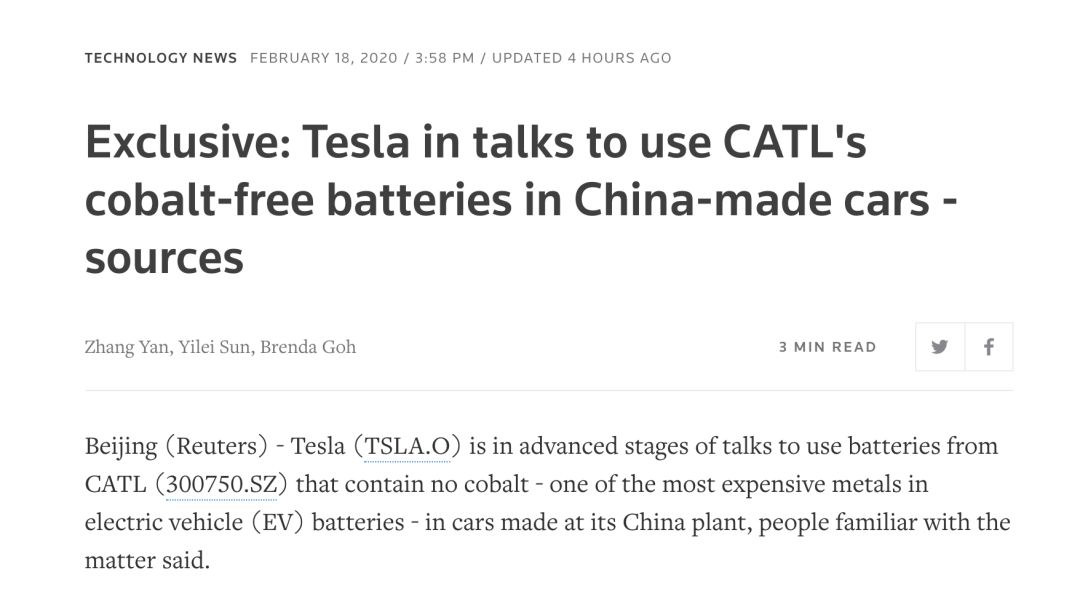

Yesterday, a Reuters report about locally-produced Tesla batteries sparked a lot of discussion in the 42 Garage community. The article’s title was “Exclusive: Tesla in talks to use CATL’s cobalt-free batteries in China-made cars.”

At first glance, the title is quite “shocking”. Currently, battery manufacturers are working to reduce the proportion of “cobalt” in the positive electrode of ternary lithium batteries. The lower the cobalt content, the lower the cost of the battery theoretically.

Currently, the lowest cobalt content in CATL’s mass-produced products is only reduced to 10%, and the proportion of cobalt in Tesla’s collaboration with Panasonic to produce NCA ternary lithium batteries only reaches a percentage of a percent. Therefore, it is indeed curious that Tesla plans to use CATL’s cobalt-free batteries.

After reading the article, it turns out that the so-called cobalt-free battery is actually an LFP lithium iron phosphate battery, which has nothing to do with ternary lithium batteries. Tesla’s plan to use CATL’s LFP battery has been revealed as early as January this year. We also mentioned it in “How many cars Tesla can sell in the end?” (http://mp.weixin.qq.com/s?_biz=MjM5NTIyMjA2MQ==&mid=2656755914&idx=1&sn=64e17c6b8db7b62cf6407d51e681e1ce&chksm=bd5587888a220e9eb2d34519aa135cd1bc6fa708398e1ab587e40dca9ed4f4bbd955a9f87d69&scene=21#wechatredirect). Furthermore, Tesla’s suppliers of positive and negative electrode materials are explicitly Nano One and Shantai respectively.

Since everyone is so concerned, let’s talk about why Tesla wants to use lithium iron phosphate batteries? Which one is better, lithium iron phosphate or ternary lithium?

Why does Tesla want to use lithium iron phosphate batteries?

To reduce costs and thus lower the price of the car.

In electric vehicles, the cost of the power battery accounts for 40% of the vehicle cost, and the price of the positive electrode material in ternary lithium batteries accounts for 40% of the cost of the power battery. The current prices of “nickel”, “cobalt” and “manganese” in positive electrode materials are 100,000 yuan/ton, 277,000 yuan/ton and 6,400 yuan/ton respectively.Therefore, in order to reduce the price of the power battery, all battery factories are committed to developing batteries with lower “cobalt” content, from 523 to 622 to 811, and the proportion of cobalt continues to decrease.

So, what’s the deal with Tesla’s use of lithium iron phosphate this time?

“Lithium iron phosphate” is also a type of power battery for electric vehicles, but the positive electrode material has been changed from the original “ternary” to “iron lithium” without “cobalt,” so the price of lithium iron phosphate batteries will be lower than that of ternary lithium batteries.

According to a research report from Guotai Junan, the current price of lithium iron phosphate is 0.65 yuan/Wh, while ternary batteries are 0.85 yuan/Wh, which is 23.5% cheaper in cost.

So it is a logical thing to use lithium iron phosphate batteries to reduce the cost of the entire vehicle material cost, but there are two details worth discussing here.

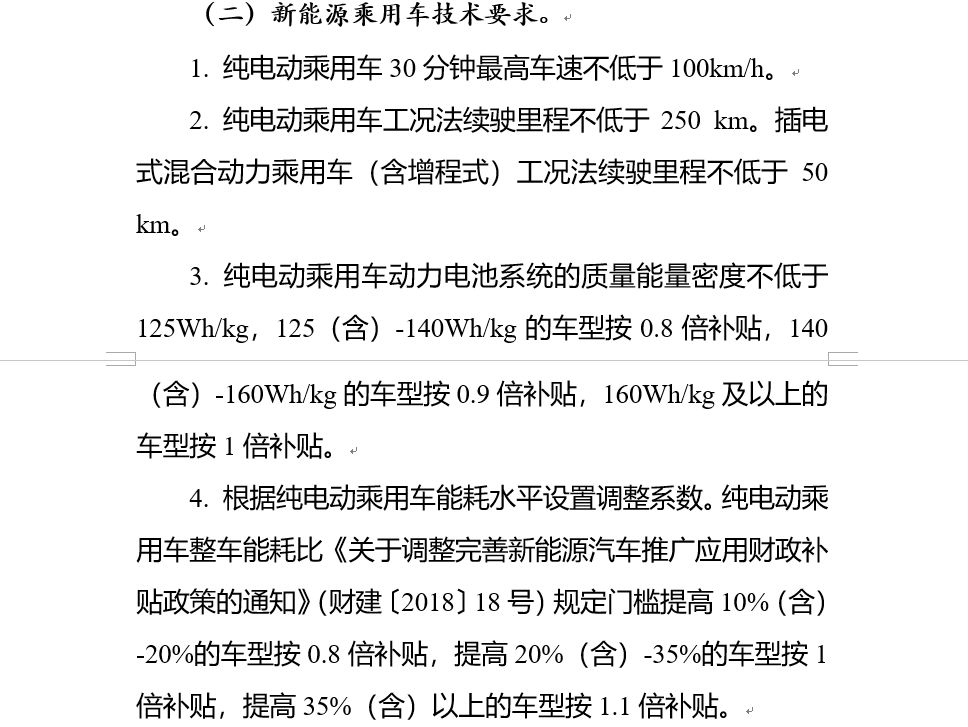

Can subsidies still be enjoyed after using lithium iron phosphate?

Although the policy has not been officially introduced, at the Electric Vehicle Hundred People Forum in January this year, Miao Wei, Minister of Industry and Information Technology, clearly stated that new energy vehicle subsidies will not be reduced in 2020.

The purpose of using lithium iron phosphate with lower conversion costs is to reduce prices. If subsidies cannot be obtained because lithium iron phosphate batteries are used, this would be counterproductive.

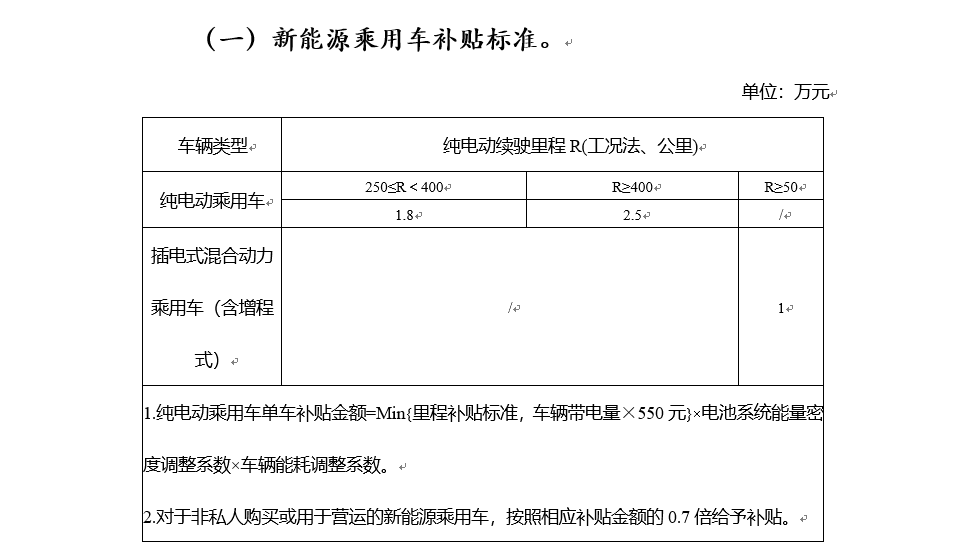

The three core thresholds for subsidies are endurance mileage, battery energy density, and comprehensive power consumption. Currently, the endurance and energy density ranges for domestically produced Model 3 are greater than 400 km and 140 Wh/kg-160 Wh/kg, respectively.

In other words, Model 3 that uses lithium iron phosphate has an endurance of more than 400 km, the battery energy density is 140 Wh/kg or higher, and if the overall power consumption is not much different from the current model, it can still enjoy a subsidy of 24,750 yuan.

Ternary lithium battery domestic Model 3 parameters

As for whether it is possible to achieve the aforementioned indicators, we believe there is absolutely no problem, and the reasons will be explained in the following section “What is the difference between lithium iron phosphate and ternary lithium?”.The second detail is that the price of the ternary lithium battery mentioned above is at the industry level. According to UBS’s analysis report in November 2018, the price of the Panasonic 2170 battery cell used by Tesla has reached $111/kWh, and Tesla’s target is to reduce the price to $100/kWh in 2019, equivalent to 0.7 yuan/Wh.

This cost is already very close to the current price of lithium iron phosphate. So why does Tesla still want to further reduce the price by using CATL’s lithium iron phosphate?

Three reasons:

First, all 2170 cells are currently produced and packed by Giga Nevada, so if Giga Shanghai wants to use Panasonic batteries for Model 3 production, they must be shipped from the US to China, which will increase transportation and tax costs and is not cost-effective.

Second, in order to increase the localization rate of vehicle components, Tesla currently uses 2170 cells from LG Chem for domestic Model 3 production, but LG Chem’s 2170 cells are not cheap.

Similarly, according to UBS’s research report, by the end of 2018, LG Chem’s battery cost was 20% higher than that of Panasonic/Tesla. This means that even if Tesla uses domestically produced LG 2170 cells, the cost is still not optimal.

Third, Tesla obtained very favorable prices for lithium iron phosphate from CATL.

According to Reuters, insiders said that the cost price of the battery is expected to be reduced by a double-digit percentage, and according to our sources, Tesla hopes CATL’s target price will be reduced by 20%.

In summary, Tesla’s main motivation for using lithium iron phosphate is cost reduction.

What is the difference between lithium iron phosphate and the current ternary lithium battery?

This is the most concerned question for the Chinese Model 3 reservation holders.According to a Ningde Times announcement, Tesla will not receive power batteries until July this year, so all differences before mass production testing are based on the electrochemical properties of lithium iron phosphate and ternary lithium.

In addition, it should be clarified that Ningde Times did not produce lithium iron phosphate batteries for Tesla. Lithium iron phosphate batteries have always accounted for a large proportion of Ningde Times’ shipments. It is only under the guidance of policies that the advantages of ternary lithium batteries are greater. Therefore, what we are currently using is primarily ternary lithium batteries.

There are three major advantages of lithium iron phosphate: low price, high safety, and long life. I will not elaborate here. The key is to talk about the disadvantages, which is also a new challenge that Tesla needs to overcome in using lithium iron phosphate for the first time.

Low energy density

In the past few years, the national energy subsidy policy has been guiding battery manufacturers to develop high-energy-density batteries to improve the overall range of the vehicles. The energy density of lithium iron phosphate batteries has already reached the limit at 120 Wh/kg, but this is just the starting point for ternary lithium batteries.

As the threshold of energy density in subsidy policies continues to increase, the advantages of lithium iron phosphate are becoming smaller and smaller. Therefore, in recent years, ternary lithium batteries have become the preferred choice for household electric vehicles.

Lithium iron phosphate is mainly used in trucks and buses that have low space requirements but high requirements for cycle life and safety.

Although the low energy density of lithium iron phosphate batteries is due to their electrochemical properties, BYD and Ningde Times hope to improve the overall energy density of battery packs through blade battery and CTP technology.

According to the parameters of BYD’s “Han” released by the Ministry of Industry and Information, the energy density of lithium iron phosphate batteries has also reached 140 Wh/kg through the use of blade battery technology.

In October 2019, Ningde Times signed a long-term strategic contract with the Volkswagen Commercial Vehicles division. Volkswagen’s e-Delivery series of pure electric light trucks will use Ningde Times’ CTP lithium iron phosphate batteries, and the energy density of the battery pack is 160 Wh/kg.

The lithium iron phosphate battery that Ningde Times provides to Tesla also uses CTP technology. Although the energy density of lithium iron phosphate is not as good as the 180 Wh/kg of ternary lithium in terms of data, it has already met the threshold of subsidies. Therefore, the domestically produced Model 3 using lithium iron phosphate batteries is most likely to receive subsidies.And CATL’s supply of lithium iron phosphate batteries to Tesla will only be used in the “Standard Range Plus” model with smaller battery capacity, so even though lithium iron phosphate has lower energy density, it can still meet the endurance requirements of the “Standard Range Plus” model with the help of CTP technology and the threshold of new energy vehicle subsidies.

Here is some additional information about the domestic long-endurance Model 3.

The domestic long-endurance rear-wheel drive version of the Model 3 has already been included in the MIIT catalogue, so mass production delivery is only a matter of time. However, it is certain that the long-endurance model will use higher energy density Nanjing LG Chemical 2170 ternary lithium batteries, due to their larger battery capacity.

Poor Low-Temperature Performance

Poor low-temperature performance is a shared characteristic of ternary lithium batteries and lithium iron phosphate batteries, but because the activity of ternary lithium batteries is higher, their low-temperature performance is relatively better, while lithium iron phosphate batteries have lower activity, so the disadvantages of poor low-temperature environment performance will be more pronounced.

The most direct impacts of poor low-temperature performance are as follow:

First, under low-temperature environments, for the same amount of electricity, the actual endurance of lithium iron phosphate is shorter than that of ternary lithium batteries.

Second, under low-temperature environments, for the same amount of electricity, the charging speed of lithium iron phosphate batteries is slower than that of ternary lithium batteries.

In summary, theoretically Model 3 vehicles using lithium iron phosphate batteries might have slightly worse endurance in low-temperature environments compared to those using ternary lithium batteries, and their ability to reach the maximum charging power of 170 kW when using Supercharger is also unknown.

I don’t think Tesla will sacrifice the vehicle’s performance on the “three-electrics” excessively just to lower costs, but based on current lithium iron phosphate electrochemical characteristics, these two problems that Tesla needs to overcome. However, we hope to solve this issue on Tesla’s Battery Day in April.

It is clear that reducing costs and improving performance has always been Tesla’s goal, and now LG Chem and CATL are being sought after to find a balance in cost and performance.

According to our latest source, Hyson has signed a 70 million yuan contract with Lingang for the supply of battery-making equipment, implying that Giga Shanghai is very likely to become the second manufacturing plant for power battery cells in addition to Tesla’s main plant in the United States.

Combined with the news of Tesla’s own battery production line at the Fremont plant, which began trial production at the beginning of the year, Tesla’s electrochemical technology, which has been stagnant for the past three years, is about to become the most shining focus on stage this year.

See you in April.

Author: 63

Editor: Daji“`markdown

“`

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.