Author: Zhu Shiyun

Editor: Qiu Kaijun

“Tank’s earliest slogan was ‘Let a novice also be able to off-road.’ Later, we recalled this sentence. It is very scary to let novices off-road. We have to be responsible to consumers.” Liu Yanzhao, general manager of Tank brand at Great Wall Motors, said this at the Hybrid Tank Communication Meeting to the Electric Car Observer:

“The most important thing for off-road is to be able to bring users out and back. It is more important than anything else.”

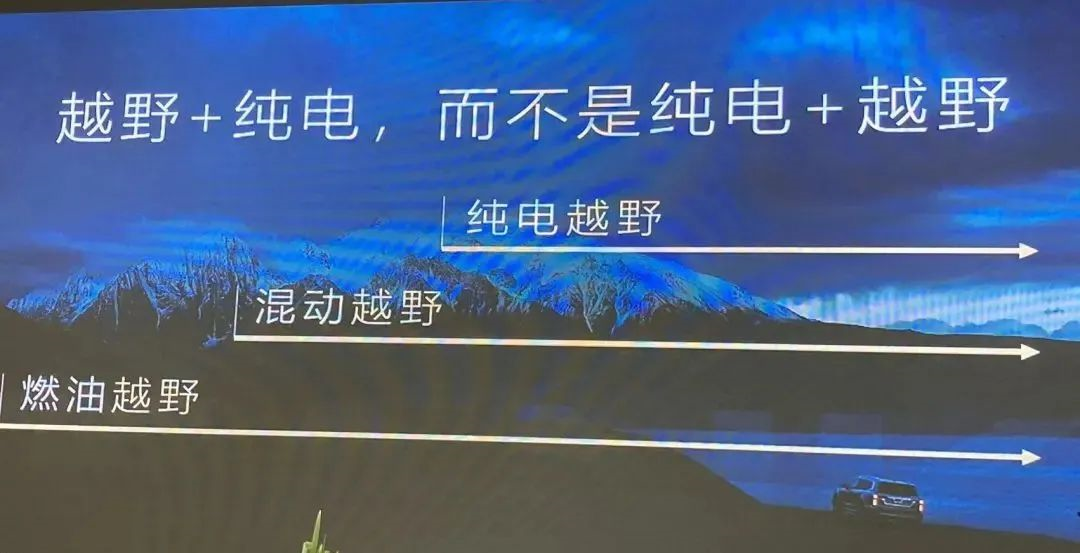

On August 26, Tank brand, which is the off-road category under Great Wall Motors, released two new energy products: Tank 300HEV and Tank 500PHEV, and proposed their optimal new energy off-road solution — “Off-road + New Energy”. They aimed to achieve the unity of reliable and stable off-road capabilities, powerful new energy power, and economic travel methods by adding pure off-road capability to new energy technology.

Tank officials stated that Tank will adhere to the hybrid route until the physical and technical barriers of pure electric off-road are broken through.

It’s no coincidence. On the 25th, some media reported that BYD’s million-level high-end pure electric brand may be named “Starry Sky”, and its first product will be a pure electric off-road vehicle.

On the new energy track, why did Tank choose the hybrid route instead of a one-step pure electric route? Can Tank 300 and 500 HEV models continue the off-road reputation that the brand has established before?

Tank’s Hybrid Off-Road Logic

“Our basic logic for hybrid is: first, to make it smoother and more fuel-efficient when users enter a city working condition, and to be able to provide power and torque immediately when off-road working conditions require it; second, to ensure the reliability, safety, and performance redundancy of the vehicle (off-road).” Liu Yanzhao said, “I want to achieve 100 points in off-road performance, with 60 points of redundancy. Because in off-road conditions, the peak of 100 points may be reached at any time, even exceeding 100 points.”

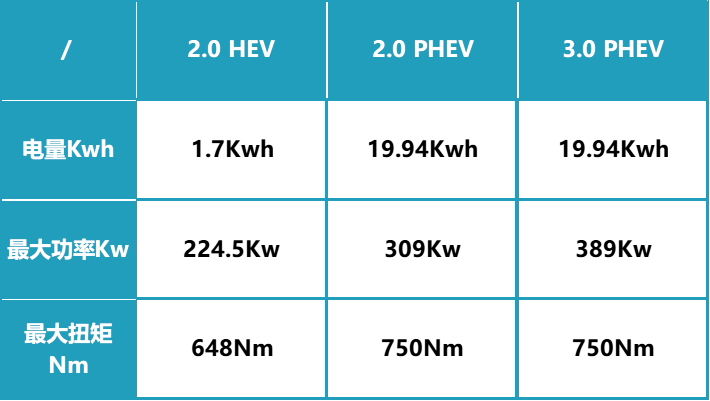

On the hybrid route, Tank did not choose to use the Lemon hybrid DHT system that Great Wall has already put into production, but adopted the off-road hybrid 9HAT system, which provides 2.0T and 3.0T hybrid engines and matches the domestically-developed longitudinal 9AT transmission. Tank calls this system “at the forefront of the world.”

From the data, the maximum power/torque of the 3.0T+9HAT hybrid system is 389 kW/750Nm, which exceeds the maximum power/torque of the Mercedes-Benz G500, which is 310 kW/610 Nm. Compared to the “Big G” G63 with a maximum power/torque of 430 kW/850 Nm, the Tank doesn’t concede much.

From the data, the maximum power/torque of the 3.0T+9HAT hybrid system is 389 kW/750Nm, which exceeds the maximum power/torque of the Mercedes-Benz G500, which is 310 kW/610 Nm. Compared to the “Big G” G63 with a maximum power/torque of 430 kW/850 Nm, the Tank doesn’t concede much.

Tank not only has stronger power but also has a special calibration and design for its hybrid system tailored to users’ city and off-road needs.

Firstly, there is the SOC energy management strategy. “The (fuel version of) the 500 has two problems, one is fuel consumption, and the other is gear shifting impact.” Liu Yanzhao said that after applying the hybrid system, Tank’s SOC energy management strategy solved these problems.

Specifically: under high battery level in urban conditions, Tank operates in EV mode, which is economical and energy-saving. Under high-speed uniform conditions, the engine performs in direct drive. When overtaking on high-speed or climbing, the motor provides synchronous assistance. On low-attachment roads such as icy and snowy roads/sandy roads/mud roads, Tank adopts full-time four-wheel drive to maximize the ground adhesion and achieve smooth driving and climbing and avoid skidding.

Multiple application modes, such as adjustable SOC, outdoor camping, and extreme comfort. In the adjustable SOC mode, the SOC threshold is automatically adjusted between 30% to 80% based on usage. In the extreme comfort mode, the SOC threshold is increased to 20%, maximizing the off-road performance of the vehicle in the desert.

Tank guarantees a balance of electricity and energy redundancy, achieving long-term and high-current discharge. The matched 4kW discharge power can fully support multiple electronic devices during camping.

In addition, based on historical data analysis of users’ driving habits (including charging habits, driving routes, etc.), Tank can match the corresponding energy management strategy to meet the user’s daily driving needs.

“Our battery is 150 kW, but I only put it at 120 kW to control the output and ensure redundancy for off-road use,” Liu Yanzhao said.

Another major “off-road hybrid design” is the placement of the battery.

The battery of the Tank HEV model is not embedded in the floor, but located on the floor of the vehicle, even in the trunk.Regarding this design, Liu Yanzhao stated that due to the complex off-road environment, if the battery is embedded in the vehicle’s floor, the risk of direct damage would be much greater than in urban road conditions. Therefore, it is placed on top of the vehicle’s floor to minimize the risk of battery damage.

Aside from the battery placement, the battery pack casing is made of reinforced alloy, and an additional collapsible thick alloy collision beam is added to the rear of the vehicle to meet the safety requirements for a rear-end collision at 80 km/h.

Why Not Pure Electric?

Although the introduction of a hybrid system greatly improves Tank’s off-road performance data, considering a series of pure electric off-road vehicle models, such as the pure electric F150 from Ford, EQG from Mercedes-Benz, pure electric Land Rover Range Rover, and the first model of BYD’s high-end brand, it begs the question: Since the new energy route is chosen, why not create a pure electric off-road product from the start?

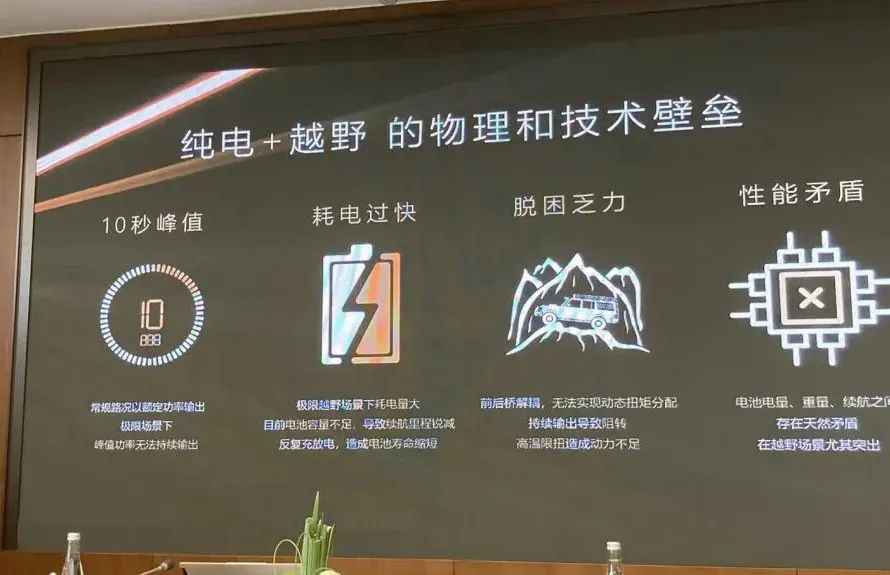

But in Tank’s opinion, pure electric products have inherent technical flaws that have yet to be resolved, specifically in moderate to heavy off-road scenarios.

Insufficient power endurance: Pure electric models output at their rated power under normal road conditions, but when faced with extreme situations that require sustained power output, the continuous peak power output of the electric motor can only be maintained for about 10 seconds. Then, due to the high temperature, the motor will experience a high-temperature torque limit, which leads to power attenuation and the risk of skidding.

Poor chassis safety: Off-road scenarios inevitably face bumpy roads, water crossings, and other situations. Currently, the battery’s resistance to shock and water absorption is poor, and the battery of pure electric vehicles is located under the chassis, which presents risks when hit by collisions during off-roading or when crossing flooded sections.

Non-mechanical four-wheel drive, limited recovery ability: Strong recovery capabilities are required for off-roading, and mechanical four-wheel drive can achieve 100% power output even if only one tire has traction.

However, the lack of a mechanical four-wheel drive structure in pure electric off-road vehicles results in complete decoupling of the power output between the front and rear axles. In an off-road scenario where only one tire touches the ground, the vehicle’s torque cannot provide additional help and can only rely on the torque of that one wheel, making it impossible to recover from the situation.

At the same time, due to the characteristics of the electric motor, when encountering a vehicle stuck in mud, for example, high torque output is needed to recover, but once the motor stalls, the thermal protection will activate, and the torque will be limited, ultimately making it impossible to recover from the situation.

Large energy consumption in extreme scenarios, insufficient energy replenishment infrastructure: High-intensity off-road scenarios require a high amount of energy consumption, and currently, the battery capacity and energy replenishment infrastructure are not adequate, resulting in a significant reduction in the range under off-road conditions. When the battery is fully charged, the off-road range may only be 10% to 20% of the range under normal city driving conditions. Repeated charging and discharging can also shorten the battery’s lifespan.

Even Hummer has yet to solve these problems. Previously, foreign media reported that the first batch of pure electric Hummers had been offline since May but have not yet been delivered. The core reason behind this may be its inability to address the issue of high-temperature torque limits.We found in practice that the performance of a car depends on the driving skills and courage of the calibration engineer. Only by driving in real-world environments can the actual performance of the car be released and tested.

According to Liu Yanzhao, “the development of ‘electric tanks’ is also one of the directions that tanks are researching and exploring, but the prerequisite is to break through the industry’s technical bottlenecks.”

That is, solving the problems of motor stalling, high current thermal protection limiting torque output; battery technology can take into account weight reduction, density improvement, and stability and reliability; and speeding up fast charging technology is fully implemented.

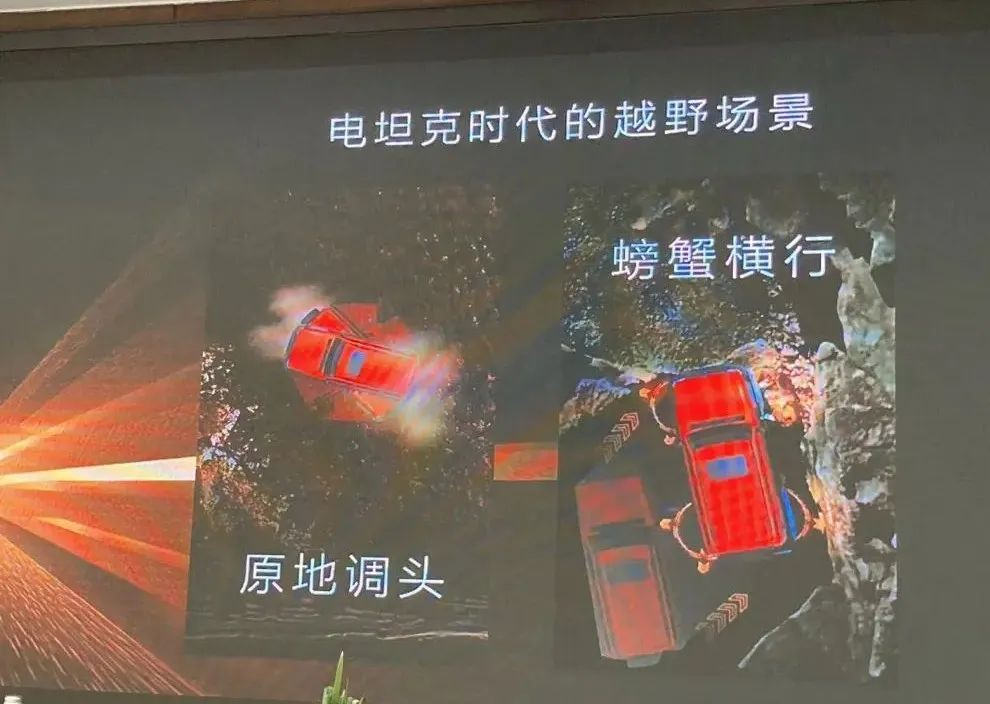

At the end of the communication meeting, the tank showed some vehicle pictures of its ability to turn in place and move sideways like a crab, indicating that it has the corresponding technical reserves. “After our internal discussion, we did not choose pure electric and did not directly use the lemon DHT, because we still care about the purity of the category, and I still care about off-road driving.”

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.