The Cybertruck, originally scheduled for release in 2021, was delayed until 2022.

According to Musk at the time, “Cybertruck will be put into production at the Texas factory by the end of 2022.” However, in March of this year, Tesla’s plan was to complete the development of the Cybertruck this year and put it into production in 2023. In June of this year, Musk stated that Tesla hopes to put the Cybertruck into production in mid-2023.

Currently, this time schedule seems reliable. At the Semi launch event, the Cybertruck was scheduled to be produced immediately after the Semi, and a one-piece casting machine for the production of the Cybertruck was found to have been transported to the Texas factory.

In the Q3 2022 earnings call, Musk revealed that the Cybertruck was in the “final stage”. In the days after the earnings call, pictures of the Cybertruck body were leaked outside the Texas factory.

The leaked picture of the Cybertruck body confirms this. The picture clearly shows that the Cybertruck uses a giant rear one-piece casting, with the front body possibly made of stainless steel formed by hydraulic pressure.

Musk recently stated that the Cybertruck uses an 8,000-ton one-piece casting machine, which exceeds the 6,000-ton casting machine used by the Model Y, and that the one-piece casting on the Cybertruck will be the largest in terms of size among mass-produced vehicles. This design gives the Cybertruck excellent body rigidity and load-bearing performance.

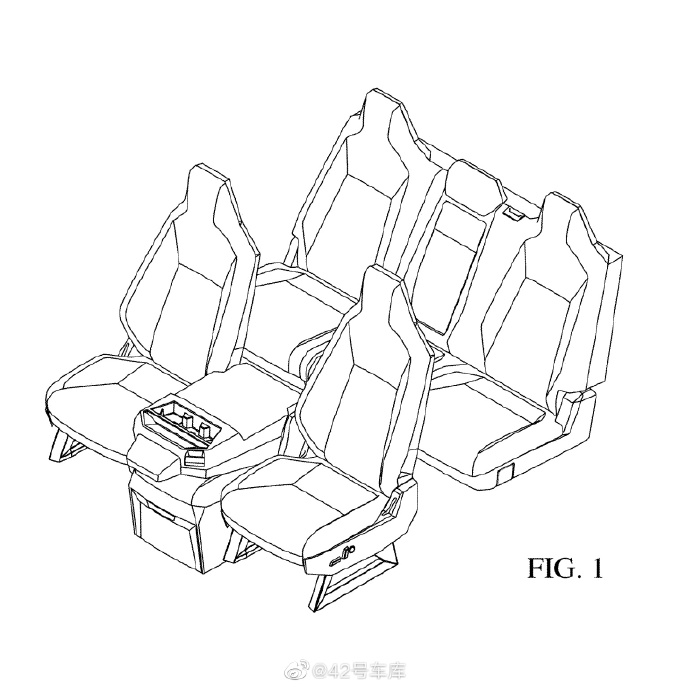

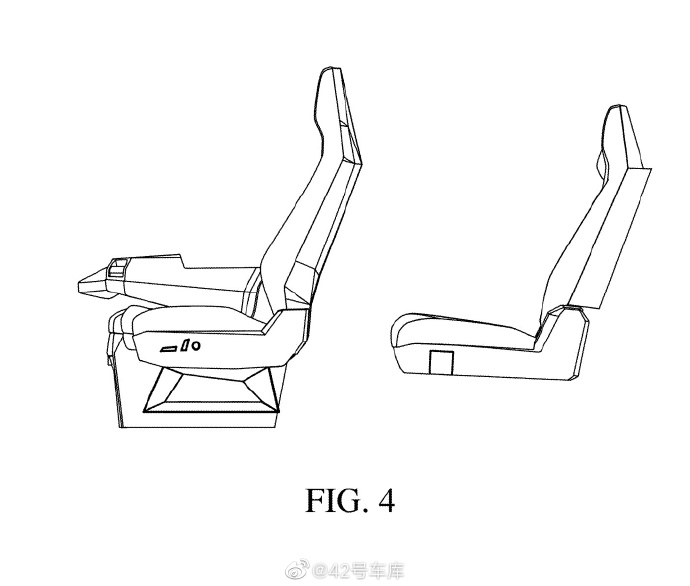

At the end of last year, Tesla applied for a patent for the seat design of the Cybertruck with the US Patent and Trademark Office. From the patent drawings, it can be seen that the front and rear seats and headrests are all designed in a single piece with a sharp and angular style, which is consistent with the futuristic design of the exterior.According to the patent images, the front row of the CyberTruck features a three-seat design, and the middle seat can be folded forward by 90 degrees to form an armrest box, which is consistent with the interior design of the original CyberTruck prototype.

One of the reasons for the Cybertruck delay is that the scale and cost are not enough to support profitability. If the annual production capacity is less than 200,000 units, the Cybertruck is likely to run at a loss. Large-scale die-casting is also a system that requires large-scale marginal cost sharing.

Tesla seems to have no problem selling the Cybertruck at all. The current pre-order volume of the Tesla Cybertruck has reached a stunning 1.5 million units. This is a terrifying figure: the global delivery volume of Model 3 in 2021 was 500,000 units.

The reservation speed of a general new car will reach its peak after a period of time after the release event and then gradually decline. However, the Cybertruck received more than 250,000 pre-orders in just one week after the release event, and the pre-order volume of Cybertruck exceeded 1 million units in 2021 and 1.5 million units in 2022.

Even during the epidemic, some Tesla official websites in certain regions can receive hundreds of pre-orders every week. So, the final obstacle is whether the production capacity can catch up quickly in 2023.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.