The Solution to the Weaknesses of Soft Pack Batteries

Author: Wang Lingfang

Editor: Qiu Kaijun

Soft pack batteries have always been a relatively marginal presence in the Chinese battery industry due to their small size, low efficiency when grouped together, and high manufacturing difficulty, making them the least popular type of battery for Chinese car companies.

With the large-scale production of square batteries by CATL and BYD, the market share of soft pack batteries has gradually declined, moving towards the edge.

So how can the shortcomings of soft pack batteries be solved?

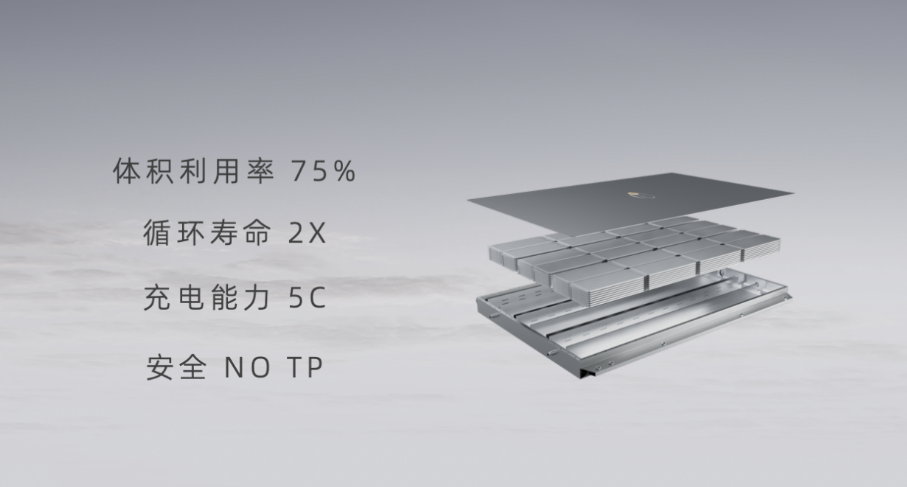

Funeng Technology has provided a solution with their release of the SPS battery technology. The new SPS soft pack power battery uses a semi-solid-state + direct integration + cooling plate bearing mode.

Not only does this mode make soft pack batteries larger, it also has a volume utilization rate of 75%, which exceeds the Kirin battery of CATL. Furthermore, it greatly reduces manufacturing costs using non-module technology and large battery cells. Additionally, it has excellent performance in terms of heat management and the thickness of the battery pack.

Higher Volume Utilization Rate Than Square and Cylindrical Batteries

Previously, the low efficiency of grouping together the battery cells was a commonly mentioned weakness of soft pack batteries for car companies and system integrators.

In recent years, with slow progress in material technology, car companies and battery companies have begun to improve battery pack structures by simplifying them to increase the proportion of battery cells and improve the energy density of the battery.

In their view, non-modular structures have become the mainstream trend for development, but the strength of the soft pack structure is insufficient, so modules cannot be removed. Although the energy density of soft pack batteries is not low, the complex module structure dilutes this advantage.

Funeng Technology has solved the problem of grouping together soft pack batteries by creating a non-modular soft pack battery structure, which integrates the battery cells into the PACK or even directly into the car chassis.

Specifically, Funeng Technology places an aluminum metal plate under each battery cell, and the folded part should have a height equivalent to the thickness of the battery cell, providing support and insulation for the battery cell.

By using non-modular technology, the proportion of battery cells in the battery pack greatly increases, and the volume utilization rate of Funeng Technology’s battery pack has been increased to 75%, breaking the record of CATL’s Kirin battery at 72%.

Of course, volume utilization rate is also more outstanding than the 4680 system. Compared to the 4680 system, the SPS system’s volume utilization rate is 12% higher. What’s more, the cycle life of the SPS is three times that of the 4680 system.

Funeng Technology’s Chairman Wang Yu also provided an example – their latest SPS design has already enabled some of their clients to increase their battery capacity by 30%. This means that an 800 km range car model that originally uses ternary batteries could now achieve 1000 km range using the new SPS system; and a 500 km range model that originally uses lithium iron phosphate batteries could now achieve 600-700 km range.The SPS battery system from Hanteng Technology has now significantly exceeded the energy density of square batteries and the 4680 battery system.

Low Cost and High Flexibility

The other two advantages of the SPS battery pack are its low cost and high flexibility.

(1) Low Cost

Soft-pack batteries have historically had higher unit costs due to limited supplier options for the aluminum-plastic film packaging.

Currently, the Chinese aluminum-plastic film market is mainly dominated by overseas companies such as Japan’s DNP, Showa, T&T, and Korea’s Kumho, which occupy about 70% of the market share. Domestic aluminum-plastic film companies have gradually begun mass applications in the past two years.

However, domestic aluminum-plastic film companies are rising, and the shortcoming of aluminum-plastic film is gradually being strengthened as the market size continues to increase and supplier technology improves.

In addition to the downward trend of material costs themselves, Hanteng Technology further reduces costs through design and manufacturing. Specifically, cost reduction is achieved through module-free technology and flexible production.

First, by eliminating modules and making battery cells larger, the number of parts is reduced, resulting in a significant decrease in Hanteng Technology’s production costs;

Second, the simplification of battery pack structure will also save a large amount of material costs;

Third, flexible production lines reduce one-time equipment investment;

Fourth, the factory area is reduced due to the benefits of flexible production lines and reduced number of parts.

Wang Yu once said at a press conference that using the SPS solution, battery technology iterations will be very easy, and through the design of the entire vehicle platform, design will be greatly simplified and investment will be significantly reduced.

The benefit to the entire vehicle enterprise customer is that it can shorten the development period of new models, have strong commonality in key components such as battery cells and chassis, reduce procurement costs, and help ensure stable supply.

(2) High Flexibility

As a systematically designed product, Hanteng Technology’s SPS system can adapt to all passenger car models with the same chassis and battery cells.

The specific approach is that Hanteng Technology can flexibly adjust the PACK thickness by adjusting the thickness of the horizontally arranged large soft-pack battery cells, thereby adjusting the height of the battery system’s chassis.The height of the SPS’s large soft pack system can be flexibly adjusted from 85mm to 145mm on the same chassis, simply by adjusting the height of the liquid-cooled plate. By using different energy density of the large soft pack cells, the battery system can have different capacities ranging from 80kWh to 150kWh, meeting the electrification needs from performance cars to city pickups.

Various SPS compatibility offered by the SPS system includes adjustable cell height and chassis height, providing convenience to automakers in the development of multiple vehicle models on the same platform/architecture.

In addition, Funeng Technology uses the full ear design of the cell, which results in higher rate performance, lower loss, and is better suited for high-rate charging.

Of course, in addition to the full ear design, it is also possible to choose various ways of ear-take-off, such as upper and lower ear-take-off, lateral ear-take-off, or even four-side ear-take-off.

Here, a comparison with the Qilin battery will reveal similarities in their ability to accommodate different material systems of cells, which is due to their excellent thermal management performance of the battery.

However, the Qilin battery uses square cells, which, although they can be used as standard cells, are less flexible in terms of chassis height.

The flexibility of the SPS system is also reflected in its material system, which can cover multiple materials, such as lithium iron phosphate and ternary, even sodium-ion. Funeng Technology can easily change material systems according to customer requirements.

NO-TP Battery is as good as the Qilin Battery, with better fast charging effect

With the popularization of no-module technology, the higher cell density without module barrier, the more obvious the danger of thermal runaway becomes. Therefore, battery companies have made NO-TP (non-propagation of thermal runaway) the ultimate goal.

In fact, as early as 2020, Funeng Technology’s 523 system used in the Guangzhou Aion V project had achieved “never catch fire”. This time, the SPS system has further upgraded this technology.

In the SPS system, Funeng Technology provides protection to the cell from all six sides, i.e. up, down, left, right, and surrounding walls. At the same time, the liquid-cooled plate has a dedicated exhaust channel, so that if a battery experiences thermal runaway, it will be automatically discharged without affecting the surrounding cells in all six directions.

Funeng Technology uses a vertical liquid-cooled plate for the SPS battery pack. The blue part in the figure below should be the liquid cooling system of the SPS battery pack. In this way, both sides of the cell can be liquid-cooled, and there is an aluminum metal plate under each cell, which is folded to a height equivalent to the thickness of the cell, i.e. the bottom and two side aluminum plates act as a heat transfer medium.

The liquid-cooled plates on both sides of the battery cells can also act as structural components to provide structural support. According to Wang Yu, the battery cells are surrounded by aluminum foil and copper foil, and if necessary, the cells can achieve cooling on all sides. In this way, the SPS battery system has improved heat efficiency by four times compared to its previous large module mode.

This cooling strategy is similar to that of CATL’s Kirin battery, both of which use a vertical liquid-cooled structure to increase the cooling area.

In addition, in terms of low-temperature performance, the full-pole ear and laminated process of the large pouch cells bring lower internal resistance and better low-temperature discharge performance to the cells, while the inclusion of liquid-cooled plates and nano-insulation materials balance the internal temperature of the battery system. To meet the normal charging needs under extreme cold conditions, SPS has adopted a new low-temperature rapid self-heating design.

Experimental data shows that the SPS system maintains a capacity of over 90% at minus 20 degrees Celsius, and the charging time is halved.

This lays a foundation for fast charging of the SPS system. According to data from Funeng Technology, the SPS system is capable of charging and discharging rates from 2.4C to 5C, or even higher.

Thermal management cannot be achieved without the participation of the BMS. The SPS uses the third-generation BMS developed by Funeng Technology. The third-generation BMS has better chips and artificial intelligence and is at the industry-leading level.

Looking back on the development of Funeng Technology’s third-generation BMS, its algorithm and intelligence have been iteratively optimized.

The first-generation BMS protected the battery through hardware and conventional algorithms; the second-generation BMS implemented self-learning features of algorithms such as SOX through software, which can automatically formulate battery strategies to improve safety and range, and can be upgraded through FOTA. The core of the third-generation BMS is the combination of cloud and big data, which can achieve safety protection, personalized driving, and performance improvement based on real-time big data models, and achieve seamless updating of models.

According to incomplete statistics, the total mileage of vehicles monitored by Funeng Technology’s BMS is close to 5 billion kilometers, or over 125,000 laps around the equator of the earth.

除了防护,孚能科技从电池本征特点着手,向固态电池发展,因为有机电解液被认为是电池热失控的「罪魁祸首」。孚能科技目前研发的半固态电池,减少了电解液的比例,有效提升了安全性,单个的半固态电芯可以做到热失控时不冒烟,且温度可控制在45摄氏度,甚至可以拿在手里。

Battery Recycling Made Easy

Responsible companies will always consider the issue of battery recycling.

Especially in the context of rising raw material prices, battery material recycling has already become economically and environmentally beneficial.

Funeng Technology can provide a closed-loop battery recycling technology for the entire life cycle of a battery.

Funeng Technology has developed and verified the direct recycling technology of lithium-ion batteries for more than 10 years, which can preserve the crystal structure of positive electrode materials and reuse them, further reducing costs and energy consumption, and increasing material utilization rate to more than 99\%.

According to third-party laboratory data in the United States, there is no significant difference in performance between battery cells made with 25\% directly recycled positive electrode materials and those made from all-new positive electrode materials.

If Funeng Technology can effectively recycle batteries, the overall material cost is expected to continue to decline, while also making contributions to carbon reduction and emissions reduction.

Square Cells Move Toward Soft Packs

Although the proportion of soft pack batteries in China has always been low, square-shaped batteries are actually constantly moving closer to soft packs, towards long and thin development. Typical representatives are the blade batteries of BYD and the short blade of bumblebee energy.

For example, the length of the blade battery cell of BYD is significantly increased compared to traditional battery cells, and the thickness is also reduced to about one-fifth of that of traditional battery cells.

Especially in the BYD DMI model, the blade battery cell uses aluminum-plastic film inside, which is already a typical soft pack battery cell, and is just covered with an aluminum shell outside.

It can be said that square batteries are becoming more and more like soft pack batteries in terms of form.

In terms of technology, the stacking process of soft pack batteries is more commonly used and more mature; square cell companies only began using it in recent years and may not be as mature as soft pack battery companies in terms of process maturity.

Therefore, although the actual share of soft pack batteries is not high, the application scale of its technology is much higher than its market share. With the entry of semi-solid-state batteries into the application stage and the development of solid-state batteries, the advantages of soft pack technology will become more pronounced. After all, soft packs can effectively improve energy density and reduce costs, and have better cycling stability for solid-state batteries.### FNNTECH’s SPS technology reveals more possibilities for soft pack batteries in the industry. This technological advancement may even bring soft pack batteries back to the mainstream from being just a supplementary power source. FNNTECH’s SPS system is going to become a strong competitor to CATL’s LFP batteries.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.