By Xuan Wang

“Autonomous driving without mass production is nothing but a cheat” may sound like a triviality, as it is meaningless for an enterprise to develop a product without pursuing mass production. However, the road to developing a heavy-duty autonomous driving technology has many technical challenges, ranging from algorithm design to hardware implementation.

It is no secret that the smart driving industry for heavy-duty vehicles is becoming increasingly crowded, but few products have truly made it into mass production. Recently, at “Yingchi Tech Day”, Yingchi Tech CEO, Ma Zheren, pointed out that “the autonomous driving industry is entering a new phase, where the focus of technology shifts from algorithm software exploration to the scarce technology, system, and experience of forward design, front-loading production of whole vehicle autonomous driving”.

How Difficult is it to Land Autonomous Driving Technology on Commercial Vehicles?

There are many differences between commercial vehicles and passenger vehicles in terms of their commercialization logic.

Firstly, the technical difficulty is higher. Commercial vehicles are larger in size and therefore have more blind spots, requiring more sensors to be installed. For example, Yingchi Tech and Dongfeng Heavy Duty’s current intelligent commercial vehicle in mass production is equipped with 7 cameras, 5 millimeter-wave radars, and 3 laser radars. Dongfeng Tianlong is also the first mass-produced heavy-duty truck in the world to be equipped with a laser radar.

More sensors mean that the intelligent driving computing platform at the decision-making level will receive more data, thus placing a higher demand on algorithms and computing power. Take Dongfeng Tianlong, which is already in mass production, as an example. It is equipped with the ADU intelligent driving platform developed by Yingchi Tech’s proprietary architecture, which can be compatible with various autonomous driving chips, with a maximum computing power of 245 TOPS, and can achieve L2-L4 level autonomous driving function configuration.

Secondly, long-term testing is needed to ensure stronger generalization ability of the autonomous driving system. The average running mileage of commercial vehicles is multiple times that of passenger vehicles per year, resulting in greater wear and tear. Accompanying that, the mechanical parts’ capability will decrease too- the decline of mechanical quality will bring enormous challenges for autonomous driving technology.

The Yingchi Xuan Yuan autonomous driving system ran millions of kilometers in testing before it entered mass production, from the coldness of Heihe to the hotness of Hainan Island. Therefore, the Yingchi’s system can ensure normal operation within a lifespan of 1.5 million kilometers.

Thirdly, the cooperation of commercial vehicle companies is required, which is also the most critical point. The difference between commercial vehicle market environment and passenger car market is that there are no “new forces” or “vehicle-making frenzy” in commercial vehicles. A handful of enterprises truly master the core technologies of heavy-duty trucks, and the competition is particularly intense in relatively small markets. Thus being able to obtain resources from heavy-duty truck companies is also a manifestation of competence.This is also what Mazhe Ren said, “Algorithm is no longer the endpoint of competition, but the experience and technology of the entire vehicle brought by mass production are the most scarce reasons in the industry“.

From Mass Production to “Unmanned”

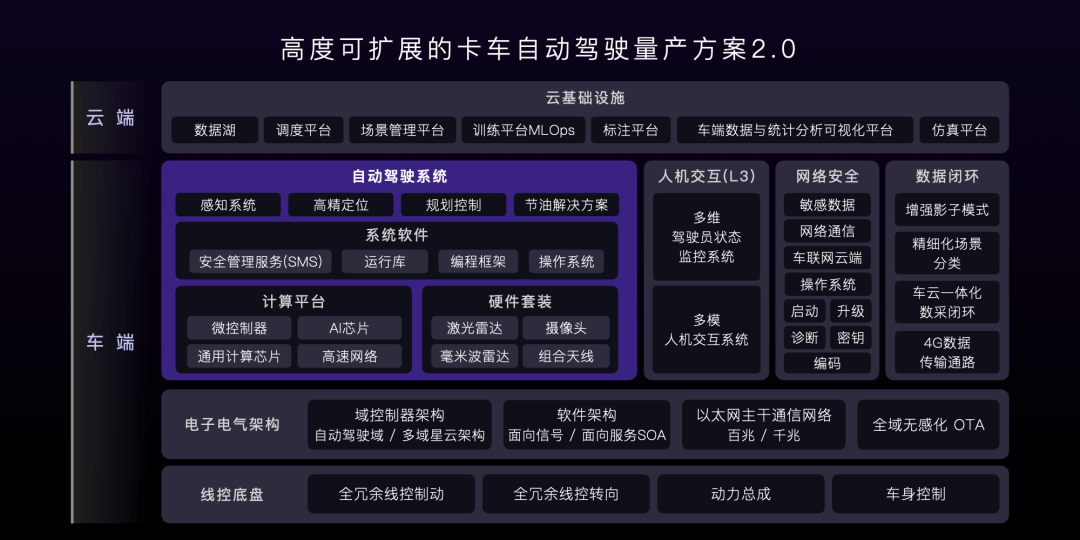

With the mass production of the Yingche Yuexuan System 1.0, Yingche’s full-stack self-developed technology has entered the 2.0 stage and made significant breakthroughs in core technology.

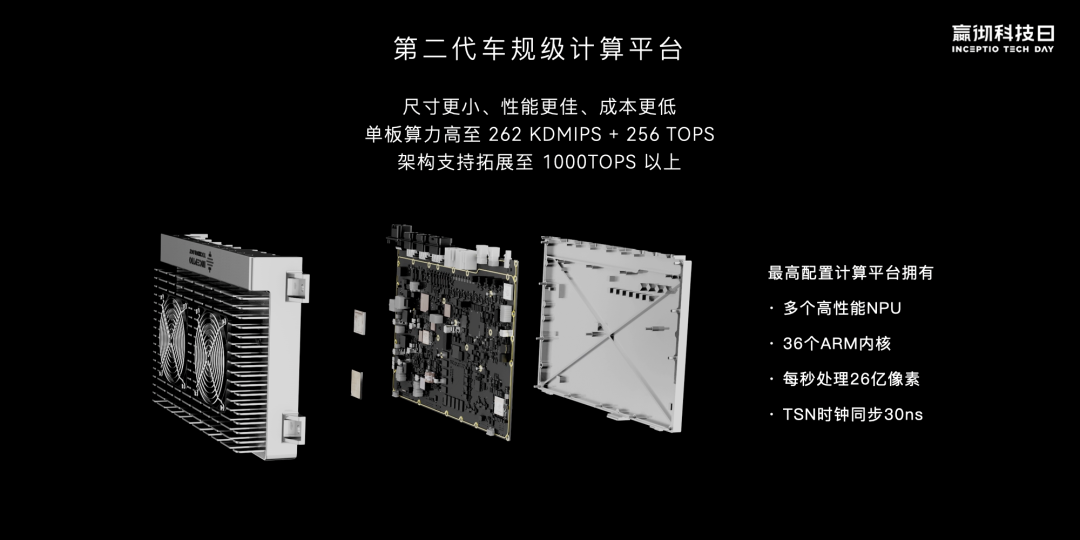

In terms of algorithm evolution, Yingche has developed three breakthrough technologies: a pre-fusion perception framework based on multi-modal and multi-perspective transformer, a tightly coupled planning and control integrated architecture, and a multi-time scale fuel-saving system. In terms of hardware iteration, the self-developed second-generation vehicle-level computing platform has lower cost. In terms of data assets, Yingche uses the innovative enhanced shadow mode data closed-loop to expand its technological advantages.

In terms of perception, Yingche uses a pre-fusion perception framework based on multi-modal and multi-perspective transformer, switches from a perspective view to a BEV view, fully integrates the feature maps of different data sources, and then uses the long short-term memory (LSTM) time-series fusion network to obtain the perception results of the video stream. This can effectively deal with the unique challenges of long-distance logistics heavy trucks, such as perceiving small objects and irregularly shaped vehicles. At the same time, by lightweighting the model, the calculation is reduced by 50%, and the traditional CV algorithm (used for pre-processing) is accelerated using NPU, achieving a speed increase of 100 times.

The difficulty of planning and control lies in simultaneously satisfying the five major commercial operating requirements of safety, accuracy, comfort, durability, and economy, which inevitably leads to three major contradictions, including accurate modeling and one-car-one-tuning, accurate control and durable economy, and the contradiction between hierarchical planning and control integration. Yingche creatively developed the PNC architecture integrating planning and control, realizing the tight coupling of prediction, decision-making, planning and control, and finding the optimal solution in strict operating requirements.

In terms of fuel-saving algorithms, Yingche comprehensively optimizes fuel consumption from sub-second, second, minute, and hour levels. Especially in the hour-level car-cloud collaborative global speed planning algorithm, a breakthrough has been made, establishing GNN (Graph Neural Network) with key waypoints as nodes in the cloud. By using historical data and real-time traffic data, the optimal speed recommendation is achieved. In actual operations, it can save 2-5% more fuel than gold medal drivers, approaching the upper limit of 7% fuel savings.At the hardware level, Yunchi’s self-developed computing platform has entered the second generation of development, with smaller size, better performance, and lower cost. The single board computing power is up to 256 TOPS, and the architecture can be expanded to over 1000 TOPS. The platform is based on TSN protocol, which can achieve time synchronization accuracy of 30ns, leading the industry.

At the data closed-loop level, with the accelerated pace of production and operation deployment, the mileage of autonomous driving is rapidly increasing. Yunchi has established the industry’s first autonomous driving truck data closed-loop system, transforming data assets into technical advantages.

Yunchi’s innovative enhanced shadow mode provides the ability to collect and evaluate long-term behaviors (such as fuel-related behaviors) required for L4-level technology iteration, compared to traditional shadow mode, enabling real-time A/B test and efficient algorithm iteration, reducing data collection costs while improving data validity and accuracy.

With these core technology breakthroughs, a comprehensive leading and highly scalable Yunchi Xuan Yuan autonomous driving system 2.0 has begun planning for mass production.

Regarding fully autonomous driving technology, Yunchi Technology believes that the current autonomous driving technology architecture is likely to encounter bottlenecks. The Yunchi Xuan Yuan autonomous driving system 3.0 proposes a new concept of autonomous driving architecture, which can remove the artificial boundaries designed between the sub-modules of the autonomous driving system and replace them with end-to-end deep neural networks. By combining deep reinforcement learning (DRL) and neural radiance field (NeRF) technology with the NeDFS (Neural Driving Field Simulator) ultimate autonomous driving simulator, end-to-end models are trained to achieve autonomous driving self-evolution and eventually move towards unmanned driving.

While leading, generously sharing experience with peers and students

Based on three years of successful production practice and exploration, Yunchi Technology released the “Autonomous Driving Truck Production White Paper”, which deeply shares the methodology system and technical innovation of autonomous driving truck production development based on the 8 principles of mass production.

After receiving the whitepaper, I quickly skimmed through it and was able to clearly feel that Inceptio’s effort is not just a show for publicity. Each chapter was written by engineers and contains substantial technical innovations and industry integration practices. The purpose of the whitepaper is to promote the sharing and collaboration of methodologies for mass-producing autonomous vehicles, and to eliminate the fragmentation of experience and knowledge for practitioners.

After receiving the whitepaper, I quickly skimmed through it and was able to clearly feel that Inceptio’s effort is not just a show for publicity. Each chapter was written by engineers and contains substantial technical innovations and industry integration practices. The purpose of the whitepaper is to promote the sharing and collaboration of methodologies for mass-producing autonomous vehicles, and to eliminate the fragmentation of experience and knowledge for practitioners.

Of course, such a practical approach deserves some advertising. If you want to learn more about Inceptio’s “Autonomous Driving Trucks Mass Production Whitepaper,” please follow Inceptio’s official WeChat account “嬴彻科技 Inceptio” and reply with “白皮书” or “whitepaper” to obtain the full version.

Meanwhile, Inceptio is committed to discovering outstanding talents in the industry for long-term development. This time, they have partnered with Tsinghua University’s Smart Industry Research Institute (AIR) to launch the “Inceptio-Tsinghua AIR Cup Autonomous Driving Technology Challenge,” which is the first competition in China to cover both the main logistics and urban road tracks.

The inaugural competition focuses on decision-making and planning algorithms, inviting global autonomous driving enthusiasts to come together to solve real-world technical challenges and push algorithm limits within mass-production constraints. The competition provides scenarios and data for both high-speed mainline heavy trucks and complex urban roads, with all the data coming from real-world situations.

Finally, for autonomous driving in freight logistics and ports, the competition is relatively crowded with numerous startups entering the market, yet very few products have been truly implemented. In contrast, Inceptio is a self-driving company with a strong product planning rhythm. They are clear about how far their technology can advance mass production and how to iterate their future products to upgrade their functions and experiences. Perhaps it is precisely because of this clear vision that they have the courage to share their experience with colleagues in the industry.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.