Author: Xiaolong Xiaojie

Author Introduction: A battery PhD student currently studying in South Korea

On June 23, 2022, CATL (Contemporary Amperex Technology or Ningde Times) released the third generation CTP 3.0 – Kirin battery, with a world-leading system integration degree, a volume utilization rate over 72%, and an energy density of up to 255Wh/kg, achieving a range of 1000 kilometers on a single charge with ease. Compared to the 4680 battery with the same chemical system and battery pack size, the Kirin battery pack can increase its energy by 13%, achieving a comprehensive improvement in range, fast charging, safety, life, efficiency, and low-temperature performance.

In fact, as early as 2019, CATL and BAIC New Energy jointly launched the world’s first CTP battery pack, leading to the era of “module-free”. This released battery pack is the updated third generation CTP 3.0 version.

Briefly reviewing the development process of CTP:

- The first generation of CTP solution reconfigured the size of the original module structure and removed the side panels to form a single larger module. By removing some structural components, it reduced the weight of the entire battery pack and achieved a volume utilization rate of 55%, breaking through 50% for the first time, and increasing the system energy density of the power battery. The first-generation battery pack was installed on the BAIC New Energy EU5 model, which was the first passenger car project to land after the technology was released.

- The second generation optimized the two endplates of the module (which provide pressure) and used the longitudinal and transverse beams on the battery box to replace the endplates, maximizing the use of existing structural design and not damaging the strength of the battery shell. According to the CATL annual report, the second generation CTP product based on lithium iron phosphate had achieved large-scale deliveries by 2021.

- The third generation, as mentioned later in this article, is the Kirin battery pack.

CTP technology, also known as Cell To Pack, or “module-free” technology, integrates battery cells directly into the battery pack. Existing battery pack structures typically consist of a three-level structure of “cells – module – full pack.” Several battery cells are combined to form a “module.” Several modules are combined, along with BMS, power distribution modules, and other components, to form a “battery pack”. For example, Tesla integrates over 7,000 battery cells into modules and then installs them into the battery box.

So, what are the highlights and innovations of the Kirin battery pack (CTP 3.0) released this time?# Materials Innovation and Structure Innovation: The Main Ways to Invent High-Performance Batteries

More advanced electrochemical systems endow the active material with greater energy. Meanwhile, a more compact structure helps the battery pack operate with maximum efficiency. It is well known that major battery manufacturers have been accelerating innovation at the structural level as the innovation iteration at the material level has slowed down. From innovative structures such as 4680 batteries to CTP and CTC technology-dominated system-level innovations, power batteries are experiencing technological revolutions. The Kirin battery released by CATL this time starts with a structural focus. The Kirin battery pack mainly has three technological innovations:

-

3-in-1, Simplify Complications

-

4x Cooling Capacity, Rapid Temperature Control

-

Space Sharing Breaks Convention

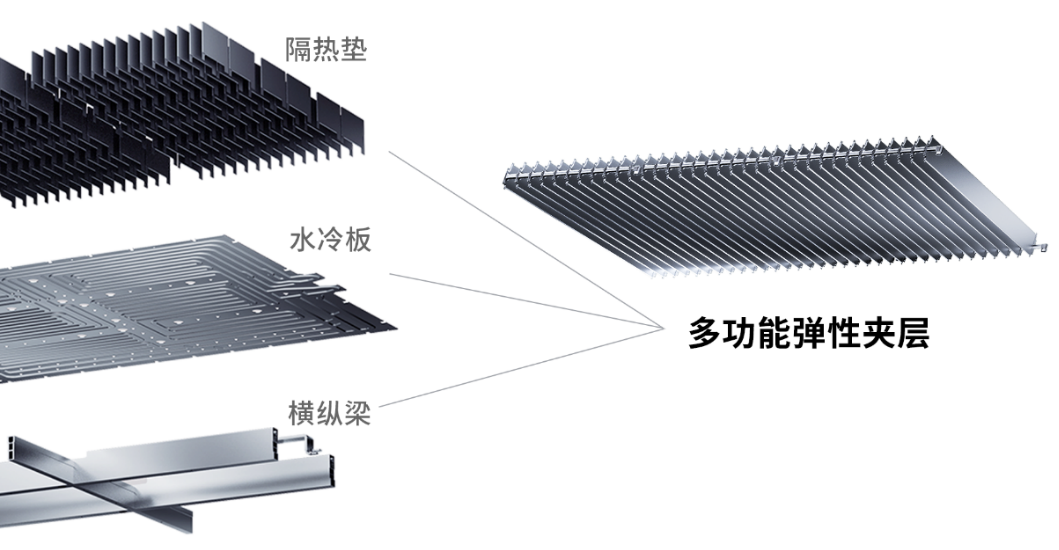

3-in-1, Simplify Complications

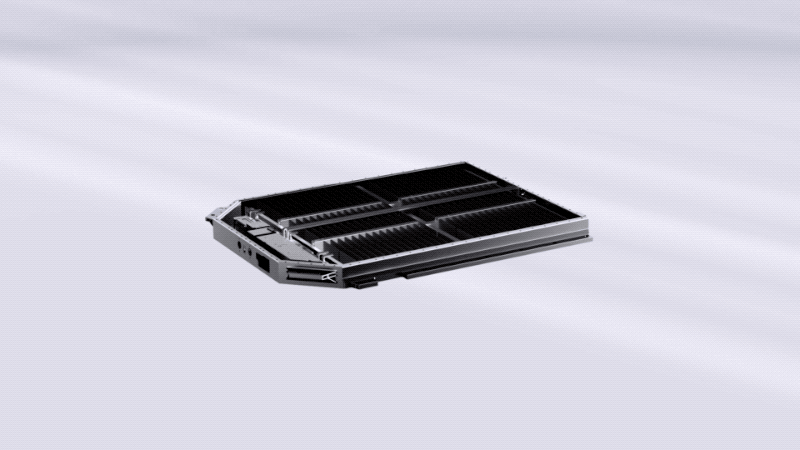

The Kirin battery breaks through functional boundaries and integrates usage requirements to combine the horizontal and vertical beams, water-cooled plates, and insulation pads into a multifunctional elastic sandwich layer. A micron bridge connection device is established in the sandwich layer to flexibly cooperate with the cell breathing and enhance the reliability of the cell’s entire lifecycle. Meanwhile, an integrated energy unit consisting of cells and the multifunctional elastic sandwich layer builds a more stable stress structure in the direction perpendicular to the driving direction, improving the battery pack’s anti-vibration and shock capabilities. The Kirin battery completely cancels the module design, converting the space originally reserved for modules into cells and effectively increasing energy density.

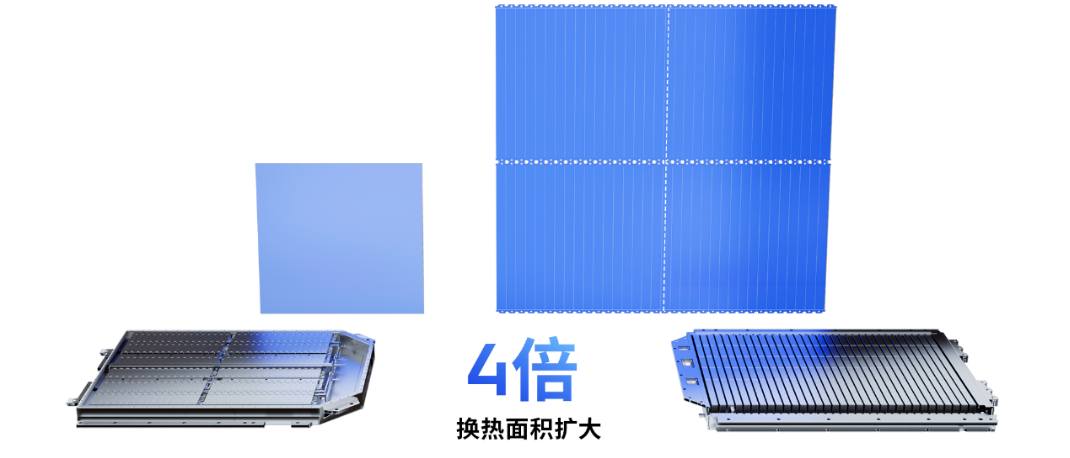

4x Cooling Capacity, Rapid Temperature Control

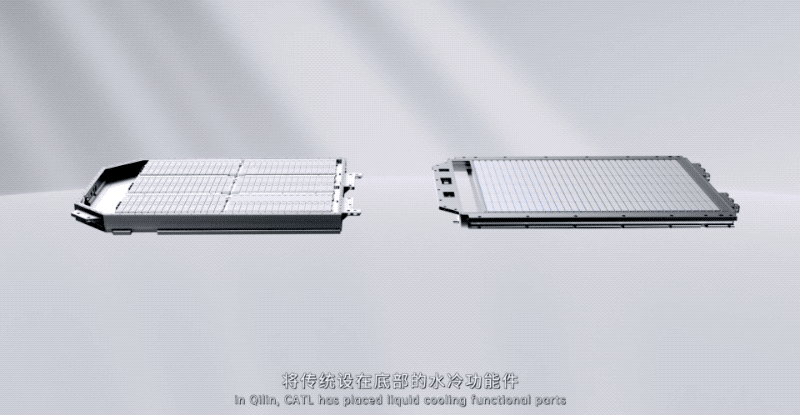

CATL subverts traditional water-cooling technology, using a globally innovative large-area cell cooling technology that places the water-cooling function between cells, enlarging the heat exchange area by four times based on changes in the cells. The cell temperature control time is shortened to half the original time, supporting rapid five-minute heat starting and 10-minute fast charging. The charging speed of the Kirin battery can reach 4C, equivalent to being fully charged in just 15 minutes. Such fast charging capability will further narrow the gap between electric vehicles and fuel in terms of energy replenishment efficiency. Moreover, in extreme situations, cells can rapidly cool down to effectively prevent abnormal heat conduction between cells.

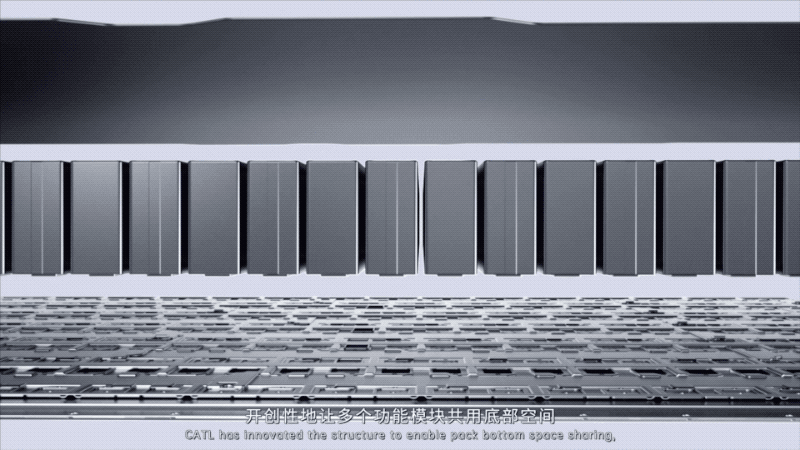

Space Sharing Breaks Convention

Ningde Times has explored the design boundaries of the entire lifecycle application scenarios of the Kirin battery through precise calculation and AI simulation. By reshaping the spatial structure and creating an innovative bottom space sharing solution, it intelligently distributes functional modules such as structure protection, high voltage connection, and thermal exhaust control, and innovatively allows multiple functional modules to share the bottom space, releasing 6% of energy space. This design allows for a high peak in endurance mileage. At the same time, it can meet the safety testing requirements of national standard battery, such as bottom ball impact.

Ningde Times implements system engineering thinking throughout the entire development chain of materials, cells, and system structures. Through three major technological innovations, the energy density of the Kirin battery’s ternary battery system can be increased to 255Wh/kg, and the energy density of the lithium iron phosphate battery system can be increased to 160Wh/kg. Under the same chemical system and battery pack size, the Kirin battery pack’s capacity can be increased by 13% compared to the 4680 system, realizing a comprehensive improvement in endurance, fast charging, safety, life, efficiency, and low temperature performance.

It can be said that Ningde Times’ first-generation CTP technology has provided new ideas and directions for the development of power batteries. The second-generation CTP technology gradually scaled up this technology and started to apply it to specific vehicle models. The third-generation CTP technology Kirin battery not only further increases the endurance mileage of power batteries, but also strengthens the overall safety performance and life of power batteries.

Kirin Battery VS 4680

In the current hot period of the Sino-US technology war, the new energy field cannot be left behind. Observant friends may have noticed that just as Tesla announced plans to mass produce and install the 4680 battery, Ningde Times unveiled their third-generation CTP technology – the Kirin battery. As shown in the figure below, the Kirin battery pack’s performance directly outperforms the recently introduced 4680 battery pack from Tesla, surpassing the 4680. As the next generation of power batteries, who will lead the way in the future power battery market?

Structural Differences

Actually, the dispute between Tesla’s 4680 battery and CATL’s Kirin battery is more about cylindrical versus square batteries. Tesla uses cylindrical cells, while CATL uses square ones. It’s a fact of nature that squares can always be more efficient in space utilization than circles! Both the efficiency of arrangement and the design of thermal management are more efficient with square structures than cylindrical arrangements. They are simpler, have higher space utilization and quality utilization rates, and are more scientific! Therefore, the volume utilization rate of CATL’s battery pack has surpassed 72%, which is 9% higher than Tesla’s 63%, breaking the industry record and becoming the battery with the highest integration density in the world.

Tesla has used cylindrical cells from 18650 to 2170 to 4680, but except for their own use, there are few other automakers in the market responding to it. Chinese automakers are especially fans of square cells. Currently, the top leaders of new forces leading the intelligent electric vehicle industry, such as Xpeng P7 and the pioneer of Chinese new energy brands, such as Ora, HiPhi, all use square cells. From the international data perspective, in 2020, square cells accounted for more than 50% of the market, while soft pack cells accounted for 27.8% in the global electric vehicle market. So why has Tesla been making cylindrical cells instead of switching to square cells? It’s simple, the cost is too high, and Tesla only has a technical accumulation in cylindrical cells. The cost of developing square cells is too high. Tesla has rich application experience in cylindrical cells and, with its high global sales and market share, its choice has scale effects and cost advantages, so some car companies and battery companies are willing to follow suit. Therefore, Tesla can go further along the road of cylindrical cells. In fact, Tesla has already widely applied CATL’s square cells, and the proportion is increasing.

Energy Density

CATL’s CTP3.0 technology, which was released this time, did not go into too much detail about the cell level, but only gave an overall introduction from the battery pack level. The energy density of LiFePO4 battery pack is 160Wh/kg, and the energy density of ternary battery pack can reach up to 255Wh/kg. With such high energy density, achieving 1000km of range is no problem at all! In contrast, the energy density of Tesla’s 4680 battery pack (ternary lithium battery) is only 217Wh/kg. After all, the integration efficiency of cylindrical cells is only about 64%, while the integration efficiency of square cells can reach up to 83%. Therefore, if the same or similar positive and negative pole materials are used as in the 4680 battery, the system energy density will naturally be higher than that of the 4680 battery.

4C Fast ChargingWhen reaching such a high energy density, CATL also achieved a 4C fast charging technology that can charge from 10% to 80% in 10 minutes, which is 5 minutes faster than the 4680, which is indeed surprising. Although the charging speed is very fast, many people worry about whether the grid in the residential area and the city can withstand the simultaneous fast charging of large numbers of cars. Of course not! The sodium-ion battery released by CATL some time ago seems to be a solution, which was prepared in advance. Sodium-ion batteries have a lower cost compared to other batteries and can be used as a killer technology for energy storage power stations.

Although the 4680 battery cell has certain advantages in energy density and fast charging performance, there are significant challenges to its safety, and the production difficulty is geometrically high. In addition, for car companies, the difficulty of grouping cylindrical batteries is high, and the cost advantage may be hard to play if the cylindrical battery grouping technology is not available.

Cooling Methods

Currently, cylindrical battery cells use side cooling. The cylindrical battery cell generally has faster axial heat conduction and slower side heat dissipation. This feature is more pronounced for the large 4680 battery cell. Under 800V high-voltage charging, the battery cell will accumulate a large amount of heat in a short time, and the side heat dissipation is slow. In the long run, it will have a significant impact on the battery cell life. CATL’s Kirin battery uses a globally innovative technology of large-surface cooling to reduce the temperature control time of the battery cell to half of the original time.

Summary

Safety issues are the primary consideration for battery innovations. In recent months, there have been several safety incidents such as electric vehicle fires. This undoubtedly increases consumer concerns. The Kirin battery significantly reduces the risk of battery thermal runaway and improves battery safety. This is because Kirin battery adds a water-cooled plate in the middle between two adjacent battery cells. It not only plays a structural support role but also increases the cooling area. This reduces the heat conduction between adjacent cells and reduces the risk of a single cell’s high temperature causing a fire in the entire battery. The endurance mileage has already met consumer expectations, and energy density is no longer the core issue. Safety is the issue that consumers are most concerned about. This is a problem that needs continuous improvement and innovation to solve.

Currently, large-scale commercial electrochemical systems still rely on conventional structural and material innovations. Among global battery companies, CATL has the most battery cell engineers and technical resources, continuously bringing innovations to the market. The simplification of the battery structure has opened up an innovative path, leading the battery market’s progress.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.