On August 26, Geely provided a technical analysis of its self-developed and self-produced Divine Shield Gold Brick Battery via a live broadcast. They revealed its performance in the industry’s first “Complete Vehicle + Complete Pack” six extreme serial tests conducted by the China Automotive Technology & Research Center New Energy Inspection Center. The tests included “dynamic corrosion immersion with load, high-temperature charging and discharging, continuous vehicle bottom scraping, vehicle wading scraping, vehicle bumping wading, and external fire with load,” simulating various extreme conditions users may encounter. Ultimately, the Divine Shield Gold Brick Battery did not catch fire or explode in any of the tests.

The Divine Shield Gold Brick Battery includes three series: super-fast charging, high energy density, and super-hybrid, covering both electric and hybrid platforms. The super-fast charging series features a maximum charge rate of 5.5 C and a 3-second pulse discharge rate of up to 22 C; the high energy density series achieves an energy density of 192 Wh/kg, an average fast charge rate of 2.45 C, a low-temperature retention rate 8.7% ahead of competitors, and a cycle life of 3,500 cycles. The super-hybrid series charges from 80% to 100% SOC in just 11.5 minutes, with a terminal charge rate 75% higher than the industry standard, a maximum discharge rate of 21.02 C, and a cycle life reaching 4,500 cycles.

In terms of technological innovation, the Divine Shield Gold Brick Battery employs self-developed multi-particle size compounding technology and high-wetting electrolyte technology to ensure the high dynamic performance needed for hybrid vehicles. It simultaneously maintains lower internal resistance than peers and high-power charge and discharge capabilities. Its unique SEI film self-repair technology allows self-repair of cracks during battery cycles, accelerates interface healing, and enhances battery cycle life.

In the market, the Divine Shield Gold Brick Battery is widely integrated into products from brands like ZEEKR, Lynk & Co, and GEELY. Geely’s new energy vehicle sales have exceeded 850,000 units from January to July this year, a 126% increase year-on-year.

Jiyao Tongxing, the main producer of the Divine Shield Gold Brick Battery, has established eight production bases in Tonglu and Quzhou, Zhejiang; Jianhu, Jiangsu; Ganzhou, Shangrao, and Yingtan, Jiangxi; Ningguo, Anhui; and Zaozhuang, Shandong. By 2027, the production capacity is expected to reach 70 GWh. The Quzhou base, with a 24 GWh short blade capacity, achieves a 24 PPM full-line design efficiency, meaning each production line can complete 24 Divine Shield Gold Brick cells per minute. As the first smart manufacturing factory in Zhejiang with a level-four maturity in the national battery cell industry, the Quzhou base features a medical surgery-grade dust-free production environment, 18 core processes, a 100% automated production system, and battery cell production lines integrating AI quality models, applying energy vibration, optical imaging, and other AI quality inspection equipment.

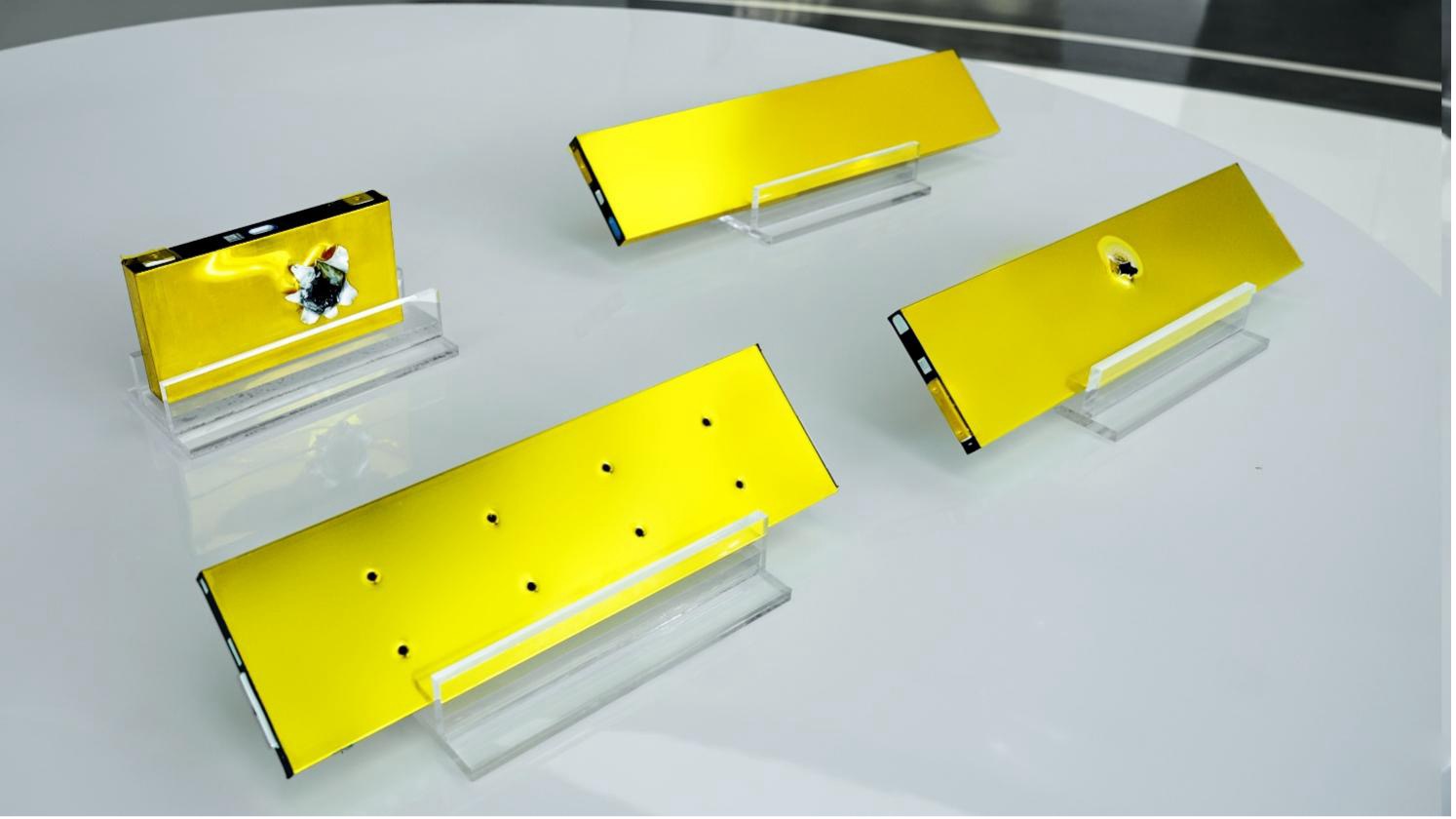

The test standards for the Shendun Gold Brick Battery far exceed the “New National Standard.” Out of 36 full-scenario extreme tests, 23 exceed the requirements of the “New National Standard.” Battery pack drop and stomping tests, among 12 test items, adhere to Geely’s corporate standards. In extreme safety tests such as puncture with 8 needles, live ammunition penetration, multi-faceted extrusion, and being run over by a 36-ton tank, the Shendun Gold Brick battery cells do not smoke, catch fire, or explode.

This article is a translation by AI of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.