On September 1st, WeRide Technology held its first annual Technology Day under the theme of “Practice Makes Perfect”. They presented their three-stage technology roadmap from mass production to unmanned vehicles and officially released the “Automatic Driving Truck Mass Production White Paper”.

In short, WeRide Technology is a company focused on operating networks for autonomous driving trucks.

WeRide Technology has achieved many successes in the field of autonomous driving trucks, including:

-

By the end of 2021, WeRide Technology and Chinese truck manufacturers jointly developed L3 level autonomous driving trucks over a three-year period.

-

As of the end of August 2022, WeRide’s Xuan Yuan autonomous driving system has rapidly exceeded 6 million km of commercial operation milestones on more than 30 standardized operating routes.

-

By the end of 2021, WeRide completed L4 level unmanned road tests over the most complicated 24-kilometer enclosed testing high-speed line in China on a mass-produced model sharing platform.

Three-Stage Technology Roadmap from Mass Production to Unmanned Vehicles

After the landing of WeRide Xuan Yuan System 1.0, WeRide Technology officially announced the entry into the 2.0 stage at the press conference:

-

In algorithm, WeRide developed three breakthrough technologies: multi-mode multi-perspective Transformer’s pre-fusion perception framework, tightly coupled integrated architecture of planning and control, and multi-time scale fuel-saving system.

-

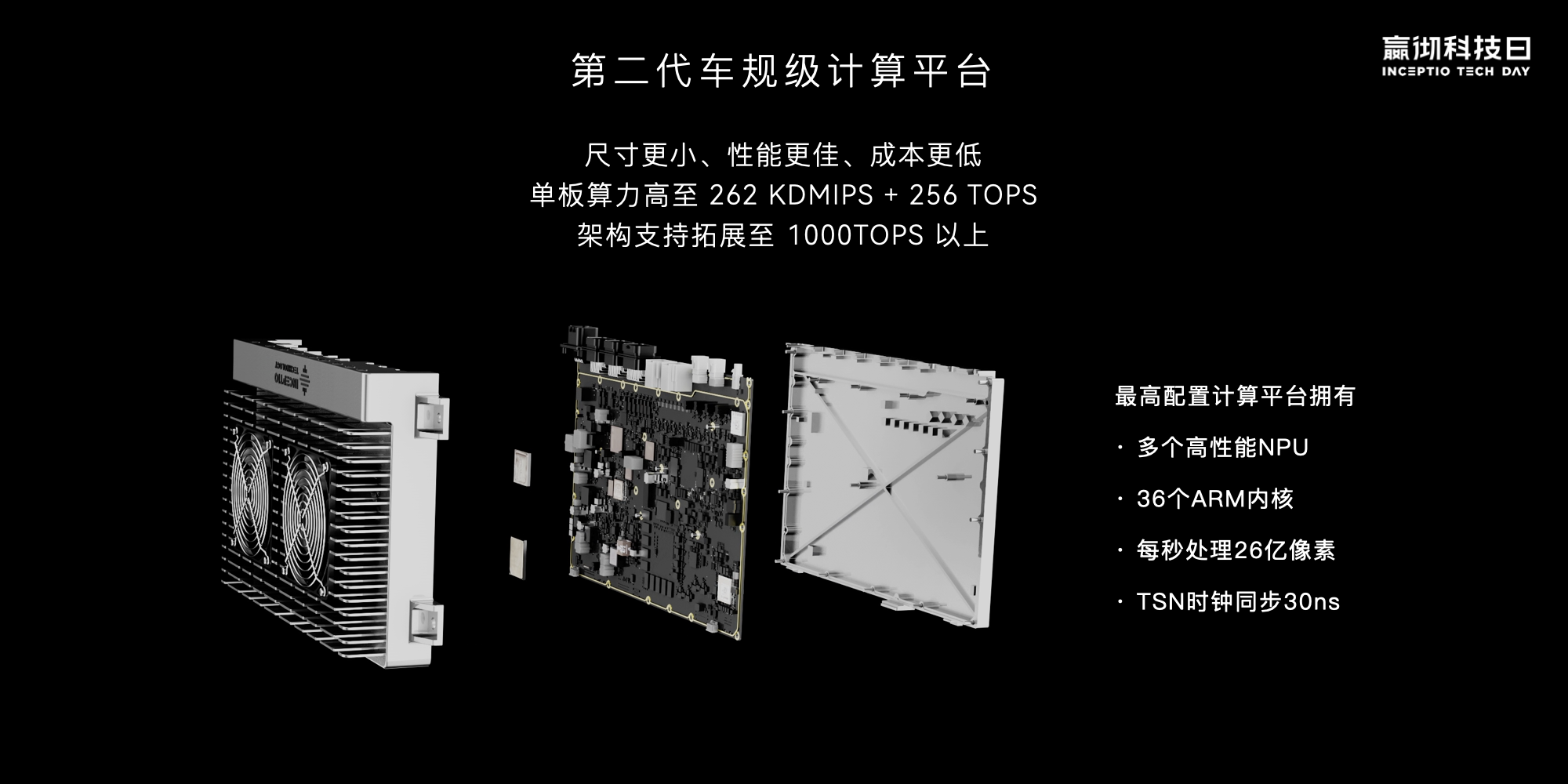

In hardware, their second-generation vehicle-level computing platform has lower cost.

-

In data, it uses a reinforced shadow mode data feedback loop.

Technical Features of the 2.0 Platform

At the perceptual level, Yunche utilizes a multi-modal and multi-view Transformer front-fusion perception framework. It switches from a perspective view to a bird’s-eye view (BEV) and fully integrates the feature maps from different data sources. Then, it uses a long short-term memory (LSTM)-based temporal fusion network to obtain the perceptual results of the video stream. This can effectively address the unique challenges of long-distance logistics heavy trucks, such as perceiving small objects and irregular vehicles.

Moreover, the computational cost is reduced by 50% through model lightweighting, and traditional computer vision (CV) algorithms are accelerated by NPU (used for pre-processing), reaching a speed up to 100 times faster.

Regarding the difficulty in planning and control, it is necessary to simultaneously meet 5 major commercial operational requirements, namely safety, precision, comfort, durability, and economy. This inevitably brings about 3 major contradictions, including the conflicts between precise modeling and one-vehicle-one-dispatch, precise control and durable economy, and hierarchical planning and control fusion.

Yunche has developed a PNC architecture that integrates planning and control to achieve a tight coupling of prediction, decision-making, planning, and control.

At the level of fuel-saving algorithms, Yunche optimizes fuel consumption at the sub-second, second, minute, and hour levels. Specifically, it made a breakthrough in the cloud-based car-cloud collaborative overall speed planning algorithm at the hourly level by establishing a graph neural network (GNN) with key waypoints as nodes in the cloud, using historical experience data and real-time traffic data to achieve optimal speed recommendations. In actual operation, it saves 2-5% more fuel than the average gold medal driver.

At the core hardware level, Yunche’s self-developed computing platform has entered its second generation of development with smaller size, better performance, and lower cost. The single-board computing power is as high as 256 TOPS, and the architecture can be expanded to over 1,000 TOPS. The platform is based on the TSN protocol and achieves a time synchronization accuracy of 30 ns.### White Paper on Mass Production of Autonomous Trucks

The white paper records WeRide’s cooperation experience with industry partners over the past three years, upholding an open and collaborative mindset, and fully sharing the mass production development system and core technology of autonomous trucks.

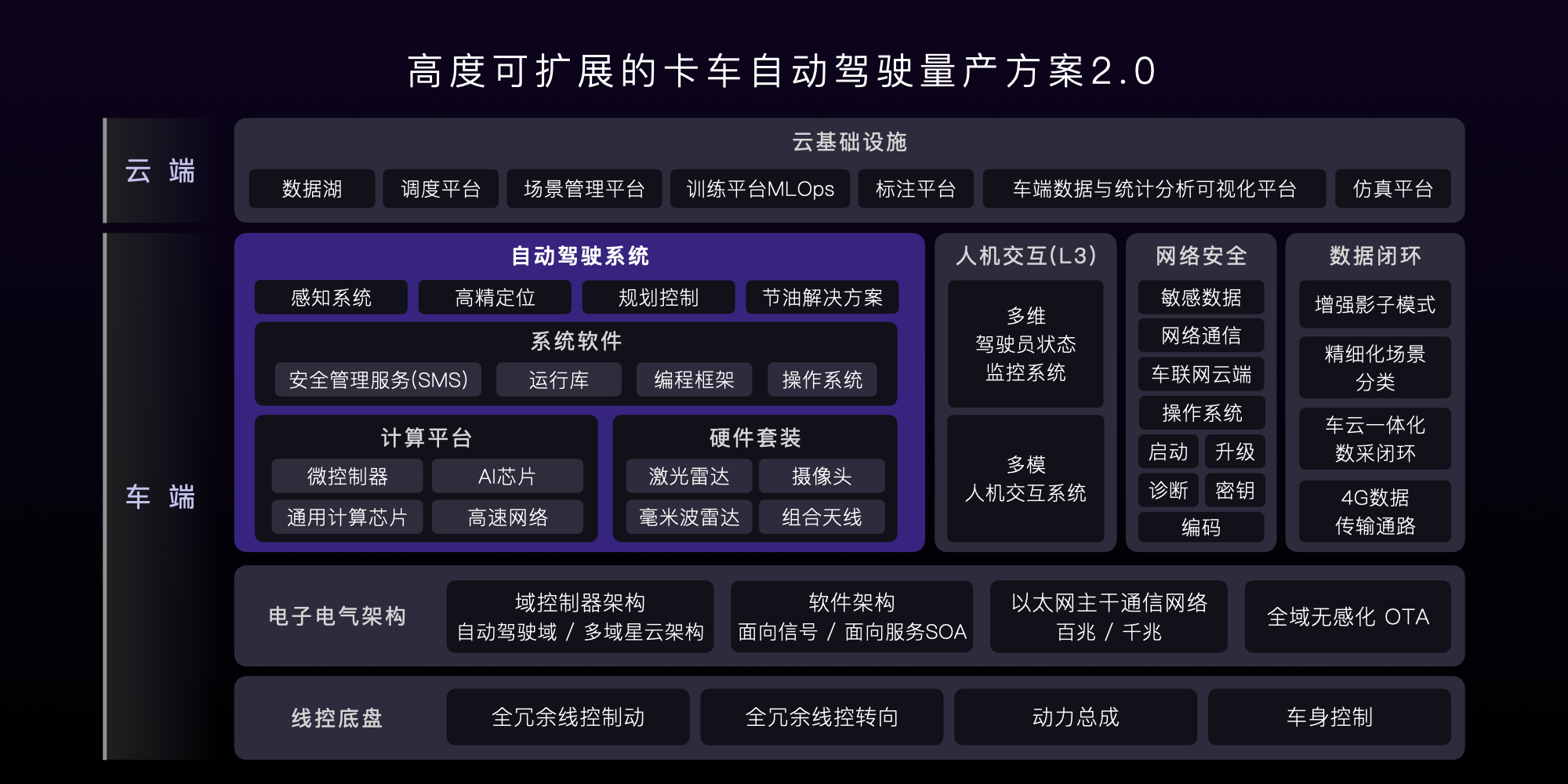

It includes 8 principles for mass production, a methodology for mass production development of 7 core systems and full-stack core technology, a complete mass production development process and measurement index system based on the principle of forward development and agile consideration, and an autonomous driving safety development system that runs through the entire R&D and mass production cycle, covering the entire vehicle and core systems and across WeRide and mass production partners.

Conclusion

As an autonomous driving company in the truck industry, why did WeRide Technology create this white paper? Founder and CEO of WeRide Technology, Tony Han, answered:

The autonomous driving industry has entered a new stage, where the technical focus has shifted from algorithm software exploration to forward production. The technology, system, and experience of forward production of autonomous driving vehicles has become a scarce asset in the industry. From the very beginning, WeRide Technology has upheld a technical strategy of full-stack self-developed, production-orientation, and industry integration. We have shared production practices with the entire industry and jointly developed systems and breakthrough technologies through tech days, and together promote development.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.