valve control and motor drive, as well as the collection of air conditioning pressure and temperature signals. LBCM controls the left-side lighting, car door and window controls, seat adjustments, and even airbag controls, which were originally executed by independent ECUs.

Therefore, ECU integration will be a major trend. Firstly, integration of functions within the domain, such as lighting, wipers, door control, and seat functions that were originally within the body domain. When integrating the door control function, the door control module is no longer needed, and it can later be extended to the cabin comfort system. For example, the air conditioning control algorithm can be directly integrated, eliminating the need for an air conditioning controller, which means a bit of domain integration. In the later stages, if OEMs have the capability or work with Tier 1 to develop, more power and chassis functions can be added. Of course, this will mostly be at the execution level, allowing for the logic to move up for easier OTA in the future.

There are also some cool features that can be added, similar to how Tesla uses lighting, music, and winged doors to dance around. Of course, for commercial vehicles, practicality is still important, such as doing a whole-car lighting self-inspection (which was originally controlled by relays and couldn’t be done), implementing fuel theft detection, and adding alarms with sound and light. With independent and controllable programmability plus OTA, the possibilities are endless.

Furthermore, after implementing an intelligent architecture, the design change process can be speeded up, iteration speed can be correspondingly faster in the later stage, and the cost of design changes will also decrease. This is particularly valuable for commercial vehicles with many models, small batches, and short development cycles. For example, in the past, changing the control logic would require rewiring or redesigning the power distribution box, which was indeed very troublesome. Now, you only need to make a few mouse clicks to reconfigure it.

For example, the electrical design for the power distribution part can be developed much faster now, taking from one month in the past to one week or even shorter (a complete vehicle restyling only takes a few months), and even OEMs can upgrade the power distribution and control logic independently without relying on Tier 1 to redesign the power distribution module. This is consistent with the trend of OEMs increasing their software capabilities and participating more deeply in component design, as currently happening in the passenger vehicle market. Most of Tesla’s components have started to be self-developed and produced.

According to the author’s understanding, in the bus industry, a semiconductor-programmable chassis power distribution box is already replacing traditional power distribution boxes on a large scale, although the cost has increased, but for the vehicle factory, it is extremely convenient to support on-site programming and design logic changes (through CAN configuration). Vehicle factory engineering designers even love this new design pattern, enabling quick changes to the entire vehicle’s electrical design based on order requirements, with very simple and fast design changes. Changes don’t require hardware redesign and they don’t have to worry about making mistakes, as they can simply change it with software, unlike before where they would have to change a large number of wires.# Improving Fire Safety Performance

Fire safety has always been a problem for commercial vehicles. Commercial vehicles have a much higher application complexity than passenger cars. It’s relatively easier for passenger buses, but for cargo trucks, it’s very complicated. There are often reports of truck fires on highways in the news. One problem with fires is that there is no evidence left behind, and it’s difficult to investigate after the fire is burned out.

According to Randolph Harris, a fire expert with 30 years of vehicle fire investigation experience, after investigating more than 2500 incidents, including more than 500 truck, heavy equipment, and vehicle fires, statistical data shows that the primary cause of truck fires is electrical fires, followed by arson (which is rare in China), tires, and accidents. There are several reasons for electrical problems:

-

Loose connection of high-power load, poor contact, contact point heating.

-

Aging lines, loose wiring harness, insulation wear, broken electric wire, and short circuits.

-

Users privately connect wires and use overloaded electrical devices in the car.

-

The fuse burned out, the larger fuse was replaced or the inferior fuse was used.

-

Electric devices get wet, causing a short circuit in the circuit, igniting nearby flammable materials.

To address the above electrical problems, the MOS-based electronic smart architecture can solve most, if not all, of the problems, thereby eliminating electrical fires and improving the fire safety performance of vehicles.

For example, for the problem of heating and catching fire due to the loosening of the wiring post, we can add a temperature sensor, which is common in electronic designs. After adding the sensor, it can be monitored in real-time, the circuit has independent switch control function. If a fault is detected, it can be immediately shut off to avoid accidents. At the same time, it can also be notified through network communication (such as an instrument) to remind the driver of the cause and specific fault line for easy maintenance.

For the problems of wiring aging, insulation wear, and slight short circuits, we can detect faults by monitoring the circuit current. Based on historical data comparison or application comparison of equivalent models, if it is a serious short circuit, the MOS-based protection sensitivity can be very high, and there is short-circuit current limit, which was mentioned in the previous article. Current limiting means that there is a small spark, and high sensitivity means that it can be detected immediately after ignition which can quickly protect already made repairs (the protection speed can exceed 1000 times that of traditional fuses), thereby reducing the risk of fire.

Users privately pull and connect wires, replace large fuses, and use overloaded electrical devices. These problems will not occur under intelligent electrical architecture.

Traditional distribution boxes are easy for users to connect the wires or change to larger fuses if the current is too high. However, MOS-based distribution boxes are fully sealed and cannot be opened or understood by users. As discussed in the previous article, even if users connect wires outside, once the current exceeds the protection threshold, overcurrent protection will be triggered, and the problem of burning wires due to replacing larger fuses will not occur.

Traditional distribution boxes are easy for users to connect the wires or change to larger fuses if the current is too high. However, MOS-based distribution boxes are fully sealed and cannot be opened or understood by users. As discussed in the previous article, even if users connect wires outside, once the current exceeds the protection threshold, overcurrent protection will be triggered, and the problem of burning wires due to replacing larger fuses will not occur.

In the case of electrical appliances short-circuiting and catching fire due to water immersion, part of the faults can be avoided based on the sensitivity of MOS protection.

Based on the above analysis, we can see that the value of MOS-based intelligent electrical architecture in improving the fire safety of commercial vehicles cannot be measured by BOM cost.

- Whole Vehicle EMC Improvement and Cost Reduction

We will not delve into the complicated knowledge of EMC today, but focus on the values that intelligent electrical architecture can bring to the whole vehicle EMC and cost of commercial vehicles.

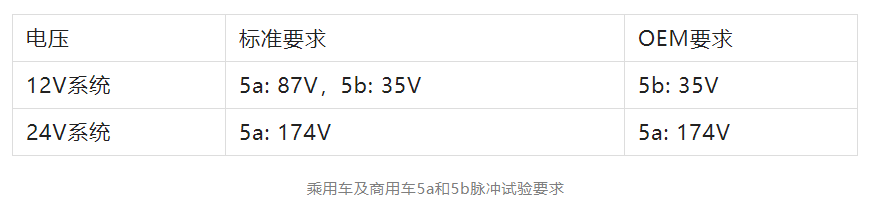

Due to the length of commercial vehicles and the complexity of load types, the electrical environment of the entire vehicle is more severe. For example, the long wiring harness is affected by stray inductances of long wires, and relay switching will produce some high-voltage pulses, which will endanger other electronic devices and affect the EMC performance of the entire vehicle. We have analyzed this in detail in the previous article. Today, we will focus on the EMC problems related to pulse in ISO7637-2 (GB/T 21437-2).

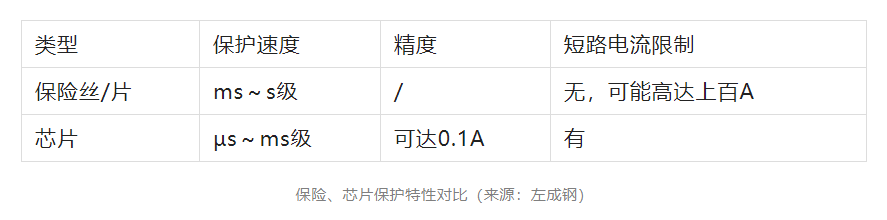

First, let’s take a look at the most stringent pulse in the standard, which is called load dump. This is also known as 5a and 5b in the industry. If you meet someone who can talk about this, it means that he/she already has a good understanding of EMC. Don’t argue that this is an old standard and the new standard does not use this name anymore. Because everyone is familiar with the old standard, and it has been used for a long time, the voltage level of the new standard is higher and the name has also been changed to Load Dump Pulse directly and integrated into ISO16750-2. Below, we will give an example to illustrate the testing requirements of the 5th load dump pulse for commercial and passenger car OEMs.

According to my understanding, most passenger cars currently do not require 5A. While local projects used to have such requirements, global projects have not required it for quite some time. This is now also the case in China. This can be understood easily. Just like in the 1980s, when the Santana was first manufactured in China, German standards required a lifespan of 50,000 uses for the horn. But it kept breaking, so Chinese researchers investigated and found that horns were used more frequently in China. So after the horns were produced domestically, they increased the lifespan requirement to 100,000 uses. The point is that designs need to consider actual situations, and foreign standards are not always correct, good design is key.

According to my understanding, most passenger cars currently do not require 5A. While local projects used to have such requirements, global projects have not required it for quite some time. This is now also the case in China. This can be understood easily. Just like in the 1980s, when the Santana was first manufactured in China, German standards required a lifespan of 50,000 uses for the horn. But it kept breaking, so Chinese researchers investigated and found that horns were used more frequently in China. So after the horns were produced domestically, they increased the lifespan requirement to 100,000 uses. The point is that designs need to consider actual situations, and foreign standards are not always correct, good design is key.

Returning to the topic, why can global OEMs dare to require less than 5A? It is based on experience and 5B is sufficient, because they have already done a good job in the overall vehicle electrical environment. This is a systemic issue. After the overall vehicle electrical environment is improved, the testing standards can be lowered, and the cost of parts and the entire vehicle can be reduced.

For example, those born in the 1980s should remember that in order to avoid television or refrigerator malfunctions due to unstable voltage, voltage stabilizers, regulators and refrigerator protectors were standard equipment in households. Of course, such equipment is no longer needed now. This is not because the quality of household appliances has improved, but because the supply voltage has become more stable, and there are fewer power outages, thanks to the national power grid.

Having said all of that, the main point is that design needs to consider actual situations and that electrical devices are influenced by the overall electrical environment. Returning to commercial vehicles, why do they still require 5A? Because the overall vehicle electrical environment is not yet good enough. As mentioned earlier, commercial vehicle technology is lagging behind that of passenger cars. Therefore, after opening up a circuit board of a commercial vehicle, we can easily notice a large component – which is the power regulator – for each ECU.

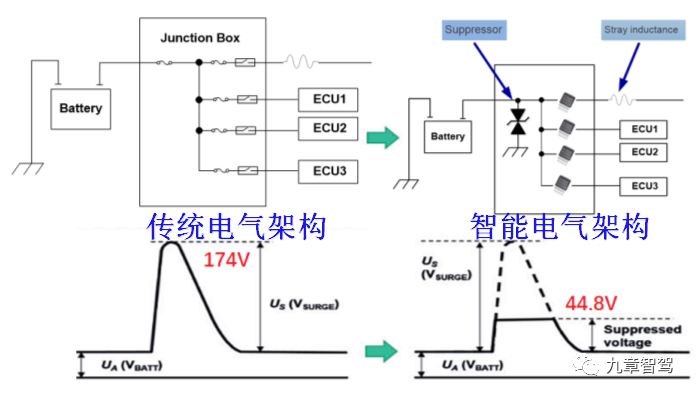

Now let us return to the main topic and examine what value intelligent electric architecture can bring to us. Intelligent electrical architecture achieves electronicization, so we can add voltage suppression design to the power input end of the chassis distribution box. Since the 5A pulse comes from the power supply end and the power supply of the entire vehicle comes from the chassis distribution box, this is tantamount to the electricity supplied to a residential area being stabilized by the distribution cabinet, then sent to each household, whereby electrical devices in the household do not need an additional voltage regulator.

From the voltage waveform, it can be seen that the pulse voltage drops from 174V to 44.8V, and the effect is significant. What value does this bring?

(1) The test standard for the vehicle ECU is reduced to level 5b, and the test cost is reduced;

(2) The vehicle cancels the ECU-level voltage suppression design, and the BOM cost is reduced. Generally, there are dozens of ECUs in a vehicle, and a TVS costs several dollars;

(3) The voltage withstand level of the primary power supply of the vehicle is reduced. In conventional 24V designs, the primary power supply voltage withstand requirement is 60V, and 60V devices are more expensive than 50V ones;

(4) Improvement of vehicle EMC environment.

In fact, the improvement of the vehicle’s EMC environment is not limited to the improvement of the power supply end of the vehicle. The mutual interference between each ECU and load will also be improved.

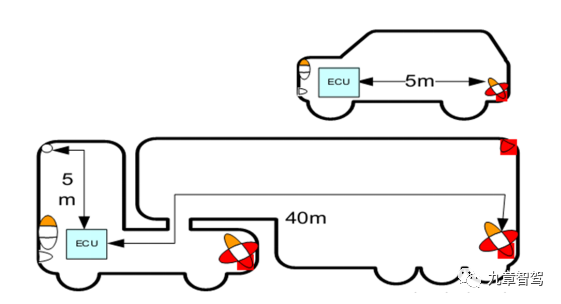

As we mentioned before, the wiring harness of commercial vehicles is very long. Due to the influence of the wire harness inductance caused by rapidly changing high current, some high-voltage pulse hazards will be generated. This is easy to understand. We learned this in junior high school physics. It is this formula: U = L*di/dt. For example, for a 1mm² wire, the inductance of one meter is approximately 1µH. This voltage can easily reach hundreds of volts, and the pulses of 2a and 3a specified by ISO7637-2 can reach -300V to +112V. This voltage is also related to the wire harness inductance.

In traditional distribution boxes, everything is connected together, and if there is a pulse, it will run everywhere, and ECUs and loads can also affect each other. The chassis distribution box of the intelligent electrical architecture not only increases the voltage suppression design at the power supply end, but each output channel also has voltage suppression design itself. This avoids mutual interference between electrical equipment, that is to say, interference pulses will not run around and will be directly absorbed.

In addition, there are chip switch characteristics for improving EMC. Chips generally have slew rate control of switches, which relays do not have. In addition, for fuses, the EMC impact caused by the unlimited short-circuit current and the fuse characteristics can also be avoided by these chips, which we will not elaborate on.

- Elimination of the impact of power reverse connection

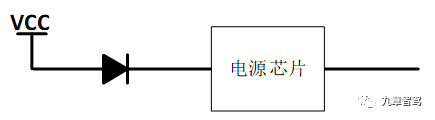

As long as small partners who have been in contact with electronic design, whether it is consumer grade, industrial grade, or automotive grade, probably know that a diode should be added to prevent reverse connection in the power supply design, like the one below:

This design is simple, practical and effective, which can help avoid many wire connection errors in use. Once wired improperly, the entire power supply will burn out, resulting in high cost and product scrap. Designers who have experience would have dealt with the issue of wire connection errors before.

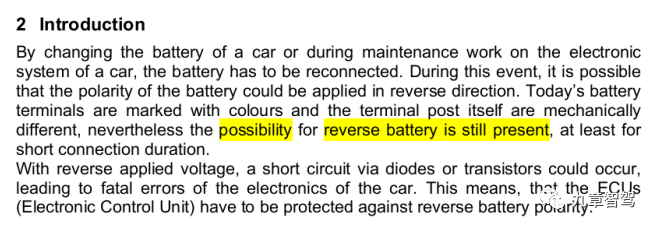

For automotive design, it is also the same because vehicles in practical applications may occasionally experience power connection errors. For example, when the vehicle battery is low and cannot start, it is likely to appear the case of power reverse connection when using another vehicle for jumper starting. In addition, it is also possible for the battery positive and negative poles to be reversed during maintenance, of course, professionals will never make such mistakes. Therefore, when designing vehicles, this situation is taken into consideration, and there are corresponding regulations in ISO standards.

Therefore, for automotive electronic design personnel, ECU power anti-reverse design is a basic design (Infineon’s introduction only mentions ECU anti-reverse design), and everyone thinks it is commonplace. Just give it a diode first for any power supply, perfectly safe and absolutely unerring. However, in the era of intelligent electrical architecture, as we realize the intelligence and electrification of the entire vehicle power distribution, a traditional design is quietly being overturned, just like mobile payment is slowly overturning the habit of using cash.

Let’s take a look at what happens?

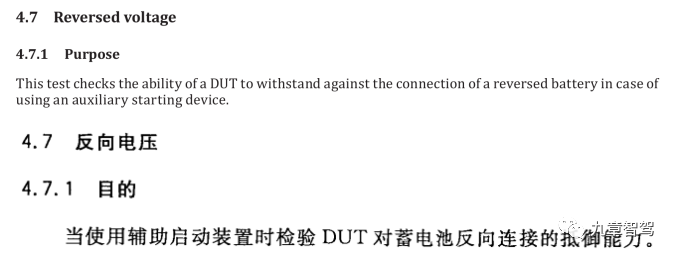

In traditional electrical architecture, the distribution box is responsible for power distribution, and there are no electronic devices inside, and no way to do power anti-reverse design (including EMC design). Once the power is reversed, all ECUs and load power supplies of the entire vehicle will be reversed.

However, in the era of intelligent electrical architecture, due to the implementation of electronic design, we can add power anti-reverse design to the power input terminal of the chassis distribution box. Because the entire vehicle’s power comes from the chassis distribution box, we have blocked the reverse current at the source after implementing anti-reverse design at the source, even if the battery power supply is reversed, there will be no reverse voltage and reverse current in the entire vehicle.What value does it bring?

(1) Except for the primary distribution module, there is no need for power anti-reverse design for all ECUs and loads of the entire vehicle, which reduces the design difficulty, design cost, and BOM cost;

(2) OEMs can cancel corresponding test items, reducing the cost of vehicle design and verification.

(3) Prevent the impact of battery power polarity reverse connection on the entire vehicle, such as damage to electronic and electrical components, and the risk of load misoperation.

Some of you may wonder why there is a risk of burning electronic and electrical components and misoperation of loads when power is reversed. Let me explain it to you.

The logical control part of the power supply for all ECUs of the vehicle has anti-reverse design, while the load control and high-current control mostly do not have it, because the anti-reverse design for high-current is very complicated and difficult, and it is not allowed to make cost for each power supply. If it is reversed, just make sure that your ECU does not misoperate or damage, and temporarily ignore the others.

Let’s take a look at what will happen if the traditional electrical architecture connects the power supply in reverse?

For conventional automobile electronic design, whether it is based on traditional relay load control or load control based on HSD (Intelligent High-Side Switch) chip, because there is no anti-reverse design in the high-current circuit, once the power polarity is reversed, the LSD (Intelligent Low-Side Switch) chip controlled by the relay will automatically conduct due to parasitic diodes, the relay will operate, and the HSD will also be automatically conductive. The load starts to work. If it is a light bulb, it will directly light up because the light bulb itself has no polarity. If it is an electric motor, it will directly reverse. As for whether it will cause vehicle malfunctions or damage to electrical components, it depends on luck. ECU will certainly not be damaged in a short time.

Therefore, the electrification of power distribution and control technology brought by intelligent electrical architecture has a huge and even subversive impact on the entire vehicle and the entire automobile industry, and even industry standards will change for it. At present, we may not be able to perceive its impact, but in the future, its impact on the automotive industry is bound to be profound and long-term, and even children who design automotive electronics in the future will forget the design of adding a diode to the power supply, just like children nowadays do not recognize paper money.

- Wire harness loop saving and cost reduction

7.1 Saving of wire harness loops

The saving of wire harness loops can be divided into several aspects:

(1). Saving of more than 30 power lines from the chassis to the cab.

Without further ado, let’s take a look at the picture, which is easier to understand:

Have you noticed that there is a basic difference between the fuses used in the chassis distribution box and the ones used in the cab distribution box? The former usually uses large plate fuses (generally 40-50A) to divide the power into multiple circuits (usually around 4 circuits), which are then pulled into the cab to be distributed to the vehicle’s electrical appliances via small fuses. This design is based on safety considerations. If one fuse or a wire is faulty, only part of the functions will be affected.

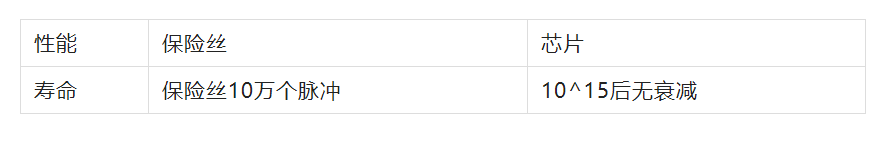

After adopting the intelligent architecture, the reliability of chips is much higher than that of fuses. In addition, the performance of chips is not significantly affected by the number of current surges, while fuses must consider this issue. To reduce risks, power supply is divided into multiple ways.

Therefore, based on the high reliability of chips, we can design the power supply line from the chassis to the cab as a single wire, which gives us the possibility of reducing costs, and the wire gauge can also be appropriately reduced. This will be analyzed in detail below.

(2) Reduction of relay control circuit

Previously, each relay required a control wire, and the entire vehicle needed dozens of wires. After adopting chips, control is localized, and communication methods such as CAN can be used to control, saving some harnesses.

(3) Reduction of other hardwire circuits

① Reduction of signal input wires. For example, some switch signals, such as door status signals and light switch input signals, used to rely on hard wires. Which ECU needs it will get a wire pulled to it, which not only increases costs, but also may cause hidden signal paths between signals, increasing design complexity and risk of failure (the issue of hidden signal paths in the entire vehicle is a complex design problem).

② Reduction of control circuit harnesses. For example, when two signals control the same function, conventional design uses two relays connected in series for control, only when both signals are effective. Using the intelligent architecture is much simpler, where both signals go through CAN communication, and the software handles it directly, with higher logic flexibility.

③ Weaken the ACC, ON and other hardwire signals. For example, if it used to rely on ON signal for power supply, you can directly supply power through ON, or through relays. The intelligent architecture can configure any output as the ON property. Also, for ECU signals that use ON, you need to pull an ON wire specifically for it. Now, the cab distribution box can collect the ignition lock signal and transmit it through CAN communication, so all ignition lock signals in the entire vehicle can be shared.7.2 Reduction of Wire Diameter

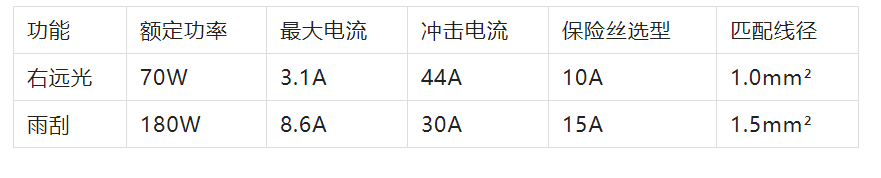

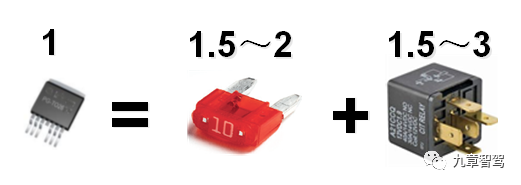

Let’s take a look at the difference in wire harness matching with two real loads.

First, let’s examine the design match using fuses:

Next, let’s see the match using chips:

Through the above comparison, we can see that for the same load, when using chip design, the chip current can be selected smaller, correspondingly, the wire diameter can also be smaller, at least one level lower.

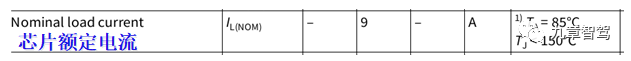

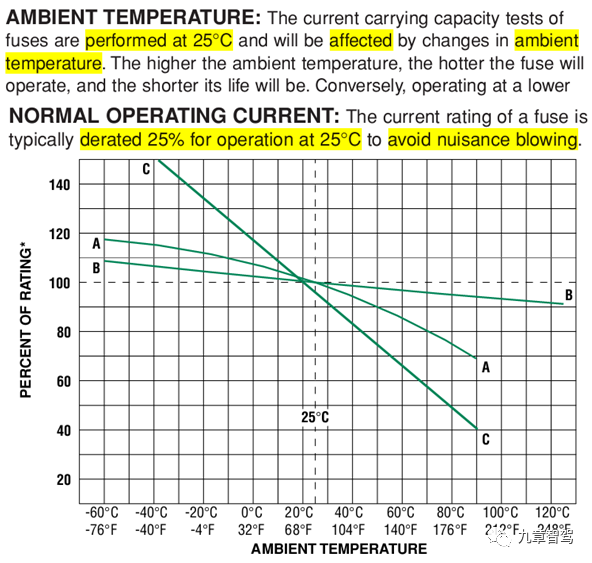

In the previous article, we detailed the reduction design of fuses and relays, but I did not mention reduction for chip design. Why not? Without further ado, let’s compare:

Through the comparison, it is clear that the rated current test condition given by chips is high temperature 85 degrees, while the fuse is at room temperature 25 degrees. High temperature requires reduction, coupled with the basic reduction of 25% for reliability considerations, how much reduction is needed after all? This is still without considering that I2t may also need to be reduced.

Attention, everyone, I’m giving the conclusion, which is important, and will be tested later:

In general, the rated current of chip design can be smaller than the original fuse design, even half of it, and the corresponding wire diameter will also be reduced.

Therefore, based on the future intelligent architecture chip design, everyone must change their thinking. When someone says the current is 20A, you need to ask if it is a fuse matched with 20A or the rated current of the load is 20A. Otherwise, everyone’s understanding will not be on the same basis, and communication problems will occur.

7.3 Avoiding Long Wire Harness Wire Effect

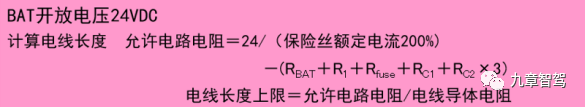

This was mentioned in the previous article, but not discussed in depth. If you are not a person who specializes in electrical design, you may not be very familiar with it. Let’s explain briefly.

We previously discussed how to match fuses and harnesses, but we didn’t mention that the length of the harness should also be considered when designing it. For commercial vehicles with long lengths, the harness length can be several tens of meters. If the wire diameter is relatively thin, the short-circuit impedance may be high, and the short-circuit current cannot be increased, resulting in the fuse not melting and the fault continuing to exist. The fault point will continue to heat up, creating a risk.

With the use of chips, high precision current detection can distinguish between normal and faulty currents, and protection can be implemented to avoid the occurrence of risks. In addition, when designing the wire harness, there is no need to calculate the wire length, which reduces the difficulty of design matching and testing verification requirements, and to some extent reduces the design cost.

7.4 Harness Cost

Finally, let’s talk about the cost, which is probably the most concerning issue. Based on the analysis of the harness of a medium-sized truck to each wire, terminal, and connector, using an intelligent architecture reduced the BOM cost of the entire vehicle harness by 15.8%. Amp also calculated that the use of a regional architecture could reduce harness costs by 25%, and similar calculations have been made by Bosch, with the results indicating that harness costs are reduced.

The specific reduction in the harness component and the overall vehicle architecture and configuration are strongly related and cannot be generalized. However, there is a general direction: the more vehicle functions and options there are, the more ECU there are, and the greater the space for cost reduction through the use of new architectures.

8. Customer Value

Commercial vehicles, unlike passenger vehicles, are production equipment with practical functions, low operating costs, high reliability, and low maintenance costs. Based on these considerations, the customer value of an intelligent electrical architecture is mainly reflected in the following aspects:

(1) Automatic sleep to prevent power loss. The power switch can be cancelled or, even if it is not cancelled, the vehicle can automatically go to sleep after parking, making it more convenient to use while completely eliminating the possibility of power loss while parked.

(2) Realizing intelligent networked vehicle functions. For example, remote vehicle power management, including remote vehicle power monitoring, self-diagnosis, and device switches. Other examples include remotely turning on the air conditioning, remotely preheating the engine, and remotely checking the lights.

(3) Reducing maintenance costs. High reliability and low maintenance mean fewer faults and less downtime, which translates into more earning opportunity.(4) Improved User Experience. After a fault is eliminated, it can automatically recover, or recover according to demand, which improves the user experience. For example, if the wire harness of the headlamp is broken and contacts the metal, the traditional fuse will definitely blow, causing the lamp to be off, but the chip can automatically restart after protection, professionally called auto-reset. If it is just occasionally touch the metal and there is no continuous short circuit, the driver will only see the lamp flashing. This way, it will not affect vehicle operation, and after parking, the instrument can remind the driver that a short circuit fault has occurred in the left high beam, which facilitates problem identification, quick positioning, and maintenance.

(5) Guide Users to Optimize Driving Habits and Achieve Energy Saving and Consumption Reduction. This requires OEM to provide vehicle usage suggestions to users through an app based on vehicle operation data and using a big data platform. This can also be considered as part of the brand value, and can be used as the selling point of OEM marketing.

Intelligent Electrical Architecture is the Infrastructure of Intelligent Vehicles

I estimate that you may still ask about the cost after reading the content.

Although we have also conducted multidimensional cost analysis, we did not mention the software part. According to AMP’s estimate, the area architecture can reduce 75% of software costs. Currently, major OEMs are also moving towards self-built software capabilities. Software costs (including integration and testing costs) must be considered in advance, because according to current trends, in future product development, software costs will far exceed hardware costs, especially toolchain purchases and software platform architecture construction.

However, I believe that intelligent architecture should be viewed from the perspective of infrastructure construction. The construction of intelligent electrical architecture will become the new infrastructure of intelligent and unmanned vehicles. It is the infrastructure for vehicles to achieve intelligence and unmanned driving. Its construction must consider its priority, public service and basic nature, instead of just BOM cost.

Conclusion

After all the discussions, we can summarize it as follows:

- Autonomous commercial vehicles require an intelligent electrical architecture that is “perceivable, controllable, and evolvable.”

- Intelligent electrical architecture can greatly reduce vehicle development and testing costs.

- The construction of intelligent electrical architecture can be in line with the inherent needs of OEM software capabilities.

- Intelligent electrical architecture can enhance OEM’s brand premium, lay a foundation for “hardware embedded, software paid,” extend the value chain, and provide assistance for OEM’s transformation from vehicle manufacturer to service provider.

- Intelligent electrical architecture is a part of regional architecture, which is the infrastructure that supports future new energy trucks and advanced unmanned driving technology.

Due to the length limit, we will conduct a more in-depth analysis of the difficulties in the implementation of intelligent electrical architecture in the next article, so stay tuned!

References:1. Fire and Explosion Investigator Randolph J. Harris https://www.fayengineering.com/randolph-j-harris

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.