Author: Mr.Yu

I have noticed that since entering 2022, the debates about screens in car cabins have never ceased.

“Do we really need so many screens?“

“Are users forced to pay for these screens?“

“New three essential items for cars: sofa, refrigerator and big screen TV.“

Media colleagues and netizens alike have been criticizing the increasing number of screens in car cabins, which can only be described as overwhelming.

We briefly discussed this topic in our article “Who can’t have a few more screens in their car?“, and it is clear that car manufacturers and suppliers are not neglecting their main business of manufacturing cars by dedicating resources to intelligent cabins.

Of course, everyone has their own opinions on this matter. The use of screens in car cabins is not a recent trend, and the first company to introduce screens into car cabins was not Tesla, as some might have thought.

During a recent interview, one of our old friends mentioned that misunderstandings persist because of a lack of effective communication between the industry and public opinion.

It is easy to follow or lead the public outrage, but we should listen to the voice of the industry, understand their thought process, and let more people know what’s going on.

A few days ago, out of curiosity, I chatted with Li Linfeng, founder and CEO of Wuhan Haiwei Technology Co., Ltd. (hereinafter referred to as “Haiwei”), the screen supplier for popular car models such as NIO NT1.0/2.0 platform, Ideal L9/L8, Flyaway R7, and Wuling Kiwi EV, about a series of issues regarding screens and cabins.

I realized that the relationship between screens and cars is much more complex than we thought.

Below is a transcript of the conversation (G for GeekCar, L for Li Linfeng):

G:

Can you please introduce HiSilicon’s main business?

L:

Generally speaking, as a first-tier supplier of components, HiSilicon is an industrial enterprise that provides design, development, validation, manufacturing and delivery of components for automakers. One of our important businesses is the screens for automotive cabins.

At present, there is a saying in the smart connected car industry called “Dual intelligence”, which refers to intelligent driving and intelligent cabins. HiSilicon is also a company that continuously strives for “dual intelligence”. The difference is that we mainly focus on intelligent cabins and smart manufacturing.

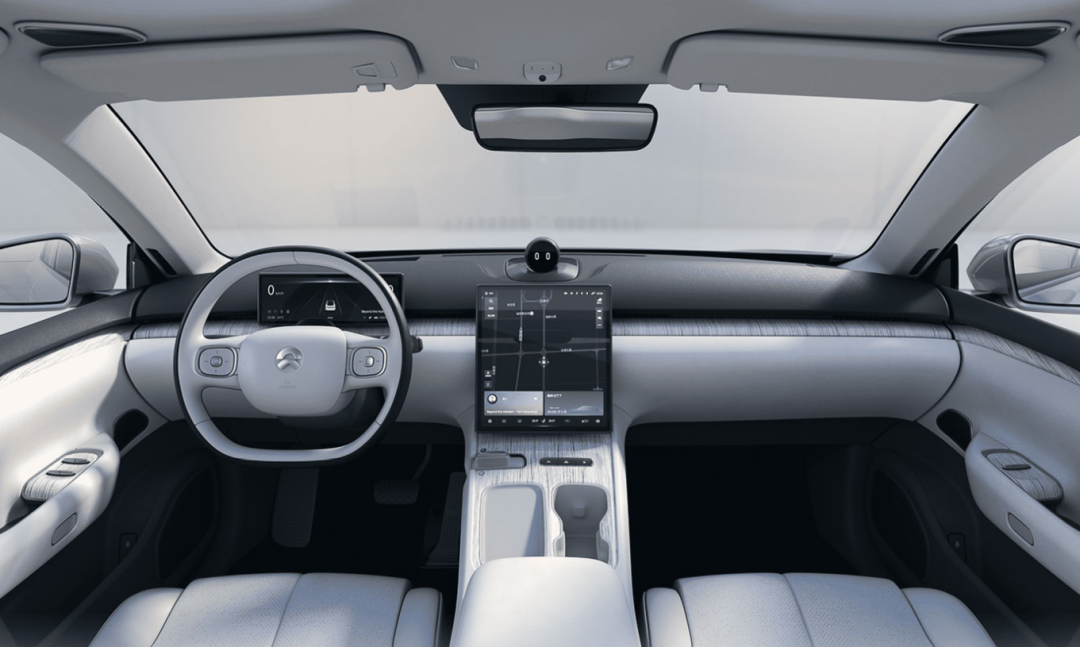

For example, we are the first-tier supplier of the central control screen, instrument screen, rear screen and the popular onboard assistant NOMI robot for the NIO NT1.0 (ES8/ES6/EC6) to NT2.0 (ET7/ES7/ET5) platform models, and the dual-screen L9 and L8 for the Li Xiang L9 and L8 models, the panoramic screen R7 for the Flymove R7, the dual-screen Kiwi EV for the Wuling Kiwi EV, and many other parts.

As of now, there are a total of 8 front screens based on Mini LED Local Dimming technology on the market in China, and 5 of them are supplied by HiSilicon.

These are the models that have already launched. There are still many models that have been designated but cannot be disclosed currently.

G:Understand. Actually, I also want to understand the “in-screen cars” thing from the beginning, including the industry consolidation recognized by car companies in recent years on in-car screens. For example, I would like to know, as a related industry practitioner, how do you view the critical attitude of public opinion towards this trend?

Before starting the technical topic, I have a topic that everyone is most concerned about, and it is also something that I haven’t figured out. I hope you can answer it in simpler terms: What do you think is the key value of in-car screens?

L:

Currently, whether it is in-car or consumer screens, they are mostly developed based on tablet display technology, which has been developed for three to four decades. It is currently the most convenient, most easily accepted, and lowest-cost human-computer interaction method, which is beyond doubt.

As you can see around us, 3-year-old children can pick up phones and tablets and use them without any training. Our lives are already full of various screens, and we interact with digital applications through screens, conveying the content of the digital world or IPs to users through screens.

Before denying the screen itself, no one can deny that the screen is a critical interface for human-computer interaction.

Cars have now become the second-largest carrier of intelligent innovation – the first-largest carrier being our mobile phones, and before mobile phones, there were PCs and laptops. Even without looking at cars, the trend is that screens are getting larger and more prevalent.

From the earliest 3-4 inch screens on mobile phones to the current mainstream 6-7 inch screens, as a portable device, mobile phones have already reached the upper limit of human handheld use. The development of the screen size of mobile phones has touched the upper limit, so the upper limit of the in-cabin screen may be from pillar A to pillar A, about 1.5 meters. This will likely be the largest physical screen for in-car use in the visible future, such as the Hyperscreen on the Mercedes EQS and the 43-inch screen on the Byton R7.

G:

In your opinion, to what extent do car users and potential users recognize the screen as an interactive medium in the present?

L:

This interpretation still needs to be combined with the previous question.

I think that the degree cannot only be viewed from the perspective of the screen as a photoelectric conversion device itself but also from the perspective of interaction. This is also the angle that the media most often observes: what makes a screen easy to use? Is it only smoothness that makes it easy to use?

There is a fundamental problem with this logic. Is a smooth appearance meaningful if there is no content behind it?

There must be valuable content behind the screen. Is it okay to only play anti-Japanese films every day if the venue and audio-visual equipment of the commercial cinema are great?

Therefore, car companies have an obligation to think about what kind of content the screen should display, what kind of interactive design to provide, and how to provide an excellent and convenient experience for users.

For example, NIO. In terms of screen size, they have always been relatively restrained, and the screen size is not very large in the industry. However, users will find that the interaction experience of the relevant models is pretty good. As a NIO car owner who has been using it for a long time, they feel the screen and the system it carries have achieved noninvasive interaction, and effectively interact with users at the right time.

Appropriately present in the right place and convey appropriate content to users are the keys to the future of the in-car display ecosystem.The entire process cannot rely solely on the screen hardware. The top-notch optical performance brought by advanced display technology is actually a hardware embedded logic. At the moment when the vehicle is offline, the user experience of the operating system is definitely not at its best, and the design of UI/UX cannot reach the highest level that the OEM can deliver in the mid-term of the vehicle’s life. For example, take a look at ES8/ES6/EC6. NIO is still upgrading their software and interface to continuously improve the user experience.

Therefore, the screen, as a hardware embedded component, can only have hardware redundancy space when the automaker is working on improving the human-machine interaction. Only then can the characteristics of human-machine interaction exhibited by the vehicle in three years not be inferior to the newly released models after three years.

This is the value of adopting various advanced technologies when selecting the screen.

G:

For in-vehicle screens, the key components typically include panels, casings, and circuit boards. How does HeiMicro’s business involve these parts?

L:

The panel definitely accounts for a large proportion of these components. In our screen assembly, it also accounts for a relatively high cost.

In addition to the panel, there is also the corresponding casing. To use an analogy, it is somewhat similar to the situation with phones. Looking at the aluminum alloy and glass rear shells used by the iPhone 6 series and 7 series, it is necessary to balance aesthetics and practicality. As a high-value interior and exterior part in the vehicle, the screen also participates in the styling of the entire vehicle, where the process and material selection are critical.

In China, HeiMicro is one of the earlier manufacturers to use magnesium-aluminum alloy materials to design interior parts. The solutions we now provide for new cars such as NIO and Li Auto are basically full magnesium-aluminum alloy casings.The third type is PCBA, which refers to printed circuit boards. There are various types of chips responsible for image processing, vehicle network communication, thermal management, backlight driving, and video transmission on the circuit board, and they are categorized in detail.

In Haiwei’s supply, the screen part has a relatively high proportion. As we are a Tier 1 supplier for automobile enterprises, we deliver parts assemblies that can be directly installed on the final assembly line.

It may not be easy to explain the industrial process. As an example, for two of the highest proportion vehicle screens in the industry, L9 and L8 of Ideal Automotive, Haiwei invested a lot of research and development resources in exploring many process-related technologies. These include critical adhesive dispensing technology, material for bonding glass with magnesium-aluminum alloy, as well as lock payment and buckle design at the back.

The lock payment process seems simple, just fastening a screw, but the design of the screw hole, screw, and screwdriver torque and number of turns involve multiple rounds of debugging and verification. It cannot affect the optical effect of the panel itself but must ensure the durability and stability of the parts assembly.

G:

“If I am a layman, how should I understand the concept of the panel?”

L:

Actually, the panel is an optoelectronic conversion device that converts electrical signals into light displays. However, a single panel cannot be called a whole machine.

To use the TV industry as an example, Sony used to own and operate its own panel factories, but later sold this business. However, this did not prevent Sony from still being the most influential TV brand globally.For car panels, how to organize electrical signals in an orderly manner, how to protect the panel from external impacts, how to make the panel’s operating environment more stable, and how to fix the panel to a more sturdy and beautiful outer shell… These are all things that component suppliers need to do for car manufacturers.

G:

Nowadays, the mobile phone industry is also booming, and the screen of the mobile phone carries a large part of the product power. At present, many consumers have established a universal understanding, and major brands are also happy to work on the screen.

So, can the technology features that mobile phone brands package be completely transferred to car screens? Or can I use the technology features of consumer electronics to demand that car screens also have these features? Such as 120Hz or higher refresh rate, 2K/4K or even higher resolution, power saving through LTPO technology, and so on? What are the reasons behind this?

L:

It’s not that easy. The screens of consumer electronics products can achieve refresh rates of 120Hz, 144Hz, and even 240Hz or higher, but this is more difficult in cars.

The biggest problem here is that the screen and the device in the car are physically separated. If you require such a high refresh rate, the transfer bandwidth requirements between the screen and device will be very high. In this regard, it is currently difficult to achieve in cars.

Because cars themselves have a very complex electromagnetic environment, it is not easy to achieve high-speed stability in data transmission with this specification in such an environment with current electronic technology.

If you want to achieve a 4K resolution and 120Hz refresh rate screen, or even HDR 10bit, the upload rate needs to reach 25 Gbit/s. However, the current Ethernet used in cars is generally at the level of 100 Mbit/s, and only a few of the latest projects are using 1 Gbit/s level.According to our observation, it may take another two years for the automotive industry to adopt the technology of 120Hz high refresh rate. However, we will have the opportunity to see 90Hz refresh rate screens in cars next year.

G:

Understood. What about other technologies mentioned in this issue, such as LTPO (Low Temperature Polycrystalline Oxide) technology often mentioned on high-end phones (Editor’s note: Control the minimum refresh rate of the screen to 1Hz to reduce power consumption and achieve power-saving purposes), and DC and PWM dimming that we often see?

L:

Actually, LTPO is specifically designed for mobile devices. The world’s first widely used screen with LTPO technology is the Apple Watch Series 5. Manufacturers only apply this technology to devices with particularly limited battery life.

The incorporation of LTPO technology into cars is basically meaningless because the car’s display does not have low refresh rate problems. The power consumption of the display itself in a car is between 20W and 50W. It is meaningless to deliberately save this tiny amount of electricity for this huge machine.

As for PWM/DC dimming technology, we have already implemented these two dimming modes in relevant car models, and they coexist in one screen. The brightness of the screen can be adjusted automatically according to the working condition and automatically switched between the two technologies depending on which one is better suited.

G:

So, can I understand that the current car display screens are catching up with the level of the consumer electronics and desktop display industries bit by bit?

L:

It’s not catching up, we’d rather use a different expression.The requirements for the display screen in the automotive industry may be even higher than those for consumer electronics products. However, these requirements may exist in places that consumers cannot see, such as durability and reliability, or the ability to resist sunlight and provide high brightness to ensure readability under different lighting conditions. These are actually issues that consumer electronics products will not encounter.

From another perspective, handheld devices are different. It doesn’t matter that the content on the screen of the mobile phone cannot be seen under the sunlight. You can simply cover it with your hand or turn it around. But we can’t just break the screen on the car with our hands, right?

Therefore, some people may say that the screens in cars are expensive and have lower display specifications than consumer electronics, and it is better to use an iPad in the car. But this is actually an irresponsible statement from people who do not understand the automotive industry.

Just as many people like to compare cars and mobile phones, the complexity of the two is fundamentally incomparable. For the entire industry of in-car screens, what peers are doing is to steadily improve the capabilities of the entire supply chain.

G:

Looking at it from another perspective, are the technological systems behind the two actually similar?

L:

The optical part is similar, but the differences between cars and mobile phones in terms of reliability, durability, and design requirements for assemblies are far apart.

G:

We happen to be talking about this. As you just said, in-car screens have to work in more complex lighting changes, and face even more extreme working environments such as temperature and humidity, vibration, dust, and electromagnetic interference. So, are there any differences between the standards for in-car screens and the display components of consumer electronics products?

L:The difference is significant. I think I can explain it with a typical industrial process.

Take Haiwei’s products as an example. To go from design to mass production and to get approval from automobile manufacturers, there are approximately 100 experiments to be conducted, including but not limited to EMC electromagnetic compatibility, ESD antistatic, high and low temperature, vibrations, dust, condensation, dew, smoke, waterproof, dustproof, abrasion, dropping, chemical corrosion, volatiles, flame retardant properties, etc.

As the glass component in the cockpit, the screen also needs to undergo a head impact experiment. To explain, after a collision, the glass debris from the screen cannot splash and cause secondary injury to the occupants.

To put it simply, it takes about 2 to 3 months for a screen to go from design to approval, and two rounds of experiments are required, with costs ranging from 2 million to 5 million yuan.

G:

Speaking of industrial processes, I have an off-topic question to ask.

Recently, the topic of HaiTian soy sauce’s “double standards” has been very hot on social networks and public opinion. Of course, I know that the vast majority of people have no concept of industrial standards, so this explosive discussion was spurred on by some video self-media. Returning to our main topic, with the globalization of manufacturing and sales, are there any differences between the domestic and international compliance standards for car screens?

L:

In fact, there is not much difference.

For example, as a supplier, we must comply with the standards of the automobile manufacturer whose project we are working on.

For new domestic power projects, they themselves want to enter the global market, and it is already known that they have had products launched in the European market. Therefore, all our validation standards must meet the regulatory requirements of countries around the world.

Why do we say there is no difference? Because we need to learn more about local laws and regulations. This is the bottom line, and no one can challenge it.The issue of the ingredients list for Haitian soy sauce that everyone talks about is also a standard issue in our industry.

Can we say that the domestic ingredients are worse and the overseas ingredients are better?

In the field of automotive parts, of course not. Do many people think that Chinese consumers have no awareness of consumer electronics? On the contrary, Chinese consumers are a group with extremely strong global awareness.

So both the OEMs and suppliers have a sense of awe when designing and selecting products. If the product experience is not good, it may be the first to be criticized by Chinese consumers.

G:

Regarding the screen safety we just talked about, I have a question. On social networks, we often see many anti-intelligence comments. Some people say that if there are too many screens in the car, and the vehicle has a collision and the airbag explodes, it will cause flying debris injury. How should we approach this kind of issue?

L:

This statement is not even half-baked.

When a car company is designing a vehicle, the position and size of the screen have already been determined. Not only the screen, but also the steering wheel, air conditioning vents, and even various popular suspension-design parts nowadays are not allowed to cause anything on the instrument panel to fly out and cause secondary harm to the driver and passengers when the airbag is blown. If this happens, it is a typical design error.

According to the current industrial process, car companies use CAD/CAE software to assist in design and analysis in the early stages of design, simulating collisions and explosions under various working conditions on computers. It is not the case that after the entire vehicle is completed, it suddenly occurs to them to conduct collision experiments and make changes when problems arise. This way, there is simply not enough time and the failure rate is extremely high.

The screens that we can see in mass-produced cars will definitely not let glass fly around and cause harm to passengers just because the airbag has exploded. Any car company that does things properly shouldn’t have this kind of problem, and this problem is certainly not caused by the screen.

G:So, as a tier-one supplier of screen assemblies for Feovan R7, can you explain why Feovan R7 is called “Screen Dominator”?

L:

First of all, it is currently the longest screen in China, using the most advanced car display technology today, and OLED and Mini LED are integrated on a single screen assembly. The 15.05-inch OLED panel in the middle of the Feovan R7 is the largest flexible OLED panel currently produced in China.

Secondly, the entire screen is arranged from the A-pillar to the A-pillar, and the total width of the screen assembly reaches 1.4 meters, which is the second largest in the world and the first in China, second only to the MBUX Hyperscreen of Mercedes-Benz EQS.

This screen used in vehicles is top-notch in terms of size and technology, and its technical specifications are not suitable for consumer electronics products. If a panel is used for a laptop, the screen brightness is not high and the durability requirements are not strong, so it cannot meet such high requirements. Similarly, if a 15-inch panel can meet the requirements of the car regulations, the difficulty will be very high, and there will be a lot of technical accumulation behind this.

G:

Just now, we mentioned the MBUX Hyperscreen of Mercedes-Benz EQS. Are there any comparability between it and Feovan R7’s screen?

L:As a professional in the car screen industry, I believe that the MBUX Hyperscreen of the Mercedes-Benz EQS is definitely top-notch in today’s automotive industry. Additionally, the larger size of the OLED panel in the middle of the EQS means lower yield, higher manufacturing difficulty, and higher cost.

In fact, our domestic RisingAuto R7 has already invested heavily in research and development, engineering, and manufacturing for this type of screen. However, we should also recognize that this is a car model with a price of 300,000 yuan, while the price of the Mercedes-Benz EQS has exceeded one million yuan.

G:

Thank you for your positive answer. The next topic may be of interest to everyone and is a common understanding of screens for the general public. In terms of car screens, has OLED become the mainstream in car interiors?

L:

Indeed, OLED is regarded by consumers as a good thing nowadays, because we have clearly felt the excellent experience of OLED in the past five or six years. Since the iPhone X, Apple has been adopting OLED on iPhones, and the OLED industrial chain has also been matured. However, this does not lead to the conclusion that OLED panels will become the mainstream direction for car screens.

OLED, as an organic light-emitting technology, has inherent defects. Because OLED itself is a current-driven technology, and the LCD that everyone is familiar with is voltage-driven technology.

The biggest problem with current-driven technology is that the level of subdivision of the current must be very fine to achieve a smooth transition of multiple gray scales in the dark field. Therefore, most OLED screens are unable to display images below 5 gray scales properly. In iOS and Android systems, pixels of 0-5 gray scales are preprocessed. This is the first issue with OLED.

G:In terms of design, professionals are all trying to avoid this problem, so it is difficult for users to perceive, right?

L:

Yes. There is also a second issue, that the photoelectric conversion efficiency of OLED is not as good as LCD. Traditional LCD emits light by illuminating the color film with a backlight unit, but OLED emits light by driving the EL device with electric current. Under the same brightness, OLED consumes more power than LCD, and the excess power will be converted into heat, causing the screen surface to heat up.

Therefore, we found that when the iPhone X was released, Apple introduced Dark Mode, which is actually to make more pixels not work or work with low power consumption. In the dark mode, pixels are in a no-current or low-current state, which can save power for the device, control the surface temperature of the touch screen, and increase the durability of the screen.

G:

So if the heat dissipation is not good, the so-called “screen burning” phenomenon that everyone is talking about may occur, right?

L:

Yes. There is also one thing, the full name of OLED is organic light-emitting diode. The problem with organic materials is that when they are exposed to UV ultraviolet radiation, they will damage their own characteristics. If an OLED screen is exposed to the sun for a period of time and then used again, the screen may have color deviation.

These are the natural characteristics of OLED technology, and the characteristics of the material itself cannot be avoided. It is a boundary problem of physics and chemistry. We are engineers and product developers, and we will not easily challenge the boundary of science. On the contrary, we often challenge the boundary of technology and engineering.

G:

I see, in fact, there is no absolute advantage of OLED over LCD in terms of engineering.Let’s switch to a more relaxed topic. We talked about night driving earlier, and there is a myth that if there is a screen in the car, it may cause eye strain or light pollution during night driving.

From a professional point of view, what is your opinion on this myth?

L:

If someone feels eye strain, it means that the contents displayed on the screen are not properly designed.

Firstly, the display should automatically switch to Dark Mode at night, and no bright images should be displayed to interfere with the driver’s normal driving.

Secondly, the screen should use optical sensors to actively detect changes in external light. If it is dark outside, the brightness level of the screen should be automatically reduced.

For example, if someone raises this kind of question, I would suggest trying it out in practice before drawing any conclusions. The first-generation platform of NIO, ES8/ES6 models, have a system theme that changes with day and night, and the screen is equipped with a light sensor that adjusts the panel brightness according to the light sensitivity. If you drive on highways, tunnels or tree-lined roads in the city at night, you will understand that there are almost no problems that interfere with driving.

Besides, car screens are not exclusive to Chinese car companies. Mercedes-Benz, BMW, and other major brands also use screens extensively. As the pioneers of the automotive industry, as huge influential luxury brands, their designs are very rigorous and would not make such errors.

So, I do not think this is a controversial topic because some people may have not experienced these excellent designs, or they may have generalized from a few cases.

When car companies design their products, after the prototype of the cabin is produced, they need to conduct an audit of the cabin lighting and brightness. The car companies that have done this work will not make mistakes in this regard.

G:

Talking about standards here, does the lighting auditing standard exist only in the EU or North American countries, or is it a global standard?

L:Exists across all markets as a common knowledge, which is a crucial issue to be monitored by car companies. However, the standard to which it should be achieved is determined by each enterprise, with their own specifications and verification methods.

When discussed, it becomes evident that talent is scarce and precious in the automotive industry. Many car companies hire individuals with work experience in competitor companies. Essentially, they bring over the standards, common knowledge, and methods from within the competition’s system and establish their own standards.

In conclusion, I find it hard to agree with the idea that larger screens will stimulate the eyes and interfere with driving during nighttime.

G:

Based on what we discussed earlier, in the future, it will require the designers from car companies and the screen suppliers to work together in a jointly developed working mode, becoming more widely established, right?

L:

Correct. As mentioned earlier, the screen is the key interface for human-machine interaction. When we communicate with many designers, especially those involved in HMI design and graphic design, we find that there is still a gap in their understanding of the screen and equipment.

Therefore, when we develop the screen assembly, we submit to the customer a UI/UX Design Guideline related to the optical and electrical performance of the screen. Everyone’s visual and interactive design can be as closely matched as possible to this design orientation. We do not intend to challenge the professional level and aesthetic ability of our customers or users. Instead, these design orientations to a certain extent conform to the trend of industry technological development and global aesthetics.

G:

Finally, I would like to talk to you about Haiwei Technology itself.I have seen in other reports that HMI’s software department has the highest proportion of people in the R&D team composition. To be honest, this is inconsistent with the inherent impression of an industrial enterprise. What is the underlying logic of building a team in this way?

L:

We believe that software capability is the core foundation for a company to enter digital operation and intelligent operation.

Therefore, HMI is now doing two things:

Externally, deliver intelligent cockpit products to customers;

Internally, achieve the output and delivery of intelligent cockpit products through intelligent manufacturing.

Intelligent manufacturing seems to consist of only four words, but in fact, there is a great need for software talents behind it. For us, including production management software, production database systems, robot control algorithms, visual recognition algorithms, all of these are developed in-house.

In HMI’s factory, you can see highly automated production lines. We do not purchase the entire production line, but integrate the components such as robots, cameras, and controllers after purchasing them, and fully connect them through our self-developed software. Our own engineering team design and develop custom production lines, without relying on third parties, which leads to a need for a large number of software talents.

For the screen, it is both an appearance component and an optical device. Regardless of whether it is a screen or a car host, even if it has an operating system, single-chip microcomputer, and so on, it will require a lot of software to verify whether it can be manufactured qualified, including using algorithms, software, cameras, optical probes, sensors to monitor.

Everything, behind the scenes, requires a lot of software teams to support, which is the entire value of our self-constructed HMI Intelligent Manufacture. So our “Dual Intelligence” refers to “Intelligent Cockpit” and “Intelligent Manufacturing.”

So from this perspective, we are an industrial enterprise that delivers parts for automakers, and software empowers industrialization.

Final Words

Every time I mention the screen in the article, I can’t help but view it with the inherent perception of consumer electronic products.As a person who enjoys playing with smart devices, I often perceive the various sizes and shapes of glass screens in cars through this lens, wondering why the user experience is so different.

Perhaps many people, including myself, have overlooked the fact that cars and phones are not that comparable.

The complexity of parts, the length of the supply chain, and the complexity of the systems differ greatly…

The closest similarity between the two is probably that, with the intensification of competition, smartphone manufacturers and automobile companies are paying more attention to the user experience.

China, as an automotive market that no clear-headed automaker can ignore, is no longer solely creating value. It is creating more demand while creating market value at the same time.

With market maturity, there is also a corresponding maturity in users’ minds. Just as discussed in this interview, Chinese people are the group with the strongest cognitive ability among global consumers.

Li Linfeng believes that if users feel that they are forced to pay for the car’s large screen, it is likely that the carmaker has not done a good job in terms of the content and interaction on the screen. If it’s done well, users won’t have such thoughts.

Perhaps not all automakers can truly recognize the value of screens, or even forget that competition is just a means, not an end.

I think this may be the truth behind the industry’s internal competition on screens that the outside world sees.

However, I still believe that even if L4/L5 level of autonomous driving really becomes popular someday, screens will accompany us for a very long time in the car.

Just before that, there are still too many things that the industry and we need to do in order to make everyone more naturally accept its existence, just like how the A-side has evolved into a complete screen on smartphones.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.